Oxygen lance opening sealing device in converter waste heat boiler

A waste heat boiler and sealing device technology, applied in the field of converter waste heat boilers, can solve the problems of large nitrogen consumption, insufficient air intake, and high operating costs, and achieve the effects of reducing operating costs, improving overall strength, and improving sealing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

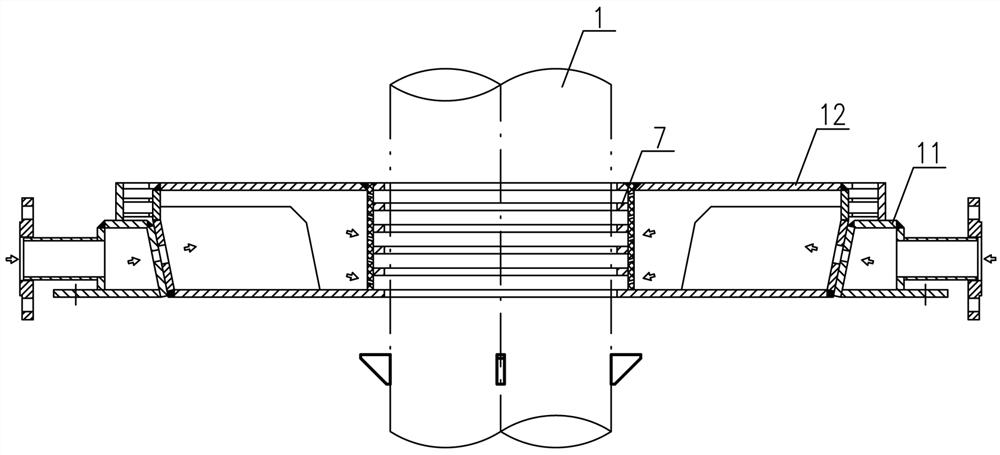

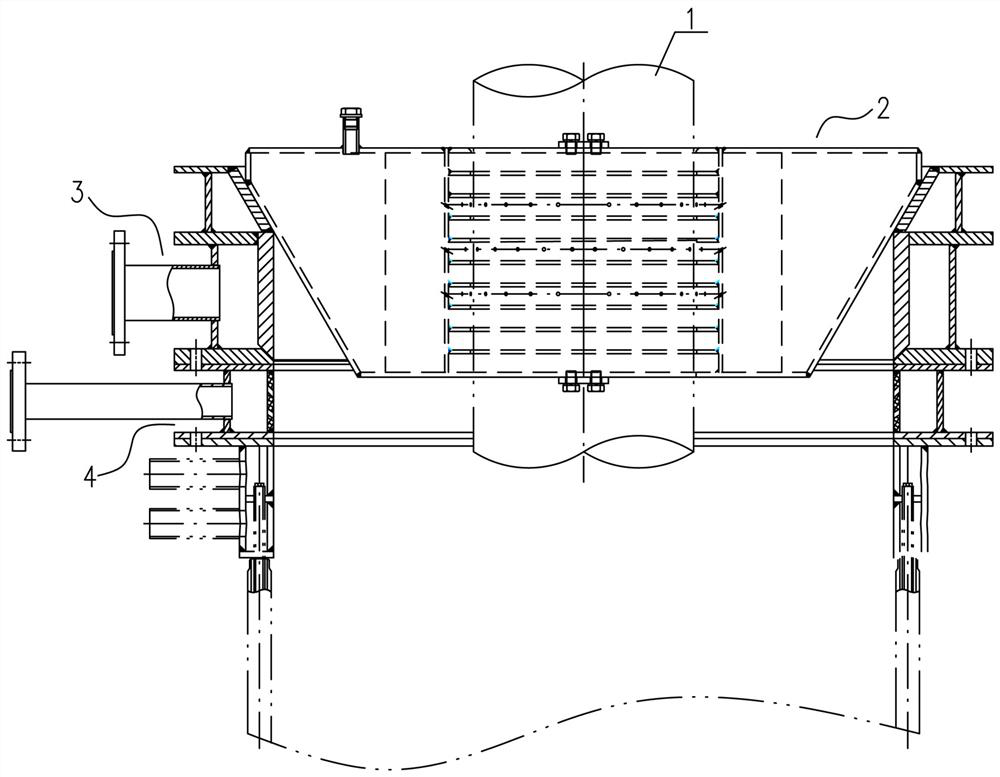

[0033] see figure 1 , figure 2 and Figure 9 As shown, the oxygen lance sealing device in the converter waste heat boiler described in this embodiment includes: a sealing seat and a nitrogen sealing plug 2 . Here the difference between the structure of the nitrogen plug 2 and the structure of the nitrogen plug in the conventional oxygen muzzle sealing device is: the number of nitrogen upper inlets 21 provided on the nitrogen plug 2 is at least one and distributed in the nitrogen plug 2 At the top, each nitrogen gas inlet 21 is sealed and connected with a nitrogen gas nozzle 22, and each nitrogen gas nozzle 22 is in sealing communication with the annular nitrogen buffer chamber 23 in the nitrogen plug 2 through the corresponding nitrogen gas inlet 21. Each nitrogen connecting