Bubble removing structure for blind hole electroplating management groove of high-density interconnected circuit board

A high-density interconnection and circuit board technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve problems such as hindering the exchange of medicinal liquids, thin copper, high resistance, etc., to reduce attractiveness and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

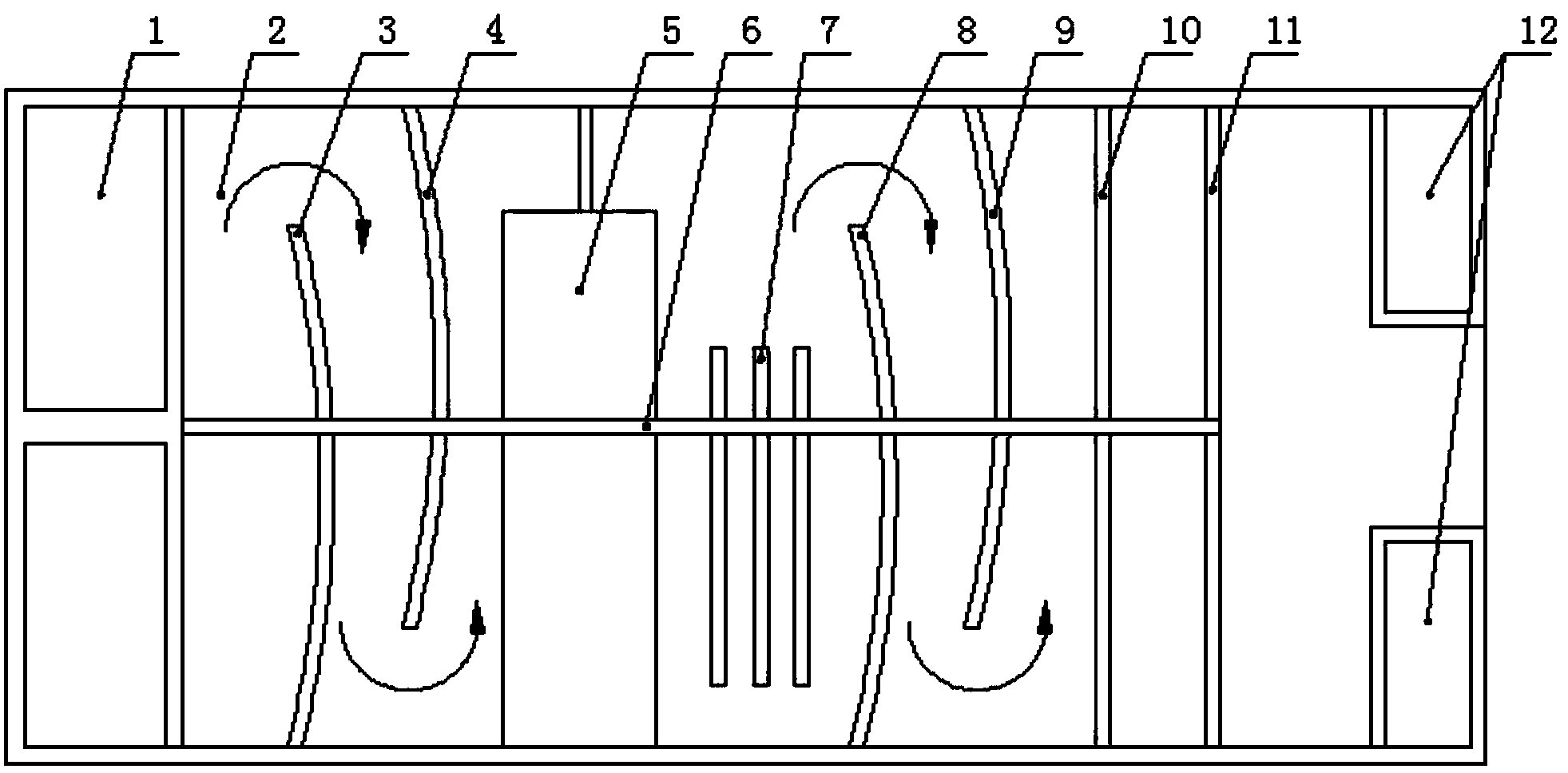

