Patents

Literature

46results about How to "Improve bronzing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

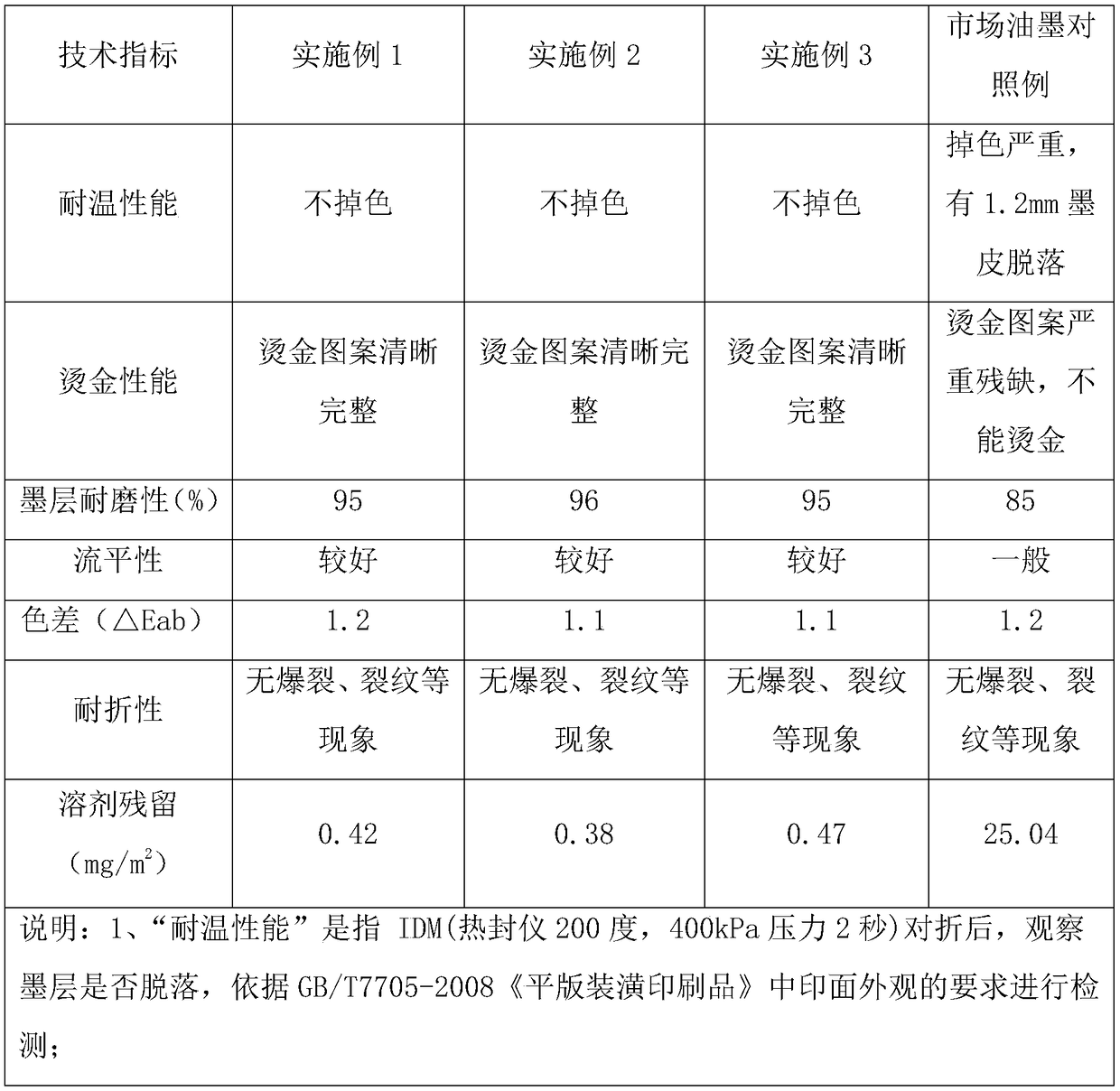

High-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and preparation method thereof

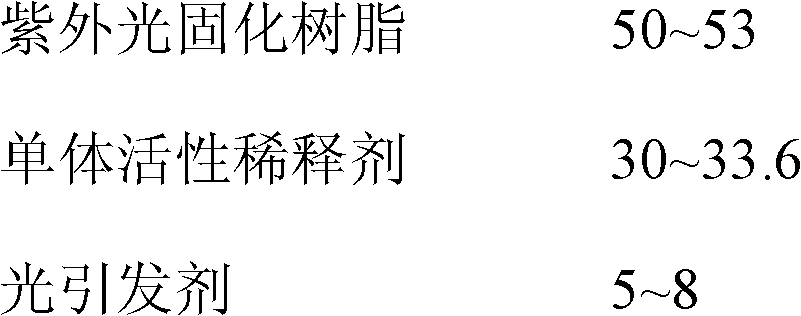

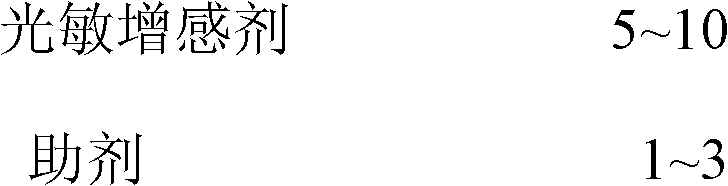

The invention provides high-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and a preparation method thereof. The high-gloss abrasion-resisting UV gold-stamping gloss oil is gold-stamping gloss oil with the viscosity of 130-150 cps / 25 DEG C and is prepared by mixing and stirring, by mass, 20-25 parts of CN9006 N six-functionality polyurethane acrylate, 25-30 parts of CN117 modified epoxy acrylate, 15-15.6 parts of SR399NS dipentaerythritol senary acrylic ester, 15-18 parts of SR238NS 1,6- hexylene glycol diacrylate, 5-8 parts of photoinitiator, 5-10 parts of photosensitivity sensitizer and1-3 parts of auxiliaries. The high-gloss abrasion-resisting UV gold-stamping gloss oil adopts monomers and resin with small acid value and corrosivity, has the advantages of being high in glossiness, good in adhesive force, friction-resisting, quick in drying speed and the like and has good gold-stamping effect when used for the cigarette packet printing.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Method for improving bronzing effect of non-ferrous metal cardboard

ActiveCN101412332AReduce consumptionAffordable supplyOther printing apparatusCardboardMaterials science

The invention discloses a method for improving the bronzing effect on a non-ferrous metal paperboard, which comprises printing layer of UV matte oil on the part of the non-ferrous metal paperboard for bronzing before bronzing, and then performing the bronzing. If the matte effect is needed, the back part of a part needing the bronzing on the non-ferrous metal paperboard can be printed with a layer of the UV matte oil, and then the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of the UV matte oil again. Before the bronzing, if the UV matte oil is used for printing, for not influencing the bronzing effect, the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of UB matte oil contained in the UV matte oil before performing the bronzing, and then the part needing the bronzing is subjected to the bronzing.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

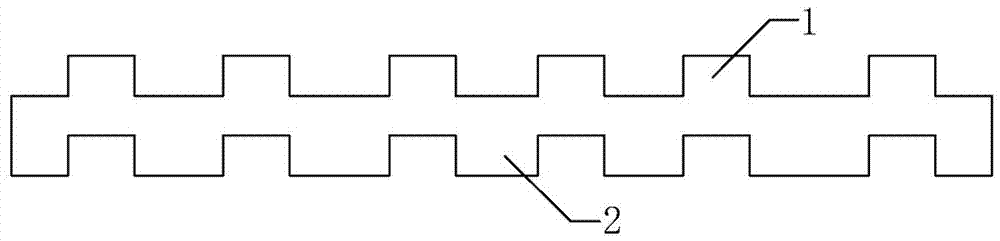

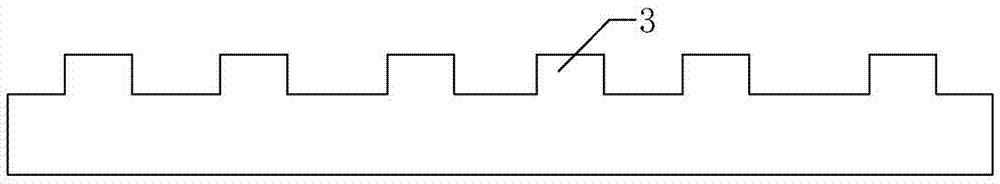

Combined high-precision hot-stamping printing plate and three-channel hot-stamping refraction anti-counterfeiting mark manufactured by same

