A chemical vapor deposition furnace gas preheating device

A chemical vapor deposition and gas preheating technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of insufficient preheating, occupying effective loading space, and affecting deposition efficiency, etc., to achieve It facilitates the initial loading, improves the circulation distance, and improves the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the drawings and specific embodiments.

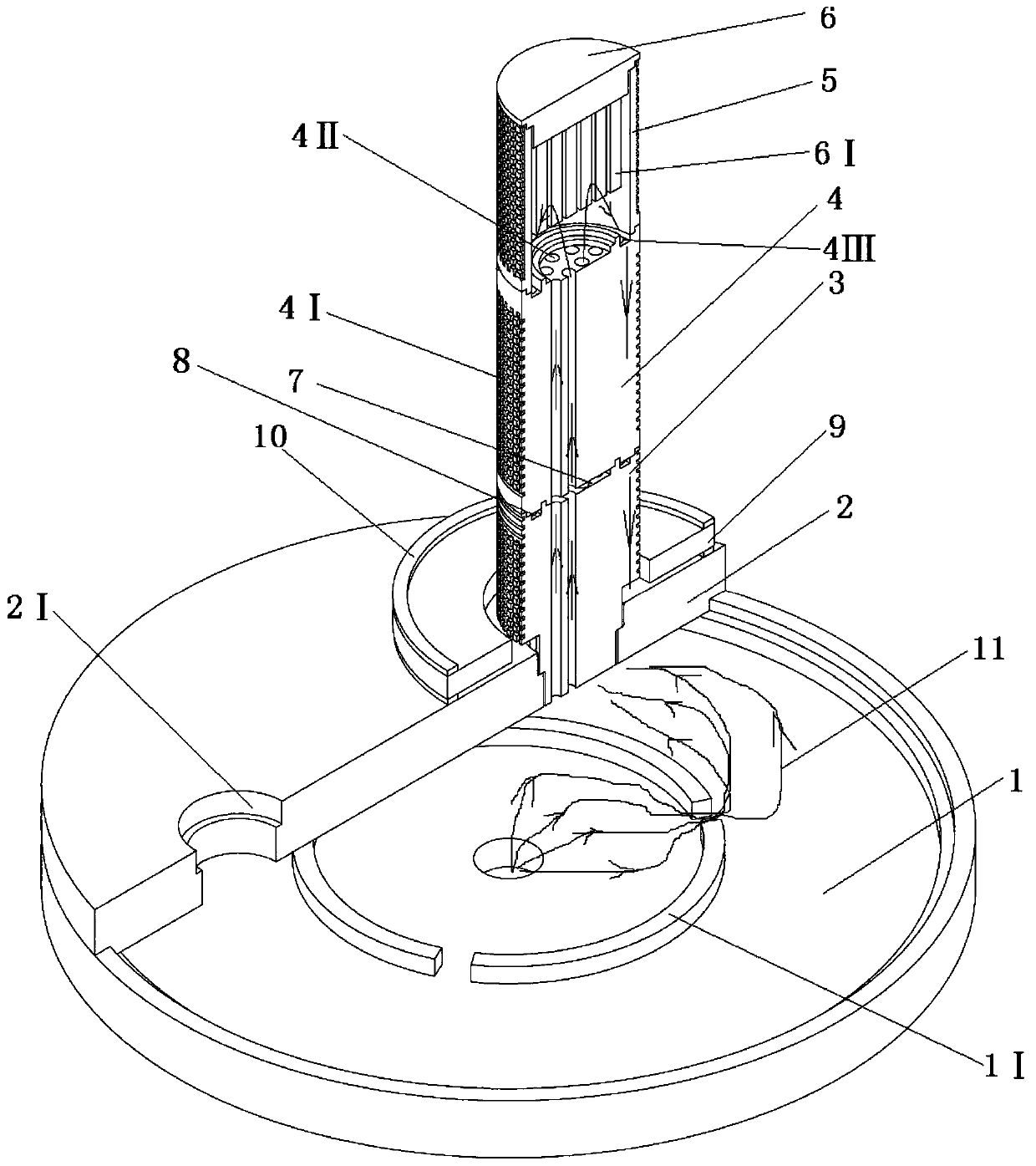

[0028] see figure 1 , a chemical vapor deposition furnace gas preheating device of the present invention is composed of a base 1, a bottom plate 2, a heat exchange base 3, a heat exchange section 4, a top cylinder 5, and a top cover 6;

[0029] The base 1 is placed on the bottom of the furnace, the center hole is aligned with the furnace inlet, and the upper middle part is provided with guide ribs 1I to extend the flow distance of carbon source gas on it, and the outer circle is designed with stepped grooves for The bottom plate 2 on its upper part is assembled and realizes the inner cavity sealing between the two.

