Patents

Literature

33results about How to "Increased circulation distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

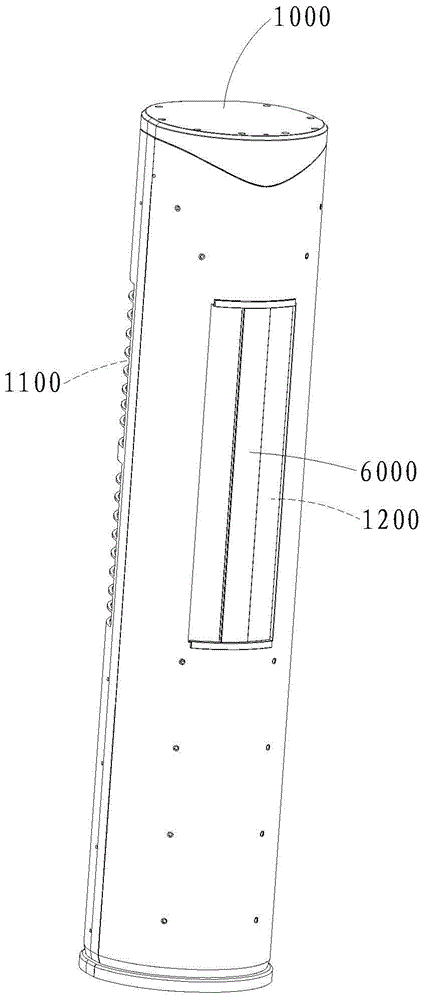

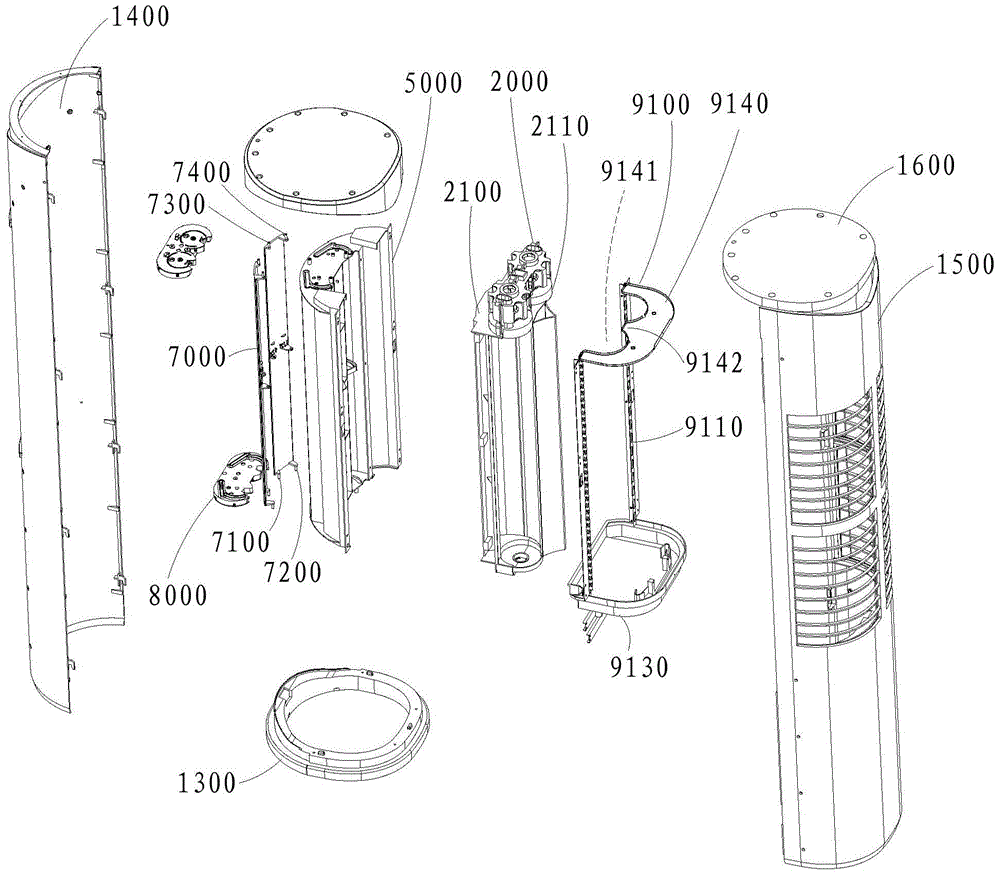

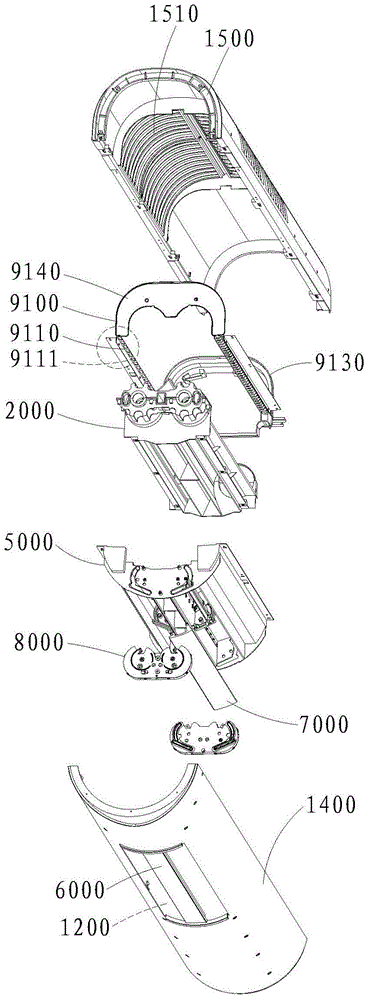

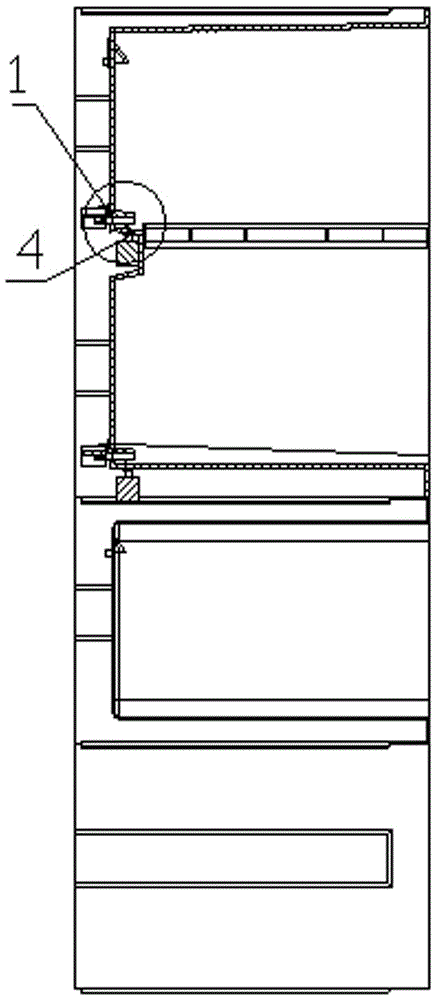

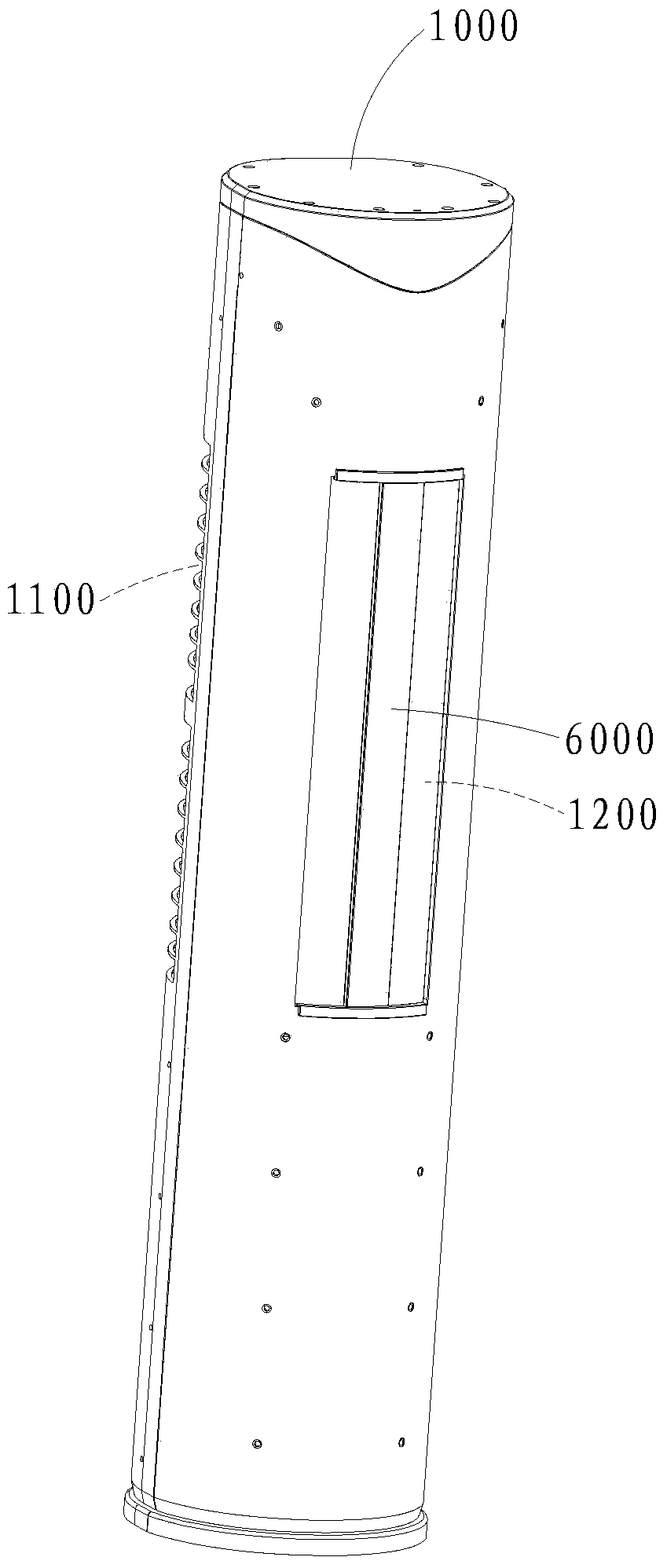

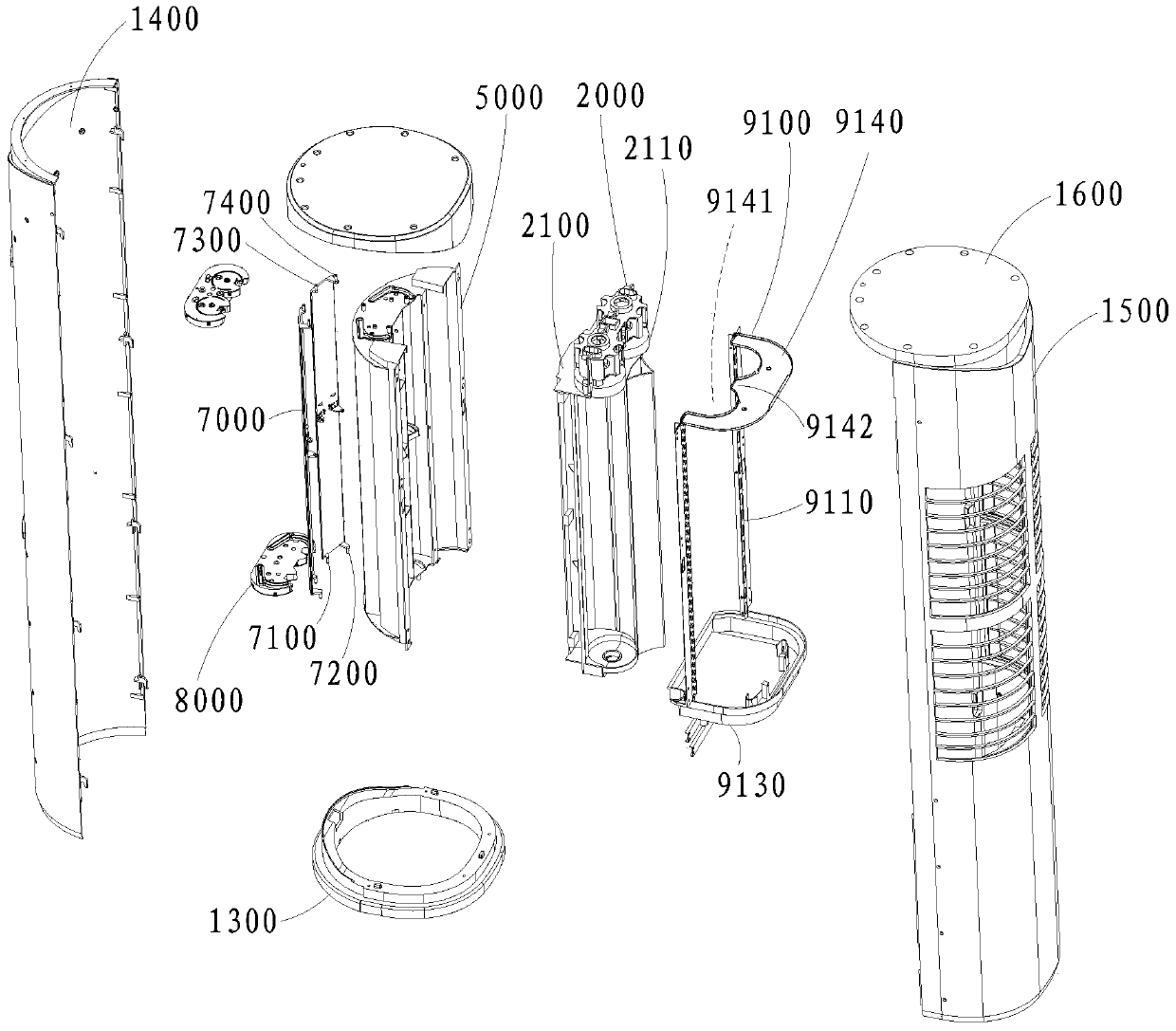

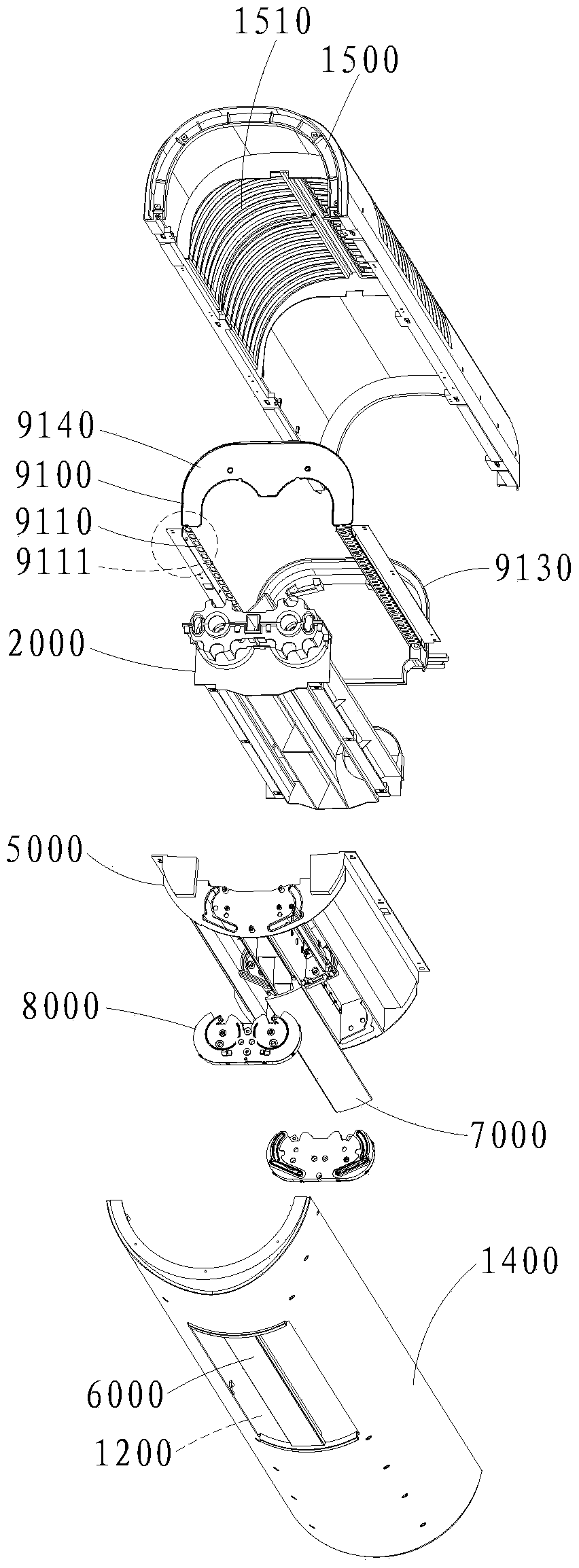

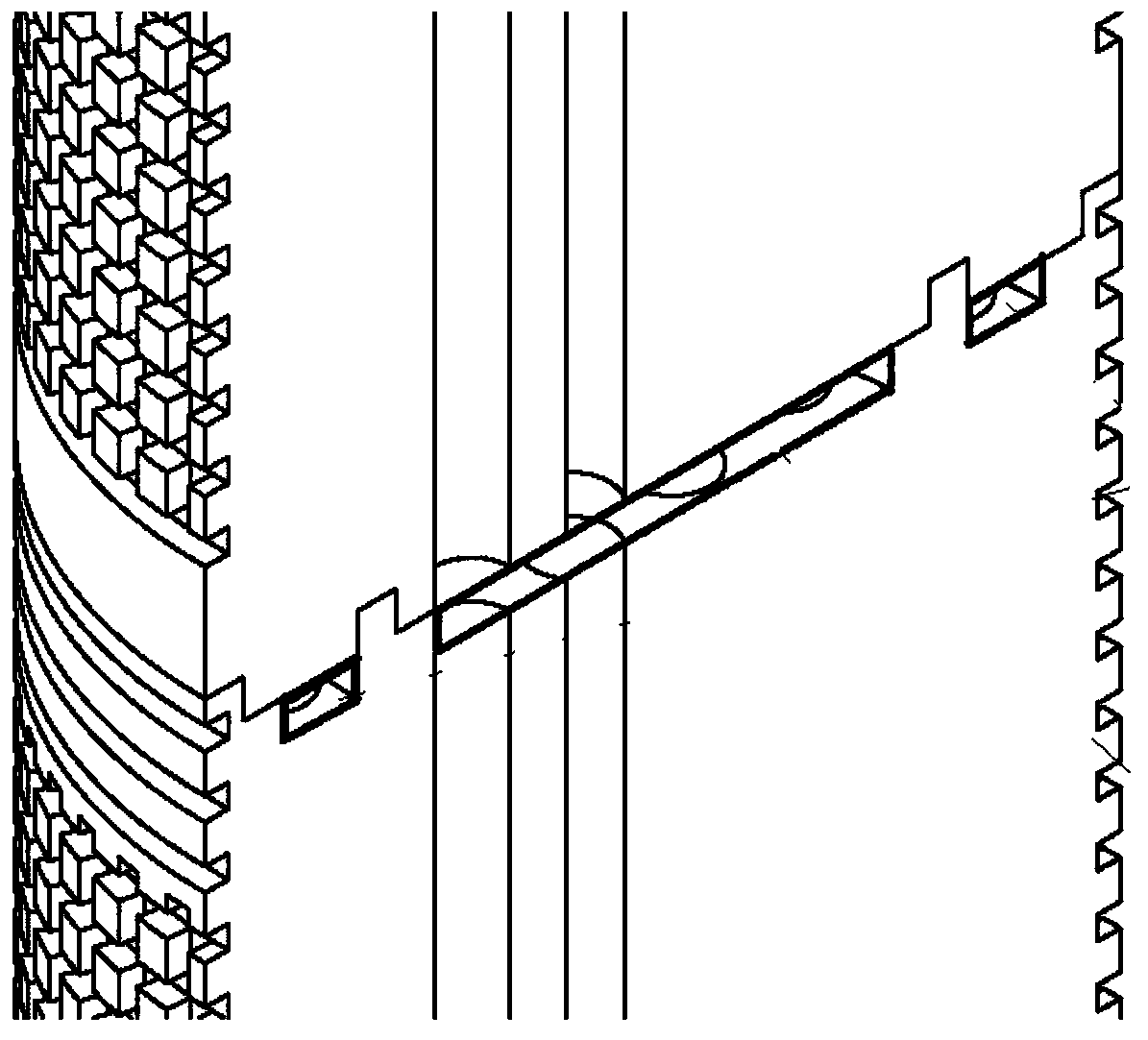

Air outlet frame, shell and cross-flow cabinet air conditioner

ActiveCN105042694ASimple structureReduce wind noiseLighting and heating apparatusHeating and ventilation casings/coversEngineering

The invention discloses an air outlet frame, a shell, a cross-flow cabinet air conditioner and a double-cross-flow cabinet air conditioner. The air outlet frame is applied to the cross-flow cabinet air conditioner. The air outlet frame is characterized in that the air outlet frame is provided with a top plate, a bottom plate and a plurality of longitudinal connecting plates, wherein the top plate, the bottom plate and the longitudinal connecting plates define connecting cavities which are used for inducing air corresponding to a cross-flow fan of the cross-flow cabinet air conditioner. The air outlet frame has the effects that outlet air is stable, and noise is small.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD

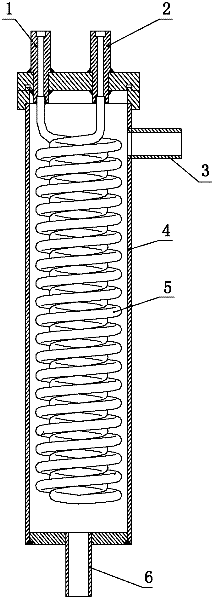

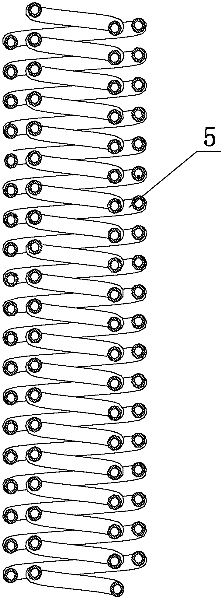

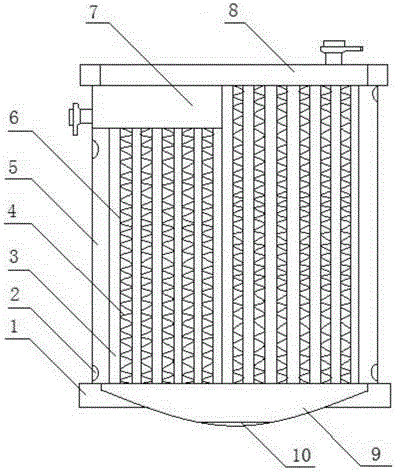

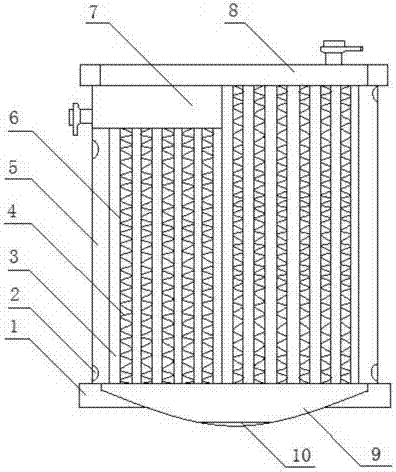

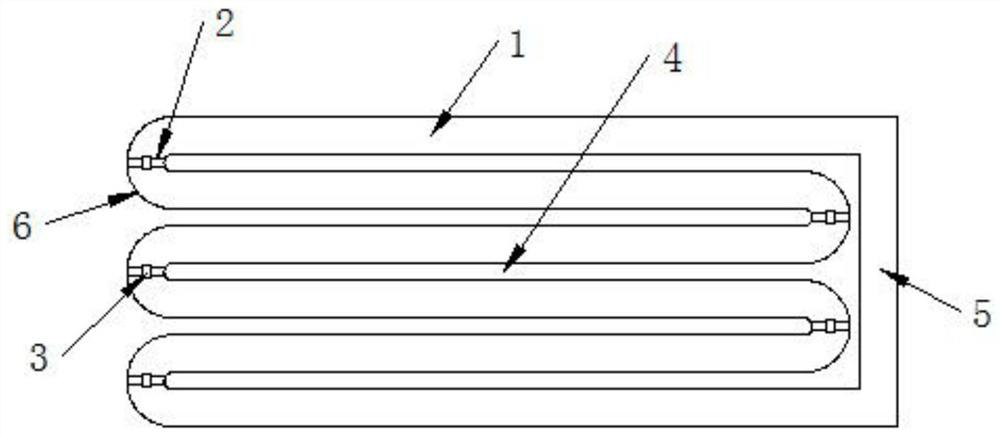

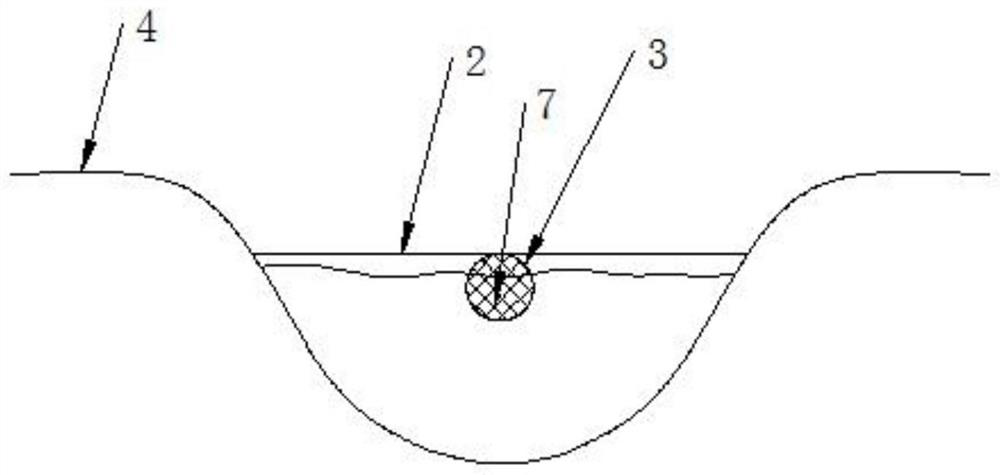

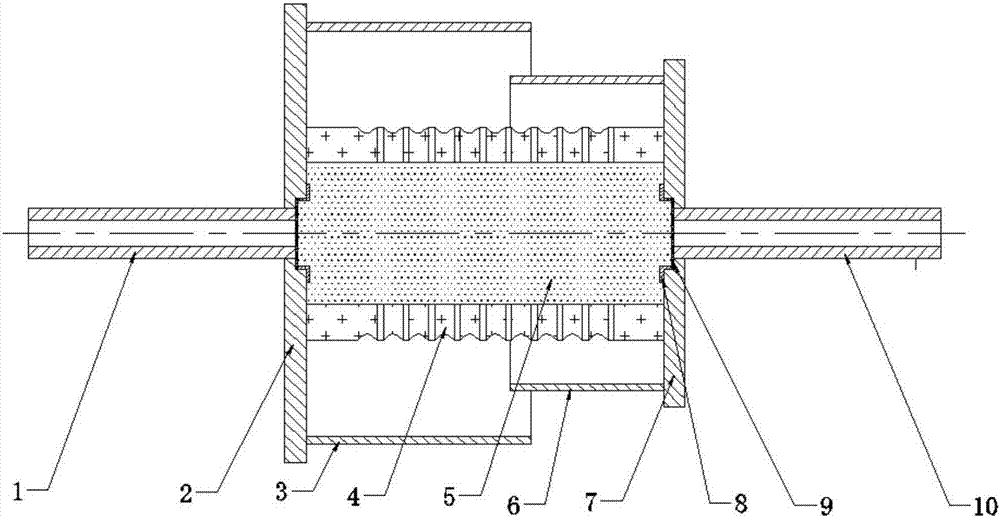

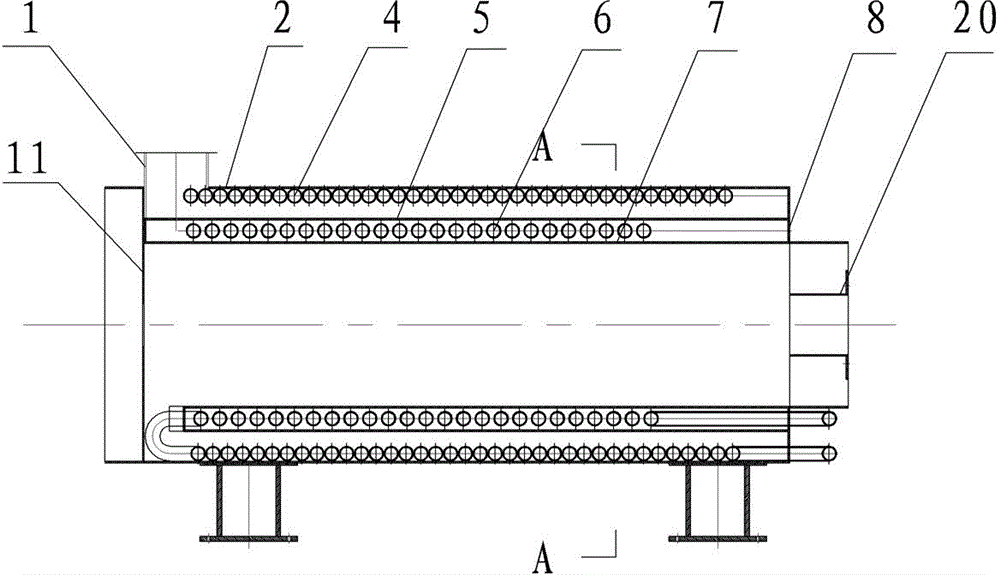

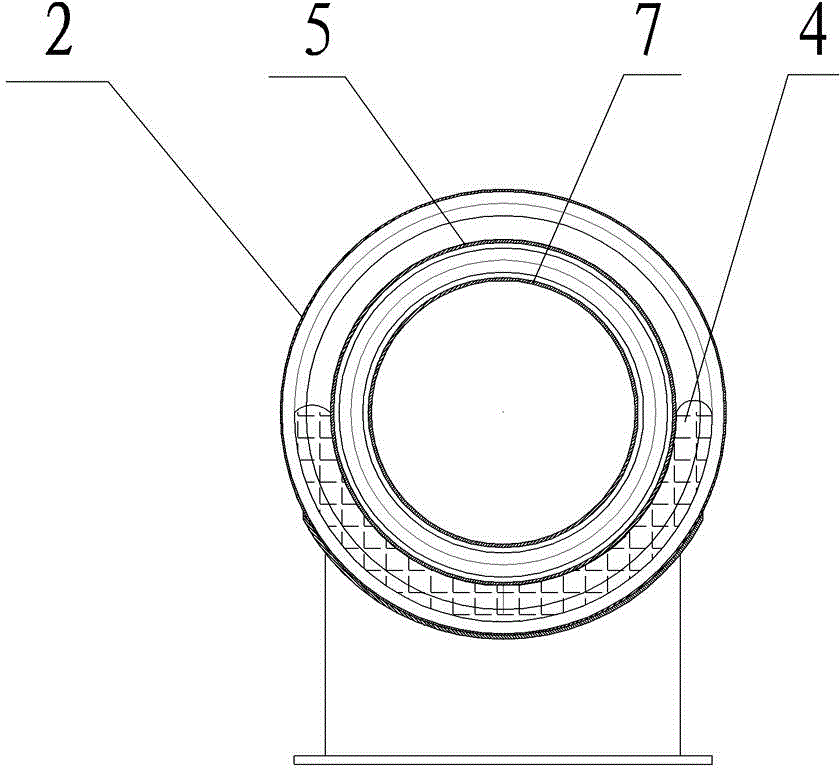

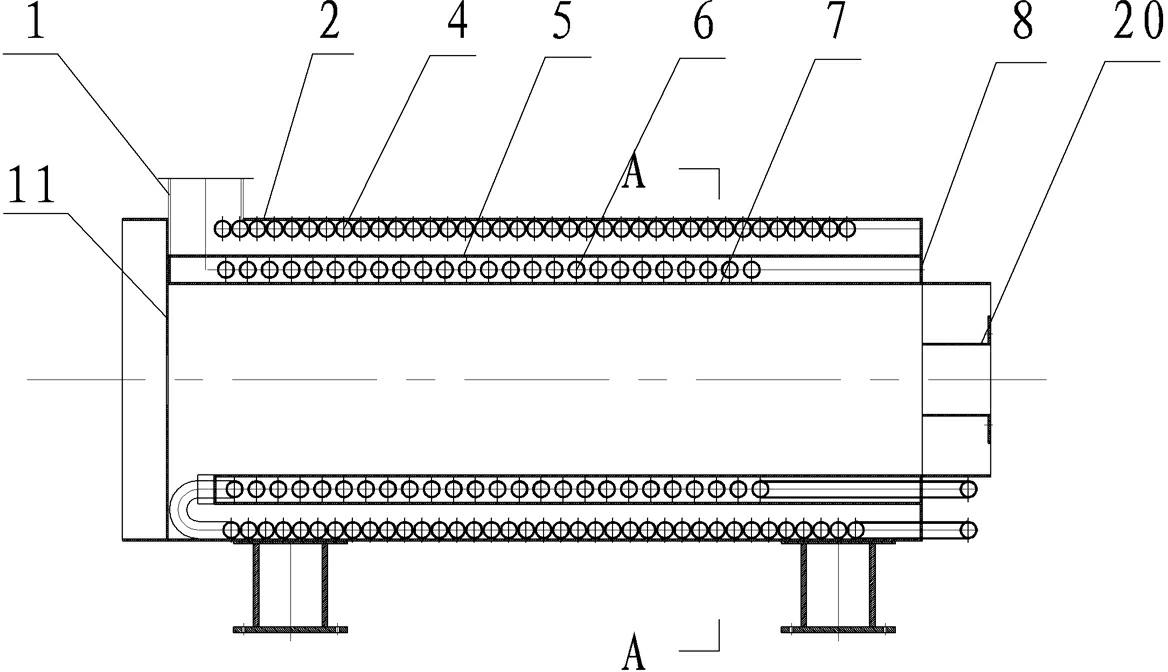

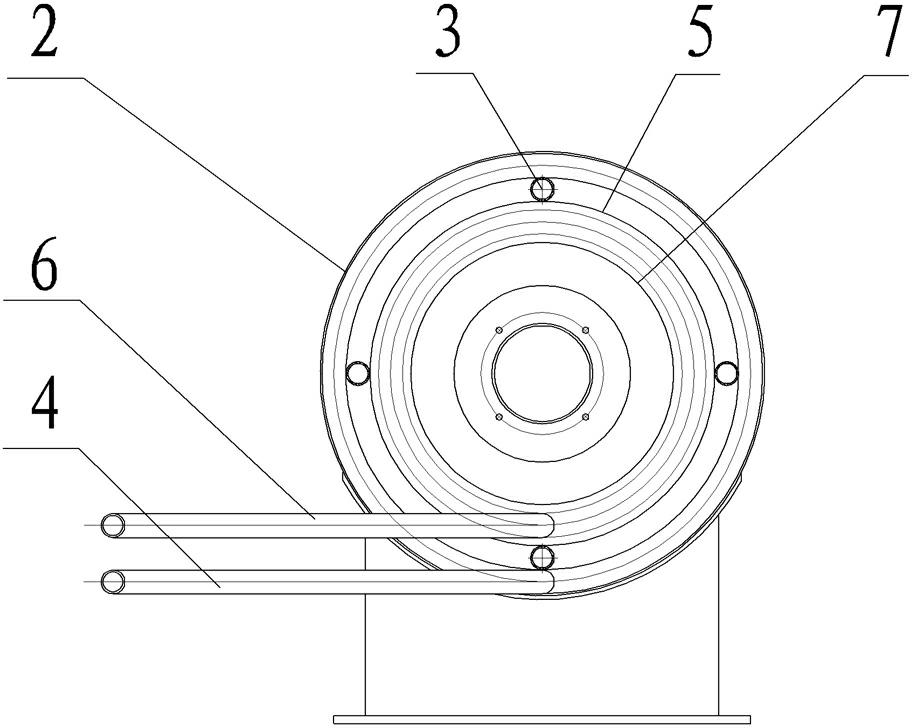

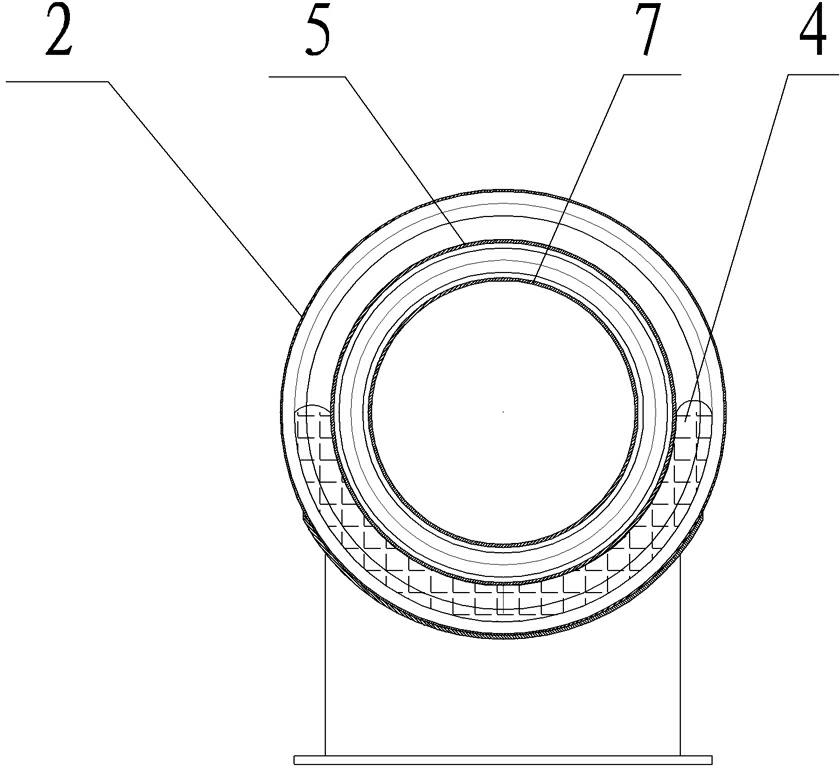

Double-layer coiled pipe cooler

InactiveCN102374800AIncreased circulation distanceExtend heat exchange timeStationary tubular conduit assembliesTubular elementsEngineeringLayer interface

The invention discloses a double-layer coiled pipe cooler, comprising a cooler cylinder body, and a cooling water inlet and a cooling water outlet arranged on the cooler cylinder body, wherein a double-layer coiled pipe is installed in the cooler cylinder body, the double-layer coiled pipe is of a structure with an inner layer and an outer layer formed by winding one pipe, the outer layer interface of the outer layer structure extends out of the cooler cylinder body to be connected with the cooling water inlet, and the inner layer extends out of the cooler cylinder body to be connected with the cooling water outlet; according to the double-layer coiled pipe cooler provided by the invention, the heat exchange performance of the cooler can be enhanced, the equipment space can be saved, and the material cost can be reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

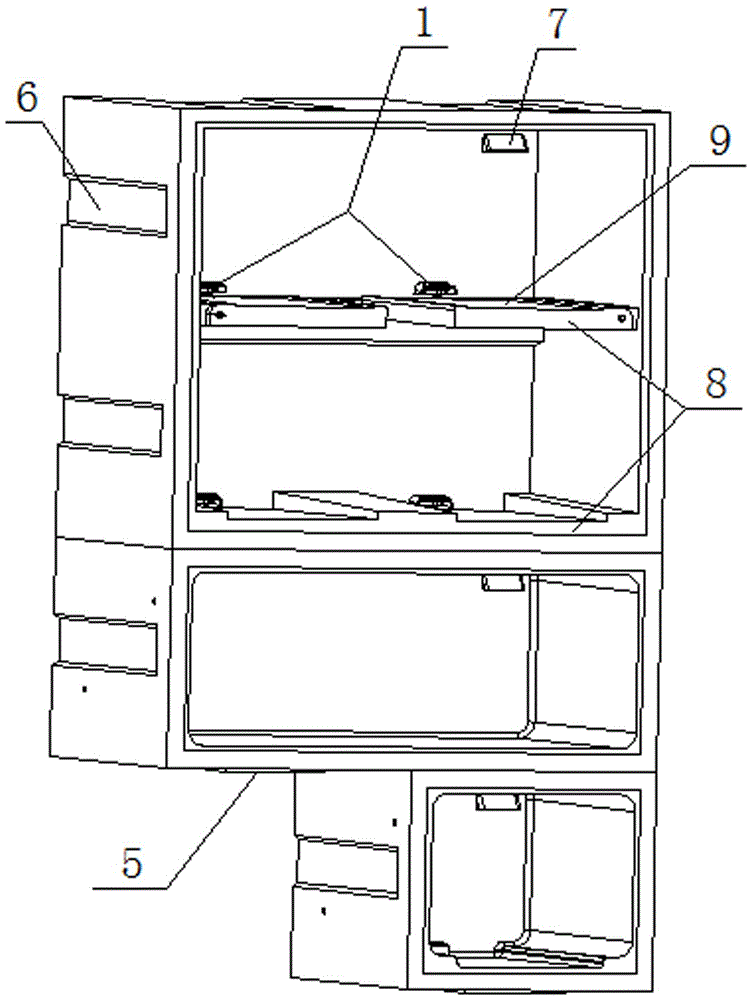

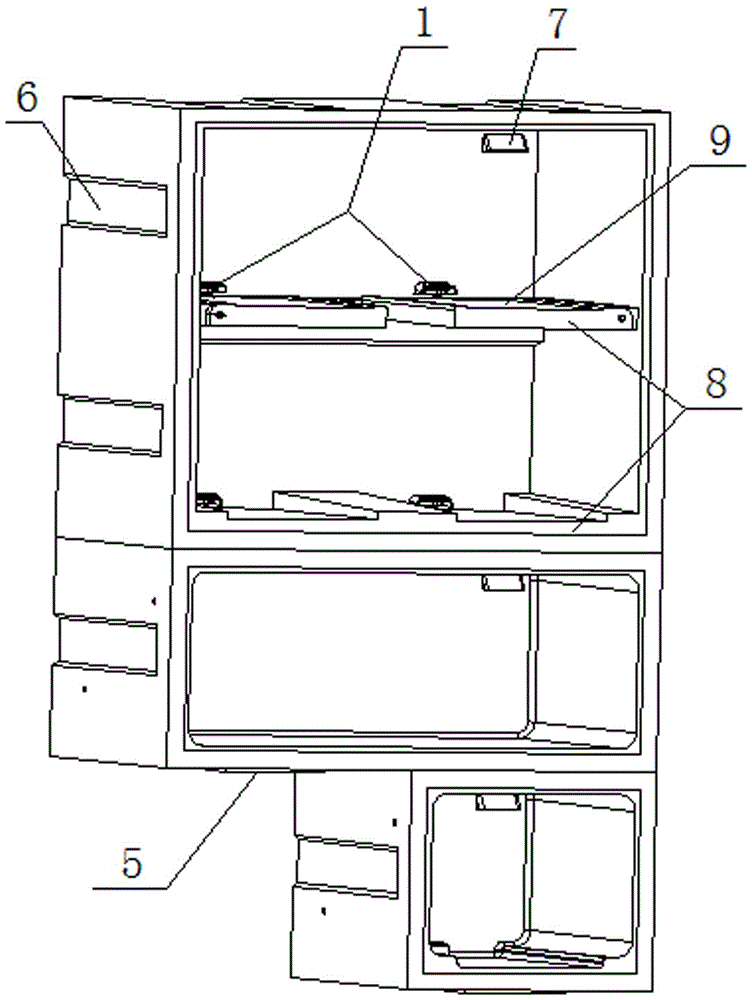

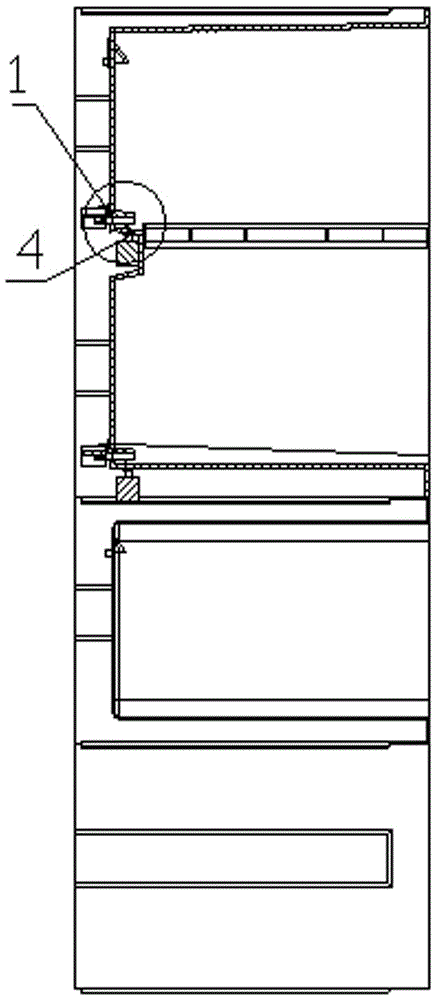

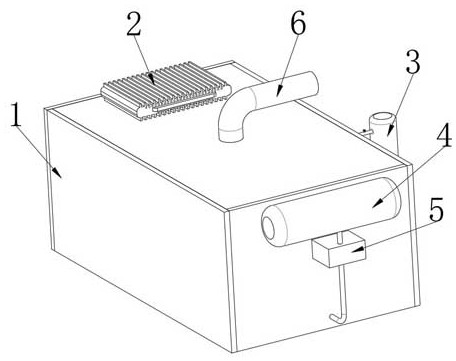

Full thermal processing-combined freighting space intelligent temperature control comprehensive delivery cabinet

ActiveCN106617774AIncreased circulation distanceImprove delivery qualityCabinetsIndividual entry/exit registersTemperature controlCool storage

The invention discloses a full thermal processing-combined freighting space intelligent temperature control comprehensive delivery cabinet. The delivery cabinet comprises a cabinet body and a heating-refrigeration heat-preservation food container; the cabinet body comprises one or more good delivering units, each of the good delivering units comprises one or more good delivering sites, a comprehensive interface is arranged corresponding to each good delivering site, the comprehensive interface comprises an air exhaust interface and a comprehensive connector, the air exhaust interface is communicated with an air exhausting pipeline, and the comprehensive connector is connected to a power supply and a central controller. According to the full thermal processing-combined freighting space intelligent temperature control comprehensive delivery cabinet, through the arrangement of interfaces of the power supply, air exhausting interface and the like in a good allocation unit, heating of the food can be achieved; meanwhile, each good allocation unit is provided with a cool air inlet in a corresponding mode, and thus the cool storage of food which needs to kept in a cool state is conducted.

Owner:李旭丹

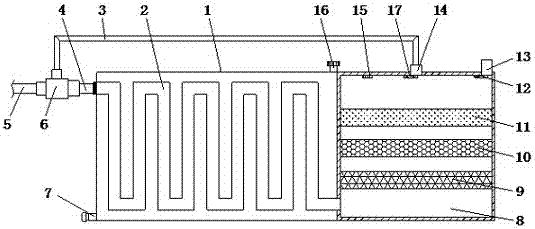

Novel automobile radiator

InactiveCN104895662AKeep the temperature consistentGuaranteed heat dissipationMachines/enginesEngine cooling apparatusLiquid temperatureEngineering

The invention discloses a novel automobile radiator. The novel automobile radiator comprises a radiator core, side plates, an upper water chamber and a lower water chamber, and further comprises a transfer water chamber, wherein the radiator core consists of a plurality of radiating tubes; the upper water chamber and the lower water chamber are arranged at one side of the radiator core; the transfer water chamber is arranged at the other side of the radiator core; and the side plates are arranged at the two transverse sides of the radiator core. According to the novel automobile radiator, the liquid temperature can be effectively ensured to be consistent, so that maximum-efficiency radiating is ensured. Besides, a circulating distance of high-temperature liquid is prolonged and the radiating time of the liquid is increased, so that the high-temperature liquid is sufficiently radiated in the radiator.