InactiveCN107521223AOmit alignment setting datumSimplify control proceduresStampsBronze printingHot stampingLaser engraving

The invention relates to a combined high-precision hot stamping plate and a three-channel hot stamping refraction anti-counterfeiting mark, which aims to solve the technical problem of poor anti-counterfeiting effect of the traditional nesting overprinting, including a set of combined high-precision The laser engraving plate and two hot stamping films with different effects and colors, through the combination of the combined hot stamping plate and the hot stamping plate, combined with the structural design characteristics of the hot stamping mold and the hot stamping mold, realize the hot stamping plate and the hot stamping plate The three-channel refraction anti-counterfeiting logo is successively folded and ironed, so that different patterns, characters or lines can be observed from different viewing angles, which solves the technical problem that the folded ironing cannot form refraction anti-counterfeiting at various angles of view in the prior art.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

Water-based coating and preparation method thereof

ActiveCN101942256AReduce pollutionPollution meetsAnti-corrosive paintsPotassium persulfateSodium acetate

The invention relates to a water-based coating. The water-based coating is prepared form the following raw materials in percentage by weight: 52 to 55 percent of water, 0.5 to 0.7 percent of sodium dodecyl sulfate, 20 to 25 percent of methyl methacrylate, 3 to 4.5 percent of butyl acrylate, 0 to 2 percent of ethyl hexyl acrylate, 1 to 1.5 percent of acrylic acid, 10 to 15 percent of butyl methacrylate, 1 to 2 percent of butyl maleate, 0.6 to 1 percent of ethyl acrylate, 0.4 to 1 percent of itaconic acid, 0.8 to 1 percent of ammonia water, 0.1 to 0.2 percent of antifoaming agent, 0.05 to 0.1 percent of sodium acetate, 0.1 to 0.2 percent of preservative and 0.1 to 0.2 percent of potassium persulfate. The invention also provides a method for preparing the water-based coating. The water-based coating of the invention is innoxious and has a small amount of environmental pollution; and a coating layer formed by coating has the advantages of high brightness, toughness, excellent anti-explosion performance, excellent subsequent processing performance, capability of stamping gold rapidly and efficiently and good gold stamping effect.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

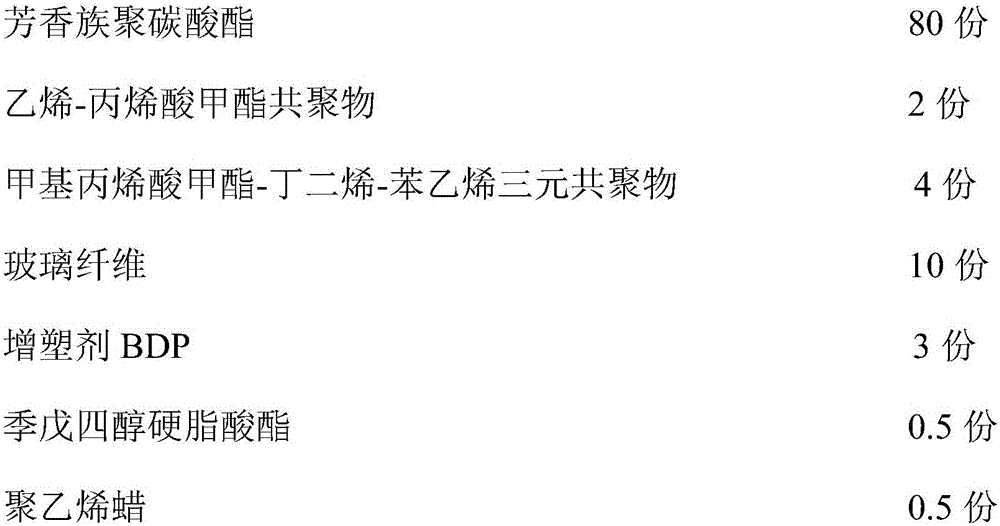

High-liquidity high-toughness reinforced PC composite material and preparing method thereof

The invention discloses a high-liquidity high-toughness reinforced PC composite material and a preparing method thereof, and belongs to the technical field of high polymer materials. The high-liquidity high-toughness reinforced PC composite material is composed of, by weight, 68-80 parts of PC resin, 0-6 pars of plasticizer BDP, 3-6 parts of flexibilizer, 10-20 parts of glass fiber, 0.2-1 part of antioxidant and 0.5-1 part of lubricant. The high-liquidity high-toughness reinforced PC composite material shows good balance on strength and toughness, has good liquidity, is suitable for thin-wall workpiece injection molding, and is successfully applied to mobile phones; the flexural modulus of the high-liquidity high-toughness reinforced PC composite material is bigger than or equal to 4000 Mpa, the cantilever beam notched impact is bigger than or equal to 160 J / m, and the liquidity is bigger than 20 g / 10min; compared with a PC+10%GF or PC+20%GF material which is adopted in an existing mobile phone rear shell or a middle frame, the high-liquidity high-toughness reinforced PC composite material has a flatter surface, a good spraying effect, and a good evaporation effect; the high-liquidity high-toughness reinforced PC composite material is prepared from universal PC, the BDP plasticizer, the flexibilizer, the lubricant and the antioxidant, and the raw material is easy to obtain and can be directly used for industrialized production.

