Full thermal processing-combined freighting space intelligent temperature control comprehensive delivery cabinet

An intelligent temperature control and delivery cabinet technology, applied in cabinets, time registers, instruments, etc., to make up for the lack of service, increase the circulation distance, and improve the quality of delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

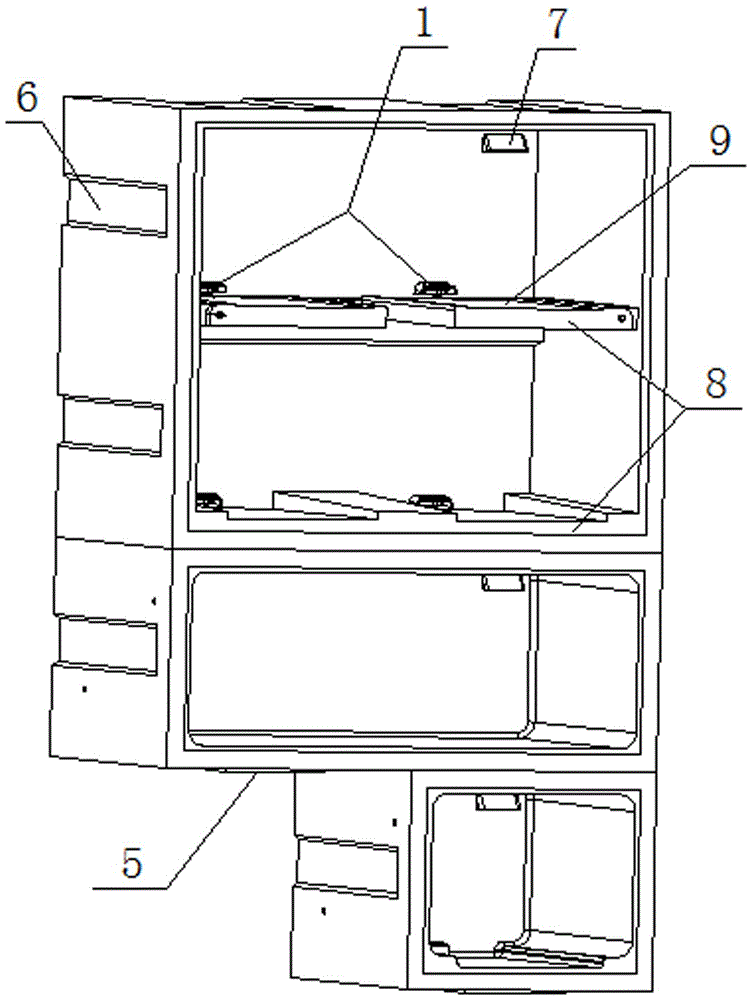

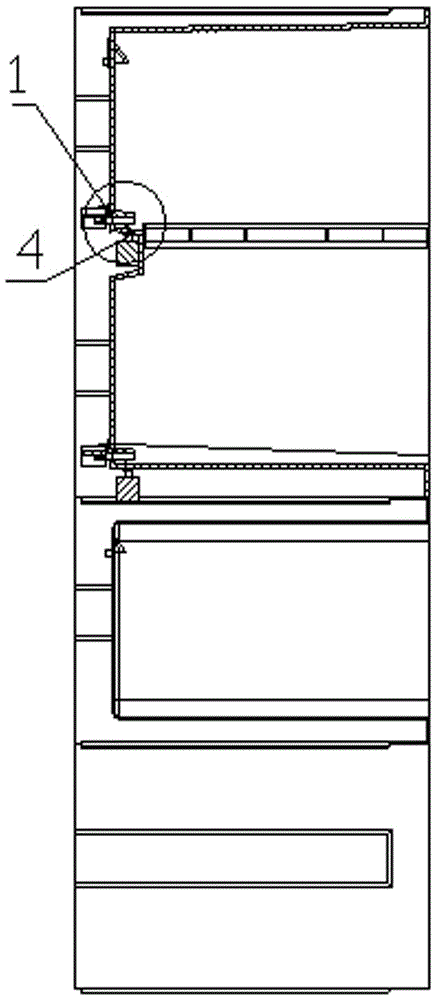

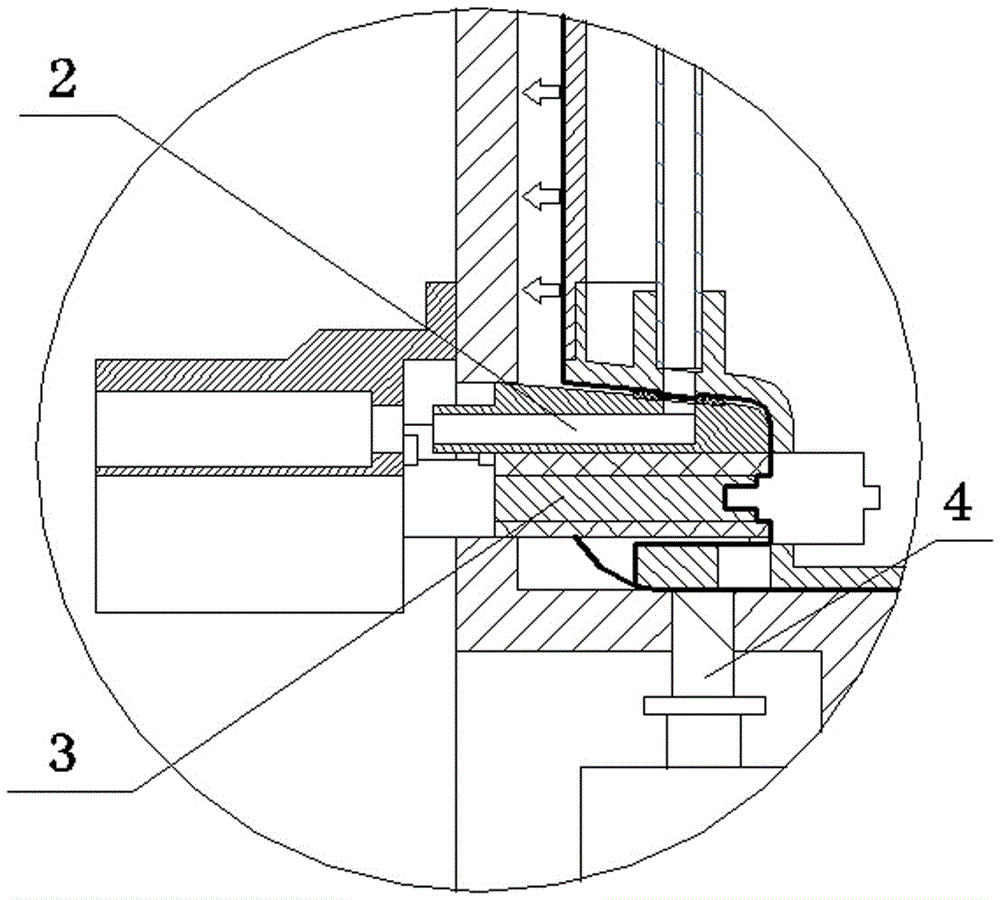

[0034] The present invention provides a full temperature range-intelligent temperature-controlled comprehensive delivery cabinet with combined storage positions. The delivery cabinet includes a cabinet body and a heating and cooling insulation lunch box; the cabinet body includes one or more delivery units 8, and each delivery unit is equipped with There are one or more delivery positions 9, and an integrated interface 1 is provided corresponding to each delivery position, and the integrated interface 1 includes an exhaust interface 2 and an integrated connector 3, and the exhaust interface 2 communicates with the exhaust pipe. The integrated connector 3 is connected to the power supply and the central controller;

[0035] Corresponding to each delivery location, there is a heating and cooling thermal insulation lunch box, which is a detachable structure that can be placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com