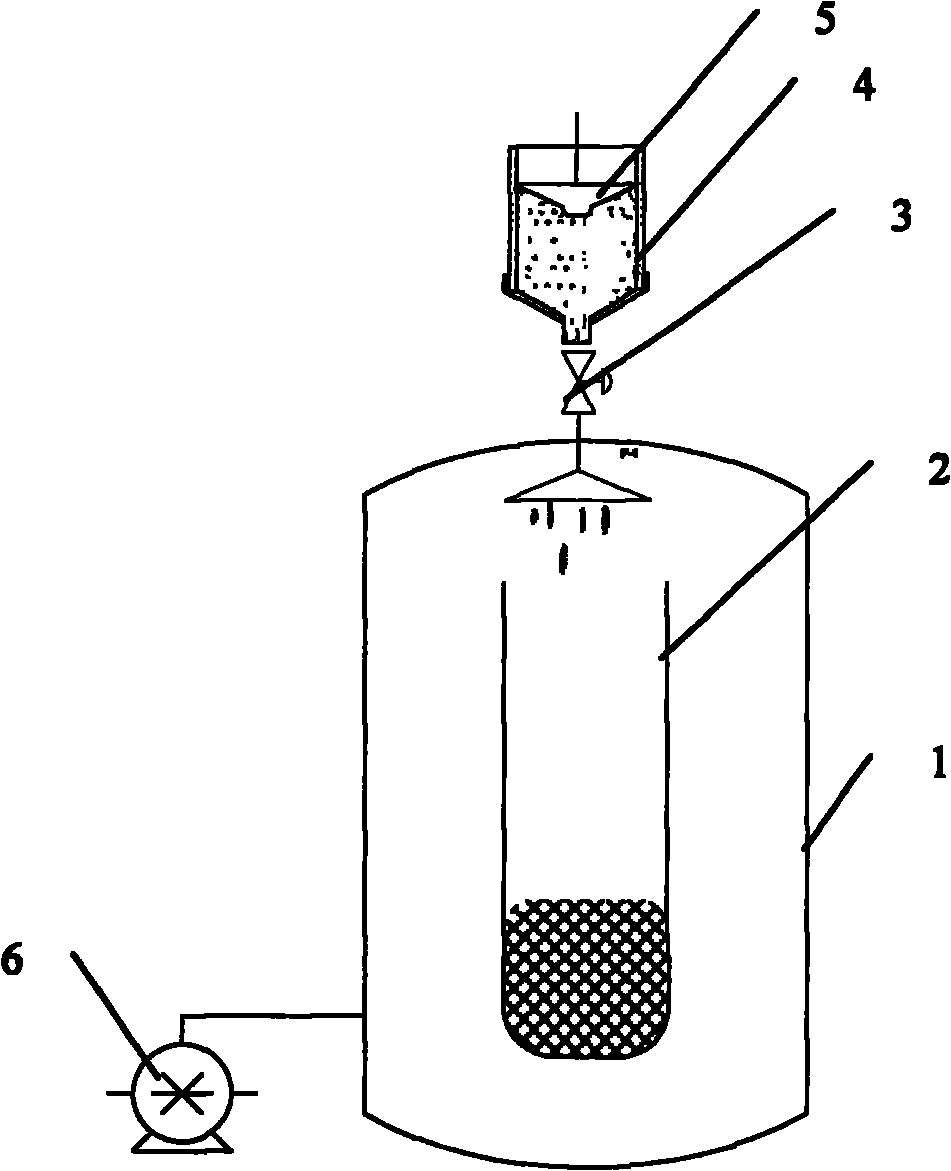

Automatically controllable explosive slurry casting system

An automatic control and pouring system technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as safety accidents, inability to clean the slurry in the material tank, unsuitable pouring system, etc., to reduce waste and reduce injuries to personnel. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In Embodiment 1, after the valve is manually opened, the pouring work can be completed automatically without manual operation. Suitable for large and small pouring systems.