Owner:ORINKO NEW MATERIAL CO LTD

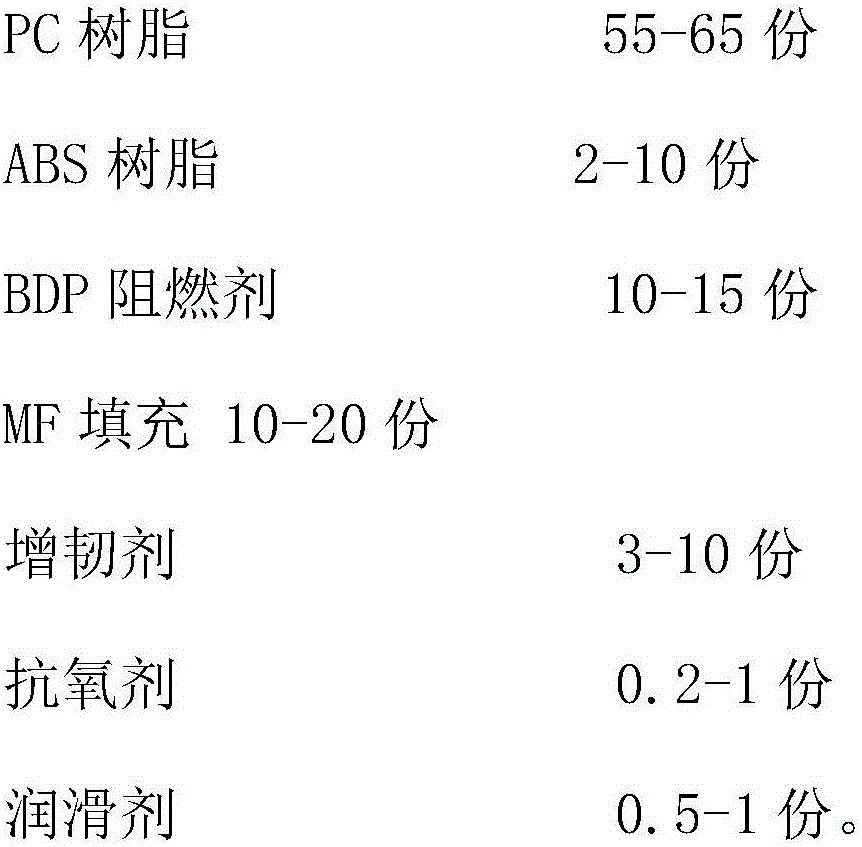

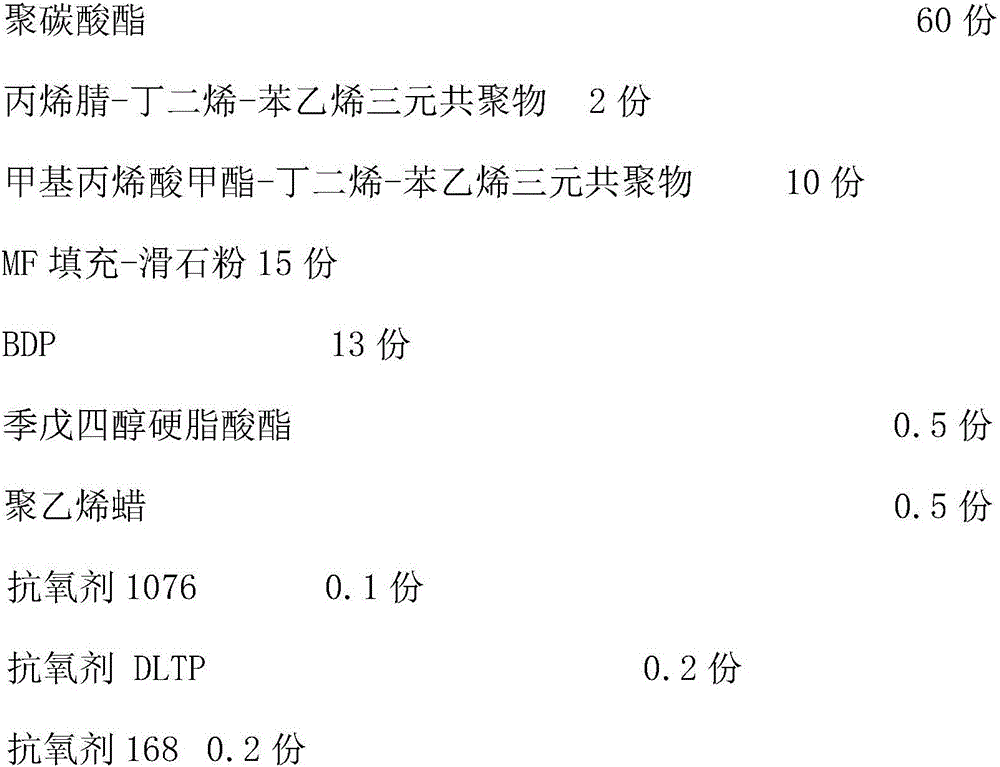

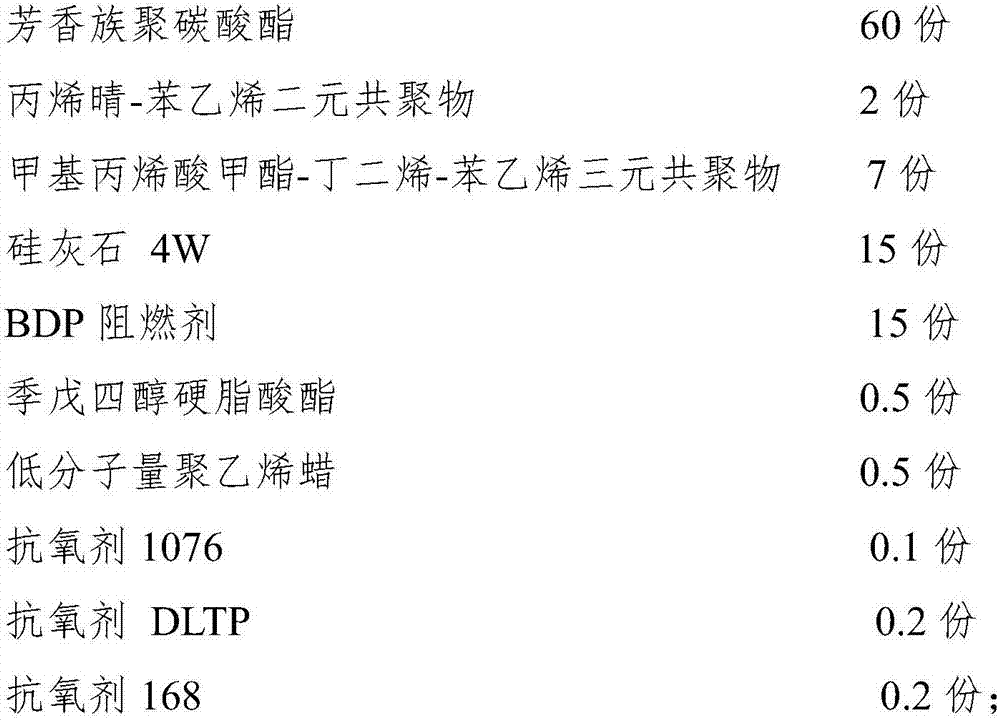

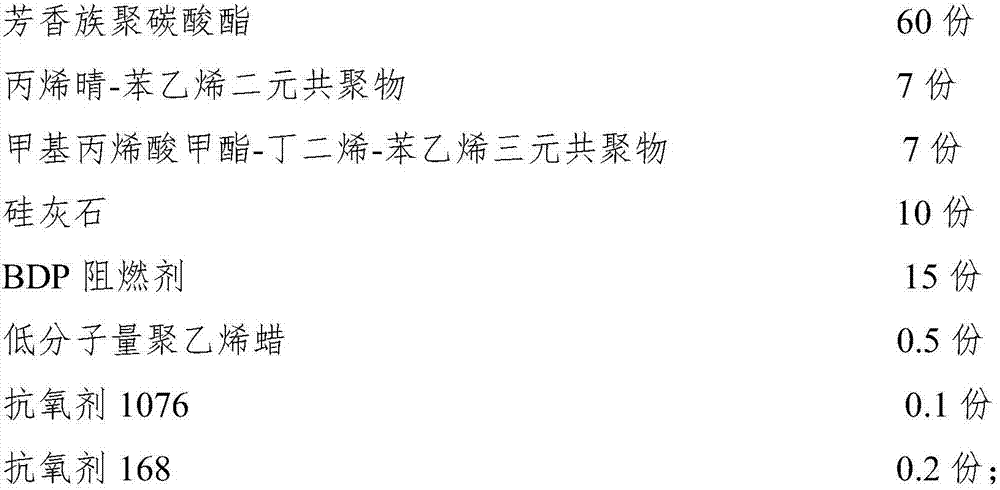

High-rigidity high-toughness PC/ABS+MF composite material and preparation method thereof

The invention relates to the technical field of macromolecules, in particular to a high-rigidity high-toughness PC / ABS+MF composite material. The high-rigidity high-toughness PC / ABS+MF composite material is prepared from the following raw materials in parts by weight: PC resin 55-65 parts, ABS resin 2-10 parts, BDP fire retardant 10-15 parts, a toughener 3-10 parts, MF filler 10-20 parts, an antioxidant 0.2-1 part and a lubricant 0.5-1 part. The mixed materials are fed into a parallel twin screw extruder, and are melted, extruded and granulated to obtain the PC / ABS+MF composite material. Strength and toughness of the prepared PC / ABS+MF composite material are balanced well, bending modulus is greater than or equal to 4,000 Mpa, notched impact of a cantilever beam is greater than or equal to 60 J / m, and density is smaller than 1.30 g / cm<3>. Compared with an existing PC / ABS+10% GF or ABS+ 10% GF material for a front frame of a television, the high-rigidity high-toughness PC / ABS+MF composite material has the characteristics that damage of glass fibers to molds in a long-time production process is reduced, the problem that highlight molds need to be polished in long-time injection molding is solved obviously, production efficiency is improved, and meanwhile, compared with a PCABS+ 10% GF or ABS+ 10% GF product, PCABS+ MF has more smooth surface, and has good gold stamping effect.

Owner:ORINKO NEW MATERIAL CO LTD

Electroless engraving thermocompression bonding gold stamping process

ActiveCN107323115AImprove aestheticsImprove bronzing effectDuplicating/marking methodsInksEngravingStamping process

The invention relates to the technical field of gold stamping, and concretely relates to an electroless engraving thermocompression bonding gold stamping process, which comprises the following steps of A, printing: printing gold stamping oil on the surface of an object to be subjected to gold stamping, and obtaining a print with a preset pattern to be subjected to gold stamping; B, curing: carrying out photocuring treatment on the print obtained through the step A, and obtaining a solid print with a preset pattern to be subjected to gold stamping; and C thermocompression bonding: covering a gold stamping film on the surface of the solid print obtained through the step B, using a soft edition for carrying out thermocompression bonding treatment on the solid print covered with the gold stamping film, and obtaining a gold stamping product with the preset gold stamping pattern. The gold stamping process provided by the invention does not need electronic engraving for gold stamping, and is convenient and fast in process operation, high in production efficiency and low in production cost, so that the prepared gold stamping product has the characteristics of high glossiness, high attractiveness, good hand feeling, excellent three-dimensional effect and the like, and is stable in quality and suitable for large-scale production.

