12Cr2Ni4A material gas carburizing and quenching method

A material gas, carburizing and quenching technology, applied in the direction of metal material coating process, coating, furnace type, etc., can solve the problems of unfavorable gear contact fatigue resistance, unfavorable carbon potential measuring device, and difficult to guarantee the size, etc. Long life, good controllability and low carbon potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

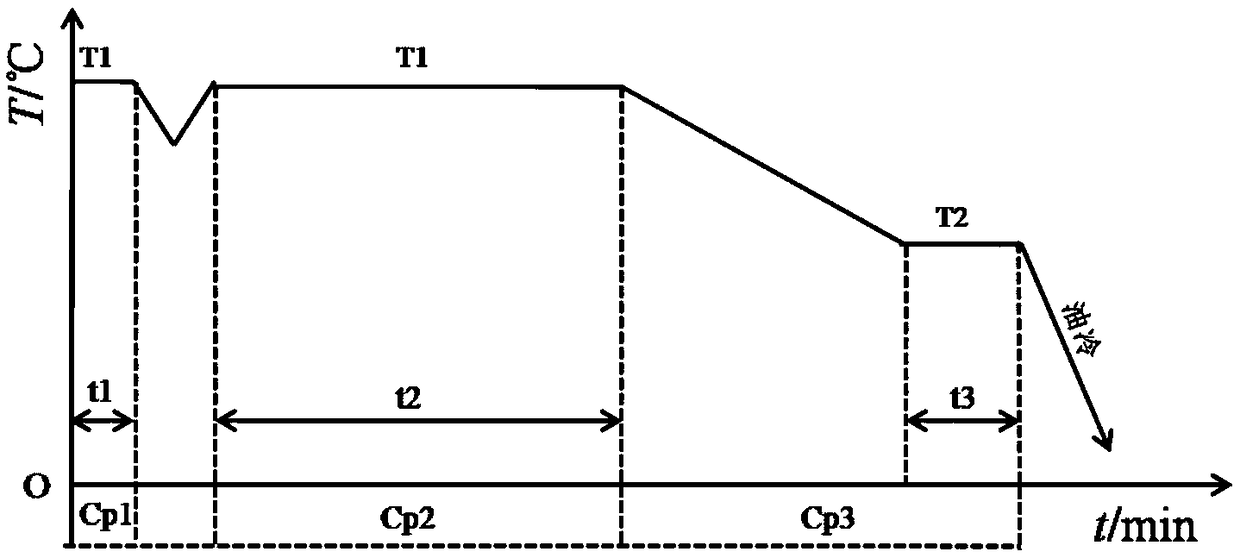

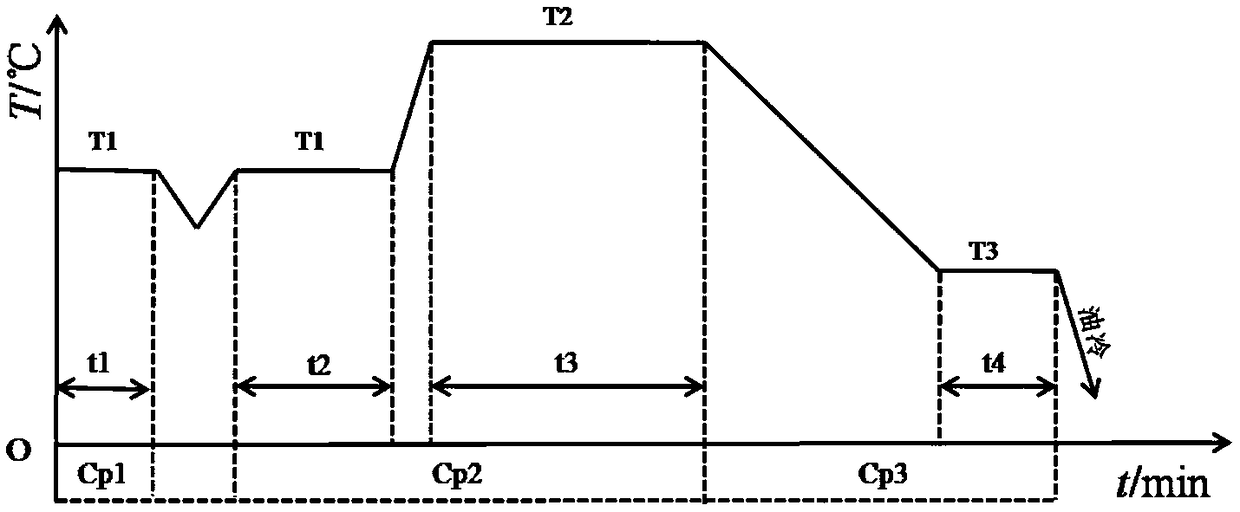

[0026] The technical solution of the present invention will be further described below with reference to the accompanying drawings, but the claimed protection scope is not limited to the above.

[0027] The general implementation steps of the present invention are as follows: The specific technical solutions are:

[0028] Atmosphere: Keep the temperature higher than the critical temperature of carburizing steel (20-40) ℃ and the carbon potential higher than the saturated carbon concentration of austenite at this temperature for a certain period of time to form a stable carburizing atmosphere in the furnace;

[0029] The workpiece enters the furnace;

[0030] Pretreatment: After the parts are installed in the furnace, they are kept for a certain time at a temperature higher than the critical temperature of carburized steel (20-40) ℃ and a carbon potential higher than the saturated carbon concentration of austenite at this temperature to make the surface of carburized steel sufficient A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com