Tube heat exchange tube

A technology of heat exchange tube and casing type, which is applied in the field of heat exchange tubes, and can solve the problems of small diameter of heat exchange tubes, low heat exchange efficiency, and affecting the working efficiency of heat pump units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

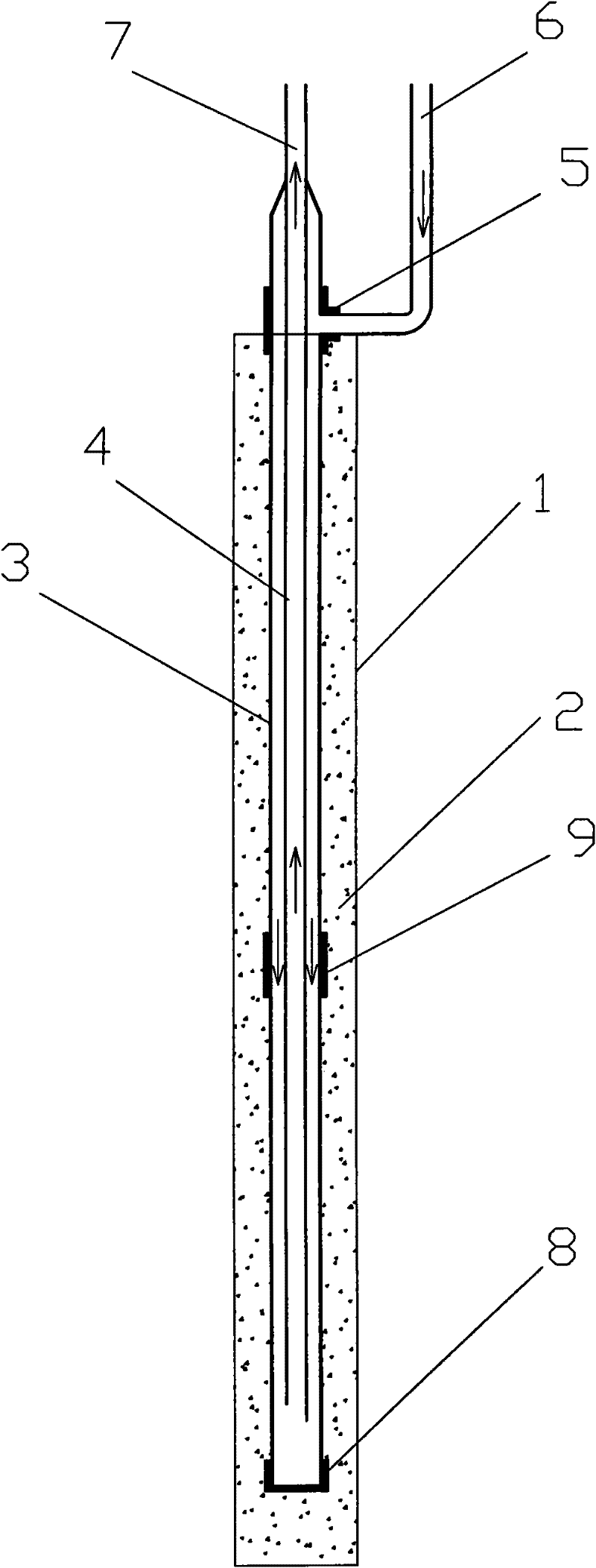

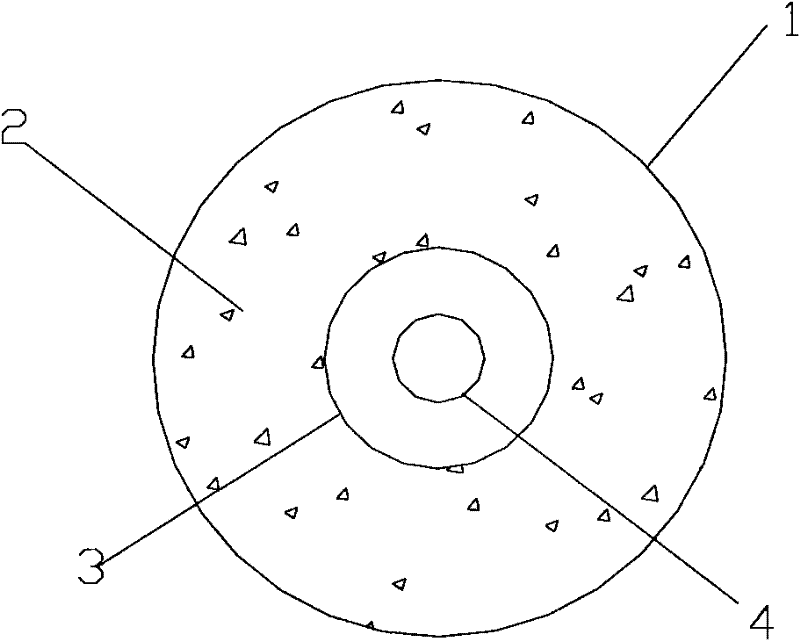

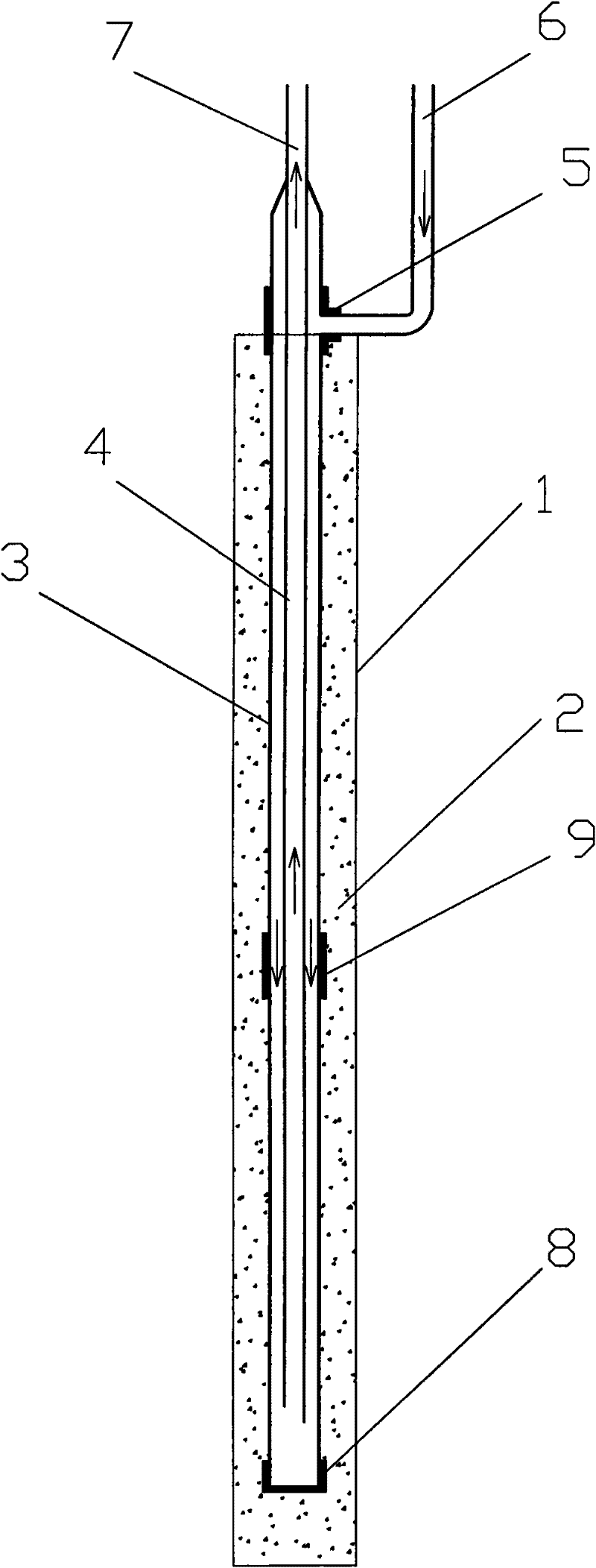

[0016] Such as figure 1 , 2 As shown, the double-pipe heat exchange tube includes an inner tube 4 and an outer tube 3. The inner tube 4 is located in the outer tube 3, and the upper end of the outer tube 3 is connected to the medium inlet 6 through a reducing tee 5. The outer tube The lower end of 3 is sealed by a sealing element 8, the upper end of the inner tube 4 is connected with the medium outlet 7, and the lower end of the inner tube 4 is open. The outer tube 3 can be formed by connecting a plurality of short tubes with connectors 9. The outer tube 3 has a diameter of 60mm-150mm, and the inner tube 4 has a diameter of 25mm-40mm. The outer tube and the inner tube are both HDPE tubes.

[0017] When the tube-in-tube heat exchange tube is used, firstly open a heat exchange hole 1 on the ground, then insert the tube-in-tube heat exchange tube into the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com