Paraffin removal device for oil wells

A technology for removing wax and oil wells. It is used in isolation devices, cleaning appliances, wellbore/well components, etc. It can solve problems such as low heating efficiency, and achieve the effect of improving heat utilization and increasing circulation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

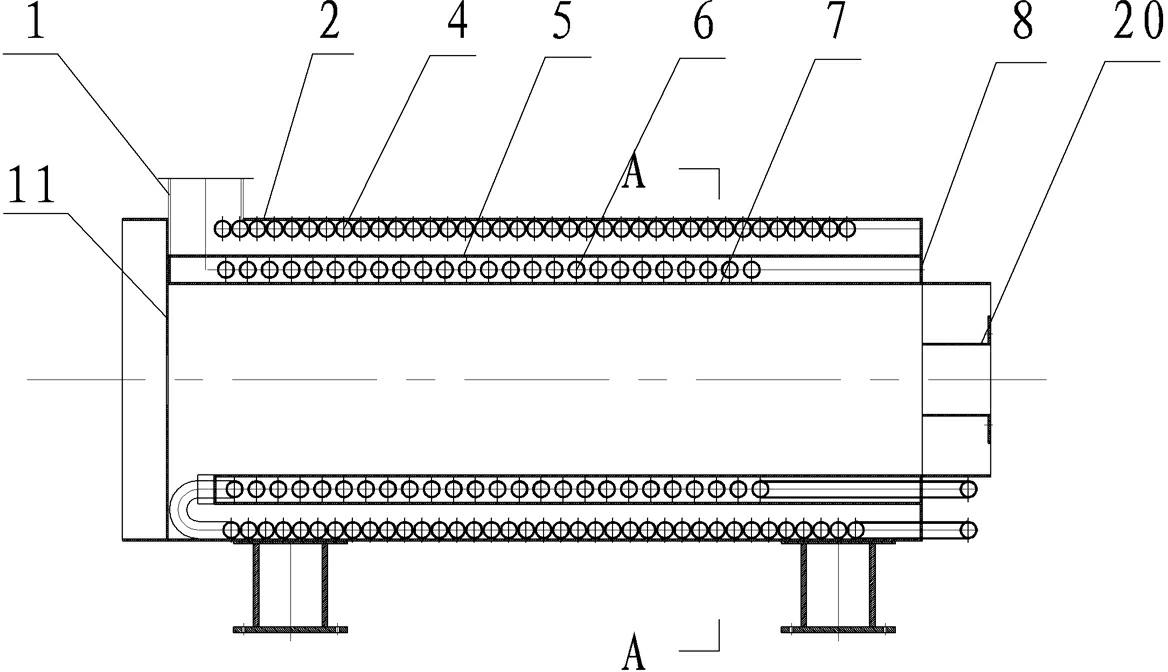

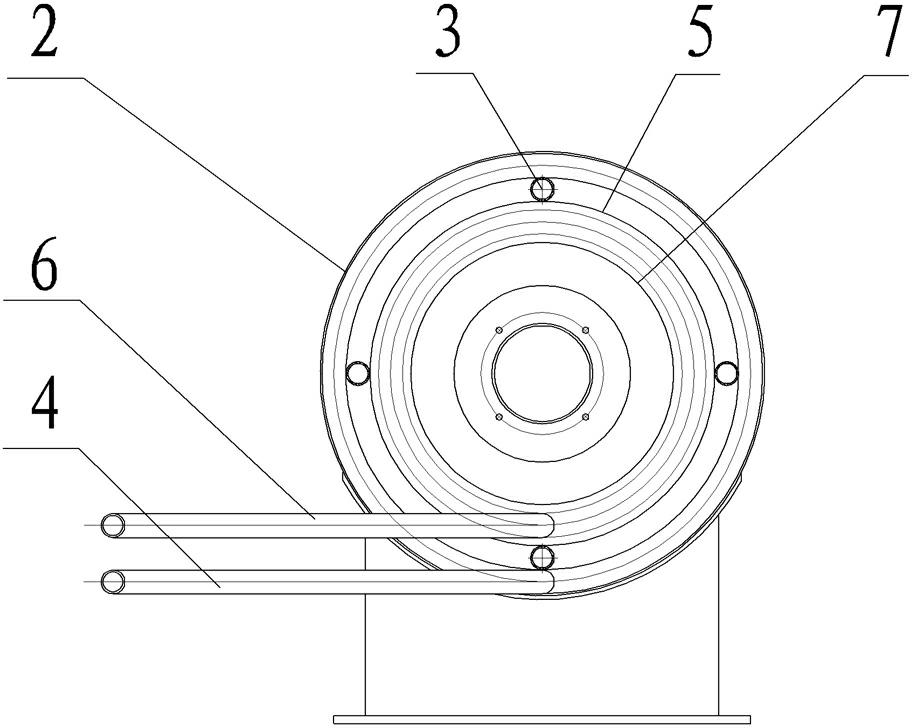

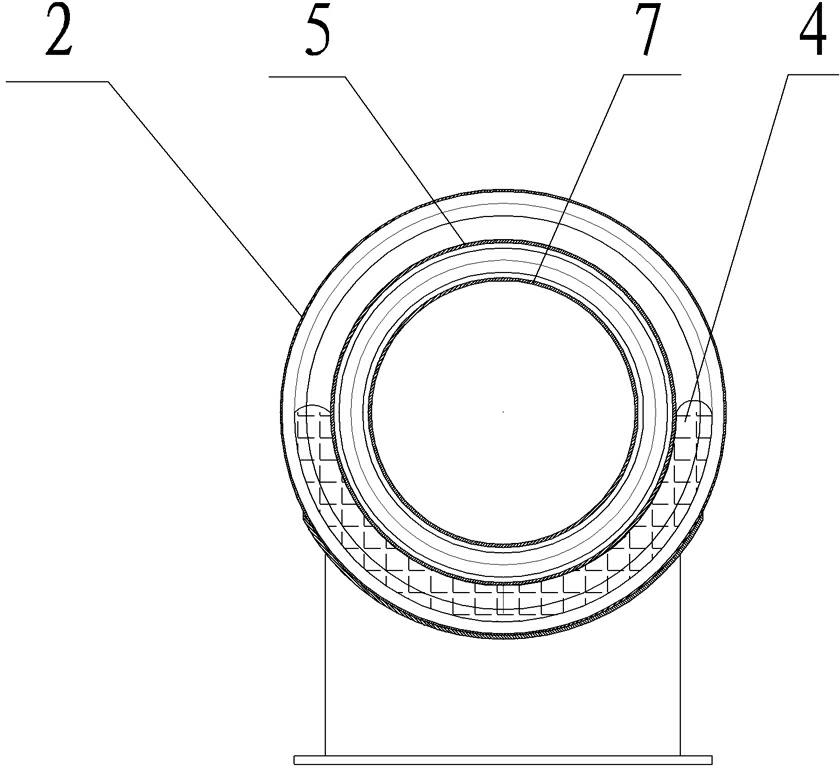

[0024] The embodiment of oil well wax removing device of the present invention: comprise heating body, the structure of heating body is as follows Figure 1-5 As shown, the heating body includes a cylinder body 2, an outer bladder 5 is sleeved in the inner gap of the cylinder body 2, and an inner bladder 7 is sleeved in the inner gap of the outer bladder 5, and the cylinder body 2, the outer bladder 5, and the inner bladder 7 are all the same A cylindrical structure where the shaft is set. The front and rear ends of the cylinder 2 are respectively fixed with head baffles sealing the cylinder 2, which are respectively the front head baffle 8 and the rear head baffle 11, the outer bladder 5 and the inner bladder 7 The front and rear ends are respectively sealed and fixedly connected with the respective corresponding head baffles, and the front end of the inner tank 7 protrudes from the front head baffle 8, so that the gap between the cylinder body 2 and the outer tank 5, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com