Owner:贵州凯宏汇达冷却系统有限公司

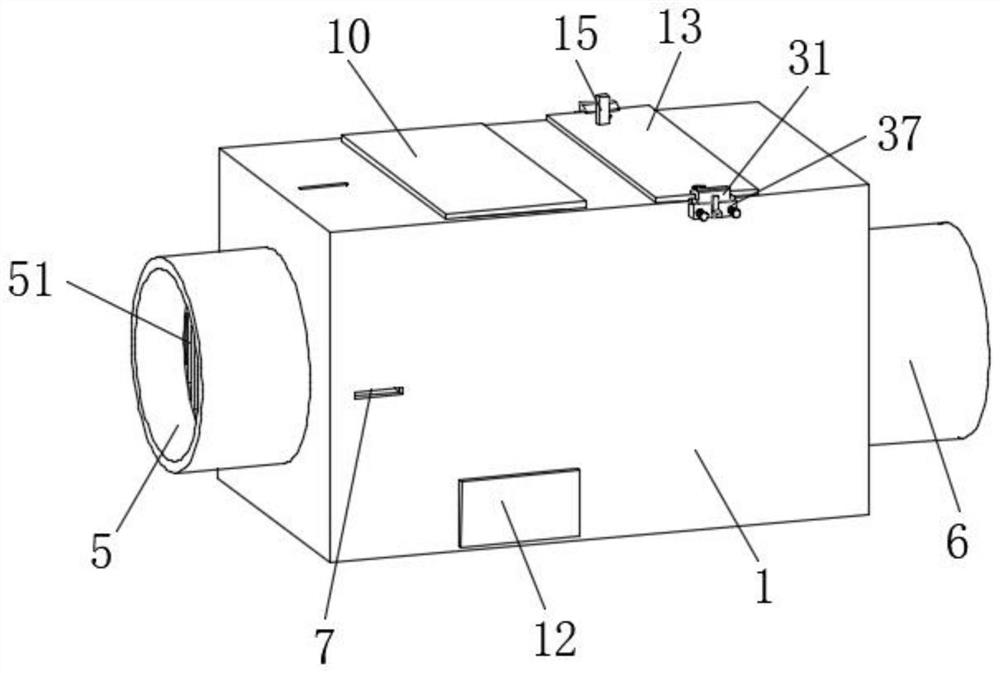

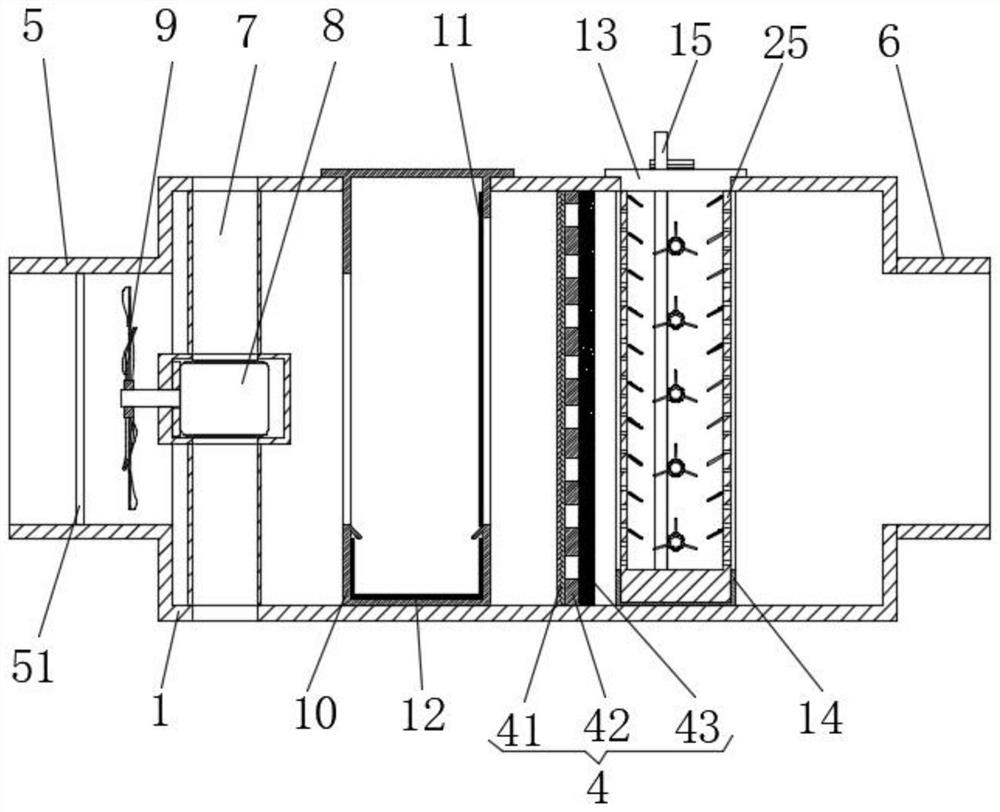

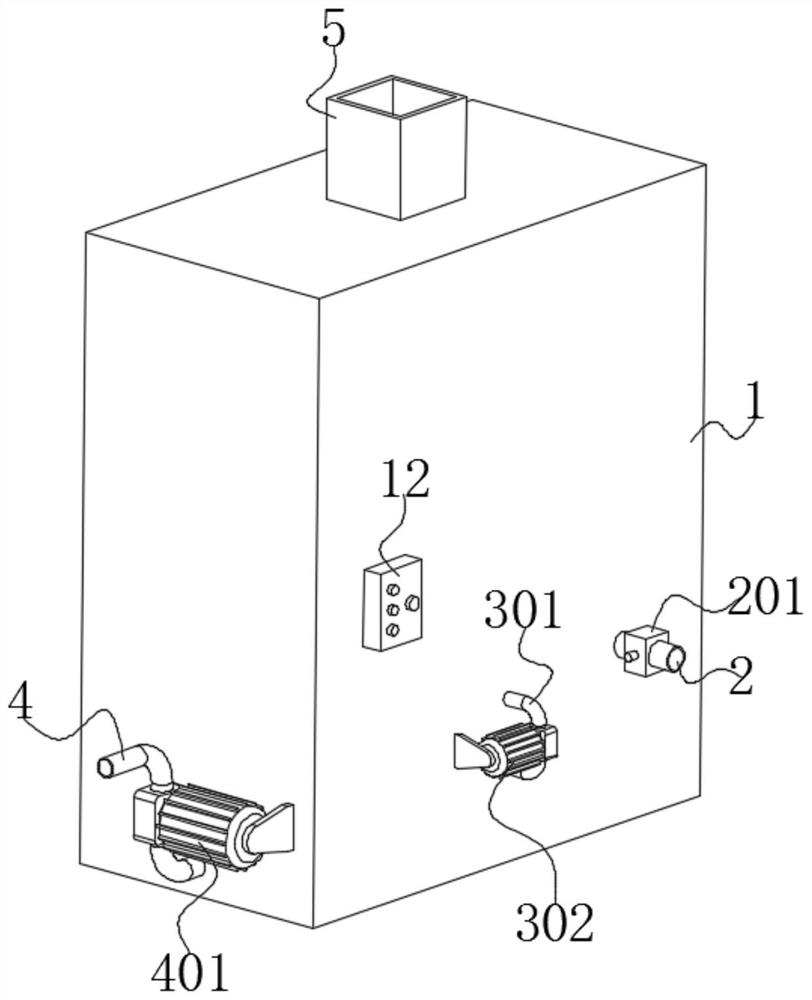

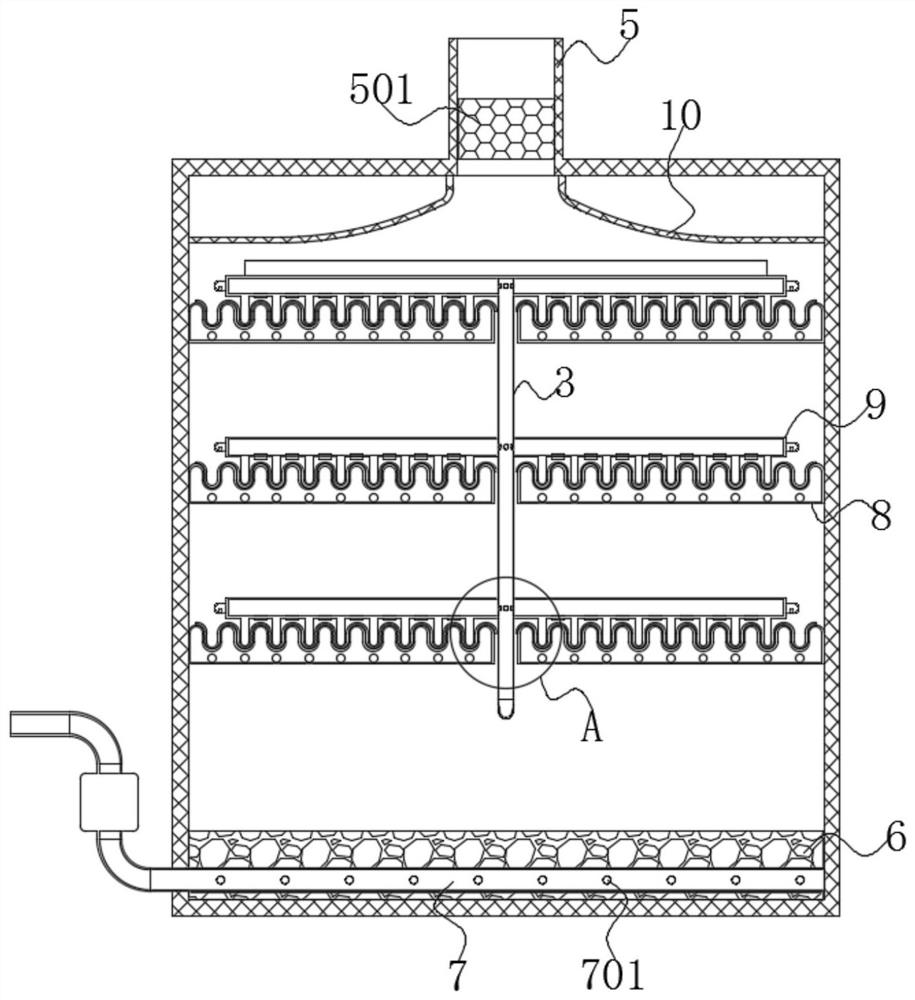

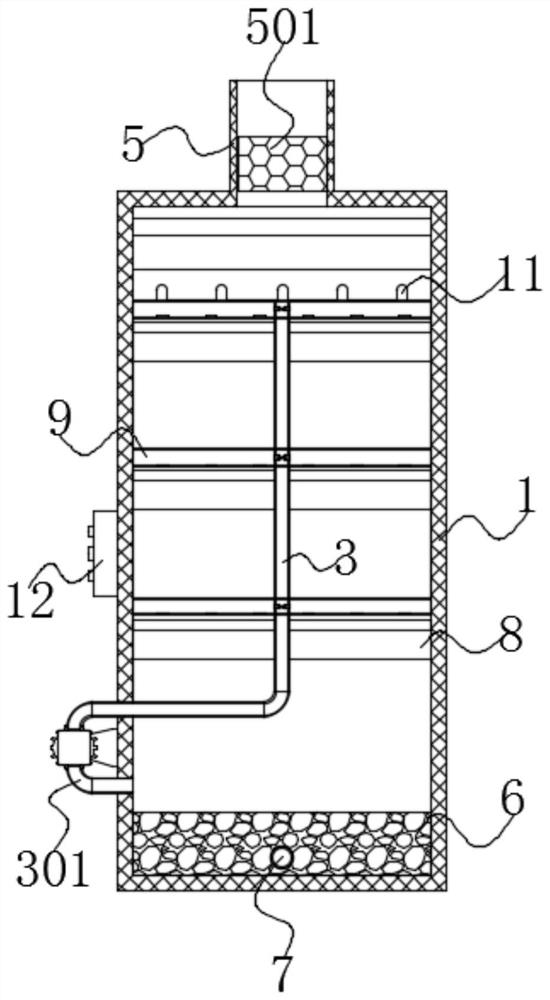

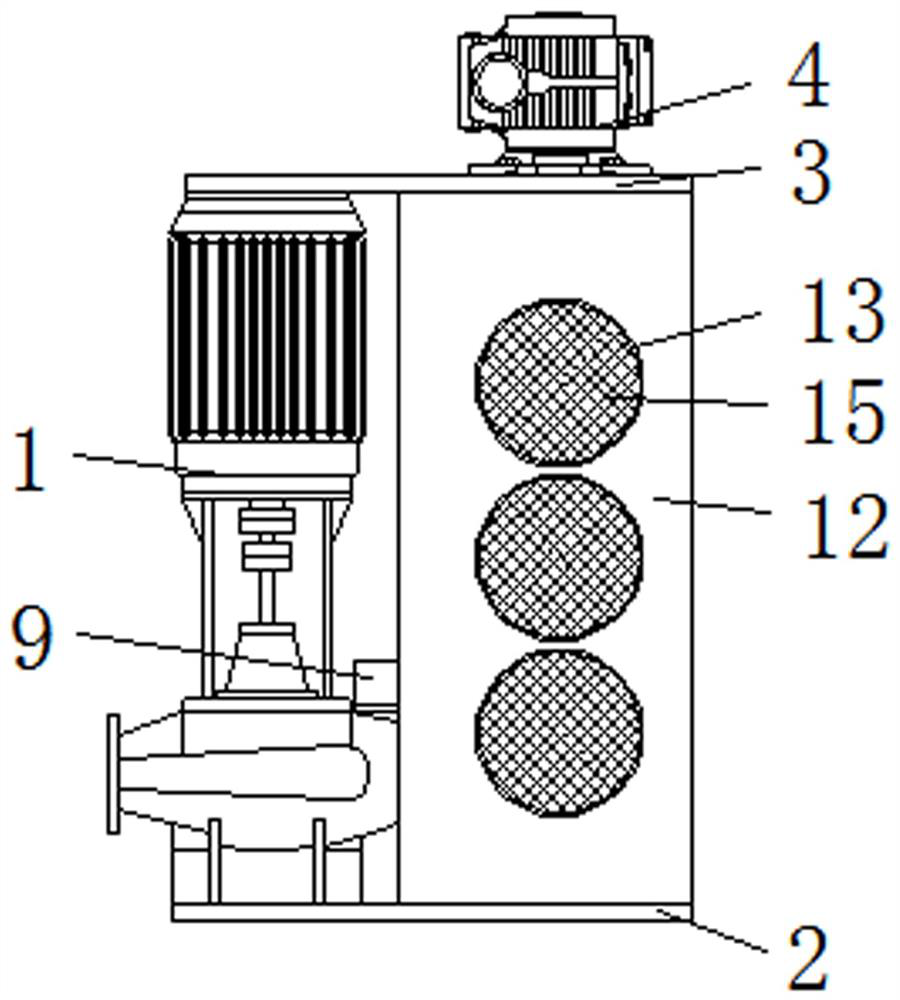

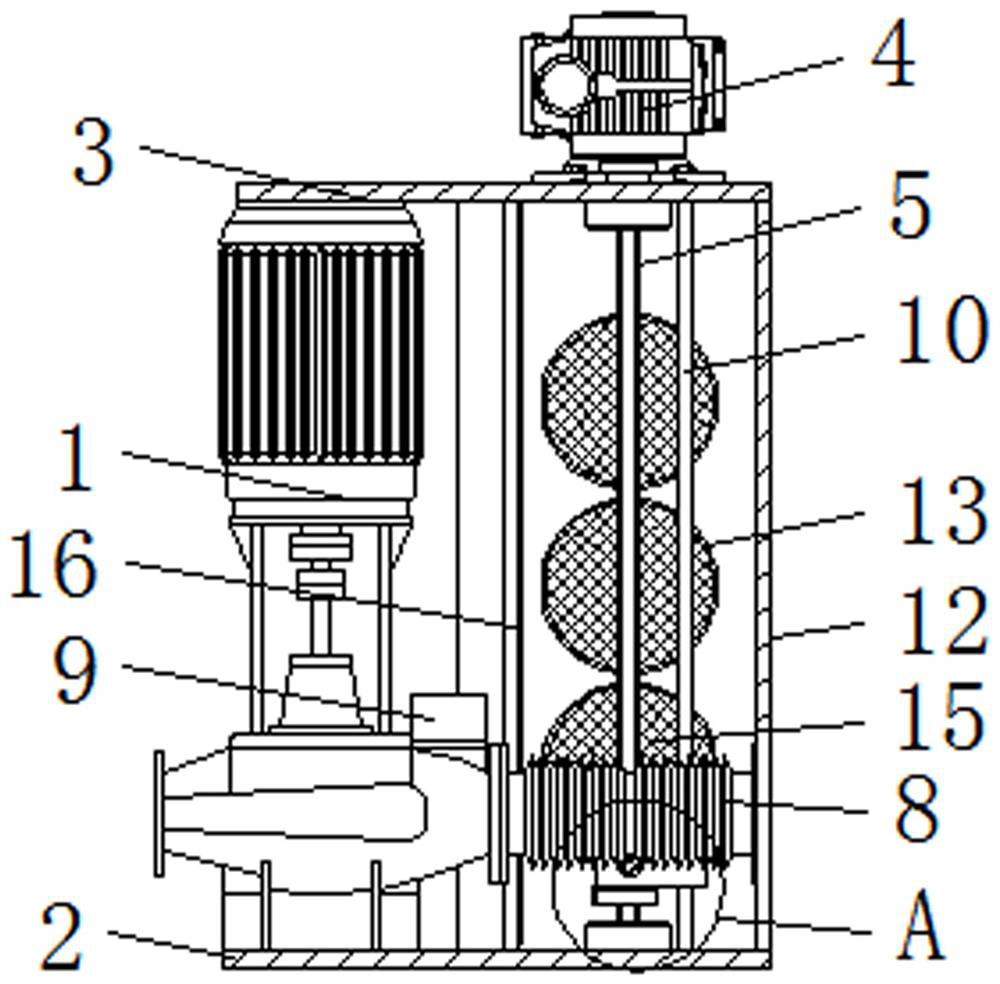

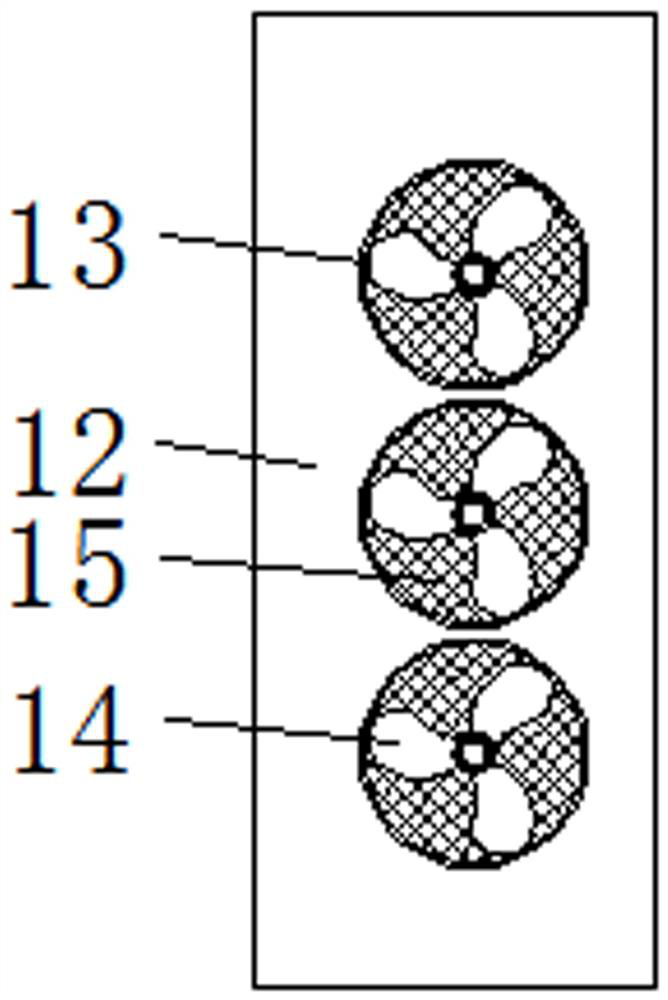

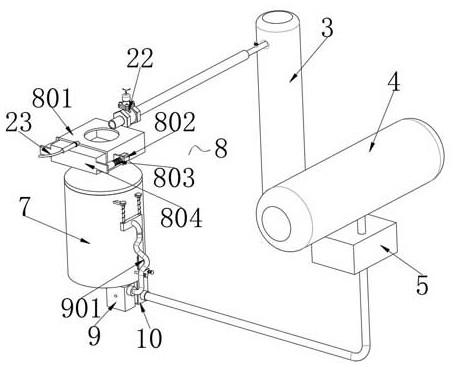

Active air inducing type zeolite adsorption multi-stage composite waste gas treatment machine

PendingCN113171670APromote withdrawalEasy to limitCombination devicesGas treatmentElectric machineStructural engineering

The invention discloses an active air inducing type zeolite adsorption multi-stage composite waste gas treatment machine. The waste gas treatment machine comprises a box body, a first adsorption mechanism, a second adsorption mechanism and a limiting mechanism, wherein an air inducing pipe is arranged at an opening in the left side of the box body, an exhaust pipe is arranged at an opening in the right side of the box body, a support is arranged at the inner left end of the box body, a motor is installed in the support, an output shaft of the motor is rotationally connected with a round hole formed in the center of the left side of the support, fan blades are arranged at an end, and the input end of the motor is electrically connected with the output end of an external control switch; and the first adsorption mechanism is slidably connected to the interior of a U-shaped sliding groove plate arranged at the inner right end of the box body, and a cover plate is installed at the upper end of the adsorption mechanism. According to the active air inducing type zeolite adsorption multi-stage composite waste gas treatment machine, particulate matters in waste gas can be filtered firstly, and then multi-stage adsorption can be conducted on the waste gas, so adsorption is more thorough, and waste gas treatment effect is better.

Owner:河南中太联创环保设备有限公司

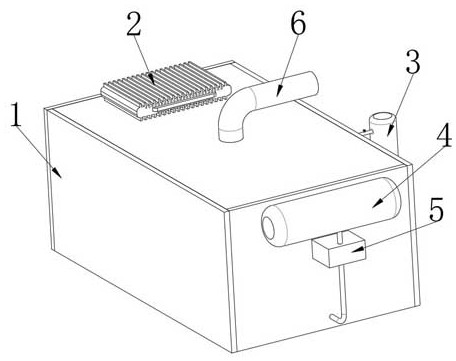

Heating power waste heat recovery device

InactiveCN107328262AIncreased circulation distanceImprove recycling ratesHuman health protectionDispersed particle filtrationActive carbonMachining process

The invention discloses a heating power waste heat recovery device, comprising a water tank and a filter box; the inner cavity of the water tank is fixedly connected to a third air inlet pipe, the left side of the third air inlet pipe is fixedly connected to a tee by a second air inlet pipe, the left side of the inner surface of the tee is fixedly connected to a first air inlet pipe, the right end of the top of the water tank is provided with a water filling opening, the bottom of the left side of the water tank is provided with a water outlet, the inner cavity of the filter box is fixedly connected to a sponge filter layer, an active carbon filter layer and a KDF filter layer from bottom to top in sequence, and the left end of the top of the inner cavity of the filter box is fixedly provided with a dust sensor. The inner cavity of the water tank is fixedly connected to the third air inlet pipe in an S-shaped structure, a circulating distance of waste gas in the water tank can be increased, a recovery use rate of heat in the waste gas is effectively improved, the waste gas produced in a machining process of industrial production is solved, not only is the problem of heat loss solved, but also the problem of pollution to the environment is also solved.