Owner:缪秉强

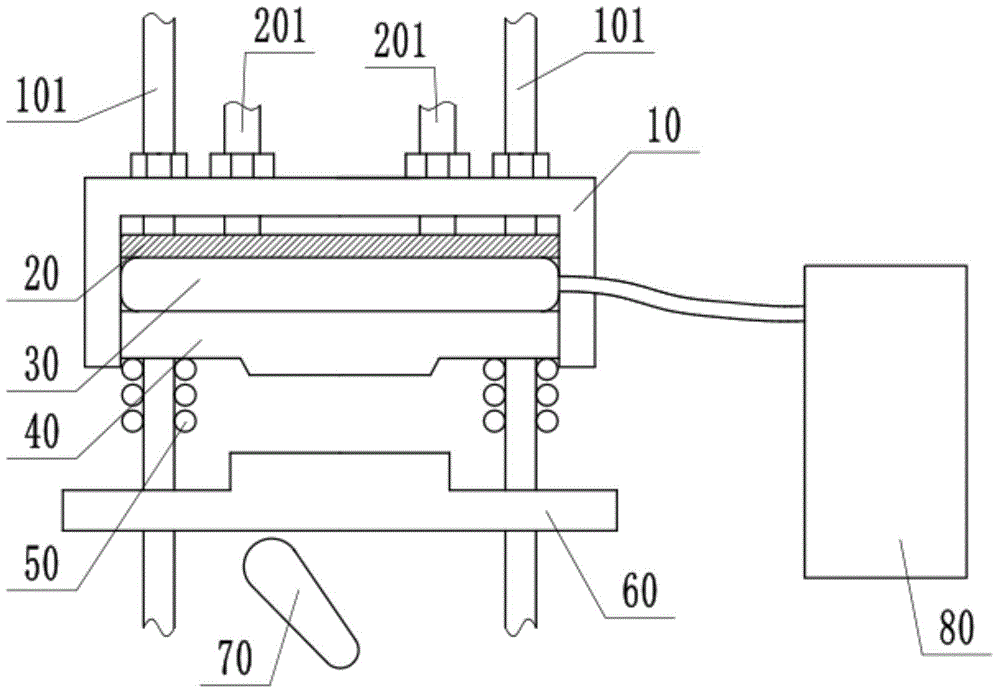

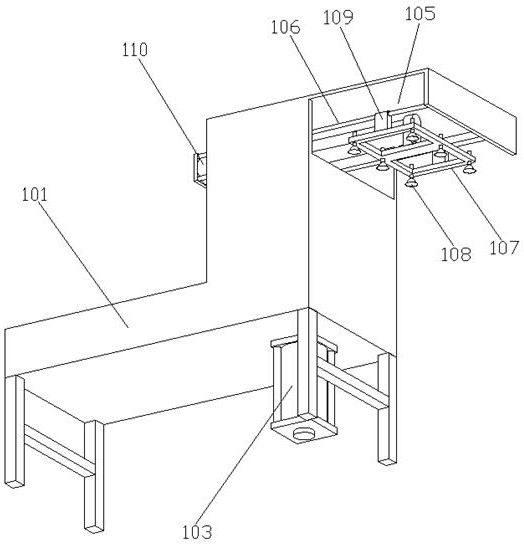

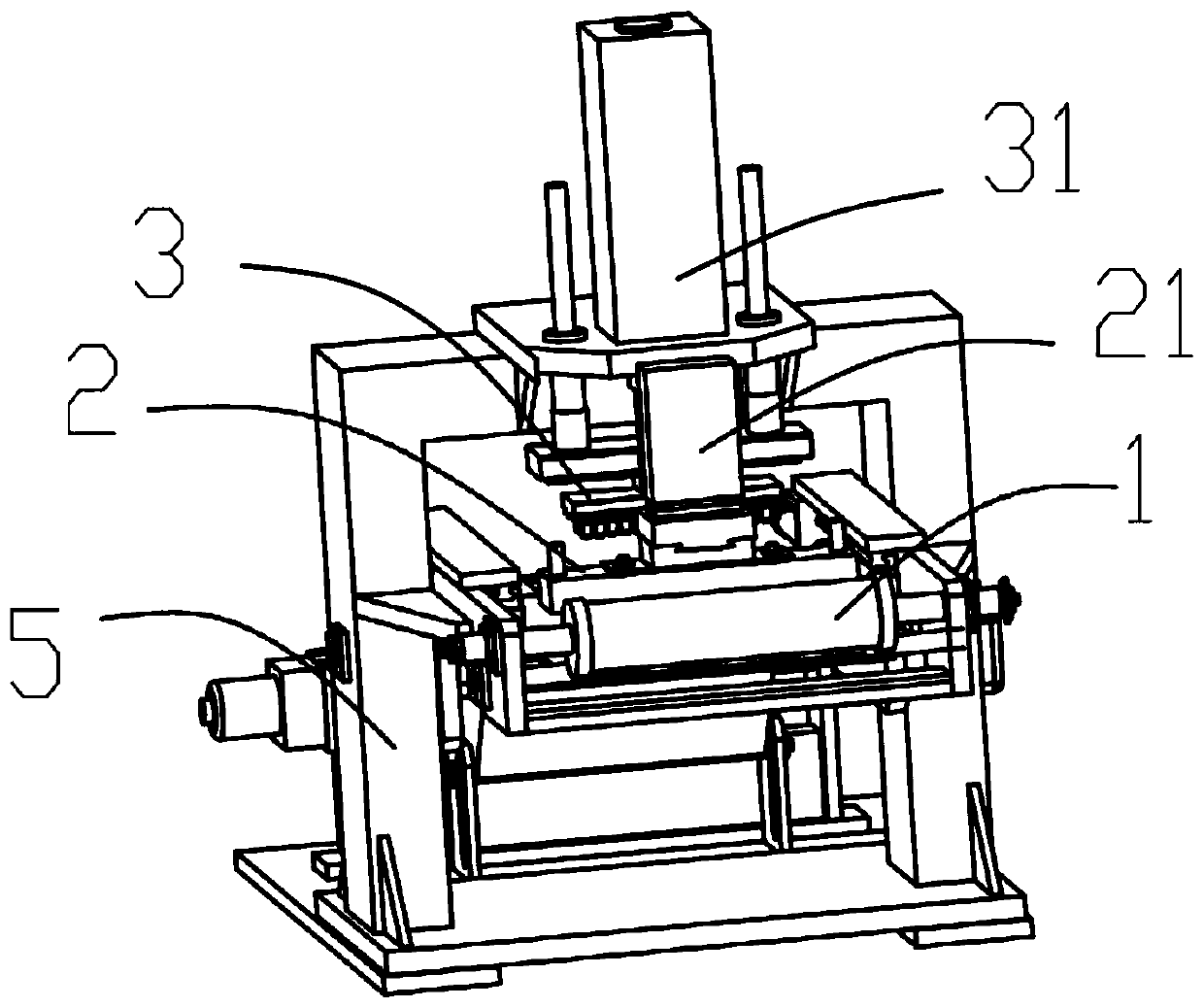

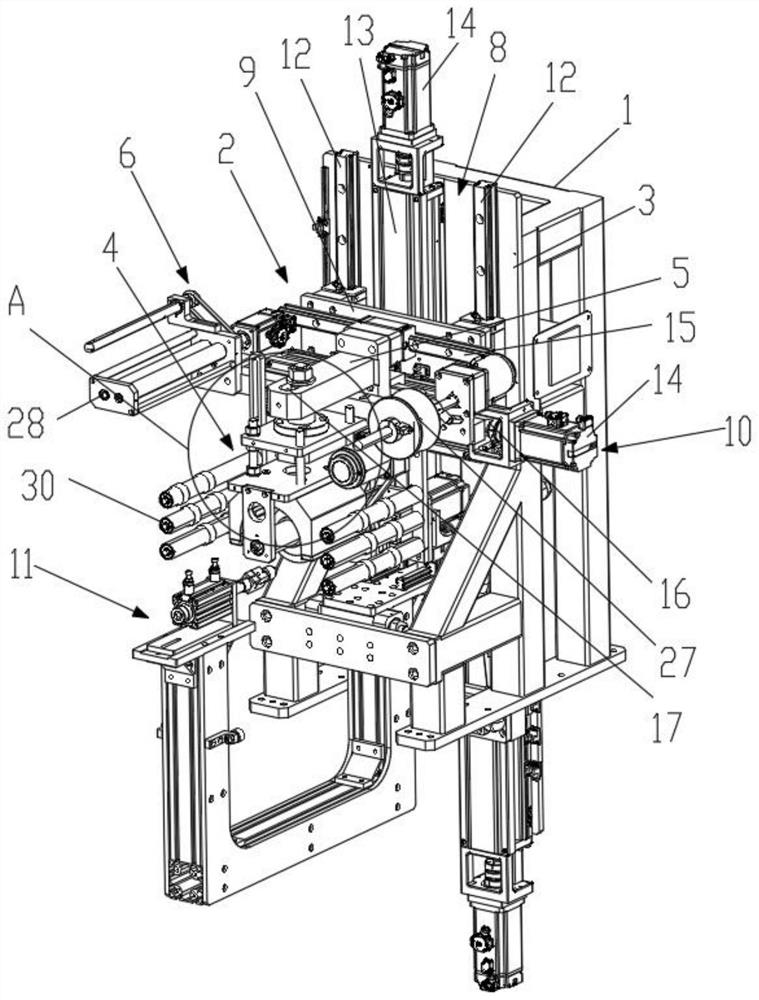

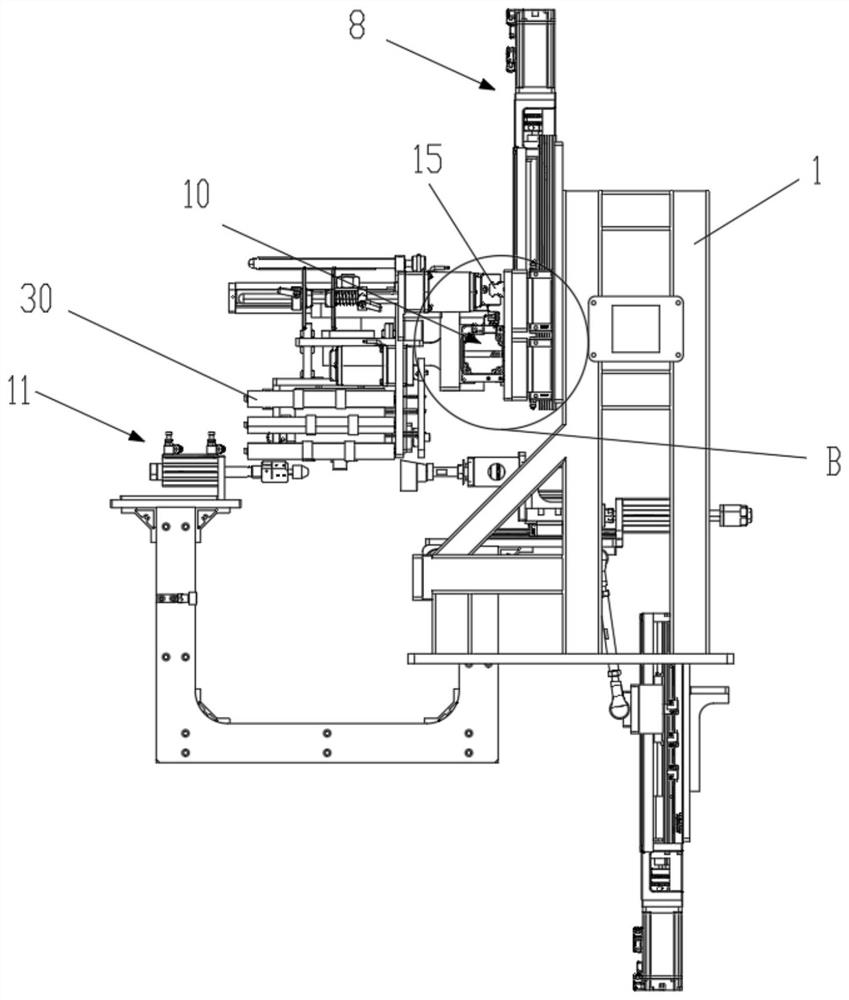

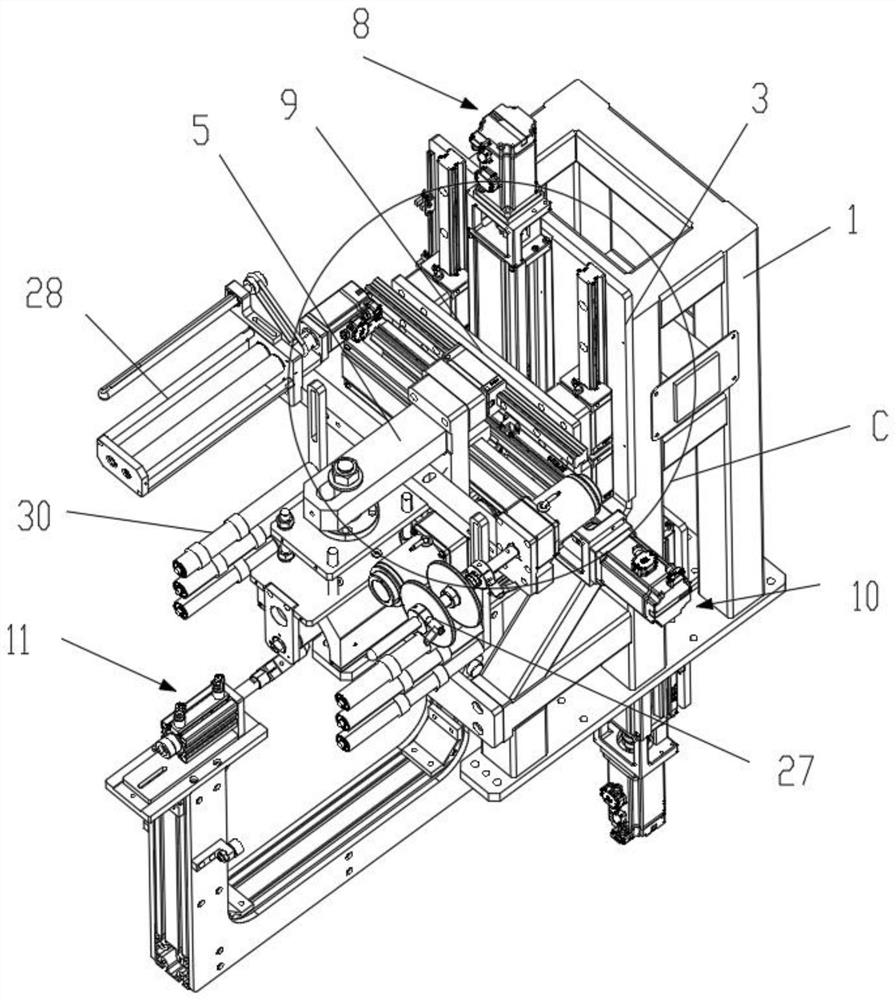

Efficient flat hot stamping device

InactiveCN105313450AIncrease contact timeImprove work efficiencyBronze printingRotary pressesHot stampingContact time

An efficient flat hot stamping device comprises an n-shaped frame cover, wherein multiple mounting holes are formed in an upper panel of the frame cover, and guide pillars are fixedly connected to the frame cover and symmetric relative to the center line of the n-shaped frame cover; a final pressure adjusting plate, a hot stamping plate and a pressing plate are arranged below the frame cover sequentially, a cam mechanism is arranged below the pressing plate, and a pressure buffer device is arranged between the final pressure adjusting plate and the hot stamping plate; a sealing gas box is connected outside the pressure buffer device. The structure design of the final pressure adjusting plate, the pressure buffer device, the hot stamping plate and the pressing plate is adopted, so that when the hot stamping plate is contacted with the pressing plate, the contact time of the hot stamping plate and the pressing plate is prolonged due to the buffer function of the pressure buffering device, pressure between the hot stamping plate and the pressing plate is basically kept unchanged, the working efficiency for flat hot stamping can be improved, and the hot stamping effect is remarkably improved.

