Casting device and method for precoated sand stacking type product

A pouring method and technology of coated sand, applied in the directions of mold, core, mold composition, etc., can solve the problems of the large number of runners, the spheroidization decline of ductile iron products, and the interruption of molten iron, so as to achieve a reasonable pouring process. , Avoid cold insulation defects and improve product efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

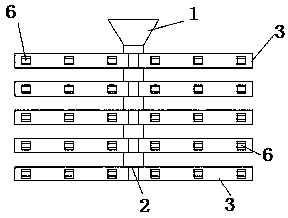

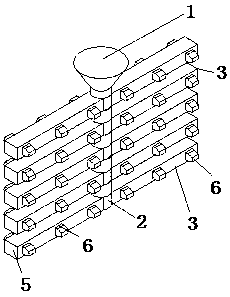

[0055] Refer to attached Figure 3-6 As shown, a pouring device for coated sand stacked products, including:

[0056] A pouring frame, which includes a sprue cup 1, a sprue 2, and a number of parallel pouring layers 3; specifically, the sprue cup 1 is arranged on the top of the pouring frame, which is a funnel-shaped structure; the bottom of the sprue cup 1 It communicates with the sprue 2;

[0057] As an improvement, in this embodiment, at least the diversion runner 4 at the bottom is included, and the diversion runner 4 forms a drainage section, and the drainage section is used to divert the casting liquid at the bottom to the upper pouring layer during pouring;

[0058] Both sides of the drainage section are respectively connected with the sprue 2 and the runner 5, the runner 5 forms the pouring layer 3, and each pouring layer 3 is provided with a number of ingates 6, and each ingate Gate 6 is connected to the casting to be poured;

[0059] In this embodiment, the height...

Embodiment 2

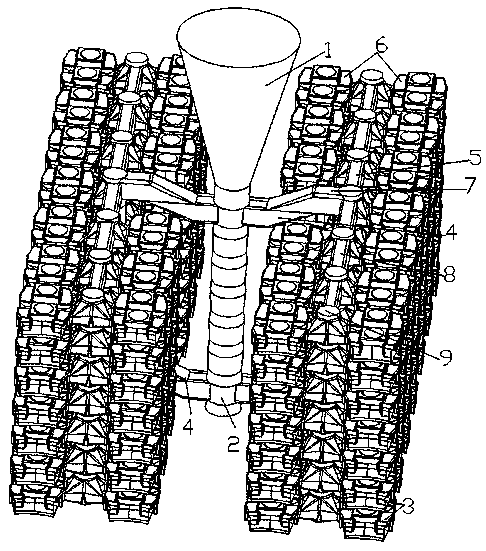

[0073] Refer to attached Figure 3-6 As shown, in this embodiment, the lower surface of the runner 5 partially overlaps with the upper surface of the runner 4 , so that the runner 5 partially overlaps the runner 4 .

[0074] Due to the partial overlap between the runner 4 and the runner 5, the molten iron can stably enter the runner 5 and the runner 4 when it flows, which reduces the risk of molten iron flow interruption and is conducive to product filling whole.

[0075] In this embodiment, the upper runner 5 and the shunt runner 4 are partially stacked, which can prevent molten iron from entering the upper runner 5 first, so that the molten iron first enters the bottom shunt runner 4 from the sprue 2 and then Enter the runner 5, and then enter the casting through the gate 6. Through such pouring, the bottom pouring form is realized, and molten iron flows from the pouring layer 3 of the next layer into the ingate 6 of the pouring layer 3 of the upper layer, and then enters ...

Embodiment 3

[0089] In this embodiment, the runner 5 at least includes a first runner 7 and a second runner 8, and the first runner 7 and the second runner 8 are respectively perpendicular to the sprue 2, And the first runner 7 is perpendicular to the second runner 8; the first runner 7 is directly arranged on the diversion runner 4, and the first runner 7 is provided with several second runners The second runner 8 is provided with the ingate 6 .

[0090] In this embodiment, the number of castings can be increased through multiple runners; compared with the prior art, when multiple pouring layers are required, the prior art can only directly connect how many runners; and this embodiment Among them, since the second runner 8 is equivalent to the direct pouring runner of the prior art, and then by adjusting the first runner, the number of runners directly connected with the sprue 2 can be reduced, so that the runner The number is adjusted by the second runner 8, and the number of the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com