Semi-continuous vacuum gas atomization powder making furnace

A semi-continuous, gas atomization technology, applied in the field of vacuum induction gas atomization powder making equipment, can solve the problems of destroying the atmosphere in the furnace, reducing production efficiency, waste of inert gas, etc., and achieves good reliability, high space utilization rate, The effect of increasing the circulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

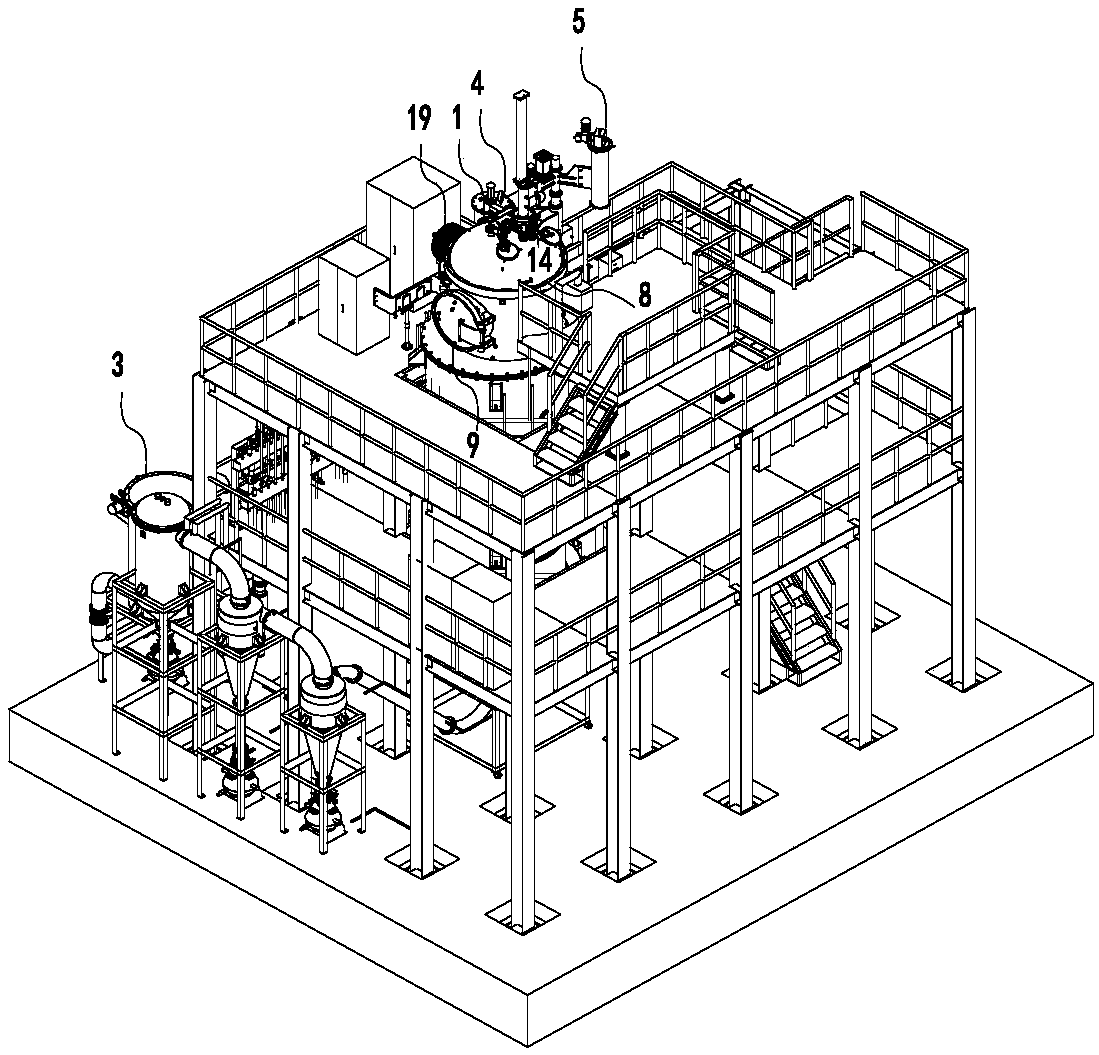

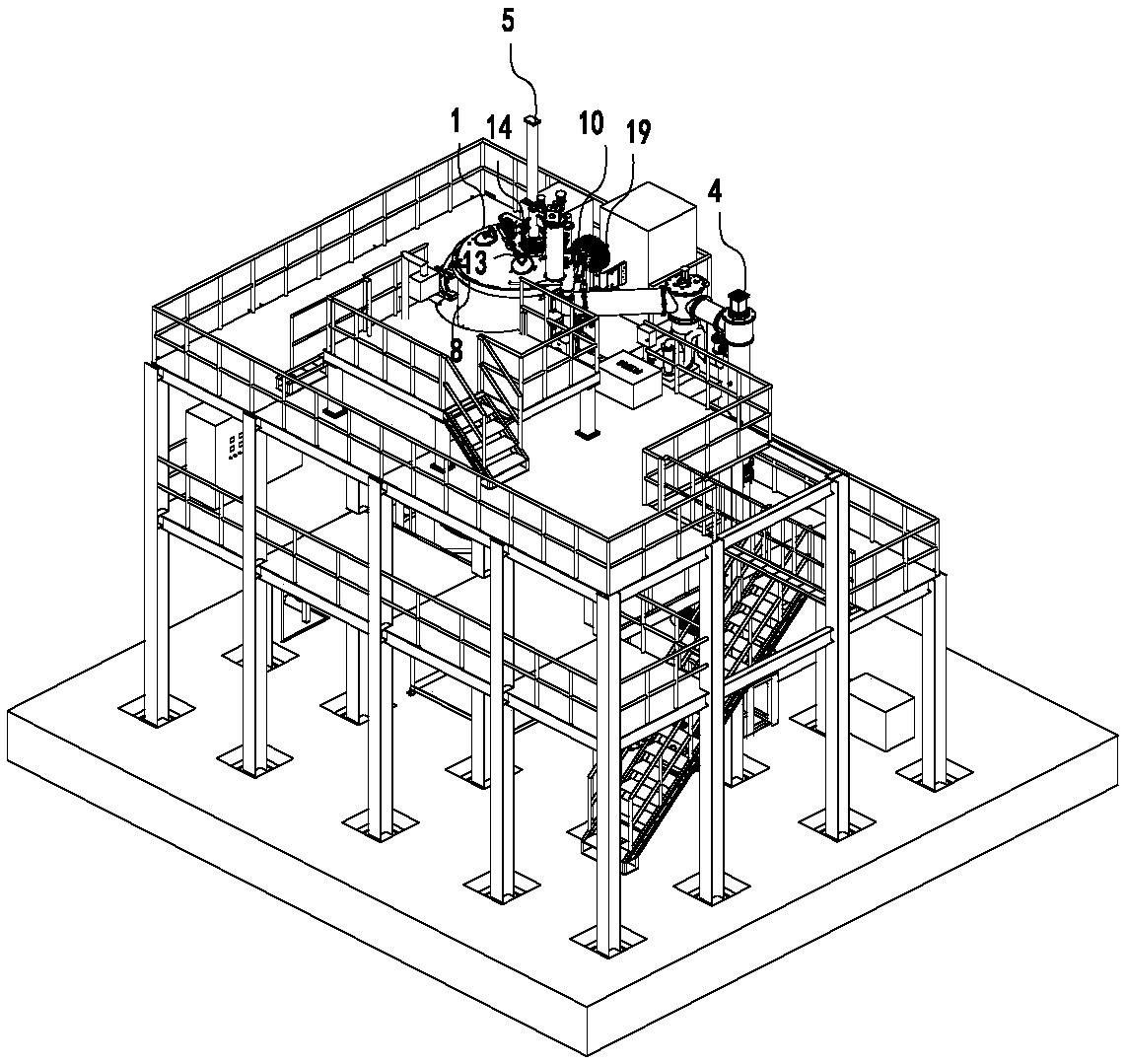

