Mesoporous selective molecular sieve and preparation method thereof

A type-selective molecular sieve and molecular sieve technology, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve problems that have not been involved in mesoporous composite IM-5 molecular sieves, and achieve good catalytic activity and use Longevity, raw material cost environmental protection, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

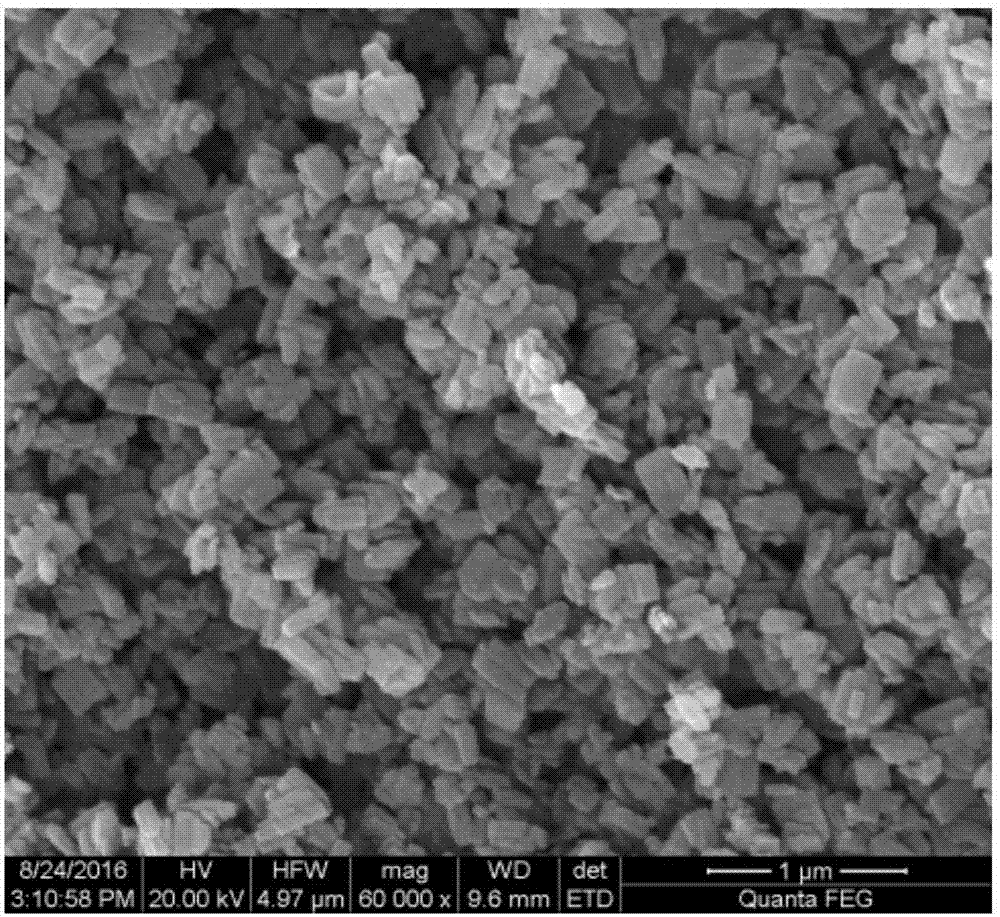

[0037] This embodiment provides a method for preparing the mesoporous IM-5 molecular sieve, which includes the following steps:

[0038] Step 1: Directly prepare Na-type microporous IM-5 zeolite with low silicon-to-aluminum ratio (Si / Al=10) through traditional hydrothermal synthesis.

[0039] Step 2: Add the low silicon-aluminum ratio IM-5 zeolite synthesized in Step 1 to the NaOH solution with a concentration of 0.2mol / L, the mass ratio of solid to liquid is 1:20, stir for 2h under the condition of 70℃ water bath, filter, The mesoporous IM-5 zeolite is obtained by washing and drying, which is recorded as IM-5A sample;

[0040] The relative crystallinity of the product determined by XRD ray diffraction is 96%, and the mesopore volume of the product is 0.149cm higher than that of the conventional ZSM-5 molecular sieve. 3 g -1 That is an increase of about 133%, reaching 0.261cm 3 g -1 (For pore volume distribution see image 3 ).