Owner:天津市安德诺德印刷股份有限公司

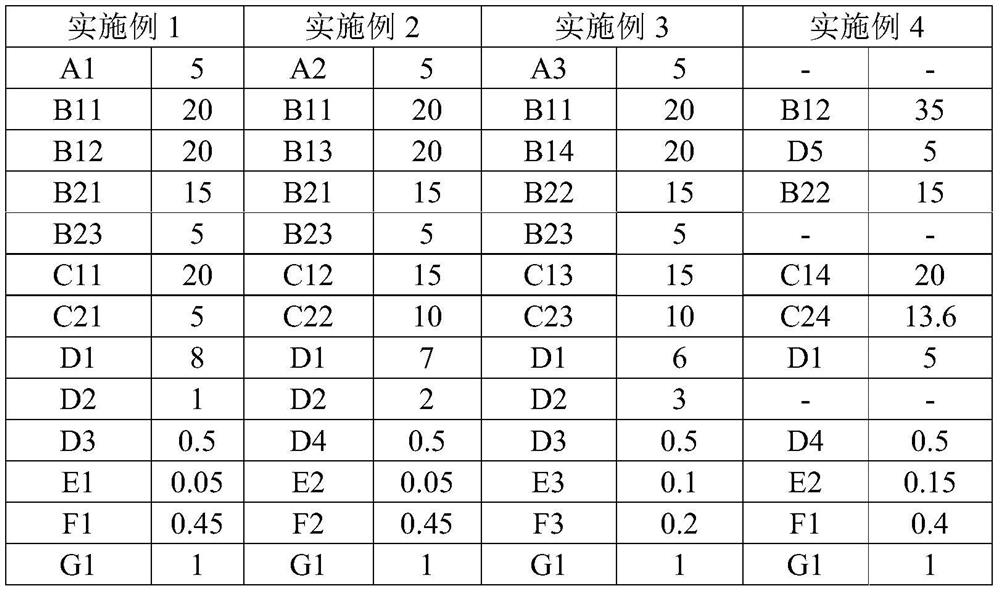

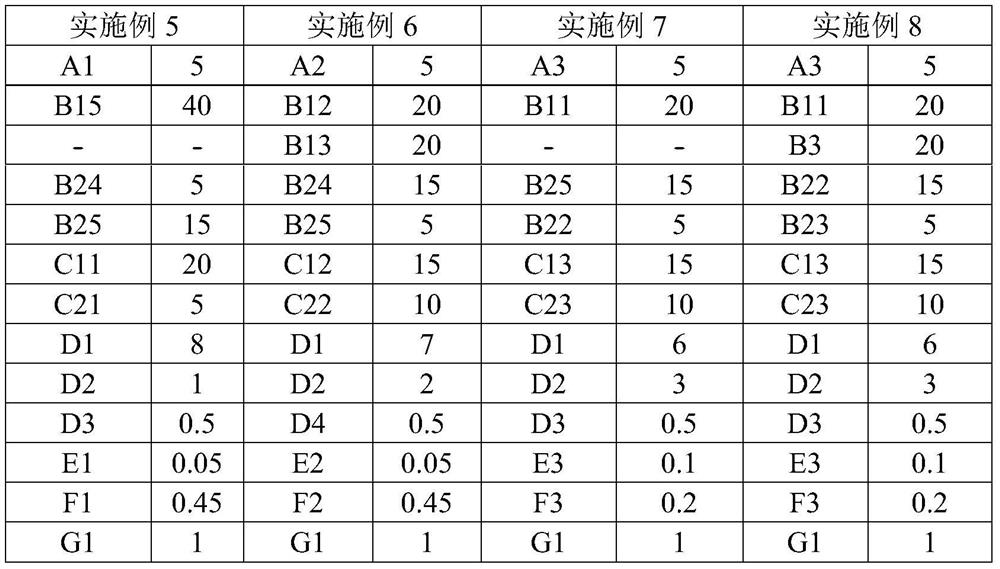

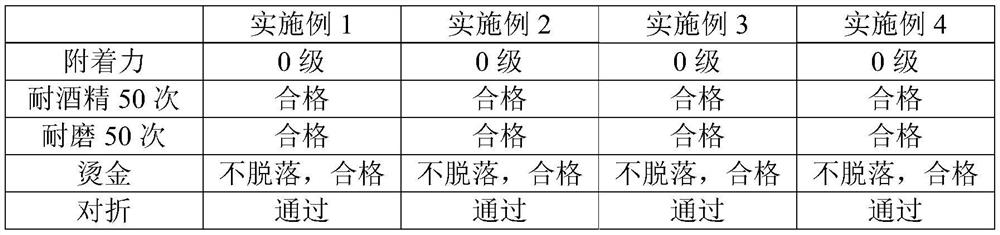

UV-curable coating and application thereof

InactiveCN111704855ALow viscosityImprove bronzing effectPolyurea/polyurethane coatingsPolymer scienceUV curing

The invention relates to the technical field of coatings, in particular to a UV curing coating and application thereof. The first aspect of the invention provides the UV curable coating. The UV curable coating comprises the following preparation raw materials in parts by weight: 35-60 parts of acrylate, 0-10 parts of thermoplastic acrylic resin, 15-40 parts of urethane acrylate and 5-12 parts of aphotoinitiator. The UV curable coating provided by the invention is solvent-free, safe and environment-friendly; the UV curable coating adopts ultraviolet light curing and is good in yellowing resistance and low in viscosity; and meanwhile, the UV curable coating gold is good in stamping performance, favorable in flexibility, bright and full, good in solvent resistance and high in firmness.

Owner:上海未希化学有限公司

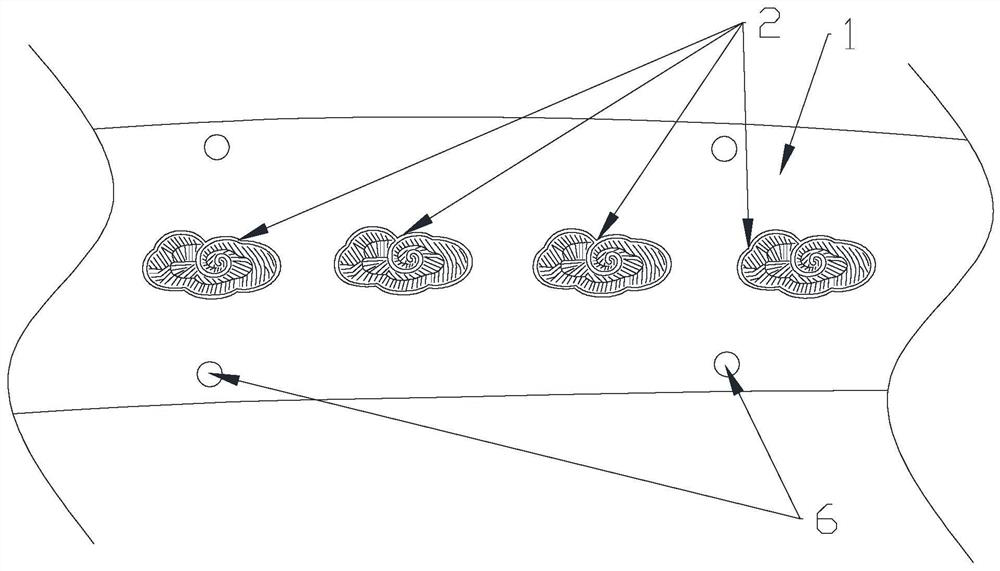

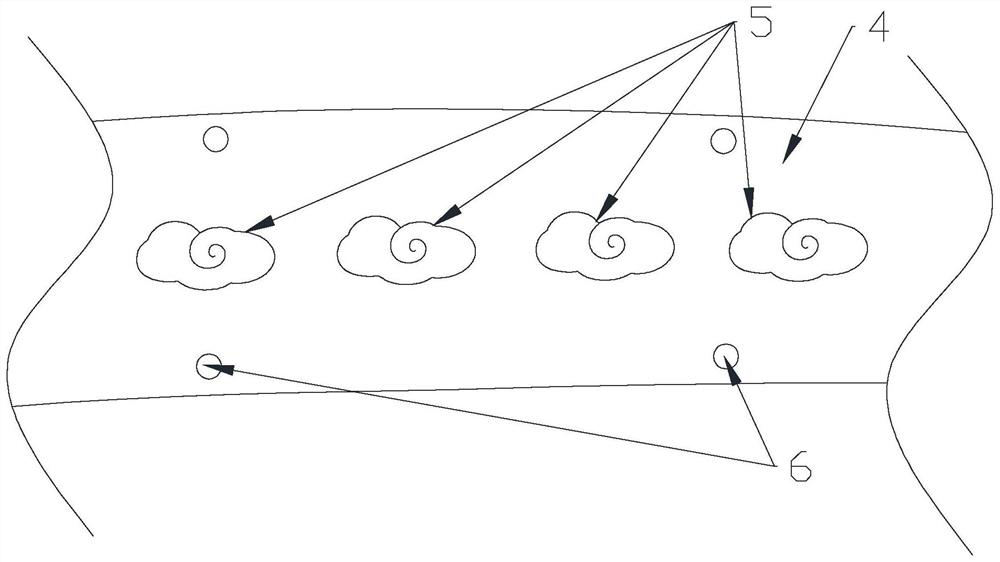

Micro-carved gold stamping plate for gold stamping of tipping paper and gold stamping technology

InactiveCN111942070AImprove yieldLow costDecorative surface effectsStampingManufacturing engineering

The invention relates to the technical field of tipping paper, in particular to a micro-carved gold stamping plate for gold stamping of the tipping paper. Micro-carved patterns are arranged on the micro-carved gold stamping plate, the micro-carved patterns are formed through micro-carving with the photoetching technology, and carved lines capable of presenting the three-dimensional effect are arranged in the micro-carved patterns. The invention further discloses a gold stamping technology. According to the technical scheme, the micro-carved patterns having the dynamic three-dimensional effectcan be formed on the gold stamping plate through micro-caving with the photoetching technology, then the three-dimensional and fine gold stamping patterns of the tipping paper can be realized, and thus the actual gold stamping requirement can be better met.

