High-reliability purification device, negative-pressure water chilling unit and control method

A control method and technology of adsorption mechanism, applied in refrigerators, refrigeration components, separation methods, etc., can solve the problems of poor purification effect, single flow channel and electric heating, etc., and achieve the improvement of filtration effect, rapid regeneration, and improved utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

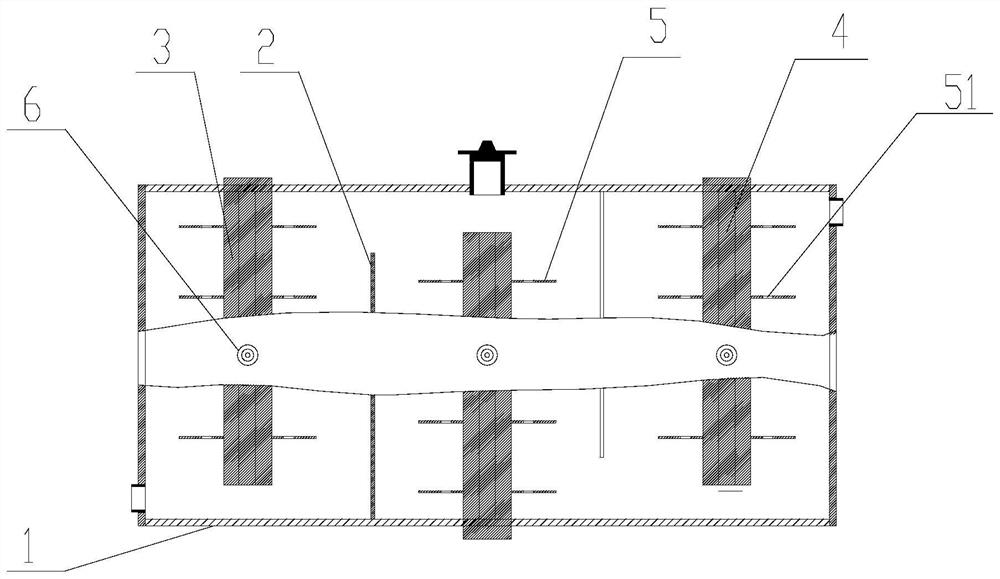

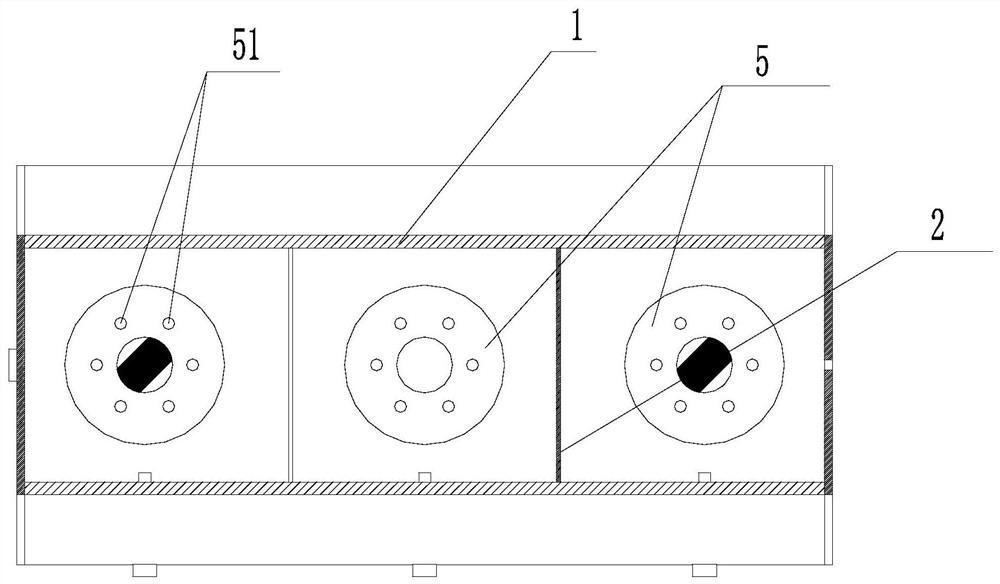

[0044] Such as figure 1 and figure 2 The purification device shown includes: a housing 1; at least two baffles 2, all of which are evenly distributed in the housing 1, and all of the baffles 2 are in the housing. 1 constitutes a gas flow channel inside; the adsorption mechanism 3 is arranged in the gas flow channel; the adsorption mechanism 3 adsorbs and purifies the gas to be purified entering the gas flow channel, and uses the baffle plate 2 to increase the flow of the gas to be purified in the shell The flow distance inside the body 1 realizes the effect of longer flow distance and lower flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com