Embodiment 2

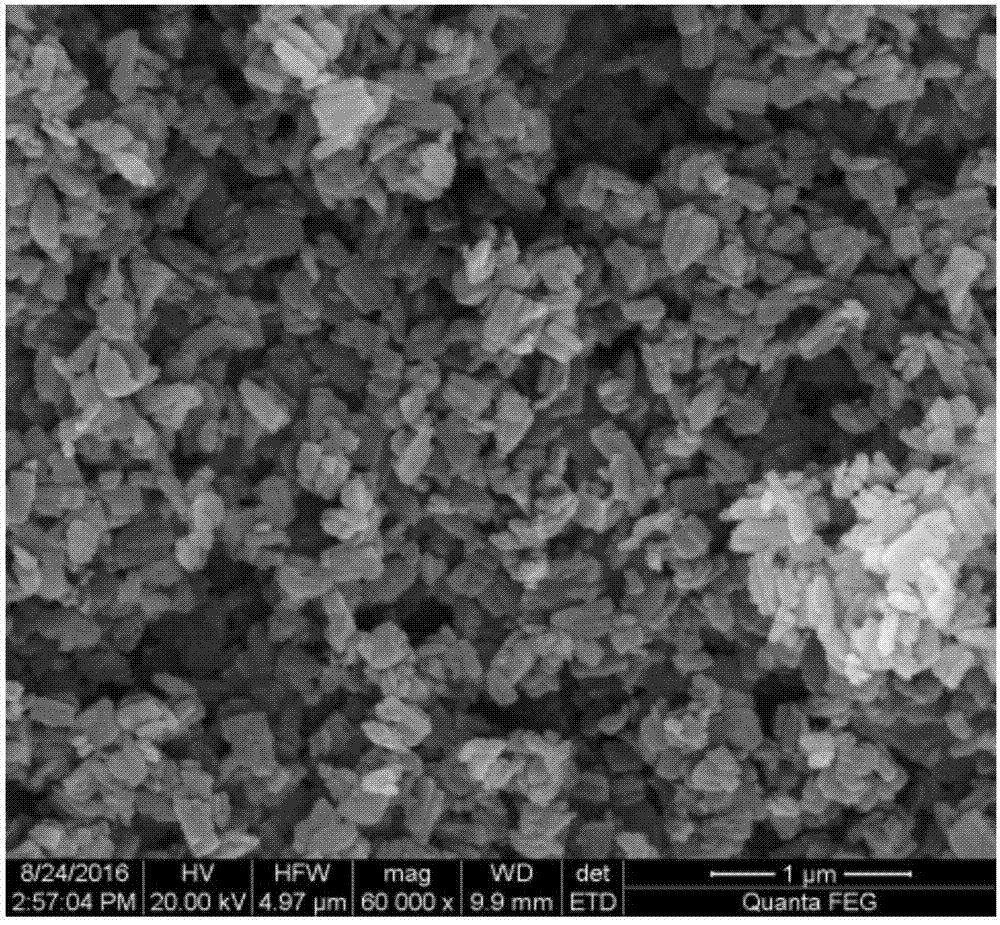

[0042] This embodiment provides a method for preparing the mesoporous IM-5 molecular sieve, which includes the following steps:

[0043] Step 1: Directly prepare Na-type microporous IM-5 zeolite with low silicon-to-aluminum ratio (Si / Al=13) through traditional hydrothermal synthesis.

[0044] Step 2: Add the low silicon-aluminum ratio IM-5 zeolite synthesized in step 1 to the NaOH solution with a concentration of 0.2mol / L, the mass ratio of solid to liquid is 1:10, stir for 2h under the condition of 70℃ water bath, filter, The mesoporous IM-5 zeolite was obtained by washing and drying, which was recorded as IM-5B sample;

[0045] The relative crystallinity of the product determined by XRD ray diffraction is 94%, and the mesopore volume of the product is increased by 0.180cm compared with the conventional ZSM-5 molecular sieve. 3 g -1 That is an increase of about 161%, reaching 0.292cm 3 g -1 (For pore volume distribution see Figure 4 ).

Embodiment 3

[0047] This embodiment provides a method for preparing the mesoporous IM-5 molecular sieve, which includes the following steps:

[0048] Step 1: Directly prepare Na-type microporous IM-5 zeolite with low silicon to aluminum ratio (Si / Al=14) through traditional hydrothermal synthesis.

[0049] Step 2: Add the low silicon-aluminum ratio IM-5 zeolite synthesized in step 1 to the NaOH solution with a concentration of 0.2mol / L, the mass ratio of solid to liquid is 1:20, and stir for 3h under the condition of 60℃ water bath, filter, The mesoporous IM-5 zeolite is obtained by washing and drying, which is recorded as IM-5C sample;

[0050] The relative crystallinity of the product determined by XRD ray diffraction is 94%, and the mesopore volume of the product is 0.158cm higher than that of the conventional ZSM-5 molecular sieve. 3 g -1 That is an increase of about 141%, reaching 0.270cm 3 g -1 (For pore volume distribution see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com