Owner:颜秋羊

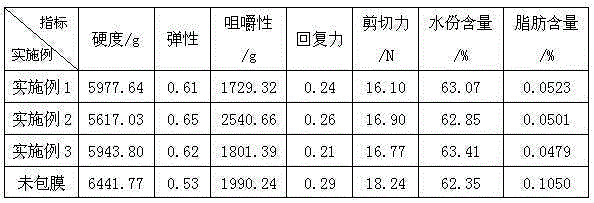

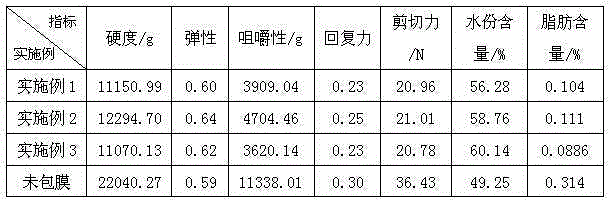

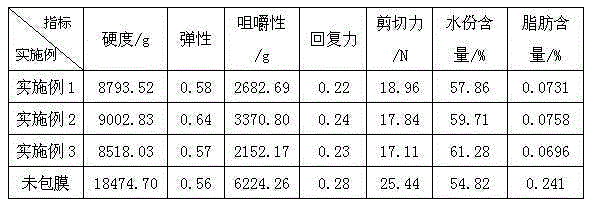

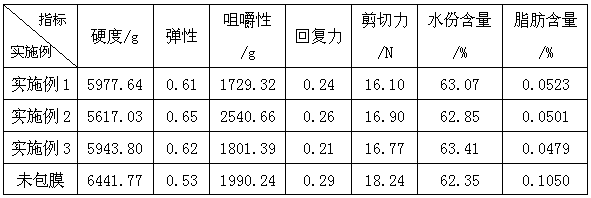

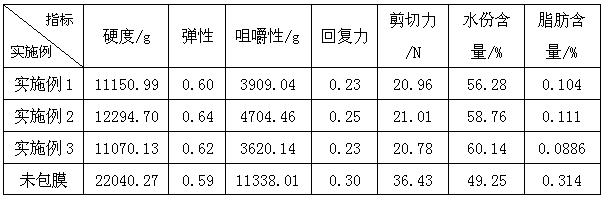

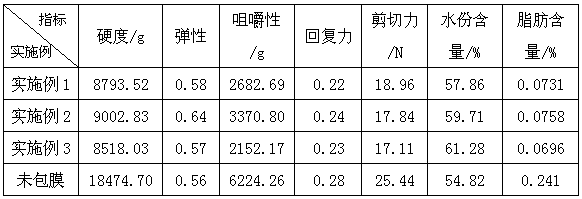

Preparation method for edibility-prolonging fried pork in scoop

The invention discloses a preparation method for edibility-prolonging fried pork in scoop, and relates to a making method for meat products. The preparation method for the edibility-prolonging fried pork in scoop comprises three steps of membrane covering, frying and juice boiling, wherein a water-retention oil-control membrane solution used in membrane covering is obtained by mixing, by weight, 30-50 parts of water, 10-40 parts of pig skin gel, 2-6 parts of rice protein isolate, 2-6 parts of soybean protein isolate, 0.1-0.5 part of carboxymethylcellulose and 0.1-0.5 part of compound antioxidants and preserving heat under the condition of 50 DEG C for 3-5 min. According to the preparation method for the edibility-prolonging fried pork in scoop, a method of membrane covering processing is adopted, and therefore the advantages of being capable of improving the tenderness of meat slices of the fried pork in scoop and the crispness of paste, prolonging the edibility period of the fried pork in scoop, reducing the bad flavor generated by oxidization, prolonging the quality guarantee period of the fried pork in scoop, and meanwhile reducing the nutritional ingredient loss are achieved.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Fruit drying device

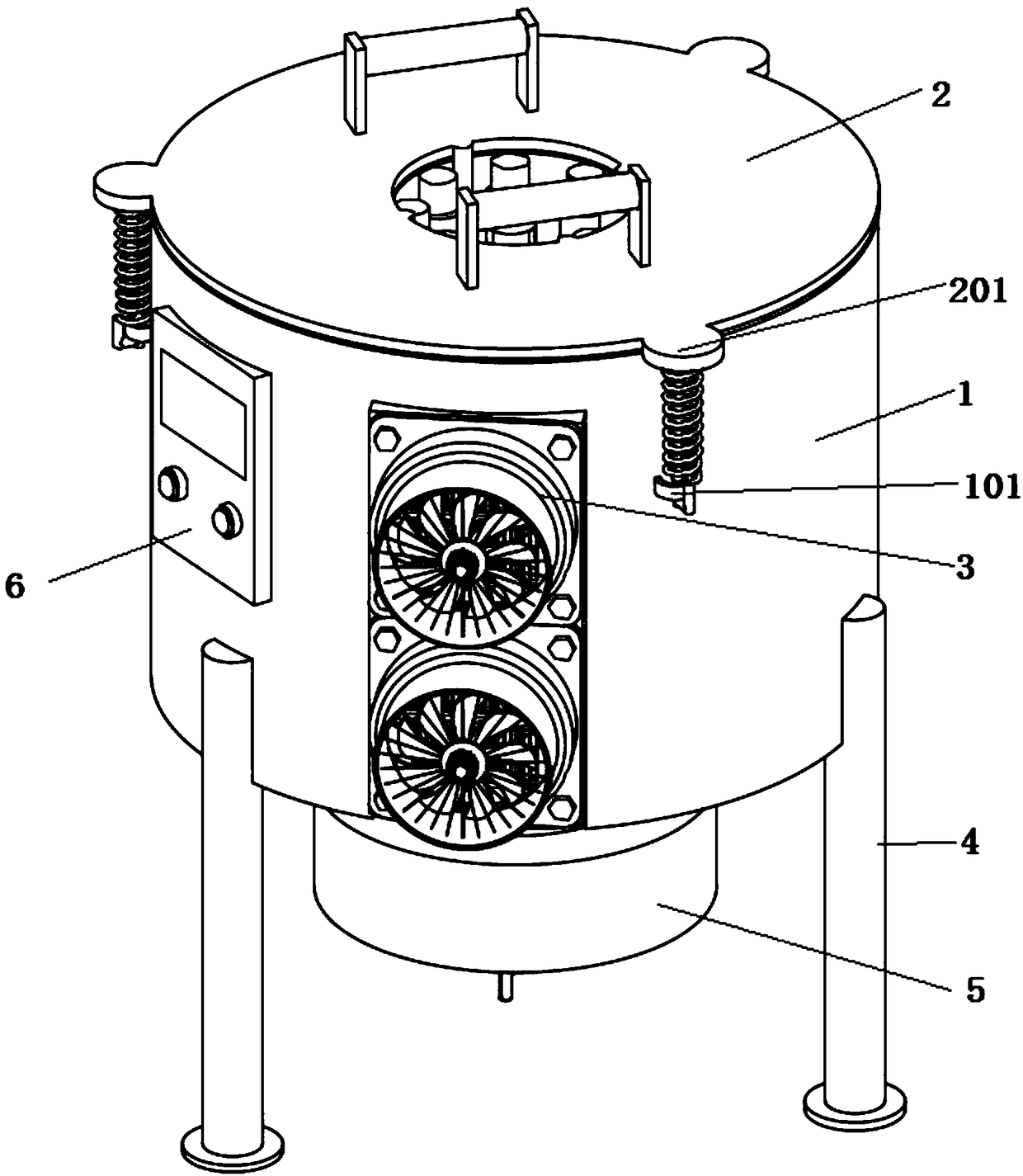

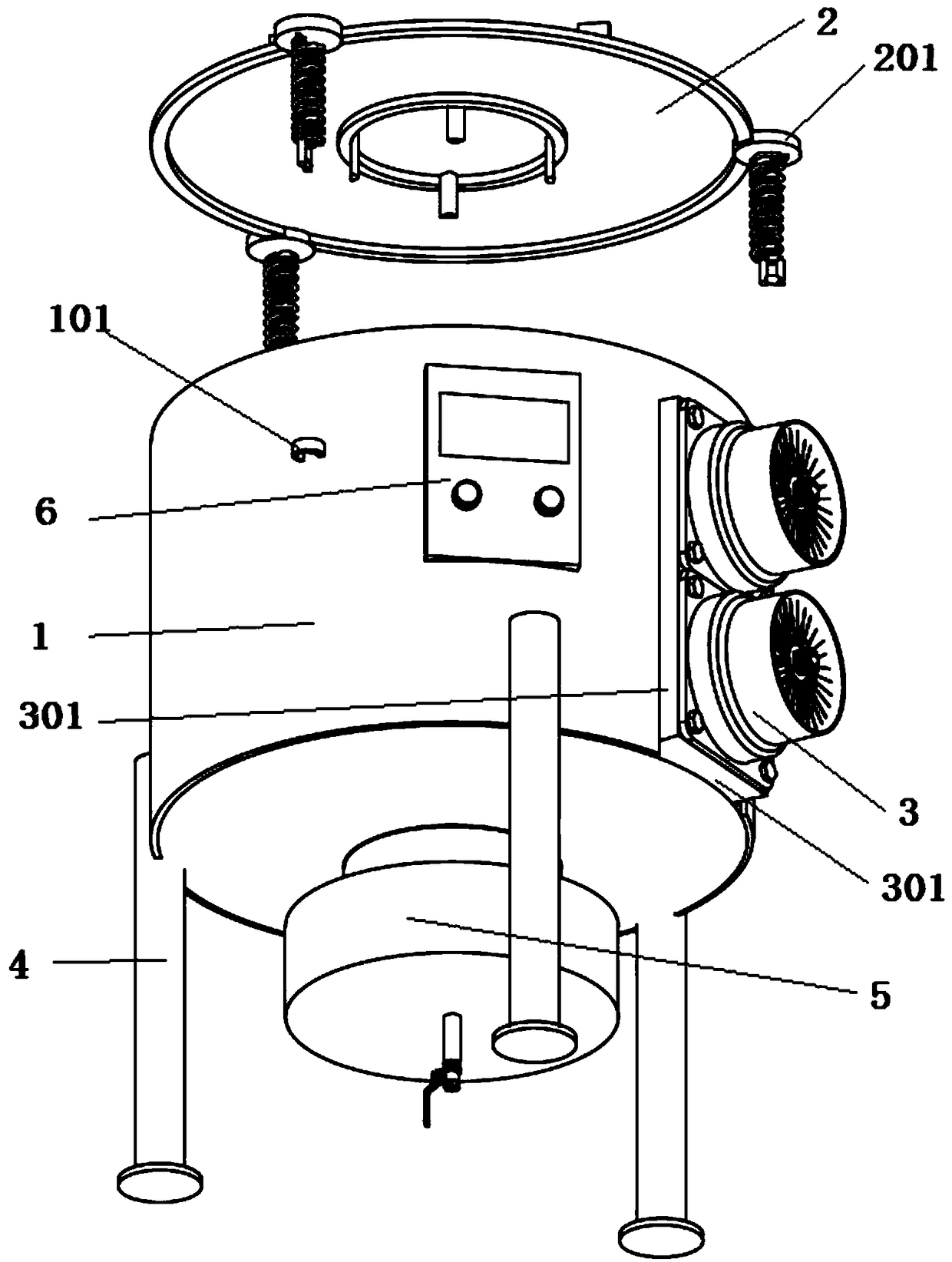

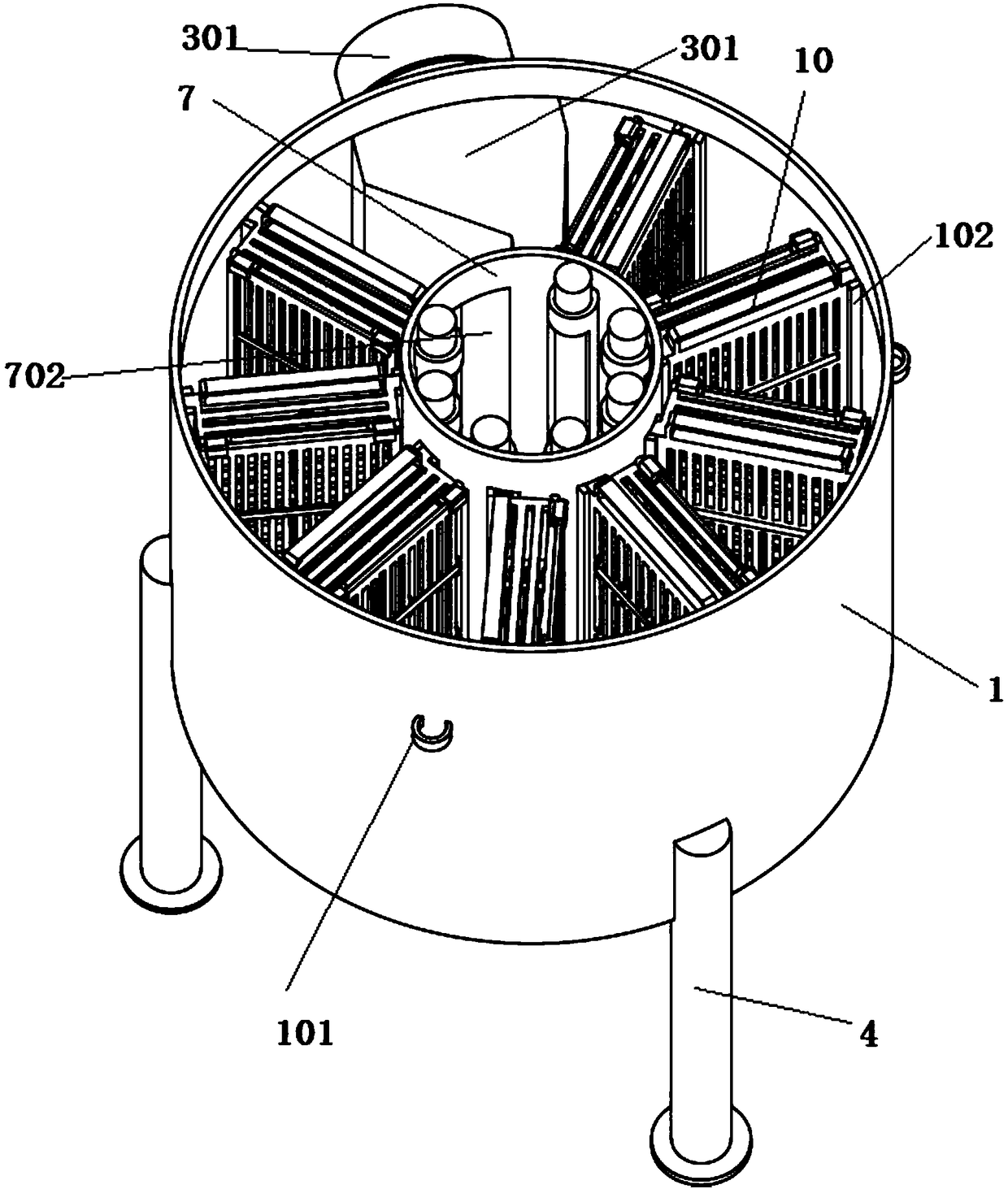

The present invention provides a fruit drying device. The fruit drying device comprises fruit loading grids, horizontal partitioning plates and water draining box covers. Periphery side walls and bottom plates of eight fruit water draining boxes are all provided with a plurality of long-strip ventilation grooves in a run-through manner; a lifting and pulling handle is also supportedly welded on the side wall of the top end of each of the fruit water draining boxes; an air outlet groove is arranged in a periphery side wall of an air outlet pipe and presents a long-strip and arc shape; the waterdraining box cover is rotatably hingedly connected with the opening of the side part of the fruit water draining box; the fruit water draining box cover is also provided with a plurality of long-strip ventilation grooves in the run-through manner; and two pressing lock catches arranged symmetrically at the bottom position of the fruit water draining box are used to conduct locking and positioningof the water draining box cover. By arranging a novel air cylinder, an inclined slicing surface of the air cylinder can space, block and separate an annular dry air passage and guide the dry air intoan air outlet groove to be discharged, and thus ensures normal circular circulation of the dry air.

