Efficient module type heat exchanger

A heat exchanger, modular technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of poor energy saving effect, low heat exchange efficiency, small heat exchange area, etc., and achieve flexible installation or disassembly, improve heat transfer efficiency, and prolong the effect of heat transfer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

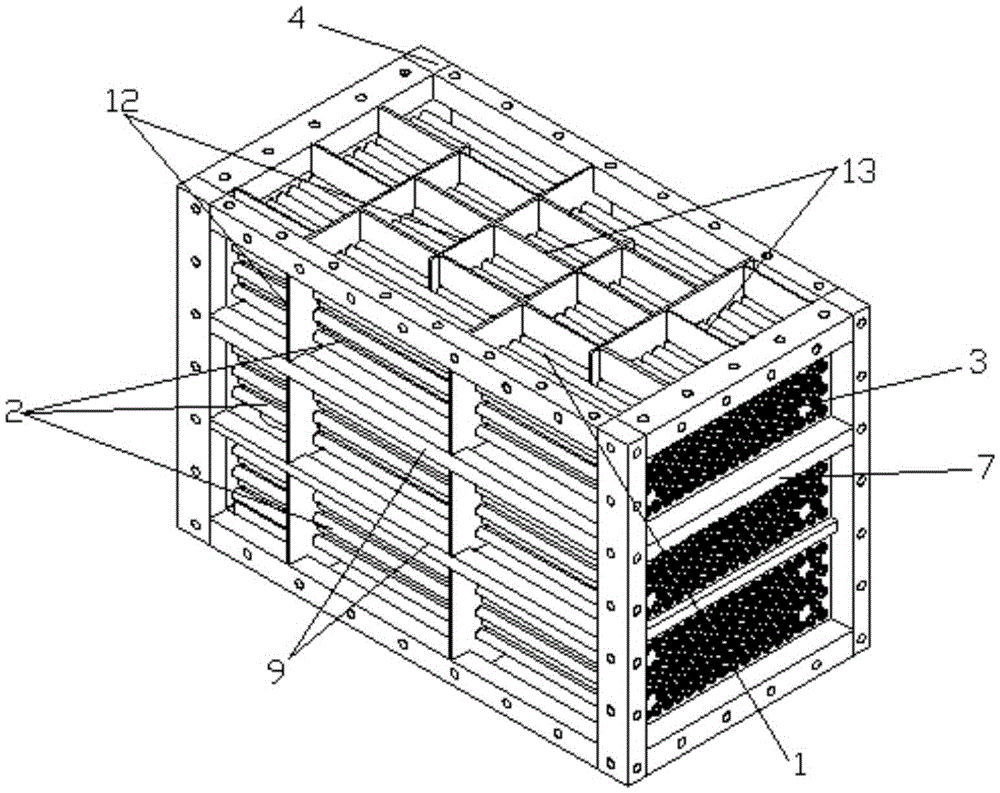

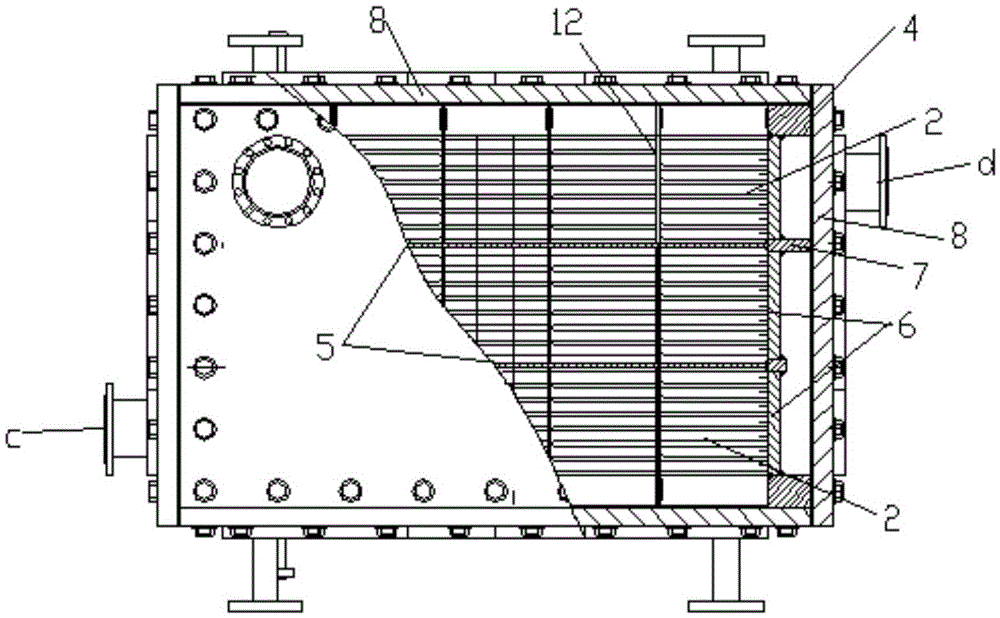

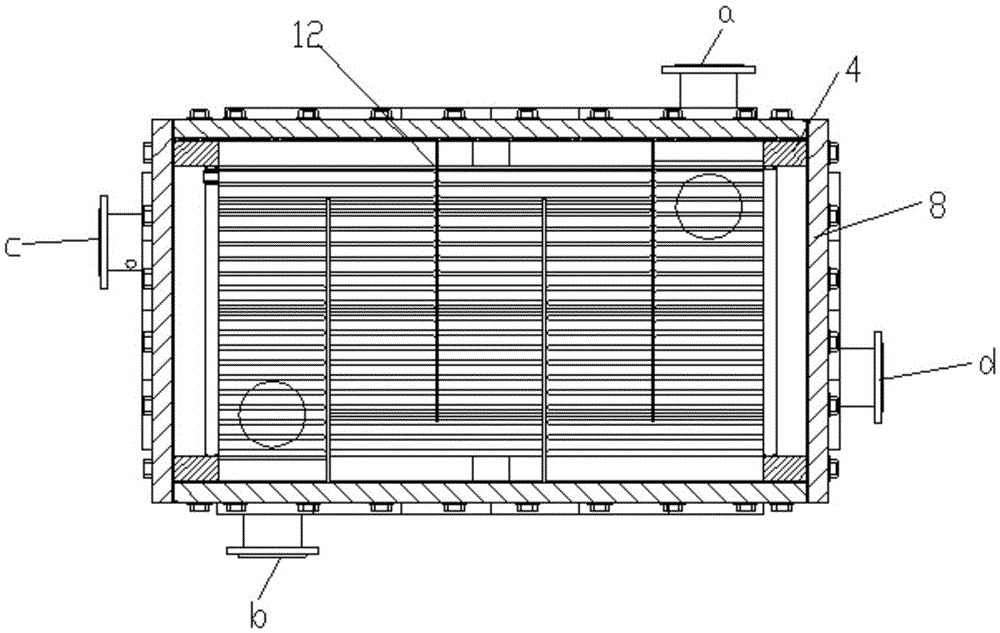

[0029] Such as figure 1 As shown, the high-efficiency modular heat exchanger of the present invention, the high-efficiency modular heat exchanger, includes a heat exchange body 1, and one or more layers of heat exchange units 2 are arranged in the heat exchange body 1, and each layer of heat exchange units 2 includes The heat exchange tubes 3 arranged horizontally and evenly in multiple layers, the heat exchange tubes 3 in each layer of heat exchange units 2 are in the same direction from left to right, and the heat exchange tubes 3 in each layer of heat exchange units 2 are used for The high-temperature fluid passes through, and one end of the heat exchange tube 3 in the heat exchange unit 2 on the top layer is used to communicate with the high-temperature fluid outside, and one end of the heat exchange tube 3 in the heat exchange unit 2 on the bottom layer is connected to the external pipeline. To connect the high-temperature fluid after heat exchange with the outside world,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com