Industrial fluidized bed reactor

A fluidized bed reactor and reactor technology, applied in chemical instruments and methods, aerobic process treatment, biological water/sewage treatment, etc., can solve the problem that it is difficult to ensure normal fluidization inside the reactor and the fluidization effect is not ideal. , the reduction of gas-liquid mass transfer efficiency, etc., to achieve the effect of improving oxygen utilization rate, satisfying optimal matching, and improving fluidization state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

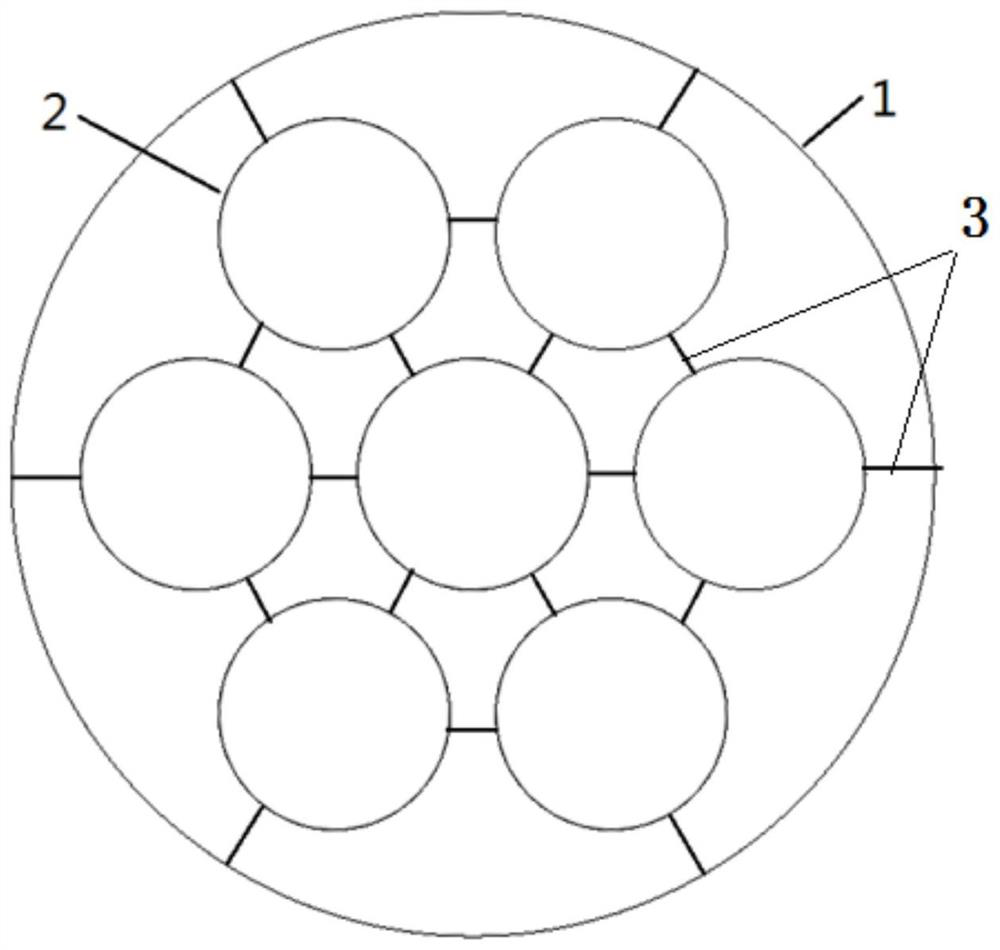

[0023] A reactor has a total height of 2m and a diameter of 1m, see figure 1 , the reactor includes a reactor shell 1 , a draft tube 2 and a support plate 3 .

[0024] The height of the inner guide tube is 1.5 meters, the height-to-diameter ratio of the guide tube 2 is 6-8, and the annular gap ratio is 0.8-1.

[0025] The interior of the reactor is divided into an area. The diameter of the guide tube 2 is 250mm, and it is arranged in a manner of one in the center and six evenly distributed on the circumference. A gas distributor (not shown) is arranged directly under each guide tube 2 .

[0026] The reactor shell 1, the guide tube 2 and the support plate 3 are made of carbon steel or stainless steel, and the guide tubes 2 and the reactor shell 1 are connected through the support plate and welded or bolted.