Owner:成超宇

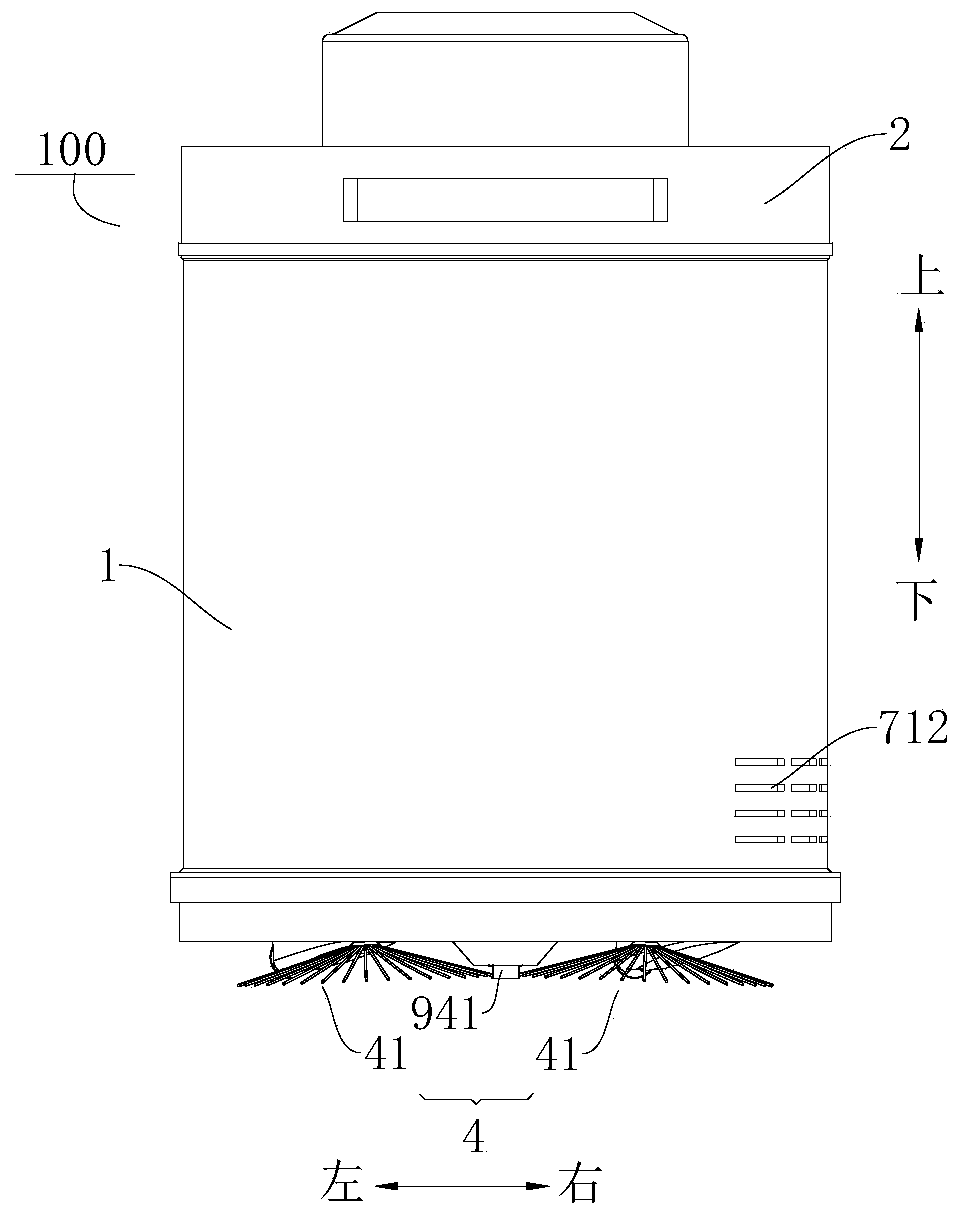

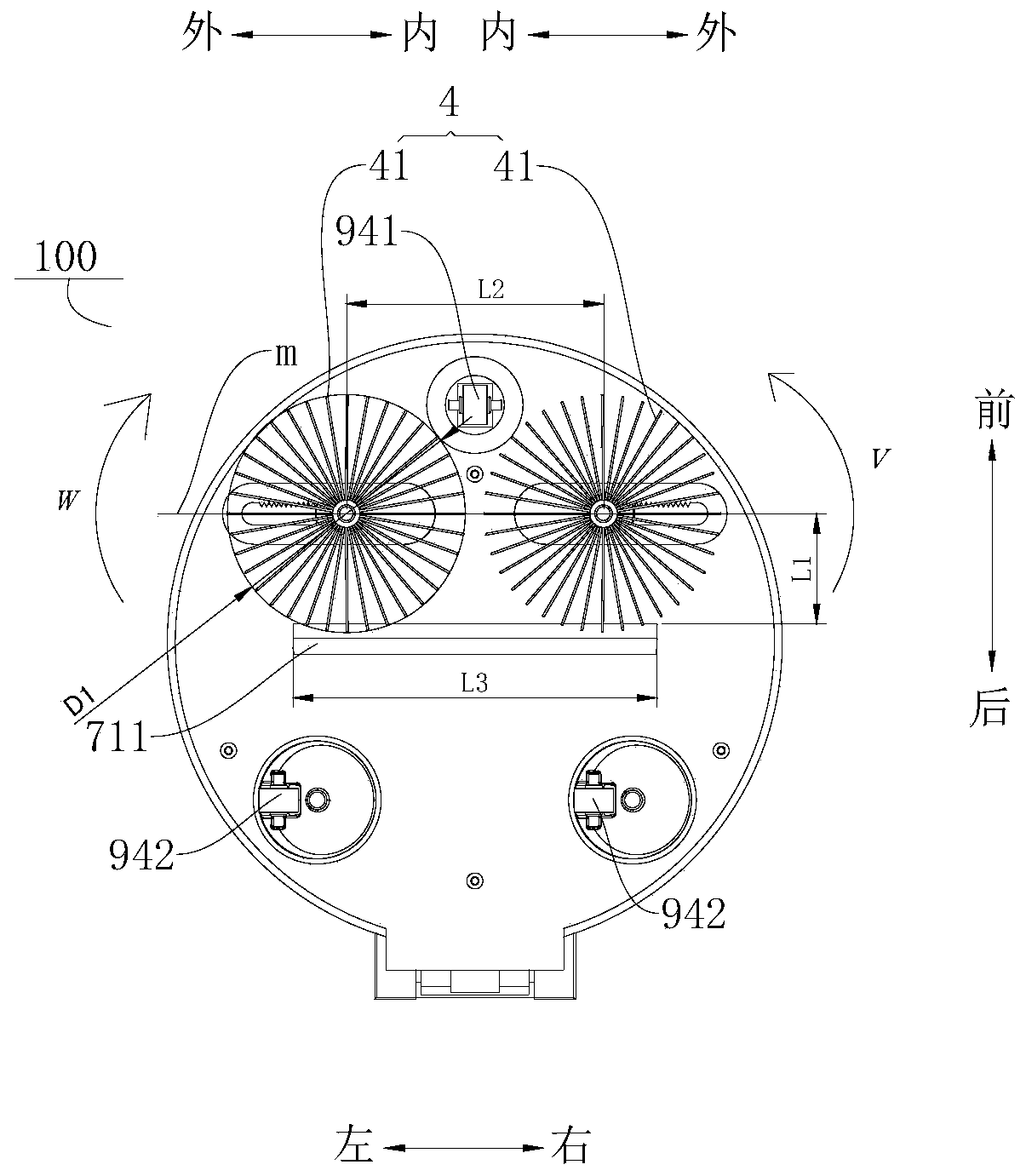

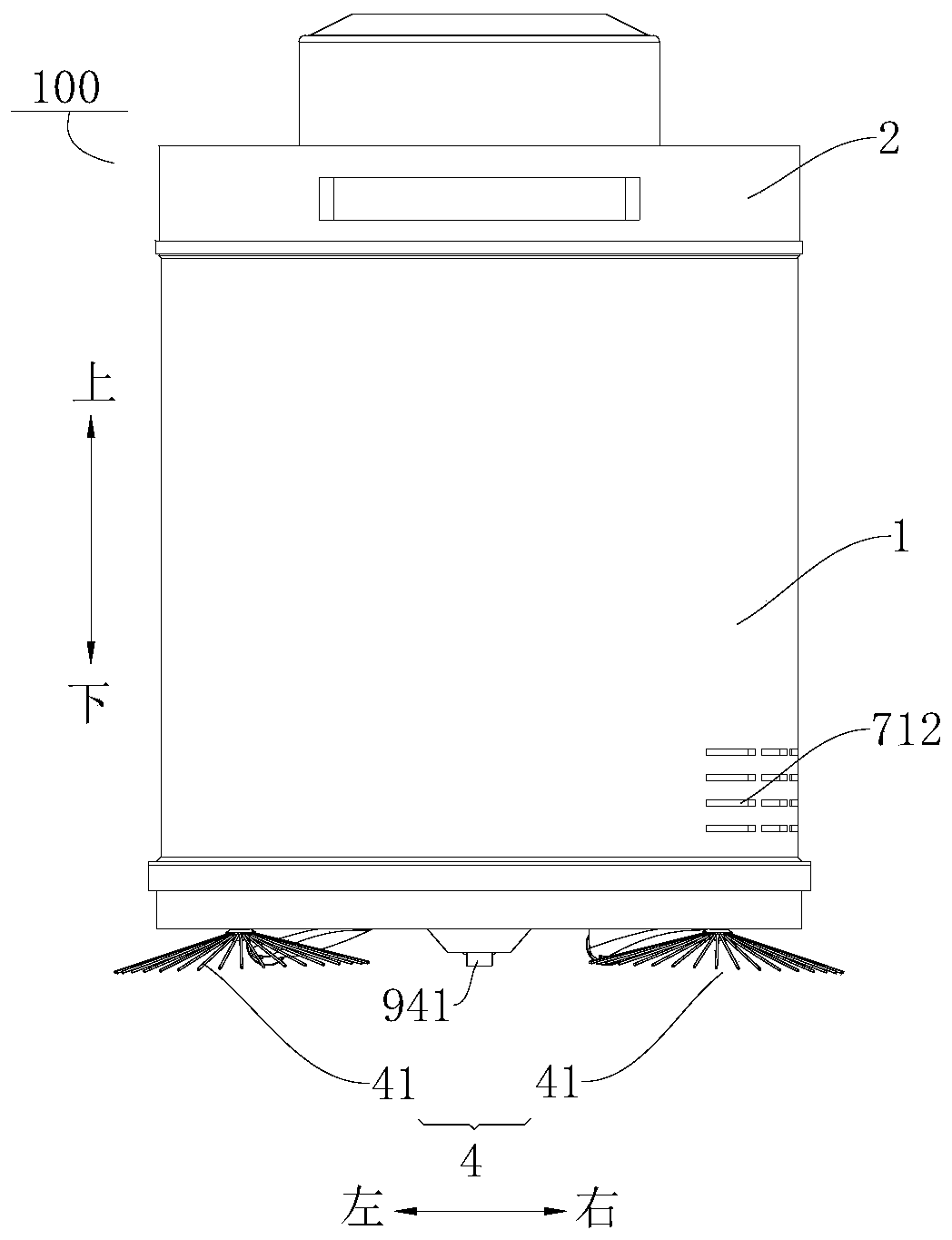

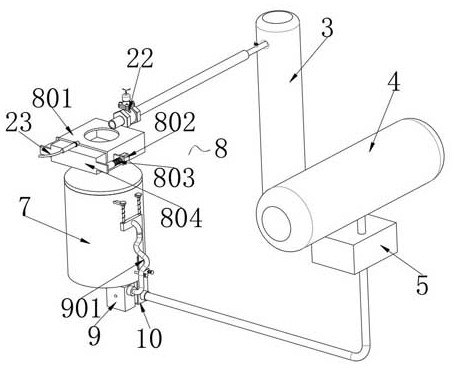

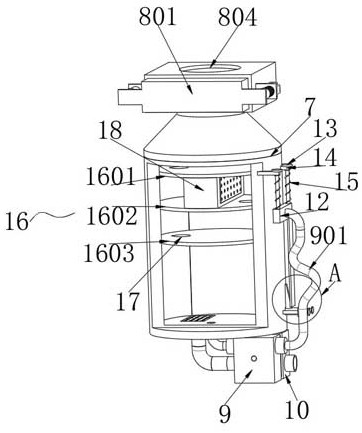

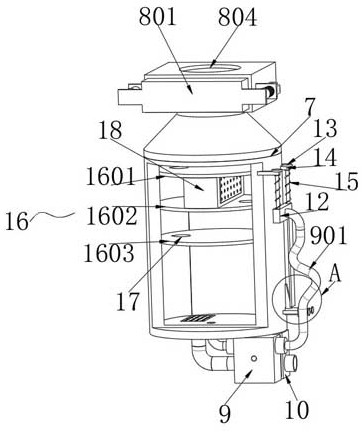

trash can vacuum cleaner

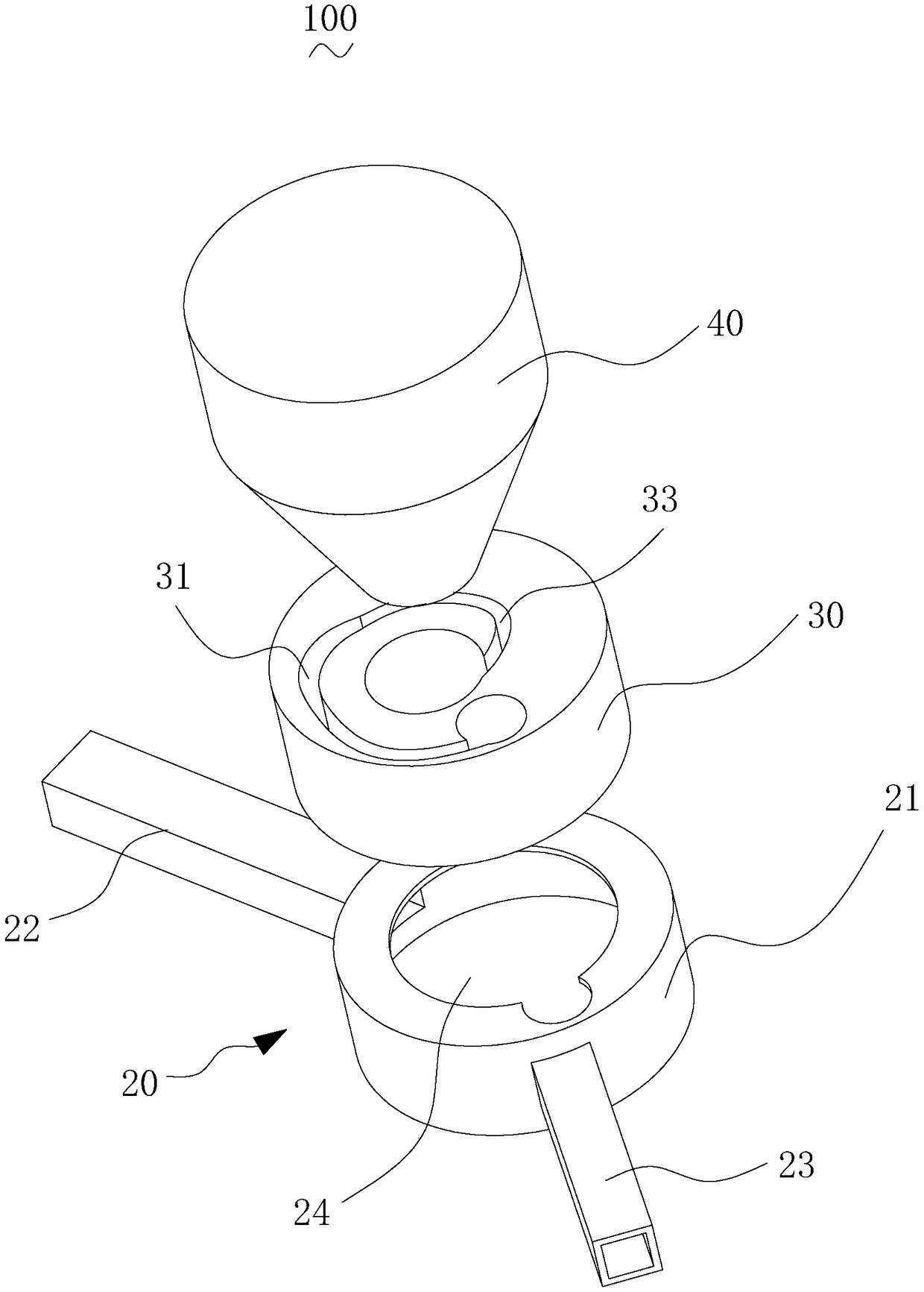

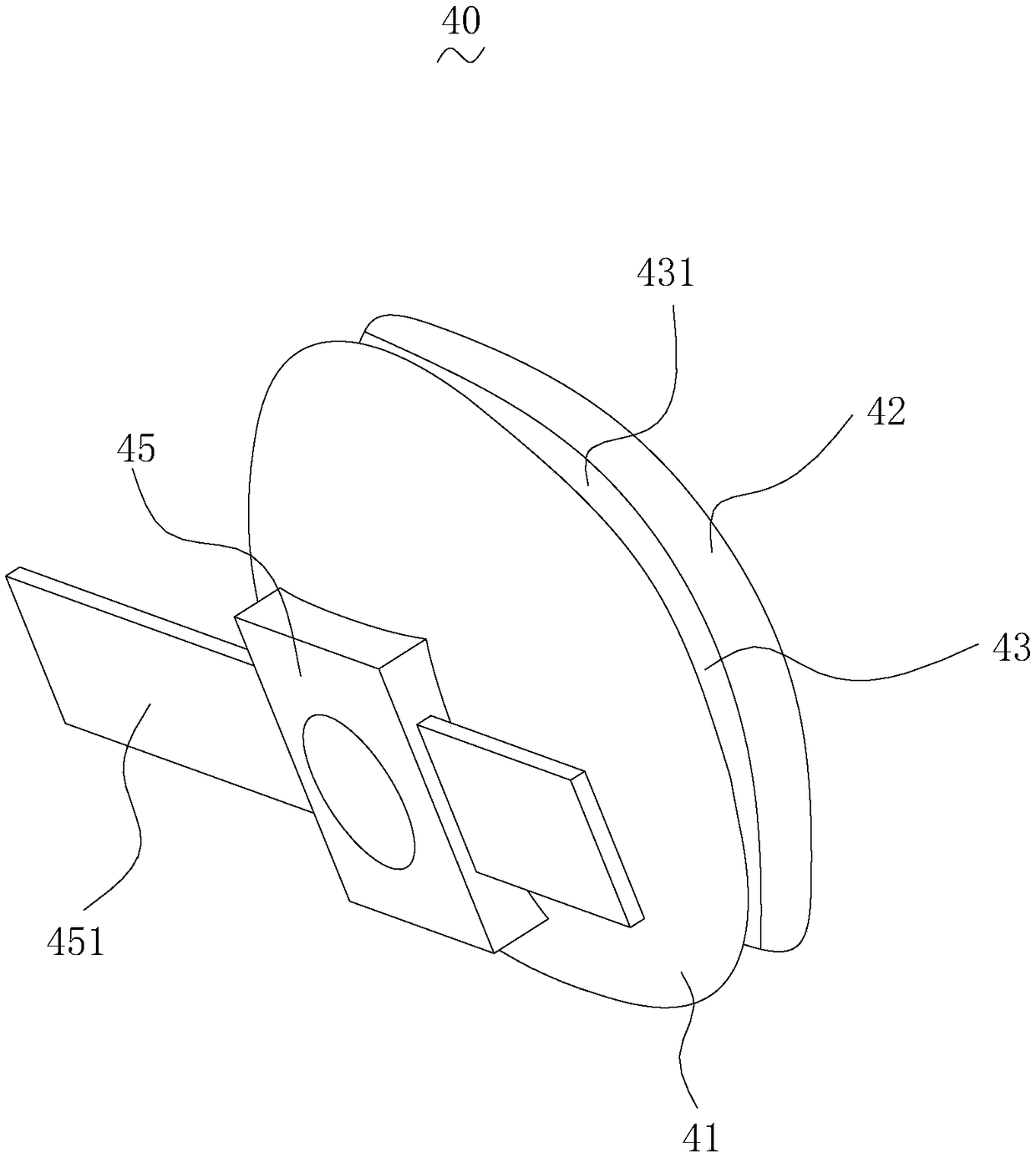

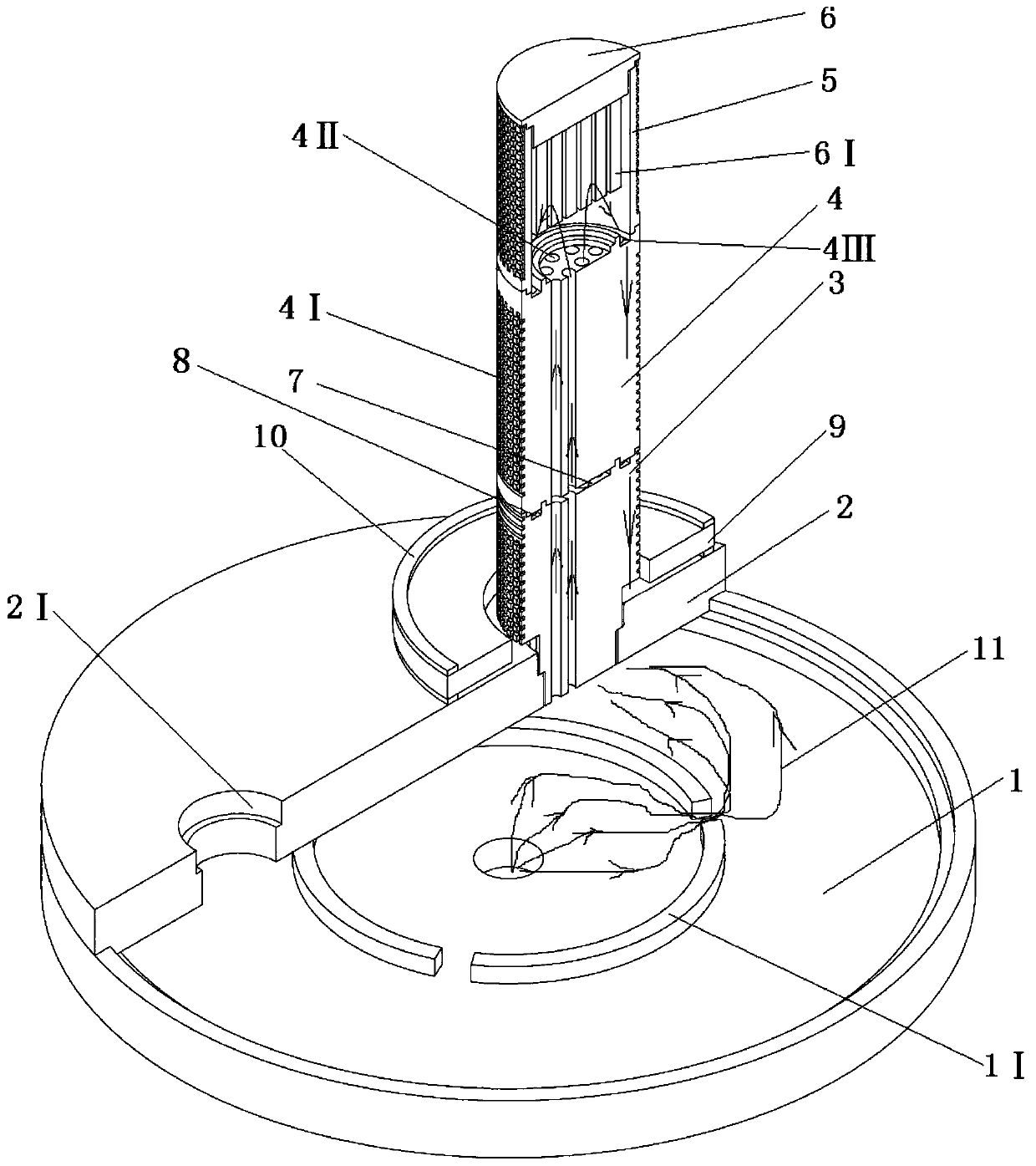

ActiveCN107334421BIncreased circulation distanceReduce flow noiseSuction filtersSuction nozzlesDust controlEnvironmental engineering

The invention discloses a garbage-can-type dust collector. The garbage-can-type dust collector comprises a can body assembly, a can cover assembly, a floor brush assembly, a dust cup assembly, an air channel assembly and a moving assembly. Both an air feeding channel and an air discharging channel are communicated with the dust cup assembly, a part of the air discharging channel is arranged on the can cover assembly, and the other part of the air discharging channel is arranged on the can body assembly, an air-feeding-channel inlet of the air feeding channel is formed in the can body assembly and located at the lower portion of the barrel body assembly, and an air-discharging-channel outlet of the air discharging channel is formed in the can body assembly and located at the lower portion of the barrel body assembly. According to the garbage-can-type dust collector, as the air-feeding-channel inlet and the air-discharging-channel outlet are formed in the lower portion of the barrel body assembly, and both the air feeding channel and the air discharging channel are communicated with the dust cup assembly, the flow distance of airflow in an airflow channel is prolonged, the flow noise of the airflow is effectively reduced, the pressure loss of the airflow in the air channel assembly can be reduced, and the dust removing efficiency is improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

