Building component self-pressurization expansion type pore-forming die

An expansion technology for building components, applied in the direction of molds, etc., can solve the problems of high labor intensity, complicated operation, and difficult to guarantee the quality of holes, so as to avoid the inability to demould, reduce the number of workers, and ensure the quality of holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

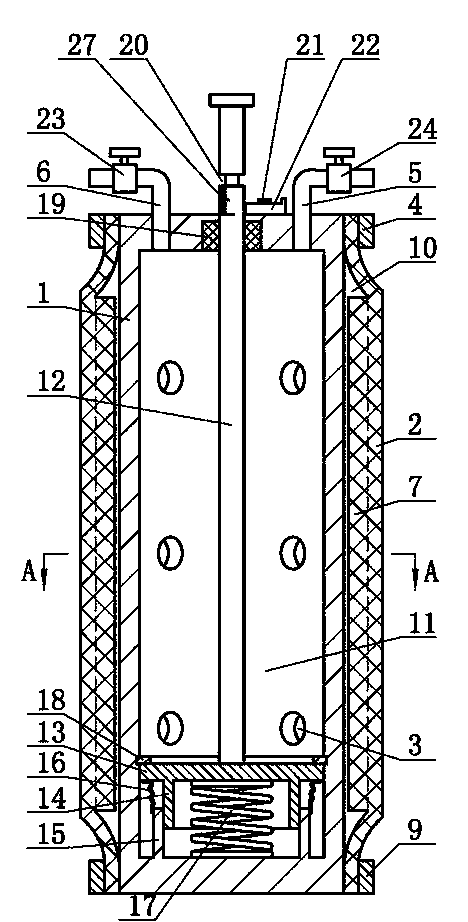

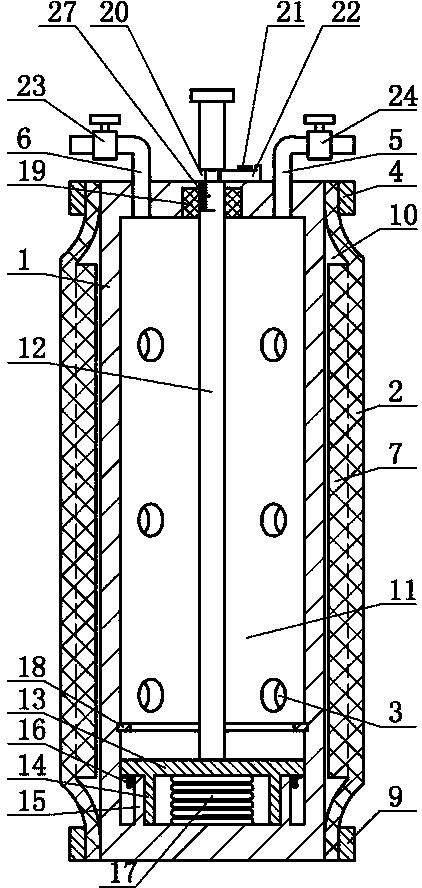

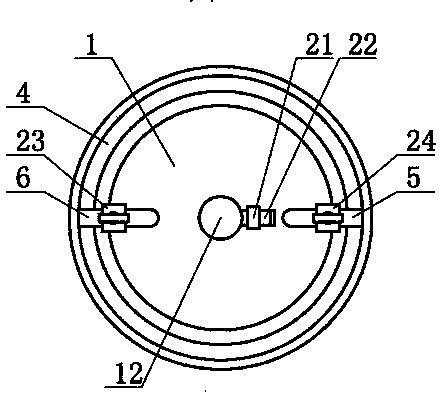

[0011] The building component self-pressurization expansion type hole-forming mold of the present invention includes a hard shell 1, the interior of the hard shell 1 is a cavity 11, and a soft cover 2 is installed around the side wall of the hard shell 1, and the soft cover 2 The two ends are respectively connected to the hard shell 1 through the first clamp 4 and the second clamp 9, an expansion chamber 10 is formed between the inner wall of the soft cover 2 and the outer wall of the hard shell 1, and a through hole is set on the side wall of the hard shell 1 3. The cavity 11 communicates with the expansion cavity 10 through the through hole 3, the piston 13 is installed in the cavity 11, one side of the piston 13 is connected with the inner sleeve 14, and the outer sleeve 15 is arranged outside the inner sleeve 14, and the outer sleeve 15 is connected with the hard The shell 1 is connected, the spring 17 is installed between the piston 13 and the hard shell 1, the other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com