Owner:WENZHOU LIKEDA PRINTING

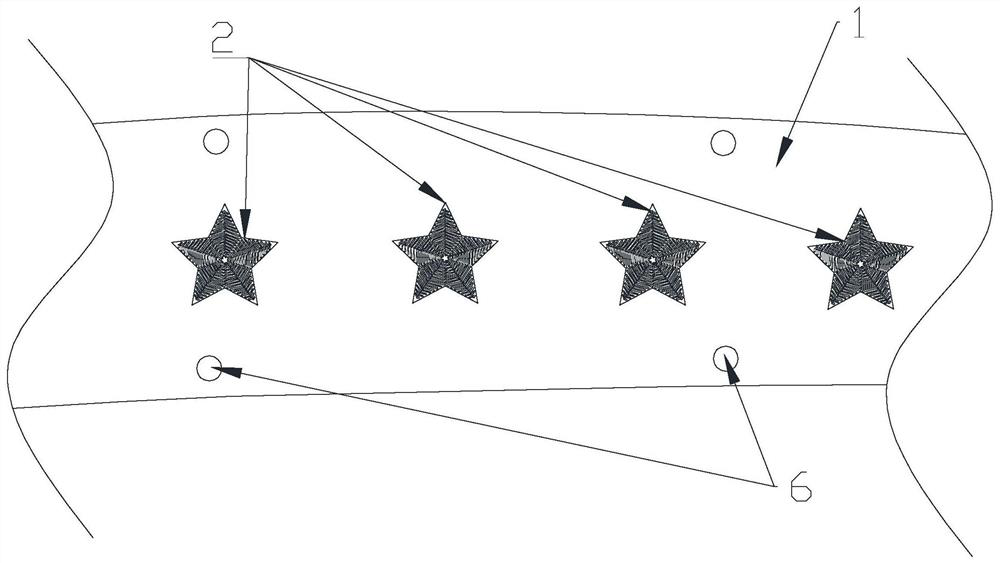

Transfer printing gilding method and device

PendingCN109109449AEfficient exclusionImprove bronzing effectTransfer printingConvex structureGold foil

The invention relates to the field of the surface decoration technology, in particular to a transfer printing gilding method and device. A glue pattern is printed on the surface of a workpiece firstly, then, gilding foil and the glue pattern are pressed through a heated rubber head, the softness characteristic of the rubber head is brought into play on one hand, and the gilding foil is extruded toadvance in an attached manner according to the workpiece surface outline; and on the other hand, the rubber head is used for directly heating the gilding foil and indirectly heating the glue patternon the surface of the workpiece, and accordingly, a metal layer of the gilding foil is arranged on the glue pattern in a transfer printing manner. The surface of the workpiece can serve as a non-plane, can also be a non-plane provided with a concave-convex structure, and cannot be achieved through an existing gilding technology.

Owner:KENT ENG GAOYAO

Production method of high-gloss one-sided dual-color heat transfer anodized aluminum

InactiveCN102303440ARealize integrated productionExcellent adhesionSynthetic resin layered productsMetal layered productsFractionationEthyl acetate

The invention discloses a production method of high-gloss one-sided dual-color heat transfer anodized aluminum, which comprises the processes of release coating, color layer coating, heating and drying, accurate aluminizing and adhesive layer curing. In the processes, anatase metal powder enabling the gloss of the anodized aluminum to be increased is added in a color layer for spraying, and ethyl acetate is added in the anatase metal powder to be used as a developing agent of color chromatographic fractionation. By adopting an anodized aluminum production technology, printing and gold blocking effects are greatly improved, and especially, gloss of thermoprinted characters, patterns and lines is greatly increased.

Owner:江苏卫星新材料股份有限公司

Black ink capable of preventing oxidizing discoloration after gilding as well as preparation method and application method thereof

ActiveCN105462341ASolve the problem of oxidative discolorationTo meet the requirement of carbon black freeInksReflexREFLEX DECREASE

The invention relates to the technical field of ink and in particular relates to black ink capable of preventing oxidizing discoloration after gilding as well as a preparation method and application method thereof. The black ink capable of preventing oxidizing discoloration after gilding is prepared by uniformly mixing yellow ink, red ink, blue ink and reflex blue. When the black ink capable of preventing oxidizing discoloration after gilding is applied to printing, the concentration requirement and the blackness effect requirement can be met by carrying out overlapped printing several times. The black ink capable of preventing oxidizing discoloration after gilding is prepared by mixing the yellow ink, the red ink, the blue ink and reflex blue, and thus, meets the requirement that carbon black is not contained, has the effect of furthest solving the problem in the prior art that oxidizing discoloration is caused by contact between the black ink containing carbon black and gilding materials, and has the advantage of good gilding effects.

