Novel automobile radiator

A car radiator and radiator technology, which is applied in the cooling of machines/engines, engine components, and engines, can solve the problems of unsatisfactory heat dissipation effects of radiators, extend the distance of circulation, fully dissipate heat, and ensure consistent temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

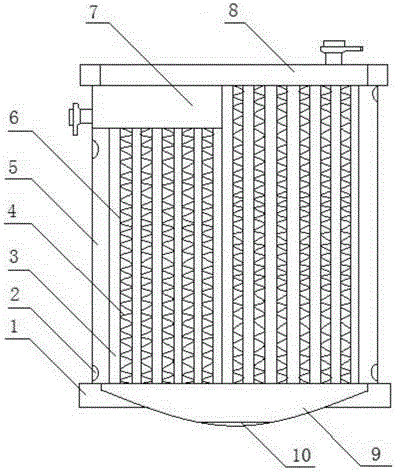

[0018] Such as figure 1 As shown, a new type of automobile radiator includes a radiator core 6, a side plate 5, an upper water chamber 8 and a lower water chamber 7, and a liquid inlet is opened on the upper water chamber 8, and a liquid outlet is opened on the lower water chamber 7. It also includes a transfer water chamber 9. The radiator core 6 is composed of several heat dissipation pipes 3. An upper water chamber 8 and a lower water chamber 7 are installed on the longitudinal side of the radiator core 6. The top of the lower water chamber 7 is lower. At the bottom of the upper water chamber 8, to ensure that the liquid can flow out, a transfer water chamber 9 is installed on the other side of the radiator core 6, and side plates 5 are fixedly installed on both lateral sides of the radiator core.

[0019] The outer surface of the transfer water chamber 9 is arc-shaped, and this structure is conducive to reducing the momentum from the liquid, so that the transfer water cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com