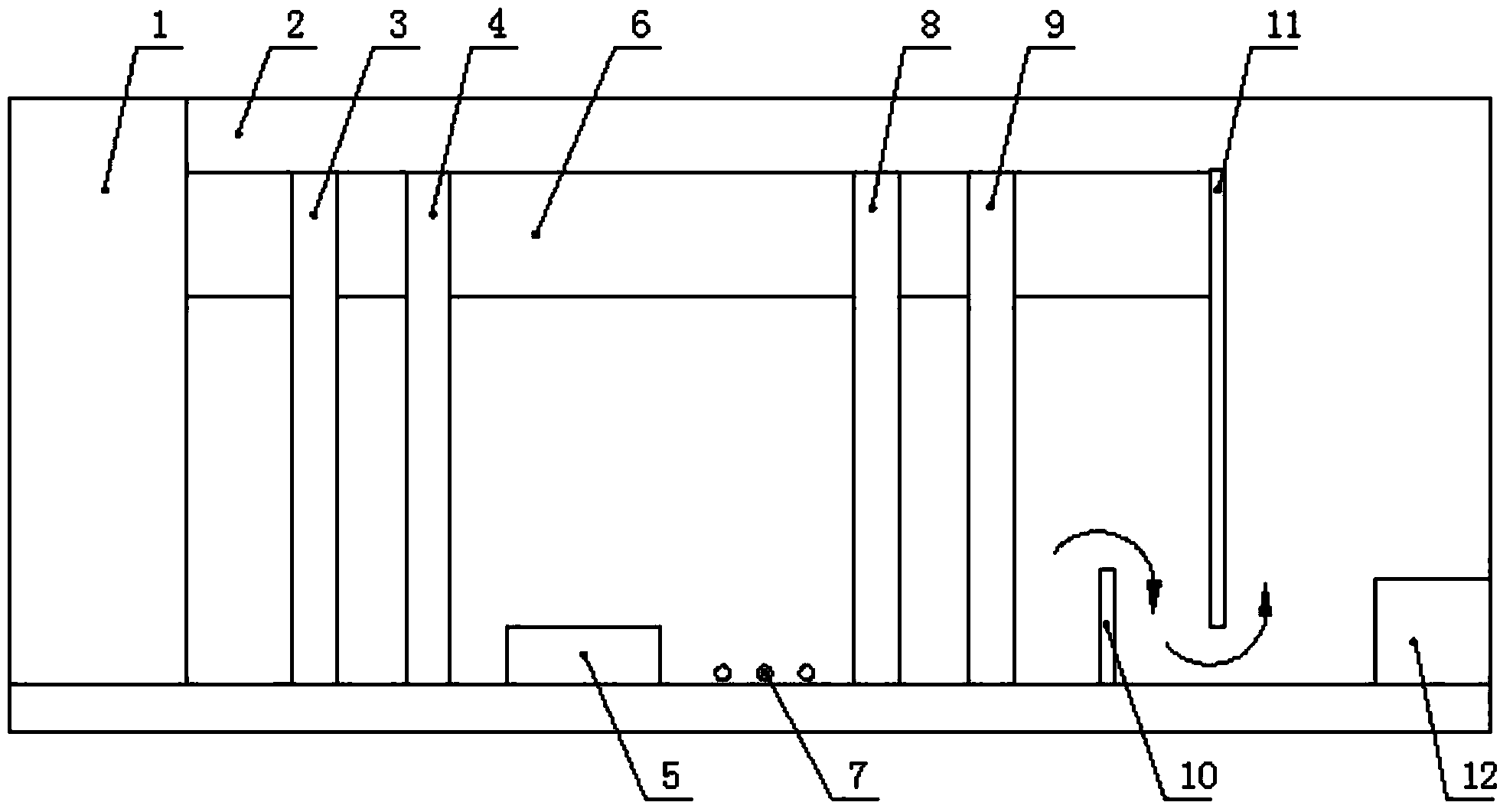

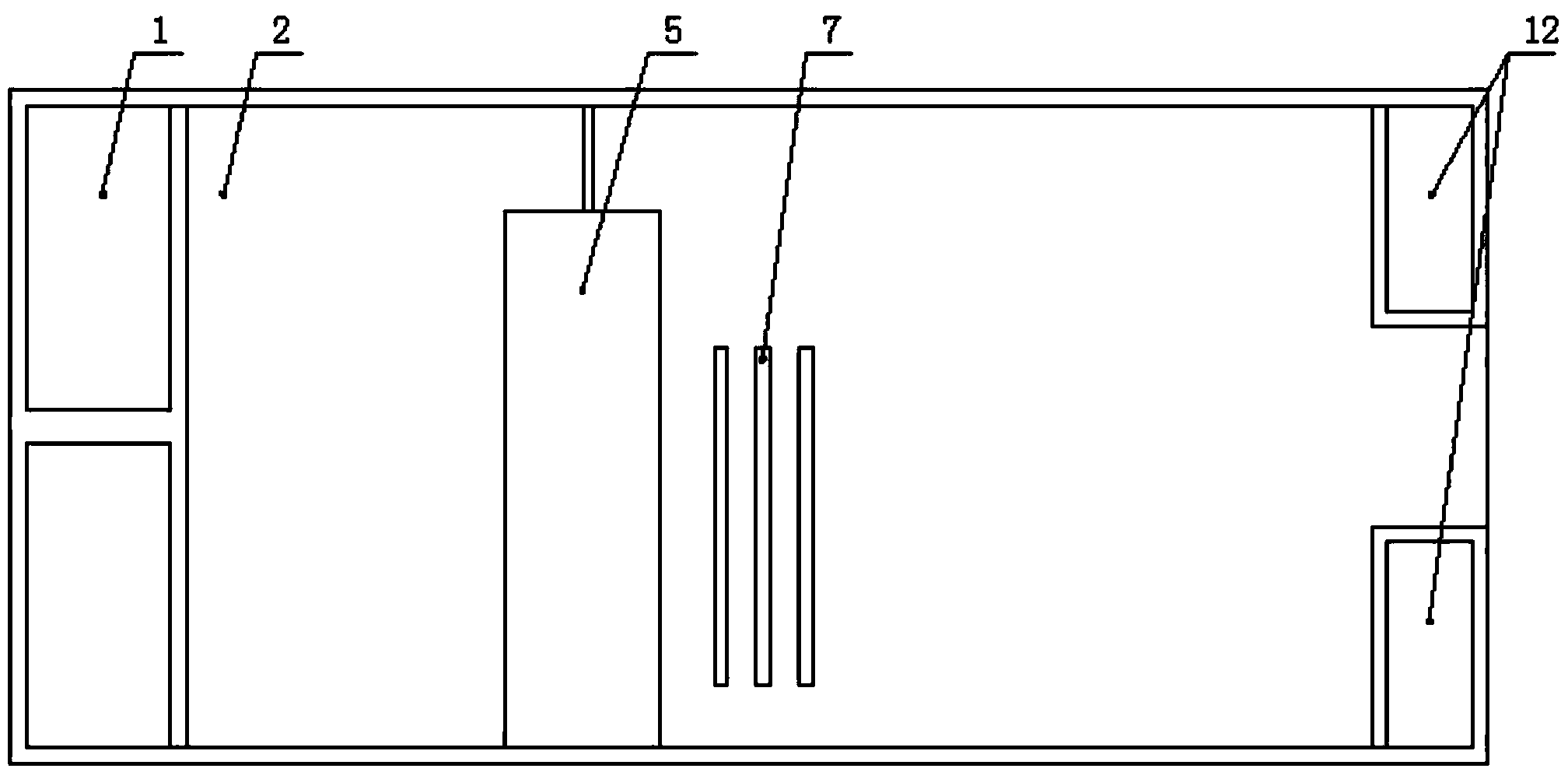

[0017] A high-density interconnect circuit board blind hole electroplating management groove bubble removal structure, such as figure 1 , 2 As shown, it includes a tank body 2, a drug inlet 1, an inflating tube 5, a heating tube 7 and a drug outlet 12. The drug inlet and the drug outlet are respectively located at two ends of the tank body, between the drug inlet and the drug outlet. The bottom of the trough between them is installed in turn with an inflating pipe and a heating pipe. The innovation of the present invention lies in that a plurality of front baffles 3 and 4 are installed on both side plates of the trough between the inflating pipe and the medicine inlet in staggered intervals. Two front baffles form a transverse serpentin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com