Preparation method of thermal fatigue crack simulation test block

A thermal fatigue, test block technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as inability to batch production, lack of contrast, and large differences in samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

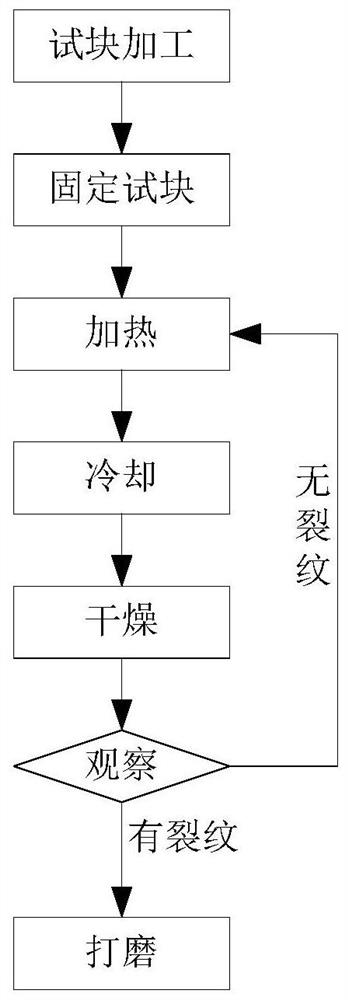

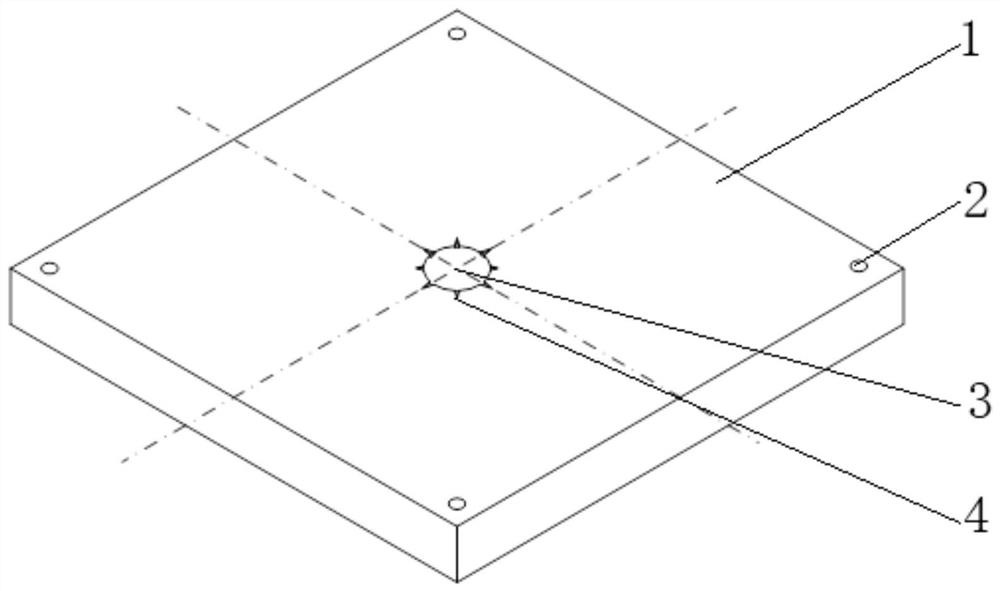

[0046] Such as figure 1 , the preparation method of thermal fatigue crack simulation test block of the present invention, comprises the following steps:

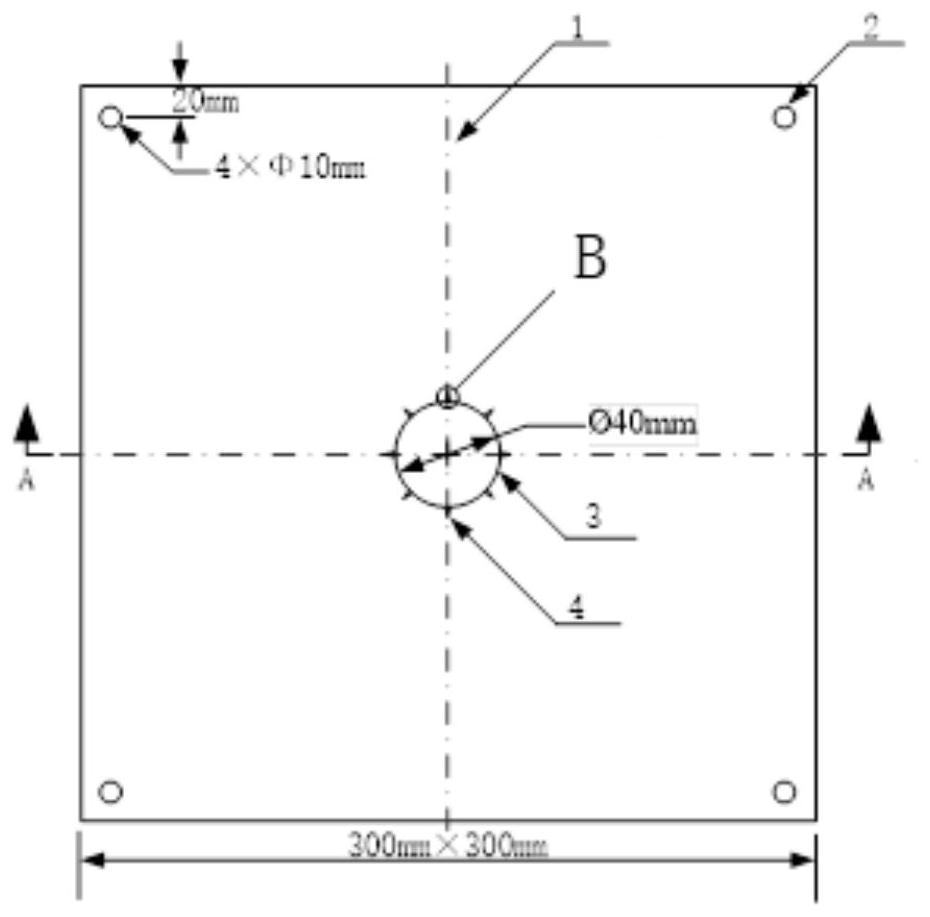

[0047] Step 1: If figure 2 , in the middle of the test block 1 through the tube hole 3 processing, around the tube hole 3 on one side of the test block 1 process a number of crack induction tip 4. The test block 1 is a cuboid, and the four corners of the test block 1 are provided with connection holes 2, and the connection holes 2 on the test block 1 are fixed on the base through connectors; a heat insulation layer is provided between the test block 1 and the base . The base is a steel plate slightly larger than the test block 1, with handles for moving the base at both ends. Preferably, the material of the test block 1 is the same as that of the workpiece to be inspected, and the curvature of the test block 1 is equal to that of the workpiece to be inspected.

[0048] Preferably, the crack induction tips 4 are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com