Preparation method for edibility-prolonging fried pork in scoop

A technology for extending food pots and meat slices, applied in food preparation, food science, application and other directions, can solve the problems of shortening the edible cycle, restricting the circulation of pot-wrapped meat, and reducing the tenderness of products, so as to reduce bad odor and reduce sensory perception. The effect of reducing the degree of brittleness and improving the brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

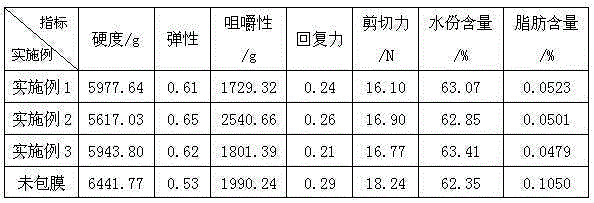

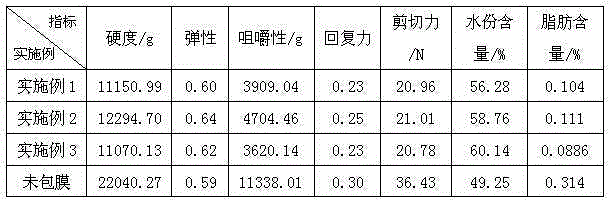

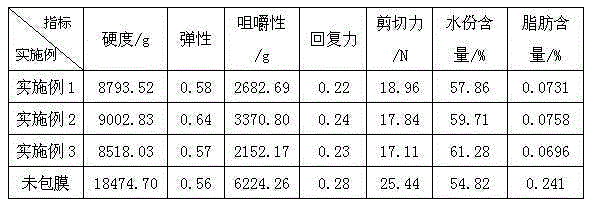

Embodiment 1

[0019] In the preparation method of the delayed food pot-wrapped meat of the present invention, the operation steps are as follows:

[0020] a. Coating: The pork is frozen for 12 hours and then cut into slices of 3mm×10cm×10cm. The surface of the pork slices is evenly wrapped with a water-retaining and oil-controlling film liquid, and then cooled to room temperature to obtain a coated meat slice;

[0021] b. Frying: the surface of the coated meat slice prepared in step a is evenly coated with corn starch slurry with a material-to-liquid weight ratio of 1:1, and then fried in oil at 180°C for 100s to prepare fried meat slices;

[0022] c. Cooking juice: Use corn germ oil to fry appropriate amount of shredded ginger and green onion, add the fried meat slices prepared in step b, cook in the juice, the weight ratio of the juice to the pork is 1:10, and stir. Sprinkle with coriander to get the finished product.

[0023] Among them, the water-retaining and oil-controlling film liquid is to ...

Embodiment 2

[0025] In the preparation method of the delayed food pot-wrapped meat of the present invention, the operation steps are as follows:

[0026] a. Coating: After freezing the pork for 18 hours, cut it into slices of 3mm×10cm×10cm, and evenly wrap the surface of the pork slices with a water-retaining and oil-controlling film liquid, and then cool to room temperature to obtain coated meat slices;

[0027] b. Frying: the surface of the coated meat slice prepared in step a is evenly coated with corn starch slurry with a material-to-liquid weight ratio of 3:1, and then fried in oil at 200°C for 200s to obtain fried meat slices;

[0028] c. Cooking juice: Use corn germ oil to fry appropriate amount of shredded ginger and green onion, add the fried meat slices prepared in step b, cook in the juice, the weight ratio of the juice to the pork is 1:15, stir Sprinkle with coriander to get the finished product.

[0029] Among them, the water-retaining and oil-controlling film liquid is to mix 50 part...

Embodiment 3

[0031] In the preparation method of the delayed food pot-wrapped meat of the present invention, the operation steps are as follows:

[0032] a. Coating: The pork is frozen for 16 hours and then cut into 3mm×10cm×10cm meat slices, the surface of the pork slices is evenly wrapped with a water-retaining and oil-controlling film liquid, and then cooled to room temperature to obtain a coated meat slice;

[0033] b. Frying: the surface of the coated meat slice prepared in step a is evenly coated with corn starch slurry with a material-to-liquid weight ratio of 12:1, and then fried in oil at 190°C for 150s to prepare fried meat slices;

[0034] c. Cooking juice: Use corn germ oil to fry appropriate amount of shredded ginger and green onion, add the fried meat slices prepared in step b, cook it with juice, the weight ratio of juice to pork is 1:12, and stir. Sprinkle with coriander to get the finished product.

[0035] Among them, the water-retaining and oil-controlling film liquid is to mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com