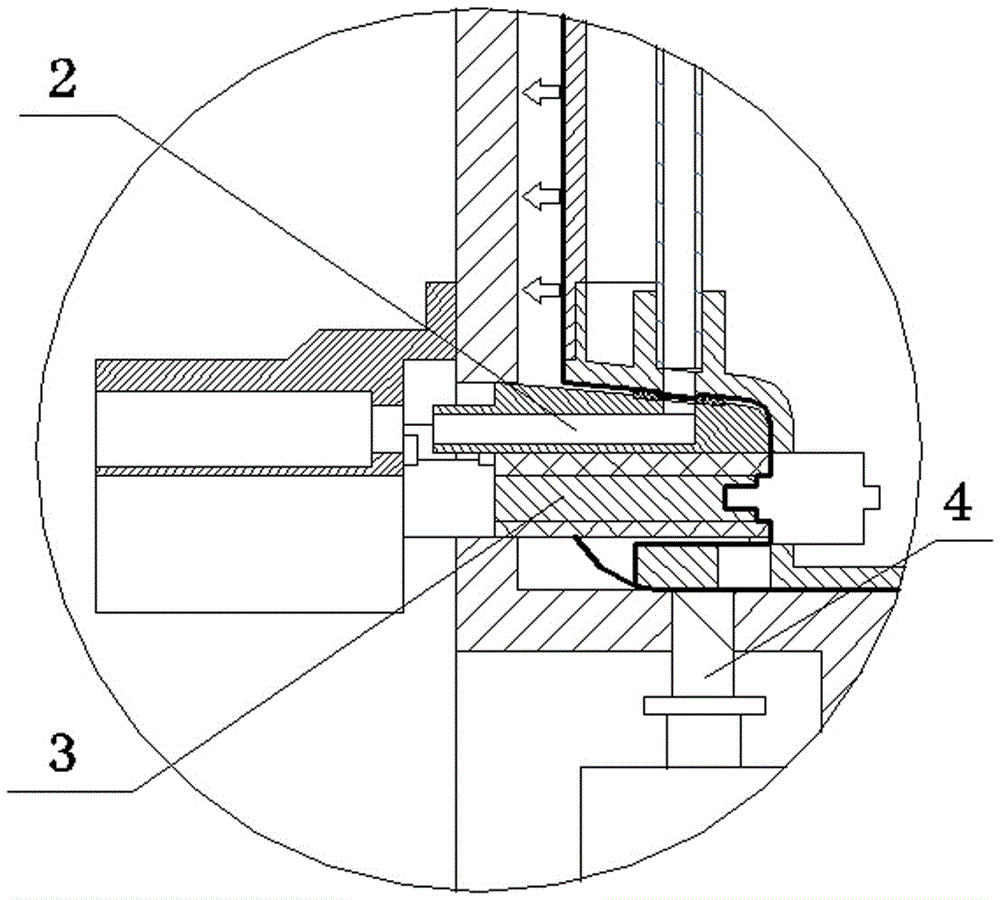

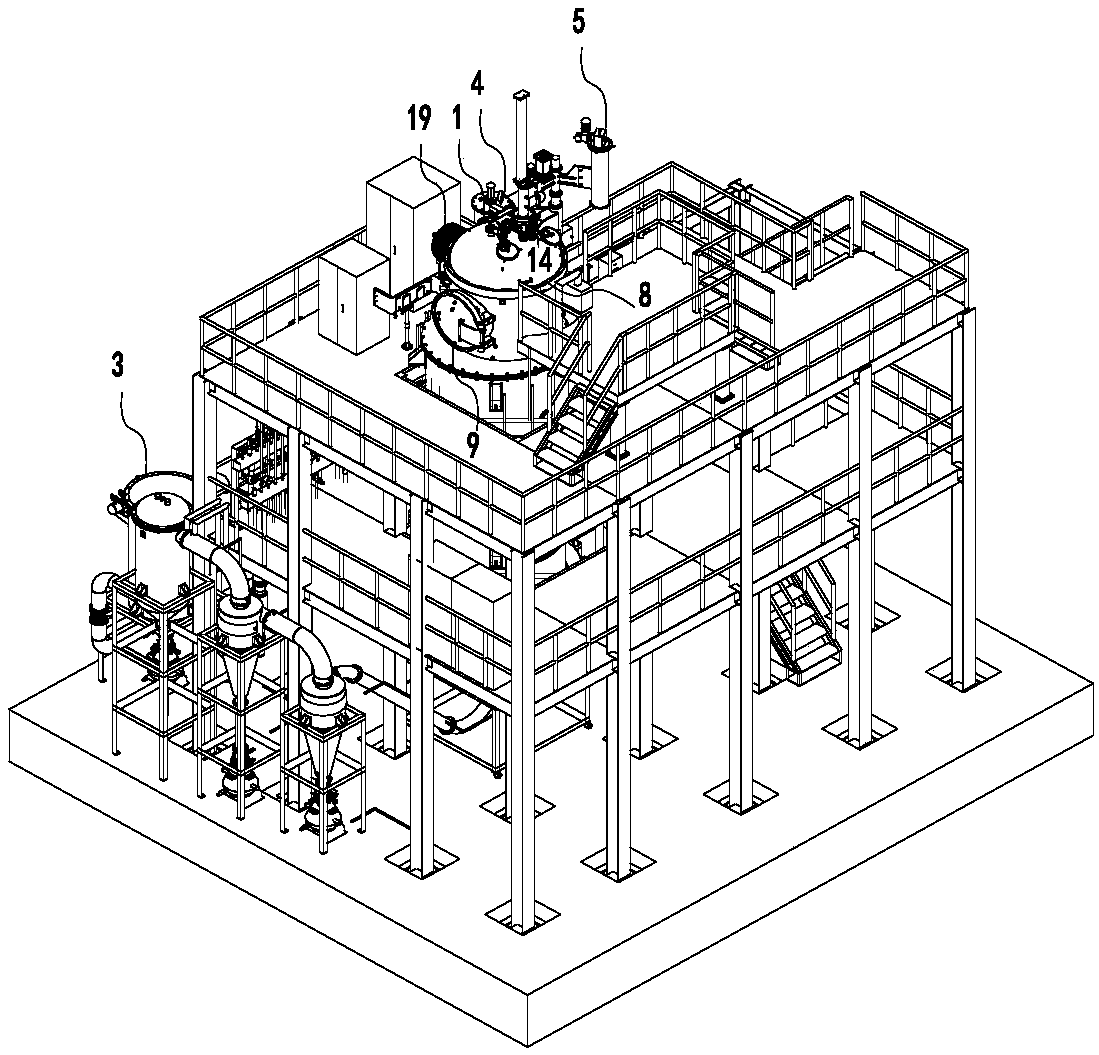

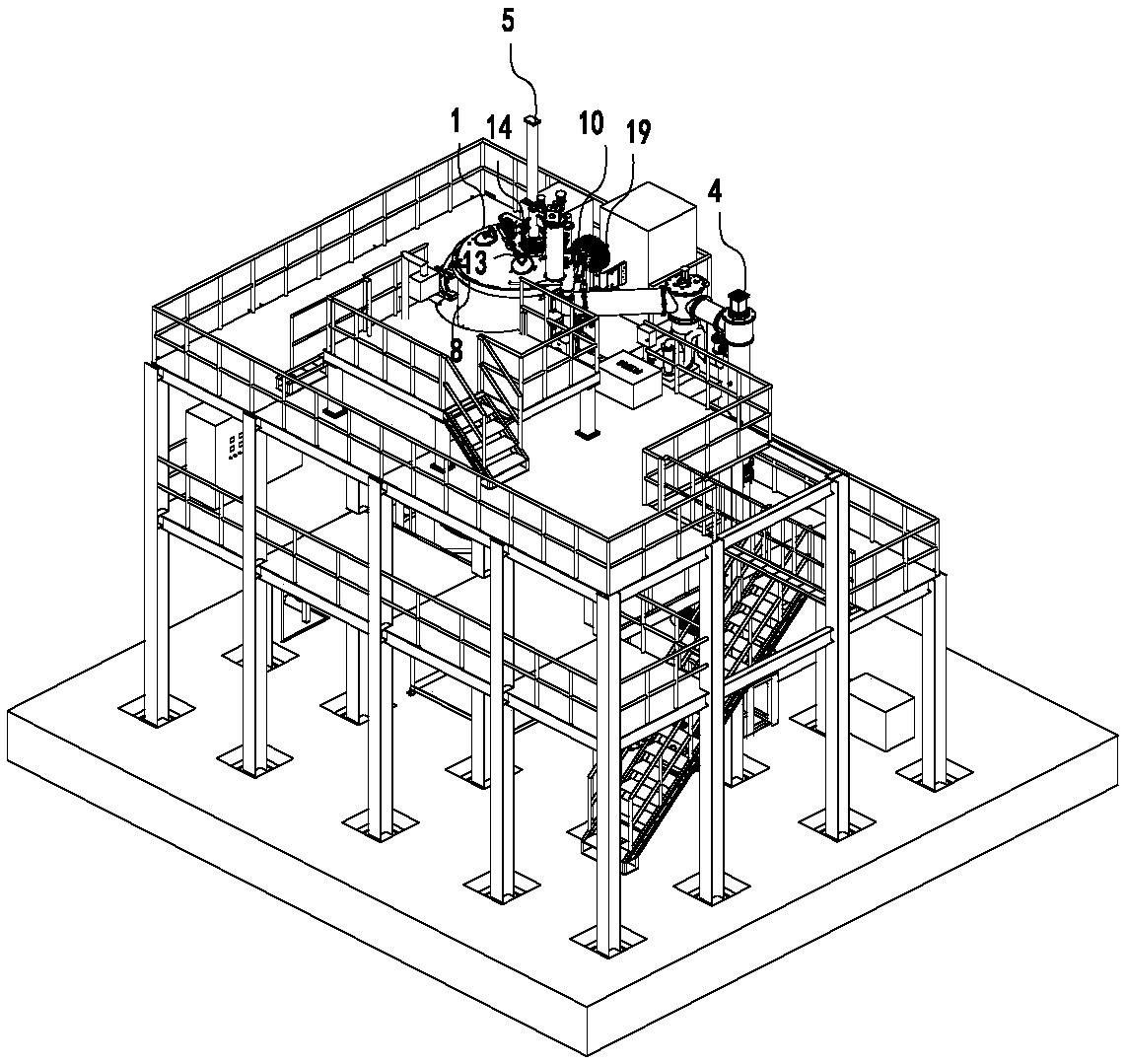

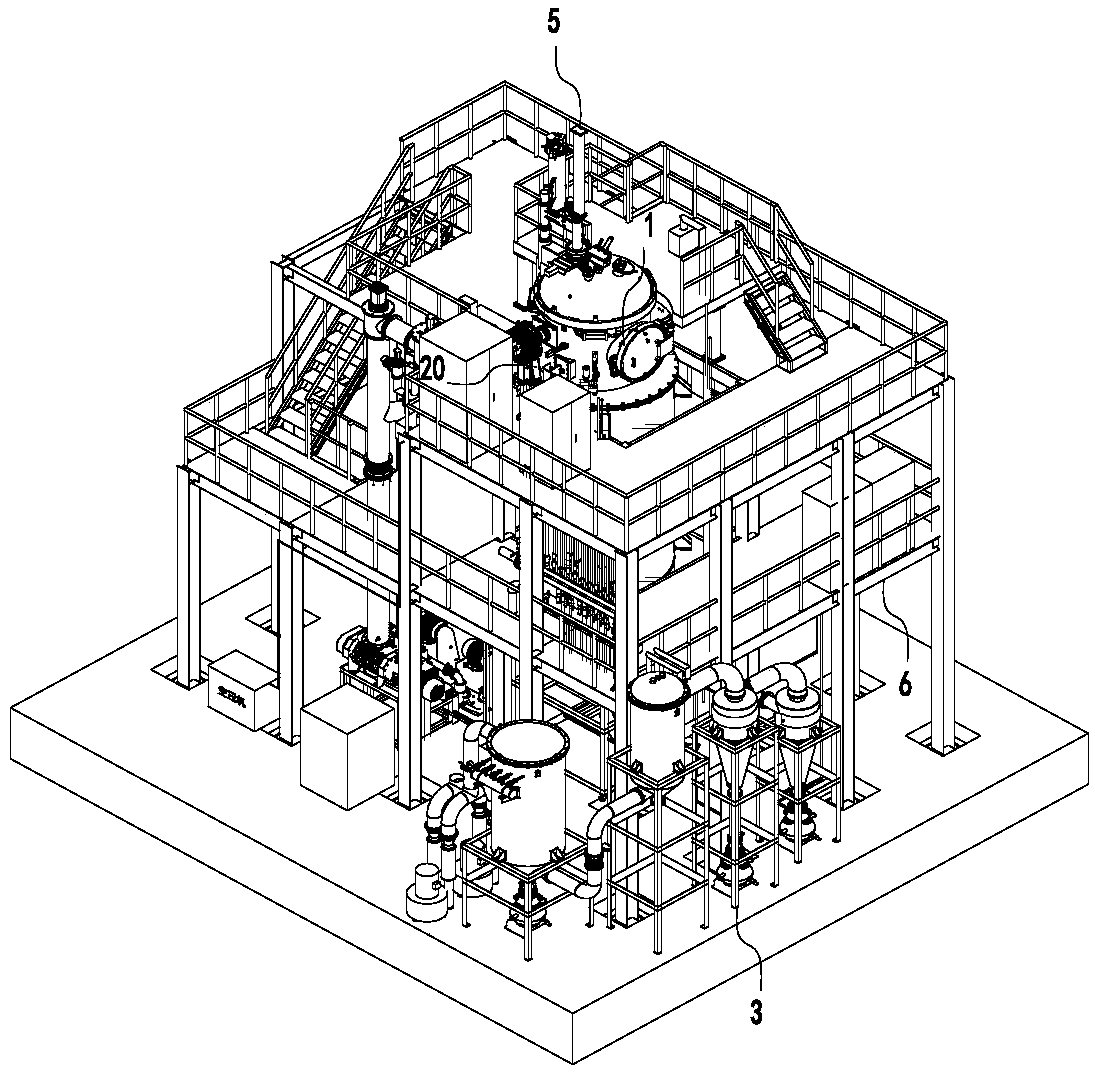

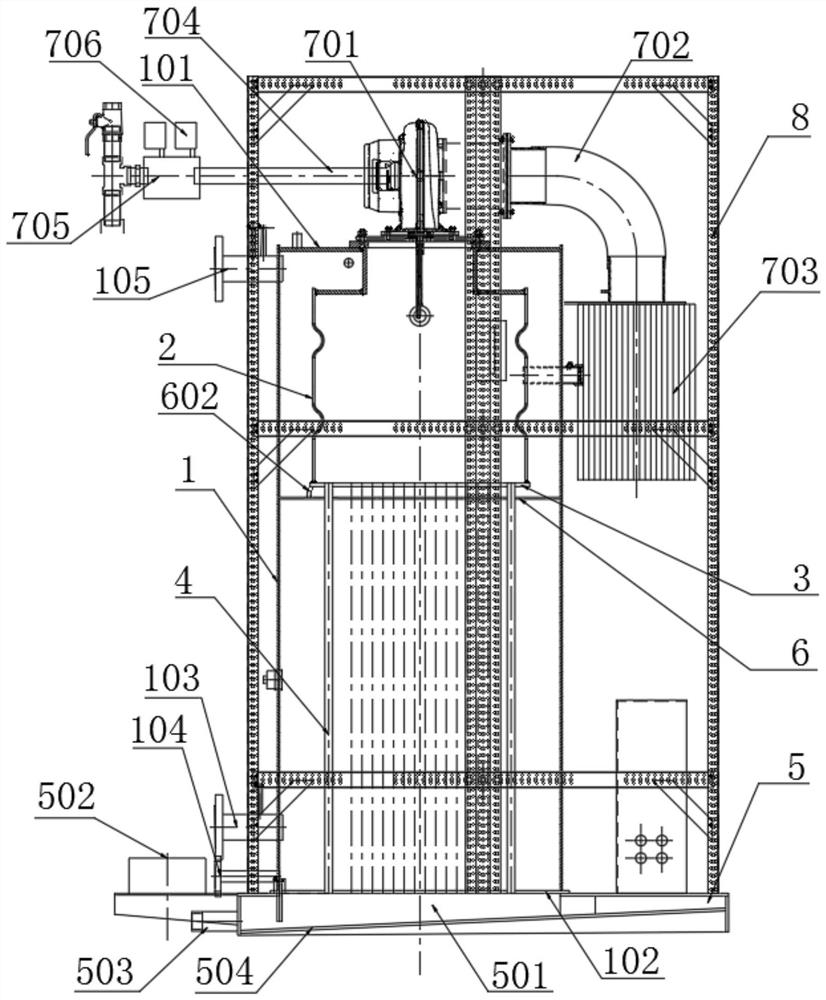

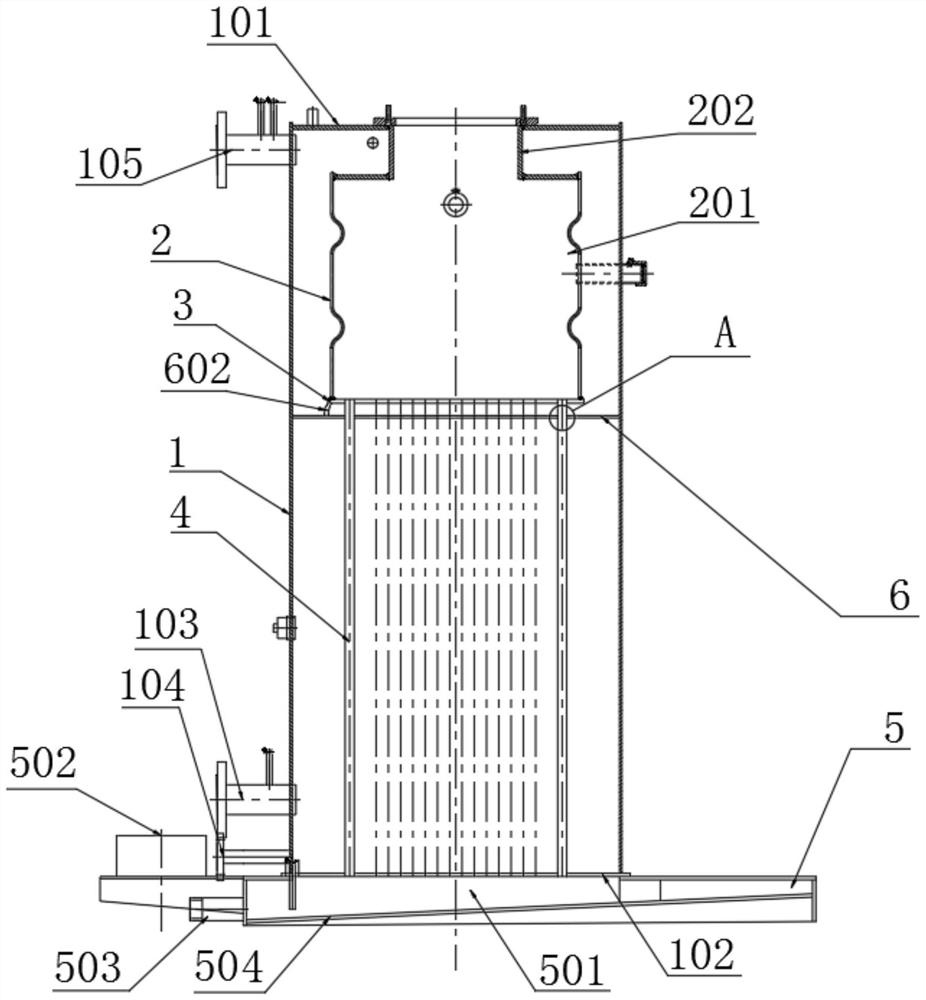

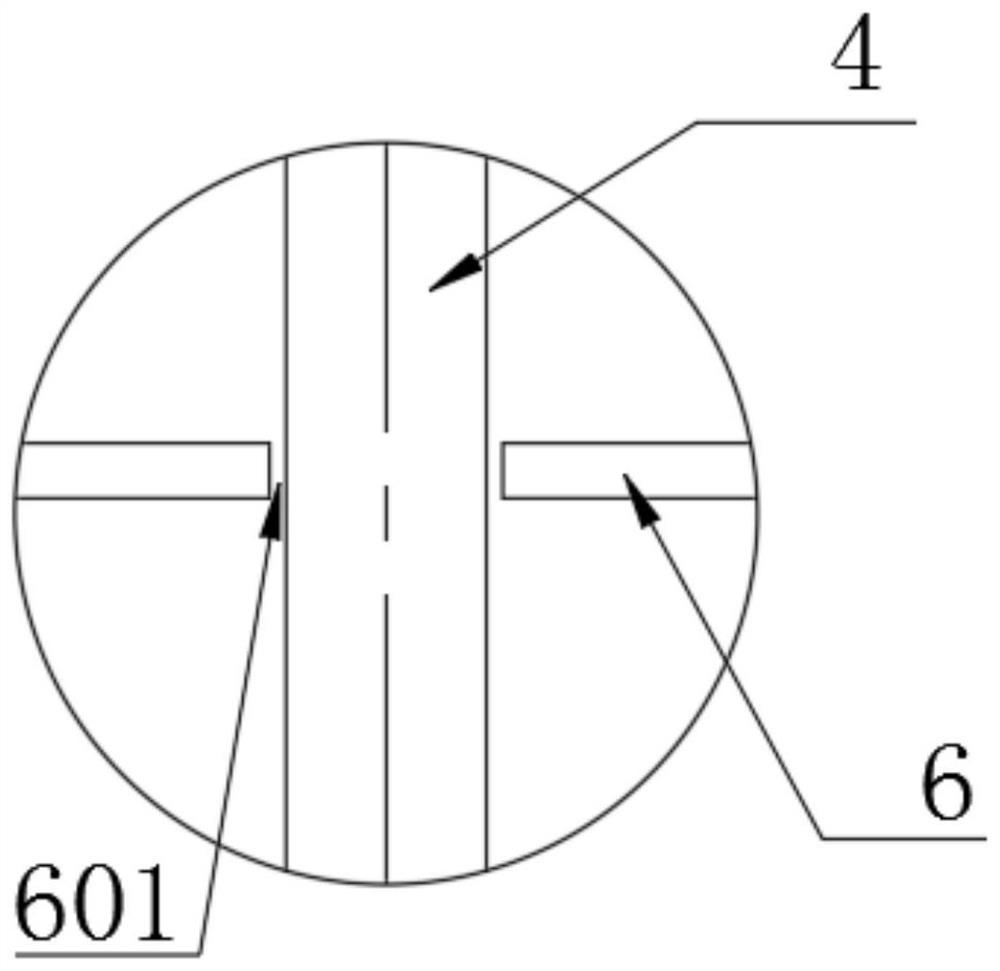

Semi-continuous vacuum gas atomization powder making furnace

The invention belongs to the field of vacuum induction gas atomization powder making equipment, in particular to a semi-continuous vacuum gas atomization powder making furnace. The semi-continuous vacuum gas atomization powder making furnace comprises a platform (6) and is characterized in that a furnace body assembly (1), an atomization chamber (2), a powder collecting assembly (3), a vacuum assembly (4) and a turret assembly (5) are arranged on the platform (6); the furnace body assembly (1) is fixedly arranged on the atomization chamber (2); a cavity of the furnace body assembly (1) is communicated with a cavity of the atomization chamber (2) through a first isolation valve (7); vacuum pipe ports of the vacuum assembly (4) are communicated with the cavity of the furnace body assembly (1) and the cavity of the atomization chamber (2); the turret assembly (5) is connected with the furnace body assembly (1); and a powder collecting port of the powder collecting assembly (3) is communicated with a powder outlet at the bottom of the atomization chamber (2). The semi-continuous vacuum gas atomization powder making furnace is simple in structure, high in the space utilization rate, good in reliability, high in heating speed, clean and pollution-free.

Owner:SHENYANG VACUUM TECH INST

Full temperature range-combined storage bin type intelligent temperature control delivery cabinet

ActiveCN106568296AIncreased circulation distanceImprove delivery qualityLighting and heating apparatusRefrigeration devicesEngineeringService mode

The invention provides a full temperature range-combined storage bin type intelligent temperature control delivery cabinet. The delivery cabinet comprises one or a plurality of delivery units, wherein each delivery unit is provided with one or a plurality of delivery sections; a comprehensive joint is arranged and corresponding to each delivery section; the comprehensive connector comprises an exhaust joint which communicates with an exhaust pipeline, and a comprehensive connector which is connected to a power supply and a central controller. The delivery cabinet is a delivery cabinet capable of setting temperature control for foods; orders can collectively distributed and delivered (many to one) through a cold-chain logistics; the delivery cabinet is used for intelligently storing the delivered foods and performing temperature-controlled distribution (one to many). With the adoption of the abovementioned service mode, the circulation distance of products in a base can be obviously increased; the delivery quality of the distributed products can be obviously improved; the shortages in service of manual distribution can be overcome.

Owner:李旭丹

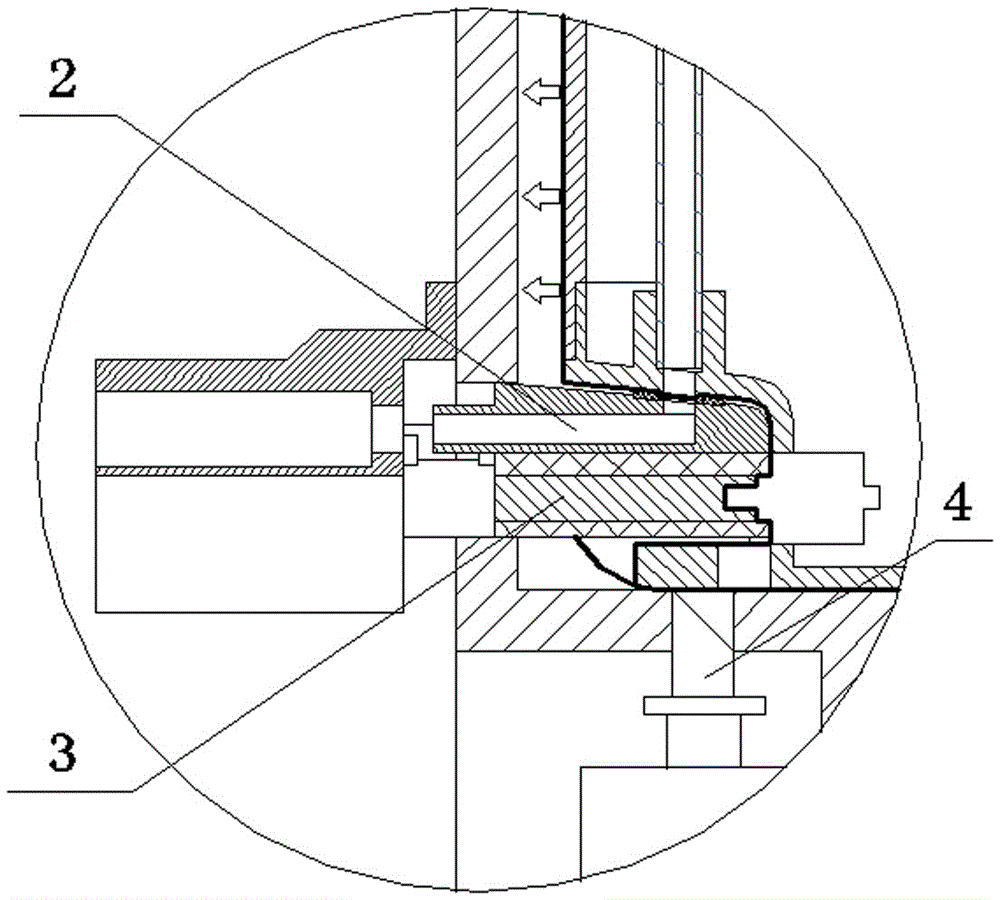

Medical breathing machine with turbopump

The invention relates to a medical breathing machine with a turbopump. The medical breathing machine with the turbopump comprises a mixing cover, an air guide rack and the turbopump. The mixing covercomprises a cover body, a first air inlet channel and a second air inlet channel, the first air inlet channel and the second air inlet channel are formed in the cover body through protruding, and a mixing cavity is formed in the cover body; the first air inlet channel and the second air inlet channel are communicated with the mixing cavity, the air guide rack is arranged on the cover body, and a first air guide channel and a second air guide channel are formed in the air guide rack; the first air guide channel is communicated with the mixing cavity and is in a bent shape, and the second air guide channel is communicated with the first air guide channel. The vibration and noise of the medical breathing machine with the turbopump are small.