pipe 22 is connected to the nitrogen gas source through a nitrogen pipeline with a first valve. In actual use, the first valve can be set as an automatic controllable valve, and the opening and closing ...

Embodiment 2

[0046] In this embodiment, on the basis of the first embodiment, an improved design is made to the structure of the nitrogen plug in the conventional oxygen gun mouth sealing device.

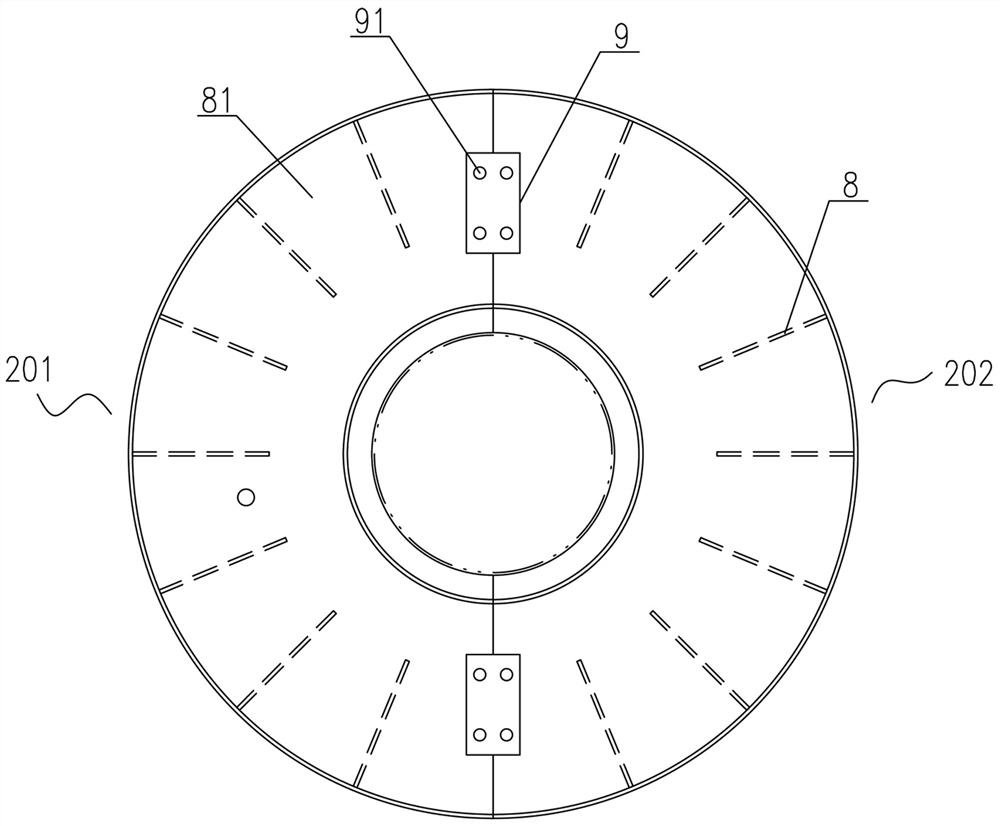

[0047] Such as figure 2 and Figure 9 As shown, the structure of the nitrogen sealing plug 2 described in this embodiment includes: surrounded by an upper positioning plate 61, a third outer cylinder 62, a lower frustum-shaped cylinder 63, a lower positioning plate 64, and a third inner cylinder 65 The casing 6 with the annular nitrogen buffer chamber 23 is formed. The contour of the inner cavity wall of the frustum-shaped cylinder 31 matches the external contour of the frustum-shaped cylinder 63 of the nitrogen sealing plug 2. Even if the oxygen lance 1 is deflected, the inner cavity of the frustum-shaped cylinder 31 can be guaranteed. The wall is effectively combined with the lower frustum-shaped cylinder 63 of the nitrogen sealing plug 2 .

[0048] On the inner cavity wall of the third in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com