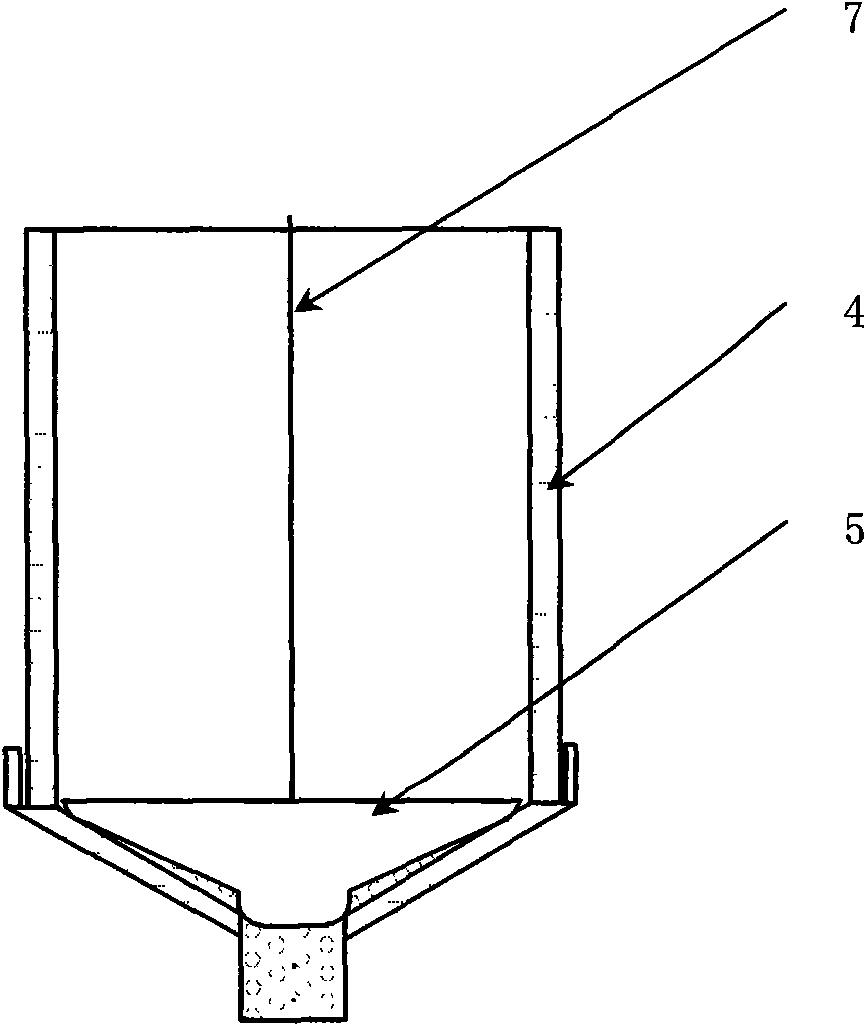

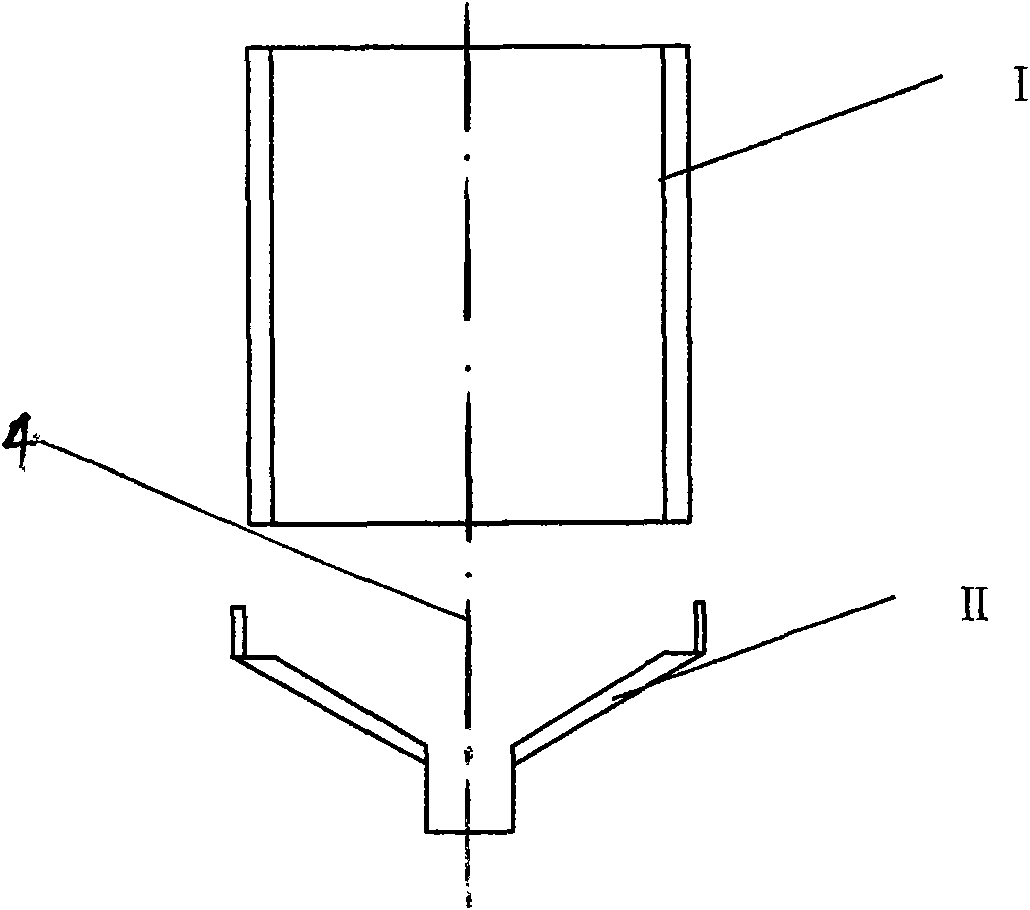

[0025] Figure 4 Among them, the hemispherical cone head at the bottom of the suspension valve 5 can closely cooperate with the pouring cylinder discharge port. This embodiment includes a photoelectric switch 9 that receives the light from the light source 8 and controls the switching of the feeding valve 3 and the alarm 10 . The light beam emitted by the light source 8 can be received by the photoelectric switch 9 when there is no shade of the scale 7, and the photoelectric switch 9 can control the switch of the feeding valve 3 and the alarm 10. When pouring is completed, the photoelectric switch 9 receives the light beam sent by the light source 8, turns on the power, starts an alarm, and closes the feeding valve 3. The pouring material cylinder 4 adopts the design mode that the straight secti...

Embodiment 2

[0026] In embodiment 2, after the valve is opened remotely with pneumatic power, no manual operation is required until the pouring work is completed. Suitable for large pouring systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com