[0027] The effective volume of the device is 2.8m 3 , the processing capacity is 0.2~0.5m 3 / h, aerobic biological fluidized bed reactor influent COD: 1500~2000mg / L, BO...

Embodiment 2

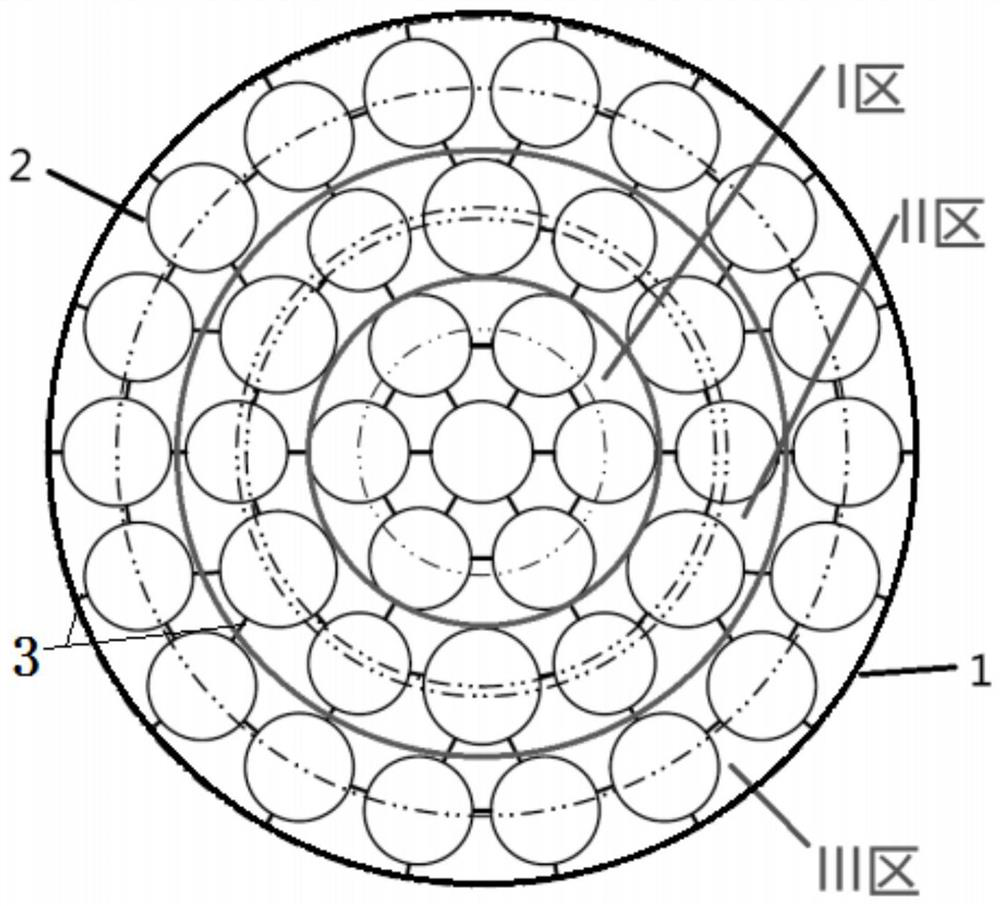

[0029] see figure 2 , the total height of the reactor is 12m, the diameter is 10m, the height of the inner guide tube 2 is 9 meters, the height-to-diameter ratio of the guide tube 2 is 7, and the annulus ratio is 0.9.

[0030] The diameter of the guide tube in Zone I is 1.2m, and it is arranged in a way of one in the center and six evenly distributed on the circumference, and the diameter of the distribution circle is 3m.

[0031] Diversion cylinders in Zone II There are two types of guide cylinders with diameters of 1.2m and 1.4m, and the intervals are distributed on the circumference with diameters of 5.7m and 5.9m. The number of guide cylinders in Zone II is 12.

[0032] The diameter of the diversion tubes in Zone III is 1.3m, distributed in a circle, the diameter of the distribution circle is 8.8m, and the number of guide tubes in Zone III is 18.

[0033] The device has an effective volume of 1000m3 and a processing capacity of 130m 3 / h, aerobic biological fluidized be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com