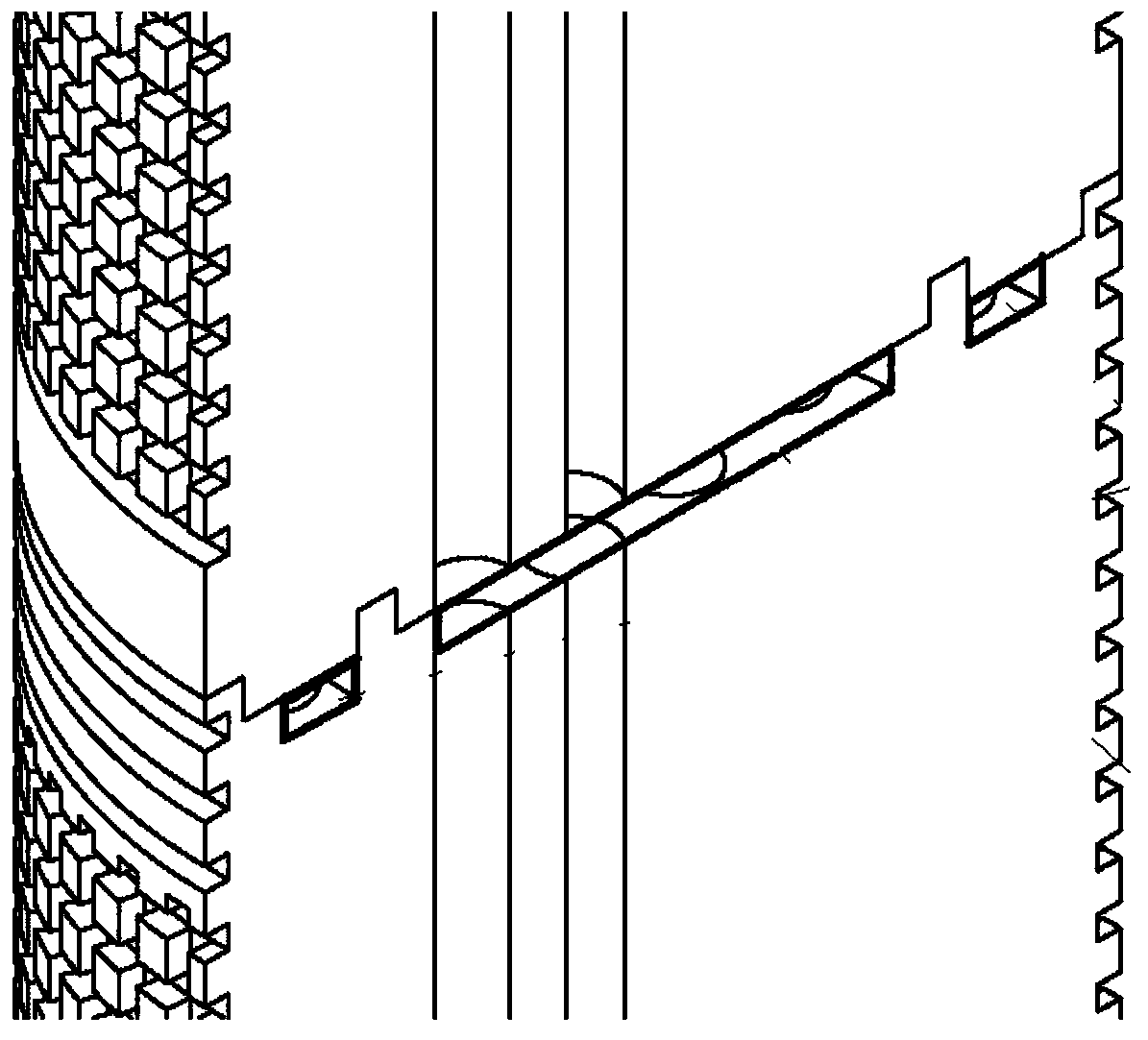

[0030] The bottom plate 2 is used to install the heat exchanger and carry the workpiece, and is assembled on the base 1 through the steps of its outer circle, forming a carbon source gas passage with the base 1 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com