Owner:钱小英

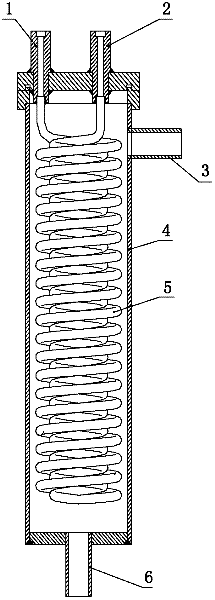

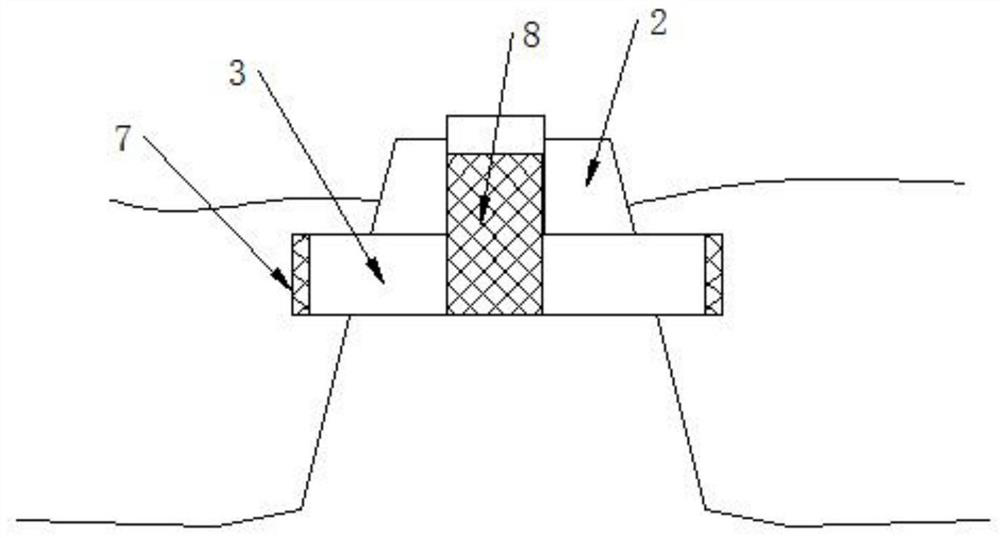

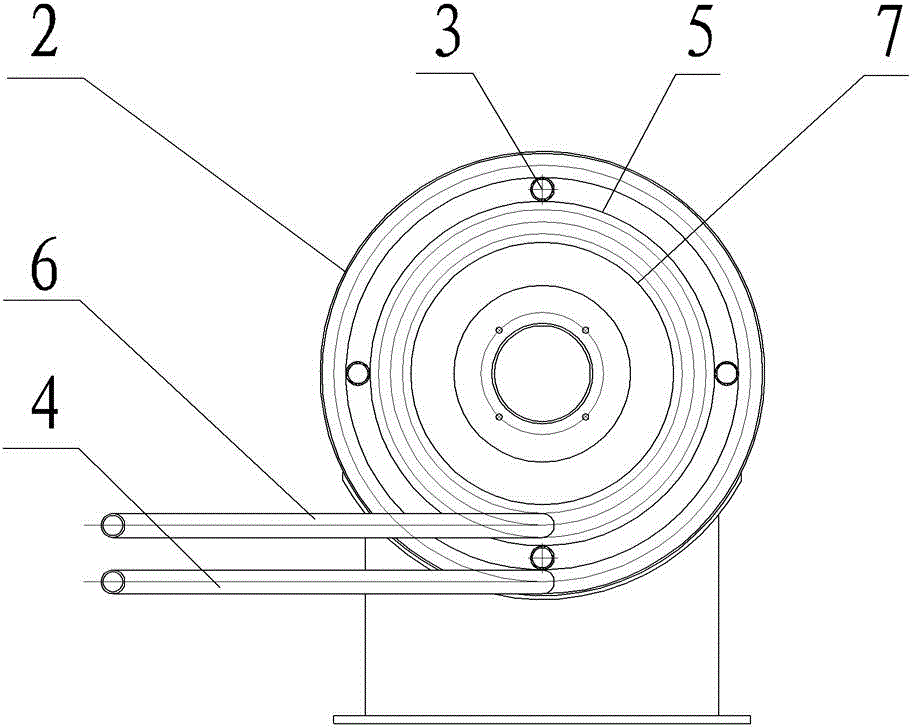

Superhigh voltage-resistance air passage electric insulator for electric thruster

ActiveCN106340360AHigh mechanical strengthIncreased circulation distancePipe elementsInsulating bodiesElectricityEngineering

The invention relates to a superhigh voltage-resistance air passage electric insulator for an electric thruster and belongs to the electric vacuum insulation technology field. The superhigh voltage-resistance air passage electric insulator mainly comprises an air inlet pipe, a flange, a shielding cover, a main insulator, ceramic particles, a gland, an isolation net and an air outlet pipe, wherein the ceramic particles are filled in the main insulator, two ends of the main insulator are fixedly connected with the flange, the gland is arranged in the main insulator and is fixedly connected with the flange, the isolation net is arranged between the gland and the flange and is pressed by the gland into a center hole of the flange, the shielding cover is fixedly connected with the flange, and an outlet end of the air inlet pipe and an inlet end of the air outlet pipe are arranged in the center hole of the flange and are fixedly connected with the flange. The air passage electric insulator has advantages of excellent voltage-resistance capability and excellent mechanics structure strength and can completely satisfy engineering application requirements.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

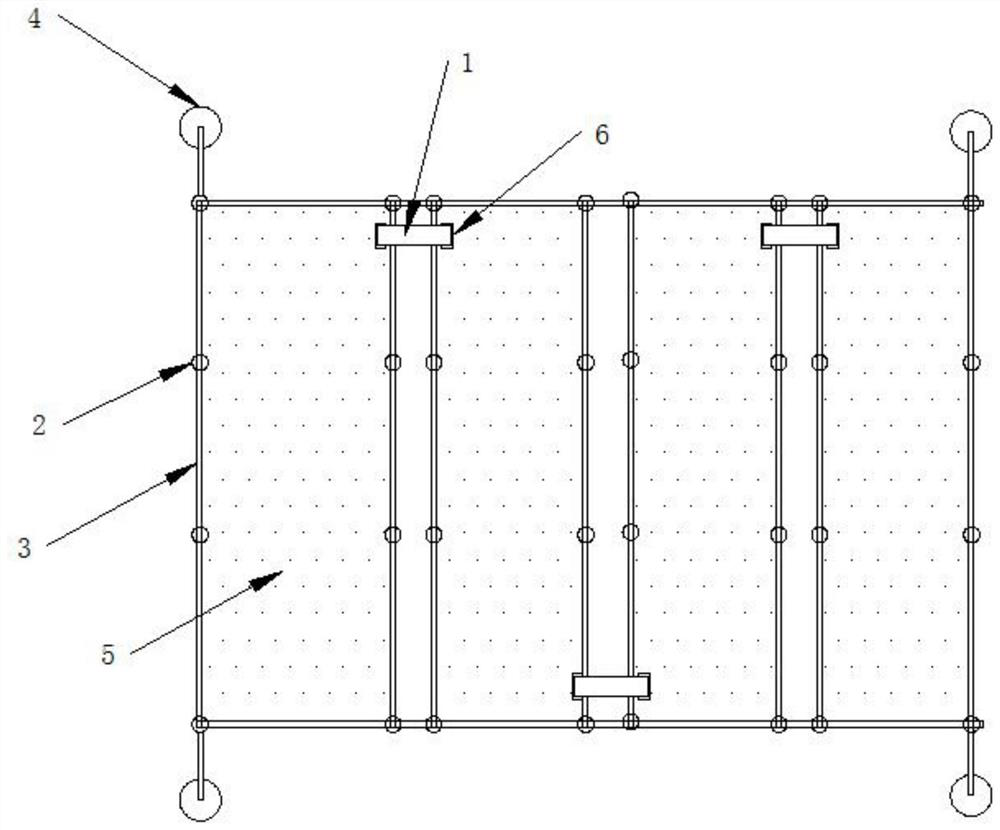

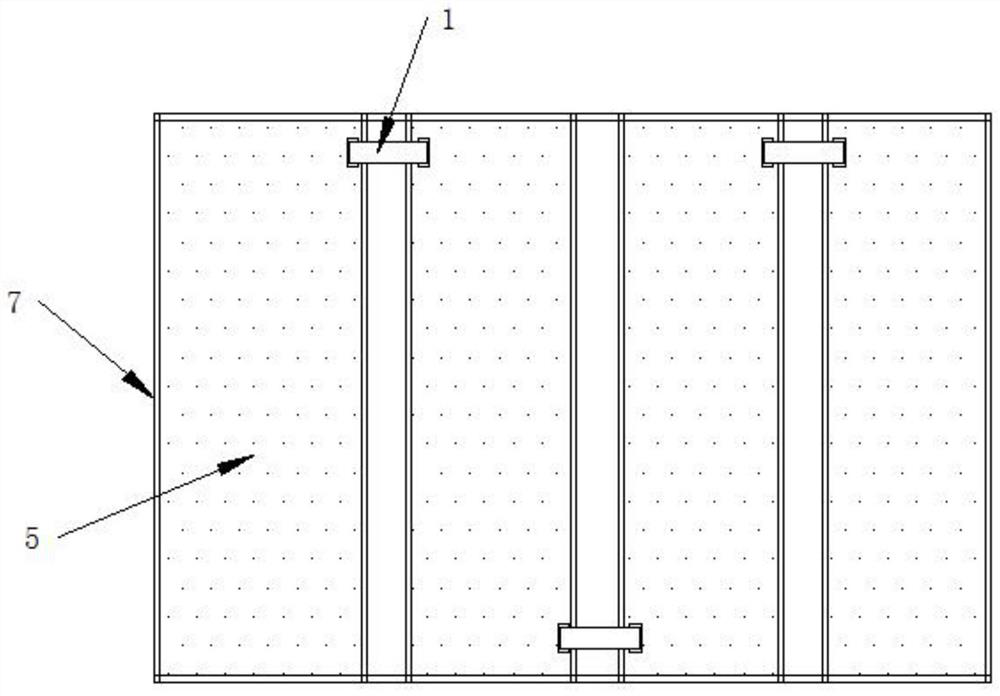

Frame high-hanging flexible running water aquaculture system

InactiveCN112106719AIncrease the areaImprove stabilityPisciculture and aquariaAquatic productWater flow

The invention relates to the technical field of aquatic product cultivation, in particular to a frame high-hanging flexible running water aquaculture system. The system comprises a plurality of aquaculture boxes arranged on the ground side by side, the multiple aquaculture boxes are sequentially communicated end to end through communicating pipes, and water flow among the multiple aquaculture boxes flows in an S shape through the multiple communicating pipes. The problems that in the prior art, a pool body is arranged in a concrete pouring manner, a series of auxiliary devices are needed for building, the work amount is large, the production cost is too high, comprehensive application and popularization are inconvenient, the existing pond body is subjected to earthwork transformation, landis seriously damaged, the water quality in each pool body cannot be uniformly regulated and controlled and the water quality difference between the pool bodies is large are solved.

Owner:WEIFANG XINLIMENG AQUATIC TECHN

High-reliability purification device, negative-pressure water chilling unit and control method

PendingCN111905518AIncreased circulation distanceMaximize exposureGas treatmentDispersed particle separationProcess engineeringEnvironmental engineering

The invention provides a purification device with high reliability, a negative pressure water chilling unit and a control method. The purification device comprises: a housing; at least two baffle plates, wherein the adsorption mechanism adsorbs and purifies the to-be-purified gas entering the gas flow channel. According to the high-reliability purification device, the negative-pressure water chilling unit and the control method, the effects of increasing the circulation distance between a refrigerant and gas and impurities permeating into equipment and reducing the flow speed are achieved, thebaffle plates are used for dividing the multiple purification areas, the electric heating mechanism and the temperature detection mechanism are independently arranged, and the purification efficiencyis improved.

Owner:GREE ELECTRIC APPLIANCES INC

A new type of car radiator

InactiveCN104895662BHeat dissipation maximum efficiencyAdequate heat dissipationMachines/enginesEngine cooling apparatusLiquid temperatureEngineering

The invention discloses a novel automobile radiator. The novel automobile radiator comprises a radiator core, side plates, an upper water chamber and a lower water chamber, and further comprises a transfer water chamber, wherein the radiator core consists of a plurality of radiating tubes; the upper water chamber and the lower water chamber are arranged at one side of the radiator core; the transfer water chamber is arranged at the other side of the radiator core; and the side plates are arranged at the two transverse sides of the radiator core. According to the novel automobile radiator, the liquid temperature can be effectively ensured to be consistent, so that maximum-efficiency radiating is ensured. Besides, a circulating distance of high-temperature liquid is prolonged and the radiating time of the liquid is increased, so that the high-temperature liquid is sufficiently radiated in the radiator.

Owner:贵州凯宏汇达冷却系统有限公司

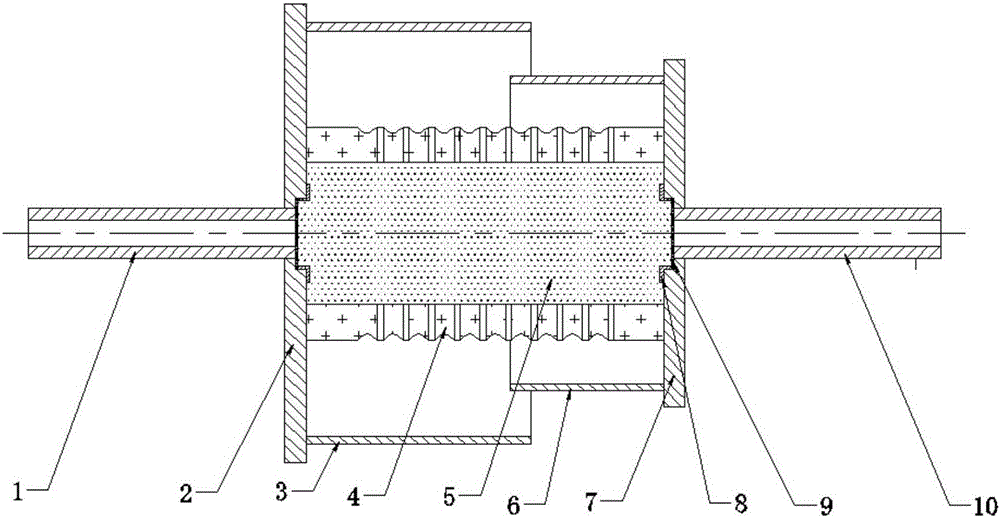

Low-nitrogen and high-efficiency condensing boiler

PendingCN111765638AFully efficient heat transferShows the effect of countercurrent heat exchangeAir heatersHeat exchanger casingsThermodynamicsBoiler furnace

The invention discloses a low-nitrogen and high-efficiency condensing boiler. The low-nitrogen and high-efficiency condensing boiler comprises a shell body and a boiler body; the boiler body comprisesa vertical cylinder body, an upper end plate with an opening in the middle is fixedly arranged at the top of the vertical cylinder body, and a lower pipe plate is fixedly arranged at the bottom of the vertical cylinder body; a boiler furnace is arranged on the upper part of the inner side of the vertical cylinder body; a full premixed combustion assembly is arranged at the top of the boiler furnace, an upper pipe plate is fixedly arranged at the bottom of the boiler furnace, and a plurality of vertical smoke pipes are fixedly arranged on the upper pipe plate; a base is arranged at the bottomof the boiler body, an exhaust cavity is formed in the base, and an exhaust pipeline and a condensate water port are arranged on one side of the exhaust cavity; a water inlet and a sewage outlet are formed in the lower part of the side wall of the vertical cylinder body; and a water outlet is formed in the upper part of the side wall of the vertical cylinder body. According to the low-nitrogen andhigh-efficiency condensing boiler, due to the position arrangement of the water inlet and the water outlet, the flow direction of water is from bottom to top; the full prefixed combustion assembly, the boiler furnace and the vertical smoke pipe are arranged, so that the flow direction of the smoke is from top to bottom; and therefore, the water and smoke have the effect of countercurrent flow andheat exchange, and the sufficient and efficient heat exchange of the smoke and water is achieved.

Owner:QINGDAO FERROLI HEATING & VENTILATION & TEMPERATURE CONTROL TECH EQUIP MFG CO LTD

A biological filter deodorization device for sewage treatment plant

ActiveCN113318581BAchieve triple deodorizationImprove decomposition efficiencyGas treatmentDispersed particle separationBiological filterDeodorant

The invention discloses a biological filter deodorization device used in a sewage treatment plant, and relates to the technical field of odor treatment. The invention includes a deodorizing box and a microbial decomposition layer, the microbial decomposition layer is fixed on the inner wall of the deodorizing box, an air intake pipe is fixedly connected to an outer side wall of the deodorizing box below the microbial decomposition layer, and an air suction pump is fixedly installed on the air intake pipe The top surface of the deodorant box is also fixed with an exhaust sleeve, and a plurality of microbial decomposition layers are arranged in parallel along the vertical direction; Below the deflector; the attachment plate and the deflector are partially overlapped on the same vertical plane, and the side of the attachment plate farther from the center of the deodorizing box extends to the outside of the deflector and is connected to the side of the deodorizing box. on the inner wall. When the present invention is used, the odor can be fully decomposed, the internal temperature can be easily controlled, the overall structure is convenient, and the secondary pollution of water can be effectively avoided.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

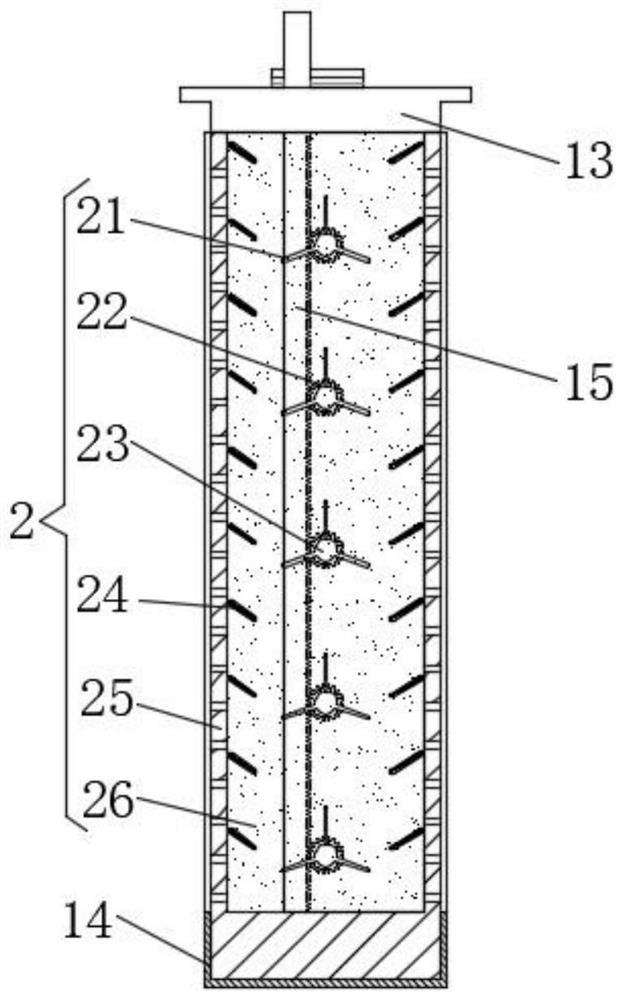

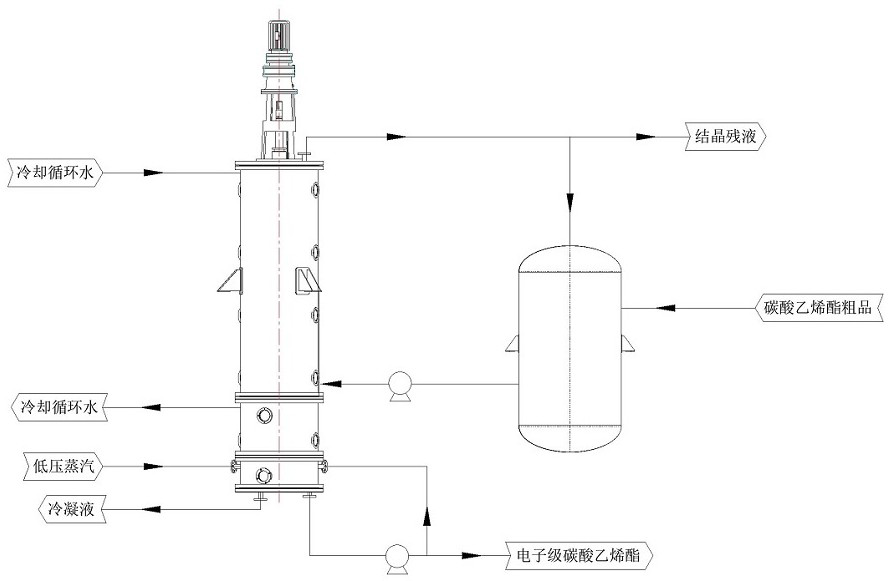

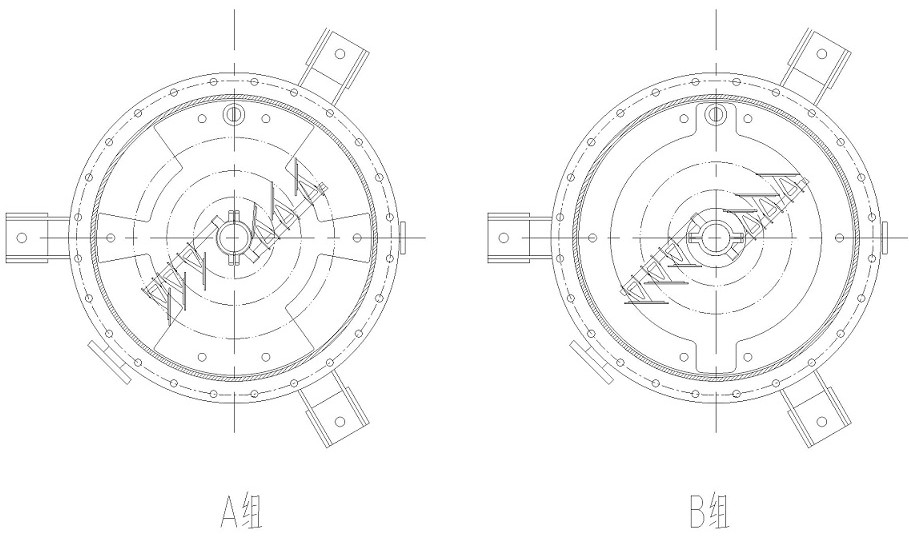

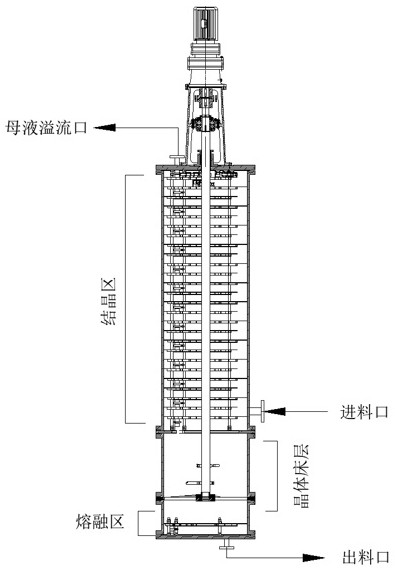

A kind of ethylene carbonate continuous melt crystallization equipment and method

ActiveCN112704901BExpand volume heat transfer areaHigh purityCrystallization conditions screeningOrganic chemistryPhysical chemistryAgitator

The invention discloses a ethylene carbonate continuous melting and crystallization equipment and method. The equipment has a vertical structure and is divided into a crystallization area, a crystal bed area and a melting area along the axial direction of the equipment. The crystallization area is equipped with heat exchange fins and stirring The scraper is used to cool down and crystallize the raw solution of ethylene carbonate. The crystals sink down into the crystal bed section under gravity and mechanical action, where they are piled up to form a crystal bed of a certain height. The melting zone is equipped with heat exchange fins to provide crystals. The heat required for melting, part of the molten liquid is discharged from the outlet at the bottom of the crystallization equipment, and part of it flows upwards through the crystal bed in the axial direction, because the high-purity molten liquid carries heat, and when it flows countercurrently, it will produce ethylene carbonate crystals in the crystal bed Heat and mass exchange to realize the sweating process of ethylene carbonate. The continuous melting and crystallization equipment and method of the present invention can be used to prepare electronic grade ethylene carbonate, and has the advantages of high product purity, high production efficiency, compact equipment structure, low energy consumption, continuous and stable operation, and the like.

