Low-nitrogen and high-efficiency condensing boiler

A condensing boiler, high-efficiency technology, applied in air heaters, combustion methods, gas fuel burners, etc., can solve the problems of inability to absorb the latent heat of flue gas vaporization, inability to achieve efficient heat exchange, and high flue gas outlet temperature, and to meet the The effect of free expansion, increased flow distance, and increased heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

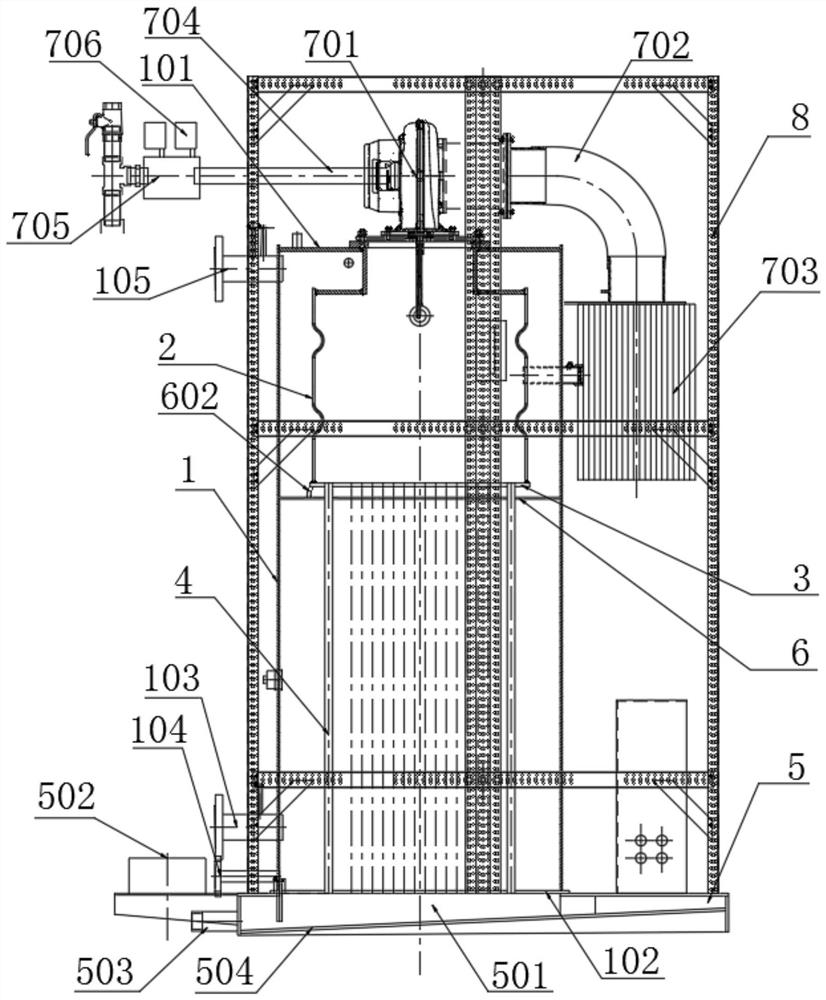

[0066] Such as figure 1 As shown, a low-nitrogen high-efficiency condensing boiler includes an outer casing and a boiler body located inside the outer casing;

[0067] The boiler body includes a vertical cylinder 1, the top of the vertical cylinder 1 is fixed with an upper end plate 101 with a middle opening, and the bottom of the vertical cylinder 1 is fixed with a lower tube plate 102;

[0068] A furnace 2 is arranged on the inner upper part of the vertical cylinder 1;

[0069] The top of the furnace 2 is provided with a fully premixed combustion assembly, and the bottom of the furnace 2 is fixed with an upper tube plate 3, and a number of vertical chimneys connected with the inner cavity of the furnace 2 are fixedly arranged on the upper tube plate 3. Tube 4; the bottom of the vertical smoke tube 4 is fixedly connected to the lower tube plate 102;

[0070] The bottom of the boiler body is provided with a base 5, the base 5 is provided with a smoke exhaust chamber 501 comm...

