Circulating fluidized bed gasification furnace starting system

A technology of circulating fluidized bed and flue gas purification system, which is applied in the field of coal chemical industry, can solve the problems of long time-consuming, long-running, and difficult in the heating process, so as to reduce the amount of unqualified synthesis gas, shorten the process of heating and boosting, and reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

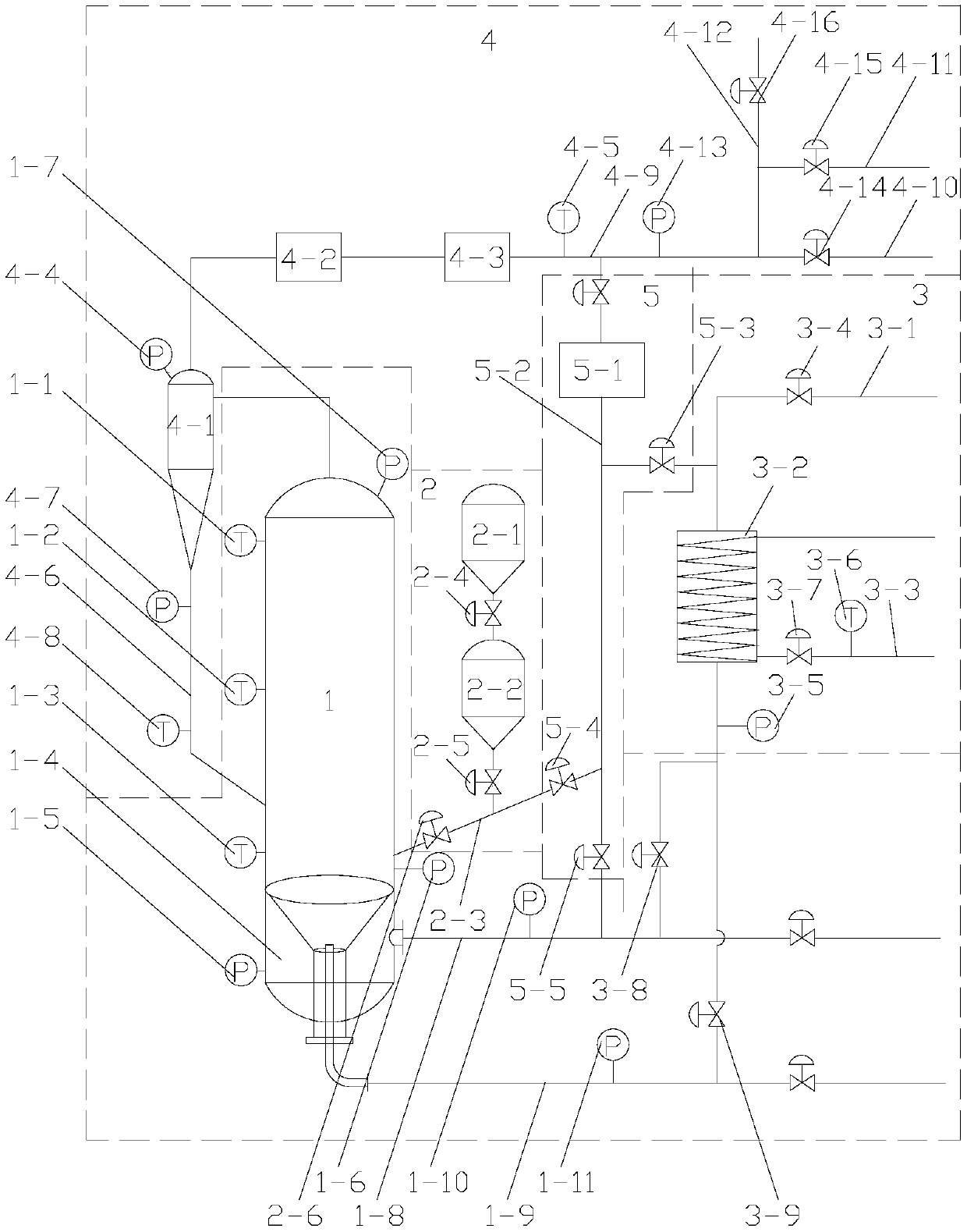

[0017] Such as figure 1 As shown, the circulating fluidized bed gasifier start-up system includes a gasifier 1, a coal feeding system 2, an oven gas system 3, a flue gas purification system 4 and a flue gas circulation system 5,

[0018] The upper, middle and lower parts of the furnace body of the gasifier 1 are respectively provided with a furnace top temperature sensor 1-1, a furnace temperature sensor 1-2 and a furnace bottom temperature sensor 1-3, and the gas chamber 1-4 of the gasifier 1 and Furnace body pressure sensors 1-5 and gas chamber pressure sensors 1-6 are respectively arranged on the furnace body above it, and furnace top pressure sensors 1-7 are arranged on the furnace body top of gasifier 1; Gasification agent pipeline 1-8 and center pipe gasification agent pipeline 1-9, distribution plate gasification agent pressure sensor 1-10 is installed on distribution plate gasification agent pipeline 1-8, center pipe gasification agent pipeline 1-9 A central pipe gasi...

Embodiment 2

[0025] The method for starting a circulating fluidized bed gasifier carried out in Example 1 is characterized in that it specifically includes the following steps:

[0026] Oven heating and boosting stage: the oven gas is nitrogen; the oven gas is transported to the preheater 3-2 through the oven gas pipeline 3-1 and heated to 100°C to obtain preheated oven gas; the distribution plate valve is opened 3-8 and the central pipe valve 3-9, transport the preheated oven gas to the distribution plate gasification agent pipeline 1-8 and the central pipe gasification agent pipeline 1-9 respectively, through the preheated oven gas to gasify The internal temperature of the furnace 1 and the cyclone separator 4-1 is raised; the preheated oven gas after heat exchange with the gasification furnace 1 and the cyclone separator 4-1 is dedusted by the dust collector 4-2, and the waste heat boiler 4- 3 After the heat is recovered, the circulating gas is obtained; the circulating gas valve 5-3 is...

Embodiment 3

[0031] The method for starting a circulating fluidized bed gasifier carried out in Example 1 is characterized in that it specifically includes the following steps:

[0032] Oven temperature and pressure increase stage: Oven gas is carbon dioxide; the oven gas is transported to the preheater 3-2 through the oven gas pipeline 3-1 and heated to 100°C to obtain preheated oven gas; the distribution plate valve is opened 3-8 and the central pipe valve 3-9, transport the preheated oven gas to the distribution plate gasification agent pipeline 1-8 and the central pipe gasification agent pipeline 1-9 respectively, through the preheated oven gas to gasify The internal temperature of the furnace 1 and the cyclone separator 4-1 is raised; the preheated oven gas after heat exchange with the gasification furnace 1 and the cyclone separator 4-1 is dedusted by the dust collector 4-2, and the waste heat boiler 4- 3 After the heat is recovered, the circulating gas is obtained; the circulating g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com