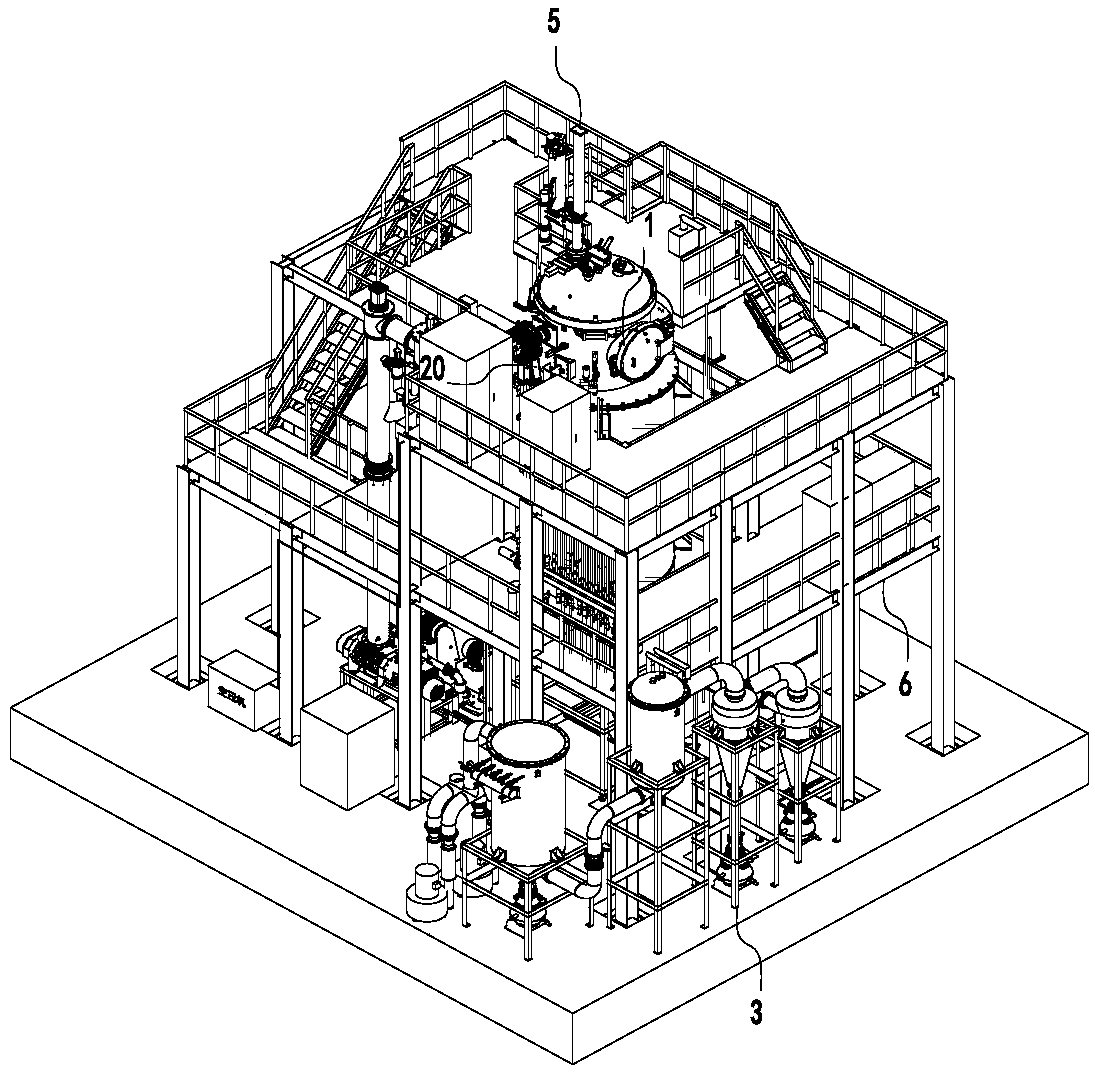

[0031] As shown in the figure, a vacuum semi-continuous gas atomization pulverizing furnace includes a platform 6; a furnace assembly 1, an atomization chamber 2, a powder collection assembly 3, a vacuum assembly 4 and a turret are respectively arranged on the platform 6. Component 5; the furnace assembly 1 is fixed on the atomization chamber 2; the cavity of the furnace assembly 1 communicates with the cavity of the atomization chamber 2 through the first isolation valve 7; the vacuum assembly 4 The ports of the vacuum pipeline communicate with the cavity of the furnace body assembly 1 and the atomization chamber 2 respectively; the turret assembly 5 is connected with the furnace body assembly 1; The powder mouth communicates.

[0032] see Figure 1~3 and Figure 5 As shown, the furnace body assembly 1 of the present invention includes a furnace cover 8, a side furnace door 9, a crucible turning mechanism 10, a heat preservation heater 11, a spray plate 12 and a first isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com