Embodiment 2

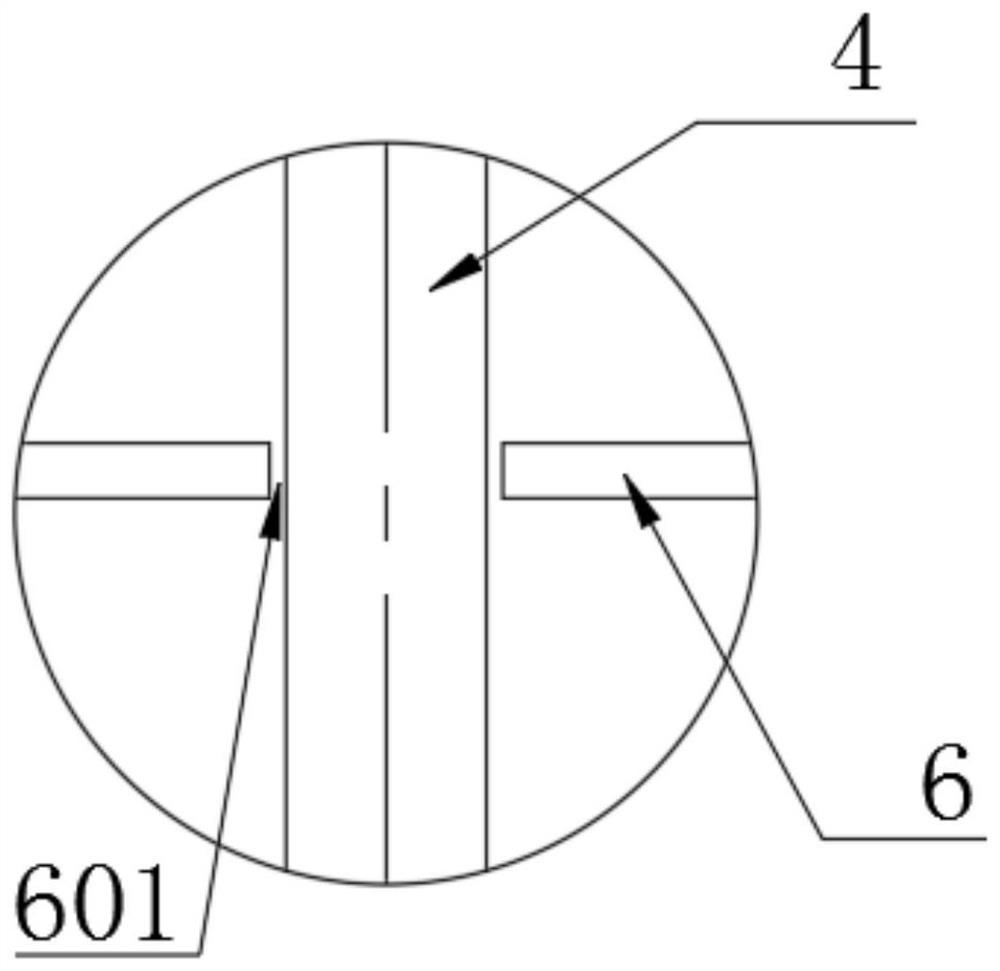

[0076] On the basis of Example 1, such as Figure 4-5 As shown, the inside of the vertical smoke pipe 4 is provided with a spoiler 401 that promotes the smoke to flow along the spiral direction, and the spoiler 401 extends from the inner upper part of the vertical smoke pipe 4 to the bottom;

[0077] The two side surfaces of the spoiler 401 are two parallel helical surfaces 402; two helical flue gas flows are formed between the two helical surfaces 402 of the spoiler 401 and the inner wall of the vertical smoke pipe 4. circulation channel.

[0078] Specifically, as Figure 6 As shown, the radial section of the spoiler 401 has a rectangular structure.

[0079] Specifically, the spoiler 401 is made of 316L stainless steel.

[0080] In this application, the spoiler 401 is easy to install. When installing, the formed spoiler 401 can be directly inserted into the vertical smoke pipe 4, so that the edge side wall of the spoiler 401 is close to the inner wall of the vertical smoke...

