Novel phase change energy storage type device and method

A technology of phase change heat storage and phase change heat storage materials, which is applied in the field of new phase change heat storage devices, can solve the problems of difficult device assembly and maintenance, restrictions on large-scale commercial applications, and short cycle life, achieving simple structure, The effect of low density and low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

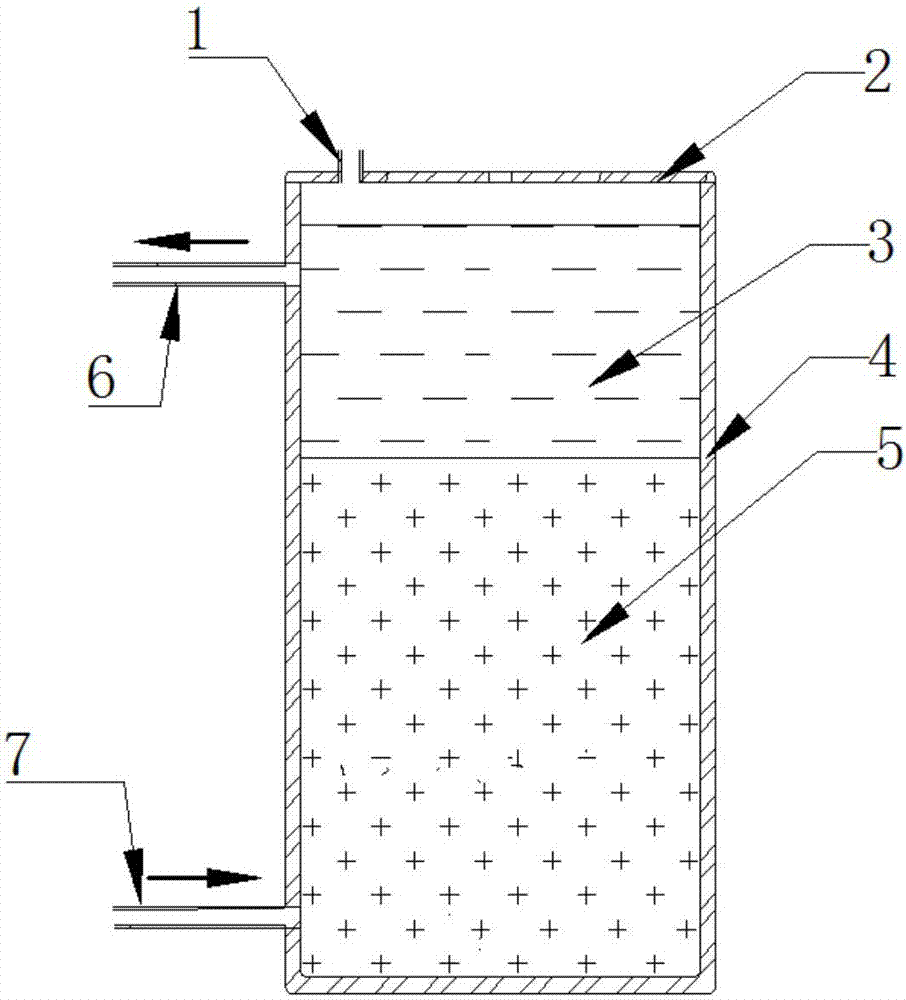

[0030] Such as figure 1 As shown, a new phase change heat storage device includes a storage container 2, an insulation layer 4 arranged outside the storage container 2, a ventilation pipe 1, a phase change heat storage material 5 and a heat exchange medium 3; the storage container 2. The side wall is also provided with an inlet pipe 7 and an outlet pipe 6. The density of the heat exchange medium 3 is lower than that of the phase-change heat storage material 5, so that the phase-change heat storage material 5 is in the lower part of the storage container 2 in both solid and liquid states. When the device is charging and discharging heat, the heat exchange medium 3 circulates and flushes the phase change heat storage material 5 to realize convective heat exchange between the two.

[0031] When in use, the heat exchange medium 3 enters the material storage container 2 from the inlet pipe 7 , directly contacts with the phase change heat storage material for heat exchange and moves...

Embodiment 2

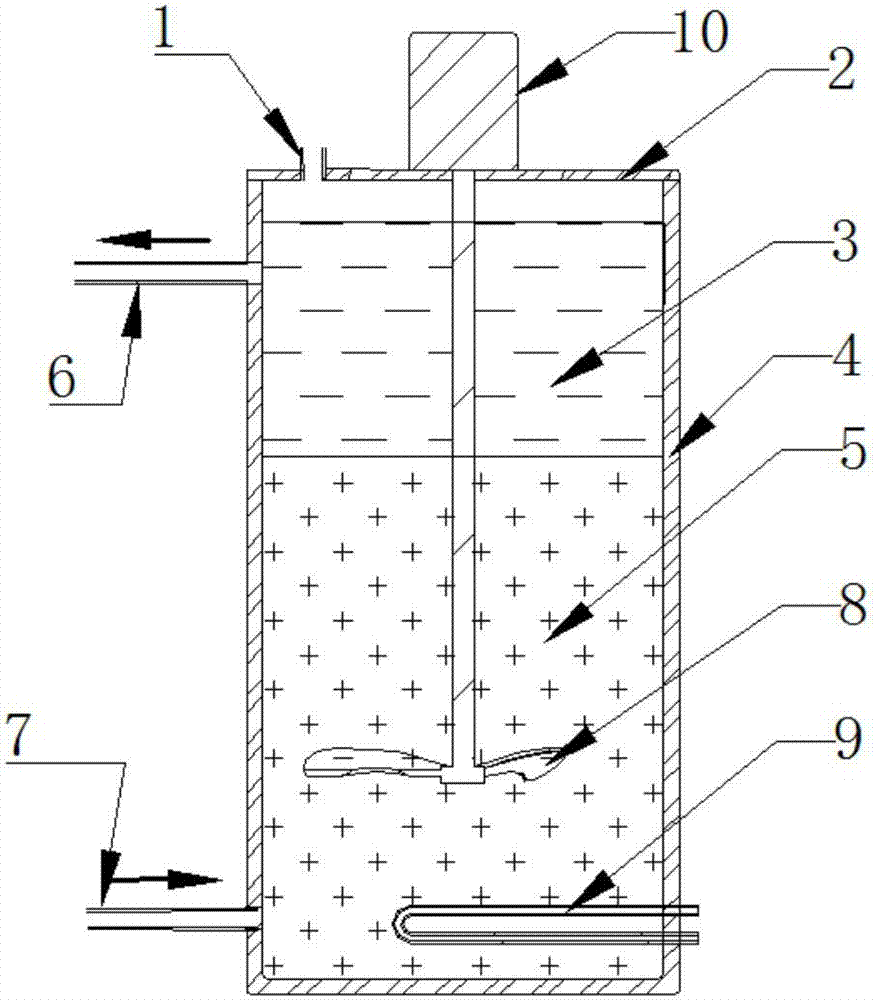

[0033] Such as figure 2 As shown, the heat of the heat source in this embodiment can come from the electric heater 9 built in the storage container 2, and the relative flow between the heat exchange medium 3 and the phase change material 5 driven by the agitation of the stirrer 10 can realize the interaction between the two. For convective heat exchange, a stirrer 10 is installed on the material storage container 2, and the stirrer 10 is equipped with a stirring paddle 8 to enhance the heat exchange effect. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com