A heat-resistant and anti-corrosion ventilation hood

A fume hood, heat-resistant technology, applied in the field of materials, can solve the problems of high cost of fume hood, shortened service life of fume hood, increased enterprise cost, etc., and achieve the effect of improving heat conduction and heat dissipation, reducing vibration and noise, and improving damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

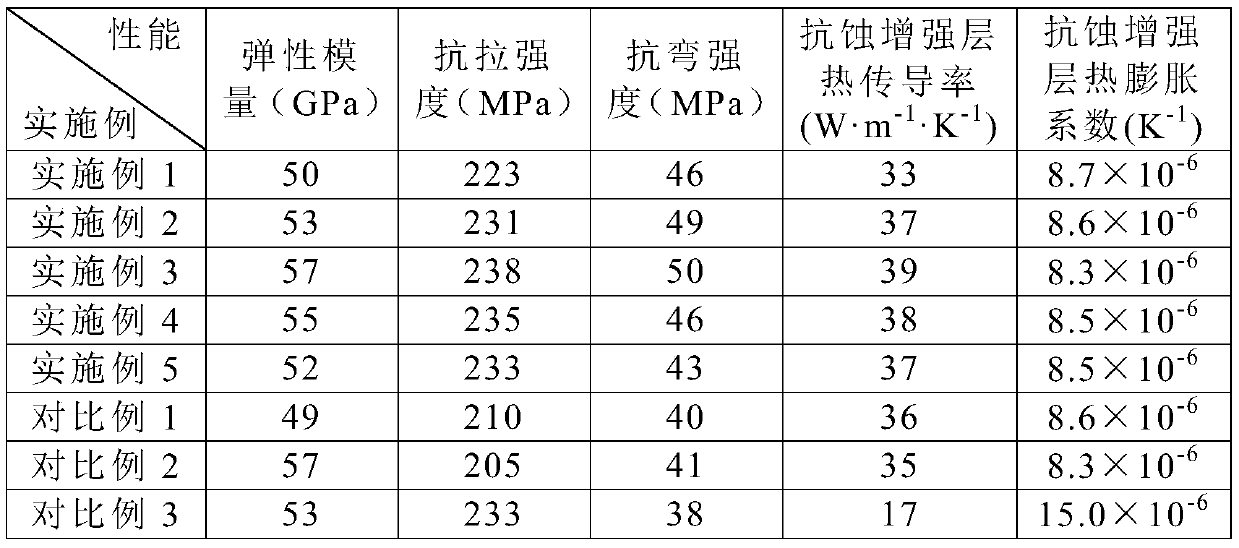

Examples

Embodiment 1

[0027] The heat-resistant and anti-corrosion ventilation hood in this embodiment includes an outer layer of fluorine-containing resin, a heat insulation layer, a metal layer, a transition layer, and an anti-corrosion enhancement layer in order from outside to inside.

[0028] The thermal insulation layer is a ceramic layer with nanometer pores;

[0029] The transition layer is SiO deposited on the surface of the metal layer after 0.5 μm 2 layer;

[0030] The manufacturing process of the anti-corrosion enhancement layer is: using abrasives with a particle size of 300 mesh on SiO 2 The sandblasting treatment was carried out on the layer for 3 minutes, and the modified carbon fiber was prepared by grafting polyurethane on the surface of the carbon fiber by plasma-induced graft polymerization, and then 100 parts of quartz powder, 36 parts of granite powder, 30 parts of β-SiC powder, 26 parts Epoxy resin, 15 parts of curing agent and 19 parts of modified carbon fiber were stirred...

Embodiment 2

[0033] The heat-resistant and anti-corrosion ventilation hood in this embodiment includes an outer layer of fluorine-containing resin, a heat insulation layer, a metal layer, a transition layer, and an anti-corrosion enhancement layer in order from outside to inside.

[0034] The thermal insulation layer is a ceramic layer with nanometer pores;

[0035] The transition layer is SiO deposited on the surface of the metal layer after 1 μm 2 layer;

[0036] The fabrication process of the anti-corrosion enhancement layer is as follows: using abrasives with a particle size of 400 mesh on SiO 2 Sand blasting treatment on the layer for 3-5 minutes, using plasma-induced graft polymerization method to graft polyurethane on the surface of carbon fiber to obtain modified carbon fiber, and then 100 parts of quartz powder, 40 parts of granite powder, 29 parts of β-SiC powder, 28 parts of epoxy resin, 17 parts of curing agent and 22 parts of modified carbon fiber were stirred and mixed in a...

Embodiment 3

[0039] The heat-resistant and anti-corrosion ventilation hood in this embodiment includes an outer layer of fluorine-containing resin, a heat insulation layer, a metal layer, a transition layer, and an anti-corrosion enhancement layer in order from outside to inside.

[0040] The thermal insulation layer is a ceramic layer with nanometer pores;

[0041] The transition layer is SiO deposited on the surface of the metal layer after 1.5 μm 2 layer;

[0042] The fabrication process of the anti-corrosion enhancement layer is as follows: using abrasives with a particle size of 400 mesh on SiO 2 Sand blasting treatment was carried out on the layer for 4 minutes, and the method of plasma-induced graft polymerization was used to graft polyurethane on the surface of carbon fiber to obtain modified carbon fiber, and then 100 parts of quartz powder, 43 parts of granite powder, 27 parts of β-SiC powder, 30 parts of Epoxy resin, 18 parts of curing agent and 25 parts of modified carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com