Embodiment 3

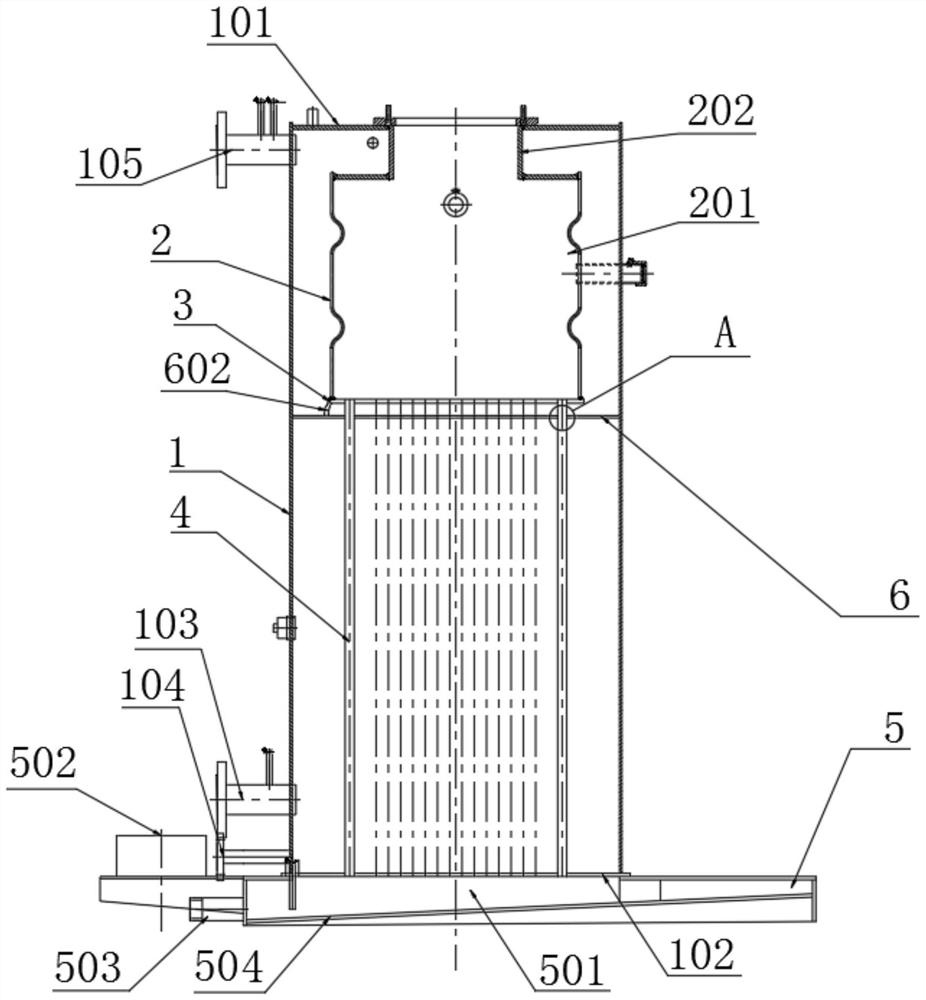

[0083] On the basis of embodiment 1 or embodiment 2, such as figure 2 As shown, the furnace 2 includes a main furnace 201, and the upper part of the main furnace 201 is coaxially provided with an auxiliary furnace 202;

[0084] The diameter of the auxiliary furnace 202 is smaller than the diameter of the main furnace 201;

[0085] The top of the auxiliary furnace 202 is fixedly connected to the side wall of the middle opening of the upper end plate 101 of the vertical cylinder 1 .

[0086] In the prior art, the furnace adopts a design with the same thickness up and down, and the top of the furnace is fixedly connected to the bottom of the upper end plate of the vertical cylinder. Since the diameter of the middle opening of the upper end plate of the vertical cylinder is smaller than the diameter of the furnace, the vertical A part of the upper end plate of the cylinder is located inside the furnace. When the boiler is running, the high temperature in the furnace will cause t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com