Fluidized bed boiler Fengshui double bed slag cooler

A technology of fluidized bed boiler and slag cooling machine, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc., so as to promote the heat exchange of slag, increase the gap between slag particles, and increase the ventilation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, combined with Figure 4-10 The relevant structure and working principle of the novel air distribution bed material system of the present invention will be described in detail.

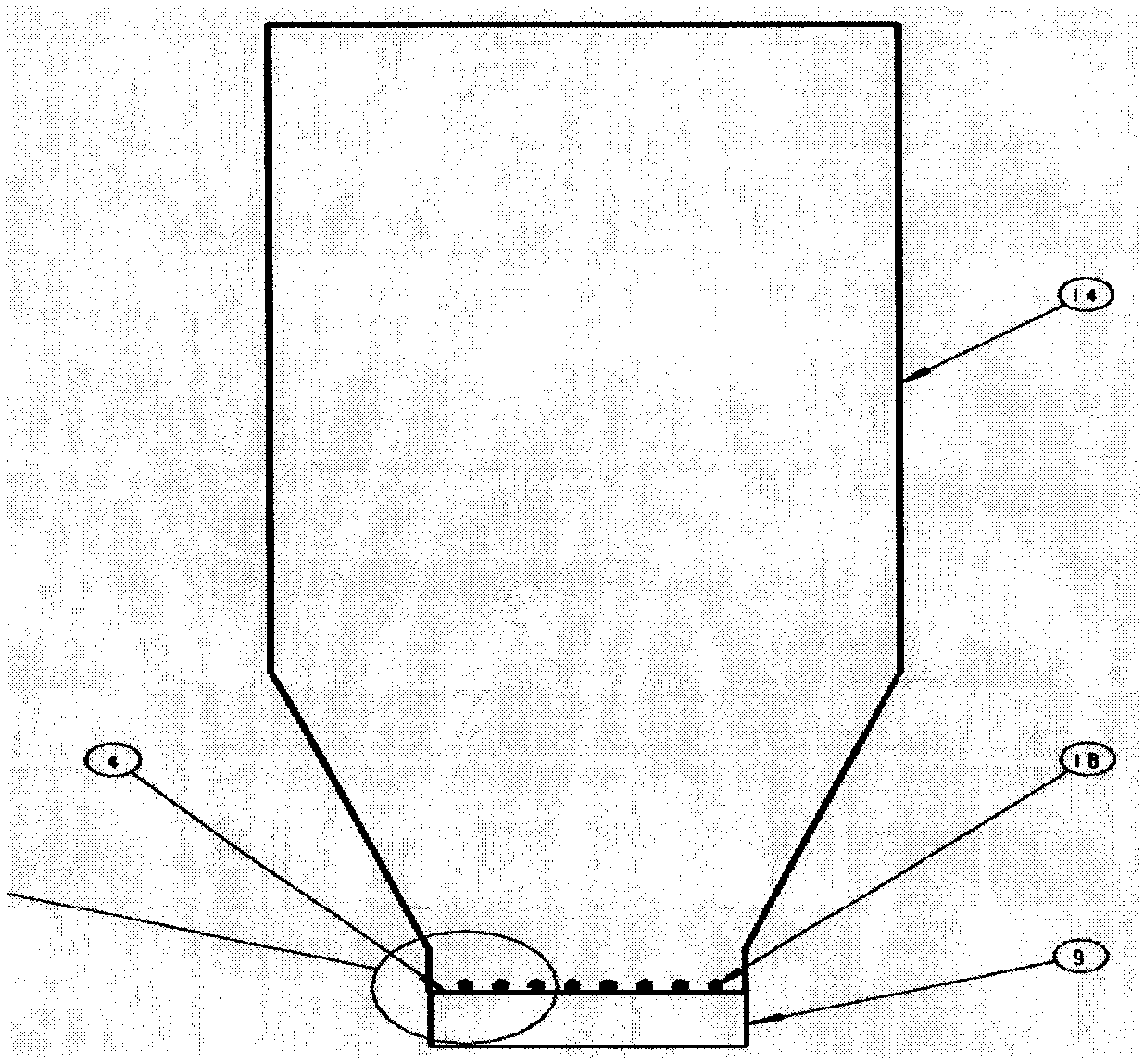

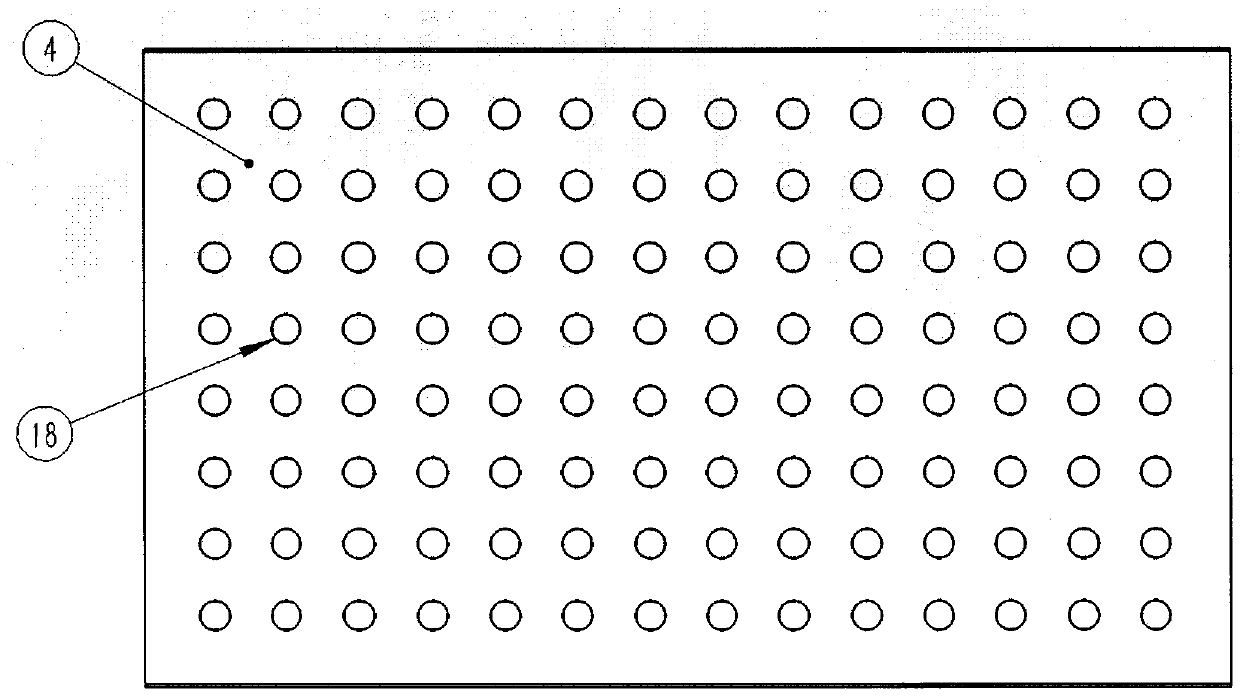

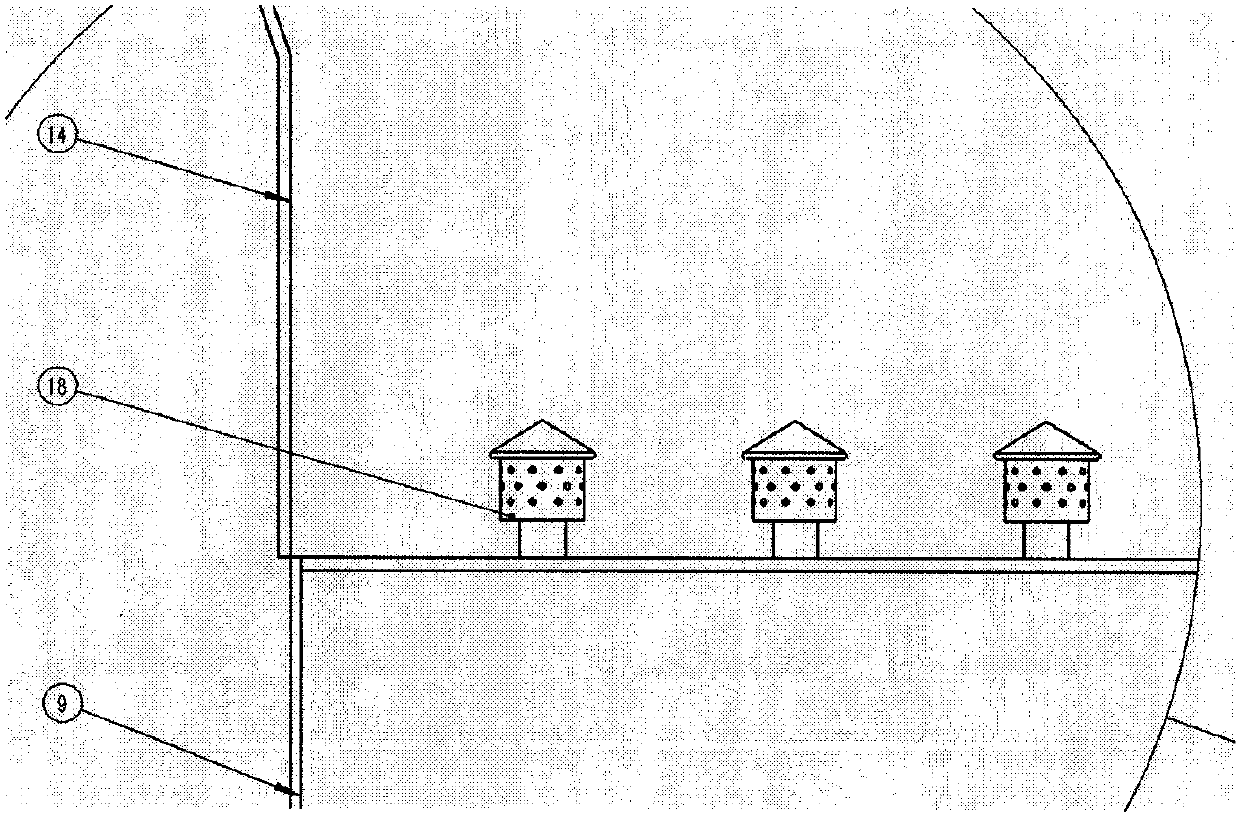

[0039] The present invention provides a fluidized bed boiler air-water double bed slag cooling machine, the slag cooling machine is composed of two parts: a water cooling system with water pipes 25 arranged on the upper water cooling wall 26 and an air distribution bed material system with wind cooling at the lower part. The air distribution bed material system includes an air chamber 9 at the bottom of the slag cooler, the air chamber 9 can be connected to the outside of the slag cooler to introduce natural wind or deliver the required wind through a fan, and an air chamber 9 is installed on the top of the air chamber 9. A trough-type air distribution system, the trough-type air distribution system includes an air distribution plate 4, a plurality of air inlets are opened under the air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com