Owner:天津乐科节能科技有限公司 +1

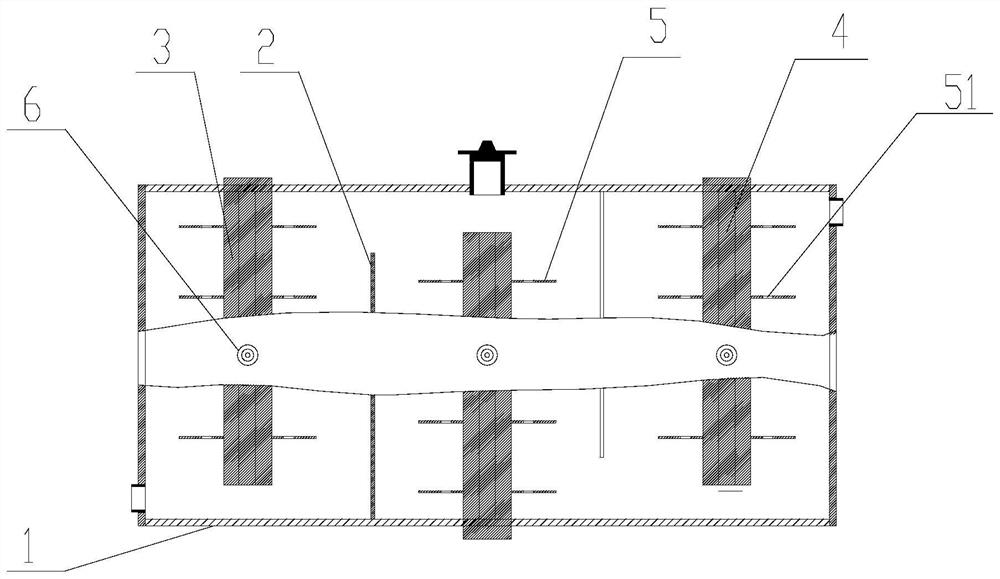

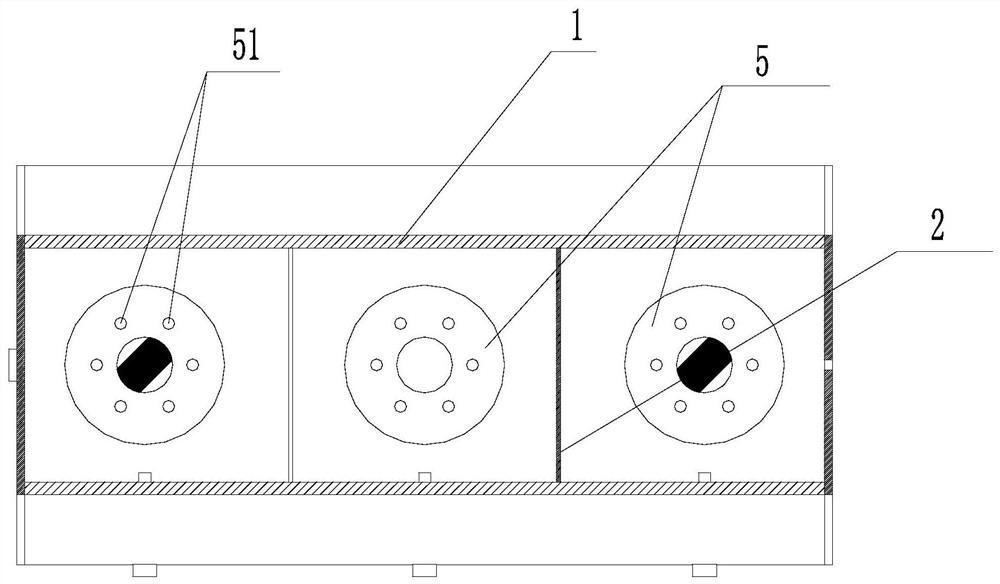

A kind of flowing water furrow breeding system

ActiveCN111602625BImprove stabilityAvoid infringementClimate change adaptationPisciculture and aquariaFisheryAquatic product

The utility model relates to a flow-type furrow cultivation system, which relates to the technical field of aquatic product cultivation, and comprises a plurality of cultivation channels dug in parallel, and the plurality of cultivation channels are integrally connected in an S-shape through connecting bends. The invention solves the problem that the pool body is set up by concrete pouring in the traditional technology, which requires a series of auxiliary equipment for establishment, and the production cost is too high, which is not convenient for comprehensive promotion and use; Reconstruction, low utilization rate; and during the breeding process, the transfer of aquatic products, due to the different water quality between the ponds, requires intermediate operations such as water passing, which reduces the work efficiency.

Owner:WEIFANG XINLIMENG AQUATIC TECHN

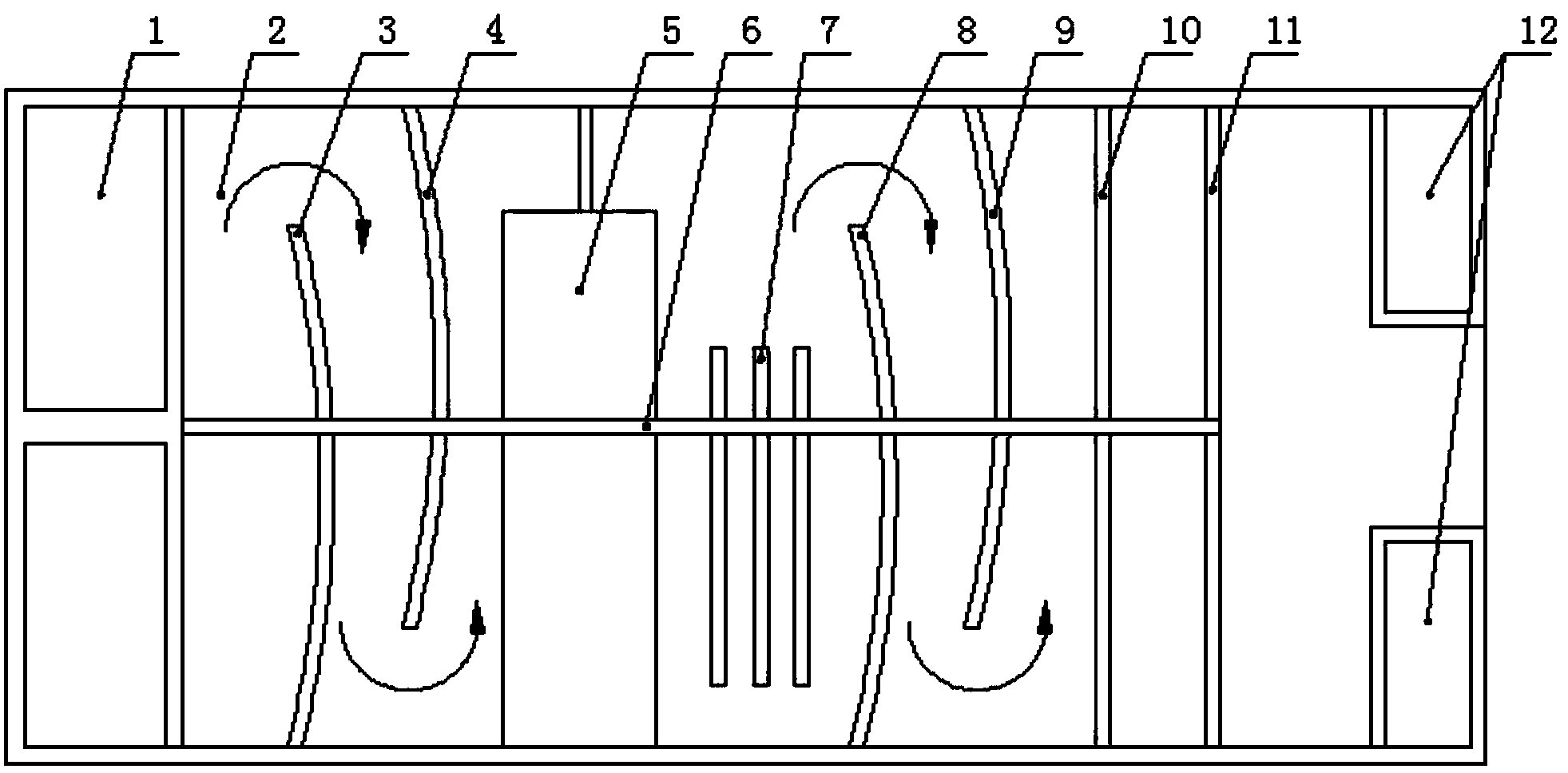

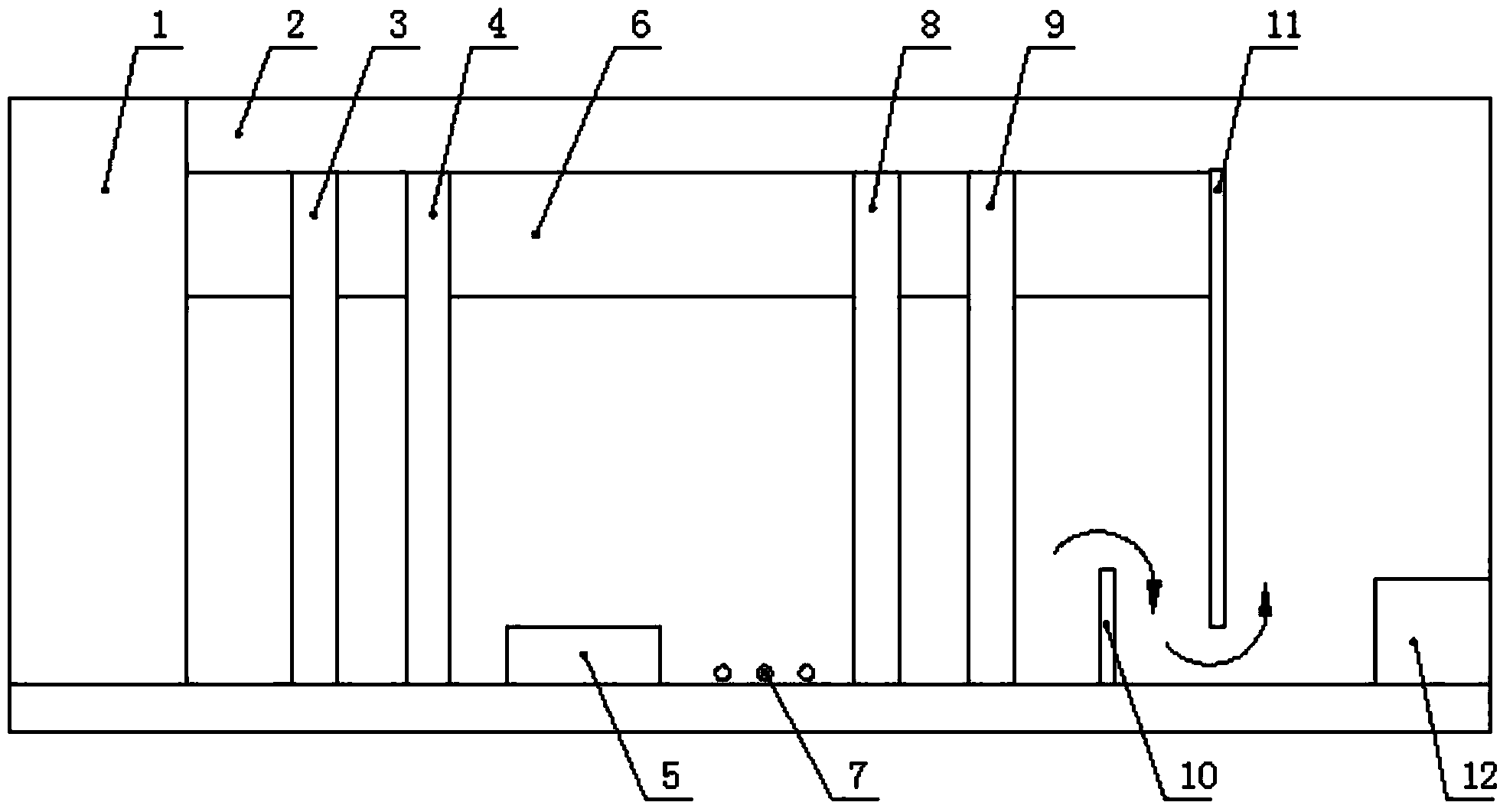

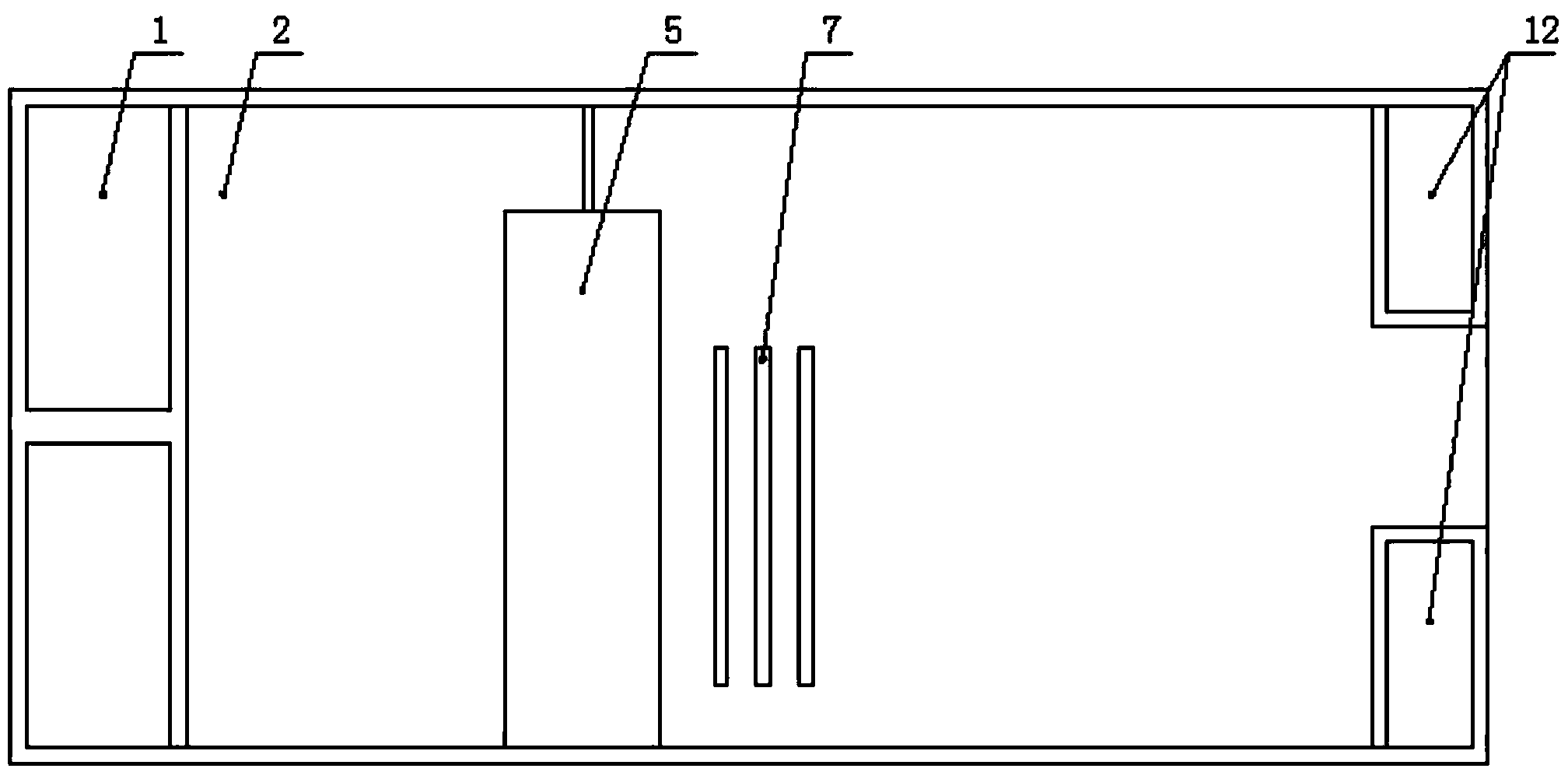

Bubble removing structure for blind hole electroplating management groove of high-density interconnected circuit board

InactiveCN104302123APlay the role of coveringDischarge fullyPrinted element electric connection formationHigh densityInlet flow

The invention relates to a bubble removing structure for a blind hole electroplating management groove of a high-density interconnected circuit board. According to the bubble removing structure for the blind hole electroplating management groove of the high-density interconnected circuit board, multiple front baffles are installed on two side plates on the portion, between an inflating pipe and a liquid chemical inlet, of a groove body in a staggered and spaced mode respectively, a transverse S-shaped liquid chemical channel is formed by the multiple front baffles, multiple rear baffles are installed on the two sides of the portion, between a heating pipe and a liquid chemical outlet, of the groove body in a staggered and spaced mode respectively, and another transverse S-shaped liquid chemical channel is formed by the multiple rear baffles. According to the bubble removing structure for the blind hole electroplating management groove of the high-density interconnected circuit board, the front baffles and the rear baffles are arranged in the staggered mode, liquid chemical entering from the liquid chemical inlet flows in the two S-shaped channels, the flowing distance is increased, and thus gas in the liquid chemical can be discharged completely; two vertical baffles play a role in blocking, and the attraction of a spraying pump in a spraying system to residual bubbles in liquid chemical is reduced; due to the fact that the two measures are taken, liquid chemical entering the spraying system contains no bubble, and the blind hole electroplating quality is guaranteed.

Owner:TIANJIN PRINTRONICS CIRCUIT CORP

Preparation method of Yanshi pot-wrapped meat

The method for preparing meat wrapped in an extended food pot according to the present invention relates to a method for making meat food. The preparation method includes three steps of coating, frying and cooking, wherein the water-retaining and oil-controlling film liquid used for the coating is made of Mix 30-50 parts of water, 10-40 parts of pigskin gel, 2-6 parts of rice protein isolate, 2-6 parts of soybean protein isolate, 0.1-0.5 part of carboxymethyl cellulose and 0.1-0.5 part of compound antioxidant, Then it is prepared by incubating at 50° C. for 3 to 5 minutes, and all the above are parts by weight. The invention adopts the coating treatment method, which has the advantages of improving the tenderness of the pot-packed meat slices and the brittleness of the paste, prolonging the edibility cycle of the pot-packed meat, reducing the bad smell produced by oxidation, and prolonging the pot-packed meat. The shelf life is longer, and the loss of nutrients is also reduced.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

An electric regulating valve for water cooling system and its regulating method

ActiveCN114562600BIncreased circulation distanceAvoid tiltingThermometer detailsValve arrangementsElectric machineEngineering

The invention discloses an electric regulating valve for a water cooling system and a regulating method thereof, comprising a valve body, the bottom of the valve body is fixedly connected with a bottom plate, the top of the valve body is fixedly connected with a top plate, and the top of the top plate is fixedly connected A transmission motor is fixedly connected, a screw rod is fixedly connected to the output end of the transmission motor, a screw sleeve is threadedly connected to the surface of the screw rod, and a pressure rod is fixedly connected to the front of the screw sleeve. In the invention, the transmission motor is turned on by the thermometer, the transmission motor drives the screw to rotate, the screw uses the thread to push the screw sleeve to move upward, the screw sleeve can squeeze the corrugated pipe through the pressure rod during the movement, and the corrugated pipe moves upward and completes the stretching deformation. , can achieve the effect of improving the circulation distance of cooling water, solve the effect that the existing electric regulating valve cannot adjust the travel distance of cooling water according to the temperature of cooling water, seriously affect the heat dissipation distance of cooling water, and cannot meet the operation requirements of water cooling system The problem.

Owner:BEIJING VALVE GENERAL FACTORY CO LTD

An ultra-high pressure-resistant gas circuit electrical insulator for electric thrusters

ActiveCN106340360BHigh mechanical strengthIncreased circulation distancePipe elementsInsulating bodiesElectricityUltimate tensile strength

The invention relates to a superhigh voltage-resistance air passage electric insulator for an electric thruster and belongs to the electric vacuum insulation technology field. The superhigh voltage-resistance air passage electric insulator mainly comprises an air inlet pipe, a flange, a shielding cover, a main insulator, ceramic particles, a gland, an isolation net and an air outlet pipe, wherein the ceramic particles are filled in the main insulator, two ends of the main insulator are fixedly connected with the flange, the gland is arranged in the main insulator and is fixedly connected with the flange, the isolation net is arranged between the gland and the flange and is pressed by the gland into a center hole of the flange, the shielding cover is fixedly connected with the flange, and an outlet end of the air inlet pipe and an inlet end of the air outlet pipe are arranged in the center hole of the flange and are fixedly connected with the flange. The air passage electric insulator has advantages of excellent voltage-resistance capability and excellent mechanics structure strength and can completely satisfy engineering application requirements.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Automatic liquid level balancing and fixed-point moving gas purification and separation device

ActiveCN113384972AReduce the floating speedReduce power sourceUsing liquid separation agentThermodynamicsSeparation technology

The invention discloses an automatic liquid level balancing and fixed-point moving gas purification and separation device which comprises a separation device shell, a purification tank is arranged in the separation device shell, a waste gas tank is arranged on one side of the separation device shell, and the bottom of the waste gas tank communicates with the bottom of the purification tank through a branch pipe; a liquid impeller pump and a gas impeller pump are fixedly arranged at the bottom of the purification tank, impeller shafts of the liquid impeller pump and the gas impeller pump penetrate through the side walls of the purification tank and are connected through a connecting assembly for the gas impeller pump to drive the liquid impeller pump to work, and the liquid impeller pump and the gas impeller pump communicate with the bottom of the purification tank through branch pipes, and the branch pipe between the waste gas tank and the purification tank is also connected with a pressure limiting valve. The invention relates to the technical field of gas purification and separation, and the separation device can accurately judge the flooding phenomenon, and can fully scatter and diminish bubbles in waste gas to prolong the purification time of the bubbles in the purification liquid so that the purification sufficiency is ensured.

Owner:NANTONG FLECK FLUID EQUIP

Paraffin removal device for oil wells

The invention discloses a paraffin removal device for oil wells. The paraffin removal device comprises a barrel and an outer container which is sheathed in the barrel in a clearance manner; an inner container is sheathed in the outer container in a clearance manner; a front seal head baffle and a rear seal head baffle, which are fixedly connected with the end parts of the outer container and the inner container in a sealing manner, are fixed at the front end and the back end of the barrel; a through hole, through which a spray nozzle of a burner is extended into the inner container, is arranged on the front seal head baffle; an outer container gap is arranged at the rear end of the outer container; an inner container gap is arranged at the rear end of the inner container; the outer container gap and the inner container gap form a first gap; an inner guiding pipe is arranged between the outer container and the inner container; an outer guiding pipe, which is communicated with the inner guiding pipe at the first gap, is arranged between the barrel and the outer container; and a chimney, which is communicated with a gap between the barrel and the outer container, is arranged on the barrel. For the paraffin removal device, the inner guiding pipe is heated by using heat generated by high-temperature fire, simultaneously, the outer guiding pipe is directly heated by using heat generated by a flue gas, thereby the heat of the high-temperature fire is fully used, and simultaneously the heat of flue gas is effectively used. The paraffin removal device has high heat efficiency and compact structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paraffin removal device for oil wells

The invention discloses a paraffin removal device for oil wells. The paraffin removal device comprises a barrel and an outer container which is sheathed in the barrel in a clearance manner; an inner container is sheathed in the outer container in a clearance manner; a front seal head baffle and a rear seal head baffle, which are fixedly connected with the end parts of the outer container and the inner container in a sealing manner, are fixed at the front end and the back end of the barrel; a through hole, through which a spray nozzle of a burner is extended into the inner container, is arranged on the front seal head baffle; an outer container gap is arranged at the rear end of the outer container; an inner container gap is arranged at the rear end of the inner container; the outer container gap and the inner container gap form a first gap; an inner guiding pipe is arranged between the outer container and the inner container; an outer guiding pipe, which is communicated with the inner guiding pipe at the first gap, is arranged between the barrel and the outer container; and a chimney, which is communicated with a gap between the barrel and the outer container, is arranged on the barrel. For the paraffin removal device, the inner guiding pipe is heated by using heat generated by high-temperature fire, simultaneously, the outer guiding pipe is directly heated by using heat generated by a flue gas, thereby the heat of the high-temperature fire is fully used, and simultaneously the heat of flue gas is effectively used. The paraffin removal device has high heat efficiency and compact structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Outlet frame, shell and cross-flow air conditioning cabinet

ActiveCN105042694BIncrease distanceIncreased circulation distanceLighting and heating apparatusHeating and ventilation casings/coversEngineering

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD

A chemical vapor deposition furnace gas preheating device

ActiveCN108588678BImprove space utilizationDoes not occupy the effective loading spaceChemical vapor deposition coatingCarbon compositesEngineering

The invention belongs to the technical field of carbon / carbon composite chemical vapor deposition, and relates to a gas preheating device of a chemical vapor deposition furnace. The gas preheating device is composed of six parts of a base, a bottom plate, a heat exchange base, a heat exchange segment, a top barrel and a top cover. According to the gas preheating device, preheating is sufficient, the preheating device does not occupy effective charging space, and the production efficiency can be greatly improved.

Owner:XIAN AVIATION BRAKE TECH

Gas purification and separation device with automatic liquid level balance and fixed-point pipetting

ActiveCN113384972BReduce the floating speedReduce power sourceUsing liquid separation agentSeparation technologyProcess engineering

The invention discloses a gas purification and separation device with automatic liquid level balance and fixed-point pipetting, which includes a separation device housing, a purification tank is provided inside the separation device housing, and an exhaust gas tank is provided on one side of the separation device housing. And the bottom of the waste gas tank and the purification tank are connected through a branch pipe, and the bottom of the purification tank is respectively fixed with a liquid impeller pump and a gas impeller pump, and the impeller shafts of the two pass through their side walls and are connected by a connecting component for The gas impeller pump drives the liquid impeller pump to work, and both the liquid impeller pump and the gas impeller pump communicate with the bottom of the purification tank through branch pipes, and the branch pipe between the waste gas tank and the purification tank is also connected with a pressure limiting valve. The invention relates to the technical field of gas purification and separation. The separation device can accurately determine the liquid flooding phenomenon, and can improve the purification time of the bubbles in the purification liquid by fully breaking up the bubbles in the exhaust gas to ensure the adequacy of the purification. .

Owner:NANTONG FLECK FLUID EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com