Owner:茂名阪田油墨有限公司

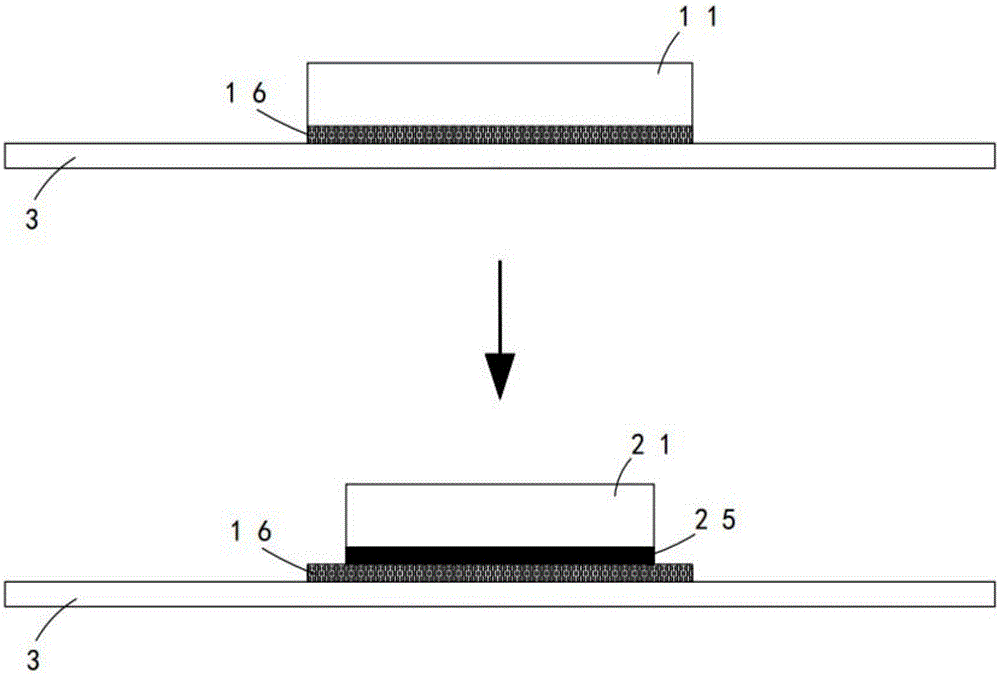

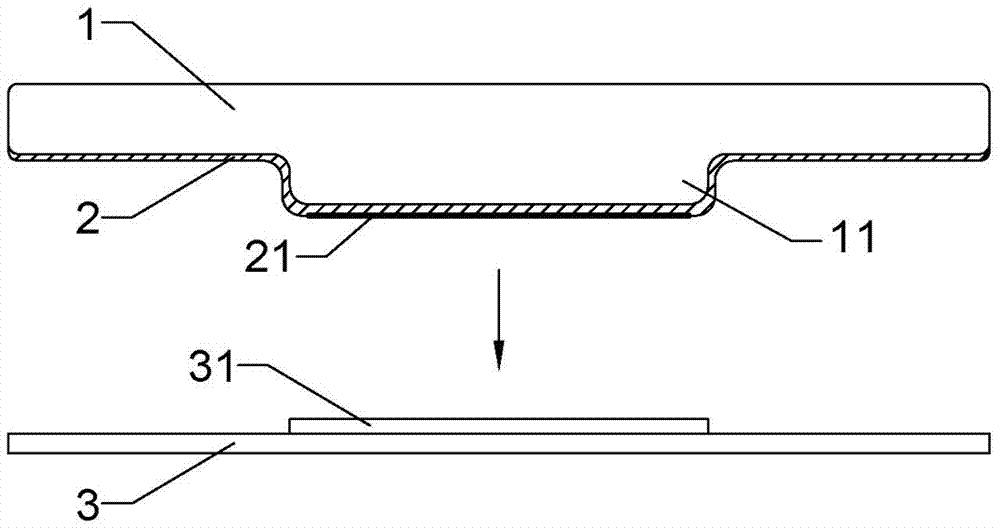

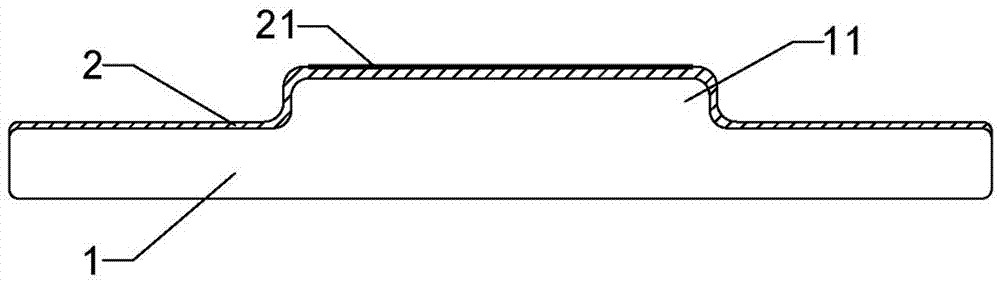

Non-alumite gold stamping product and preparation process thereof

ActiveCN107042723AHigh reuse rateAvoid wastingNon-macromolecular adhesive additivesDecorative surface effectsGraphicsHot stamping

The invention relates to the technical field of printing gold stamping, in particular to a non-alumite gold stamping product and a preparation process thereof. The preparation process of the non-alumite gold stamping product comprises the following steps that A, a combination plate is prepared, specifically, a gold stamping plate and a laser nickel plate with graphics and text information being carved are subjected to alignment and laminating through high temperature resistant glue to prepare the combination plate; B, paper is coated, specifically, the position, needing gold stamping, of the paper is coated with thermoplastic light oil or high-reflectivity coating to prepare a coating layer; and C, coating and gold stamping are conducted, specifically, the combination plate prepared in the step A is subjected to lock up and put on a machine, the coating layer prepared in the step B is pressed and subjected to gold stamping, and the non-alumite gold stamping product is prepared. The graphics and text information of the laser nickel plate can be printed on the paper in a hot stamping mode under the condition of no alumite medium, various laser effects can be shown on the paper through one procedure, the production cost is low, durability is good, the customization period is short, safety and environmental friendliness are achieved, and the multi-batch and small-amount production requirements are met.

Owner:HUCAIS PRINTING

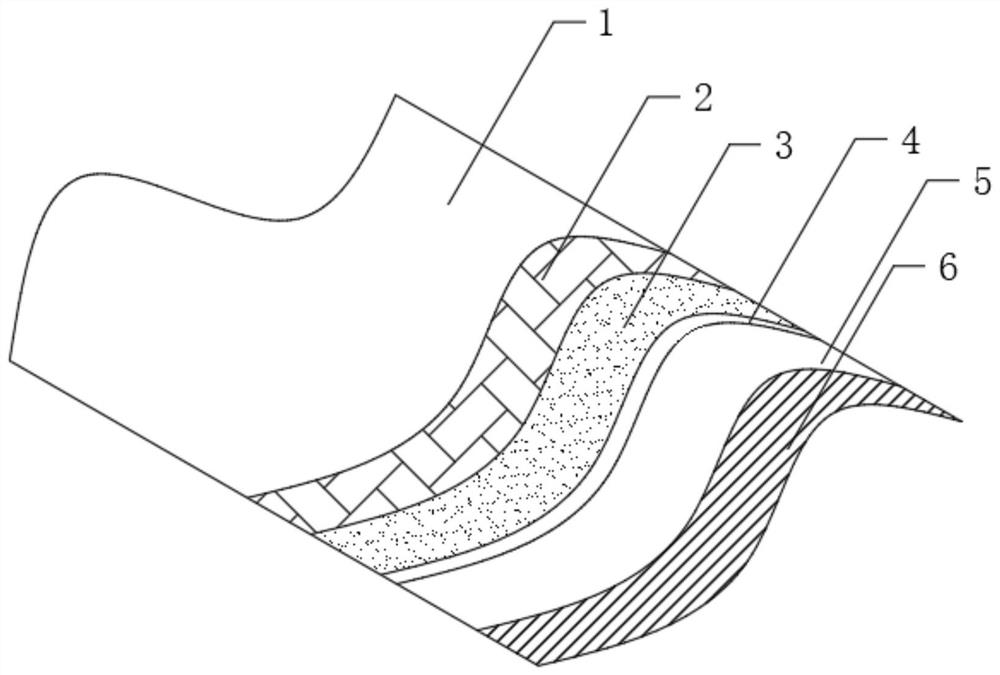

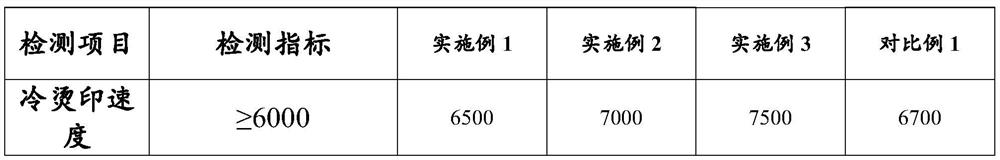

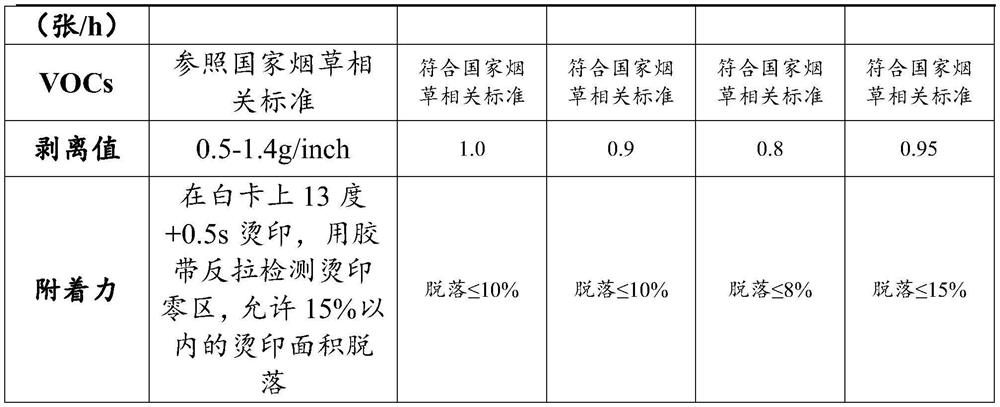

Alumite hot stamping foil suitable for offset printing and cold stamping technology and preparation method thereof

ActiveCN113442622ASmall peeling forceGood transferabilityDecorative surface effectsCoatingsHot stampingStamping

The invention provides alumite hot stamping foil suitable for an offset printing and cold stamping technology and a preparation method thereof. The alumite hot stamping foil comprises a sheet base layer, an isolating layer, a dyeing layer, a fluorescent layer, an aluminized base layer and a protective layer. The dyeing layer is prepared from the following components including, by weight, 15 to 20.5 percent of organic silicon modified acrylic resin, 30.2 to 35 percent of thermoplastic methacrylic resin, 25 to 27.5 percent of butanone, 15 to 20 percent of butyl ester, 2 to 2.5 percent of toner, 0.5 to 0.8 percent of an active agent and 0.7 to 1.3 percent of a modifier. The resin of the dyeing layer of the alumite hot stamping foil is composed of the organic silicon modified acrylic resin and the thermoplastic methacrylic resin, the active agent and the modifier are added at the same time, and therefore the film breaking force of the dyeing layer is reduced, and the prepared alumite hot stamping foil has the advantages of being small in stripping force and good in transferability; and meanwhile, the preparation cost of the alumite hot stamping foil is considered, the hot stamping foil can be suitable for the offset printing and cold stamping technology, pollution to the environment in the metal printing plate manufacturing process is avoided, and the cold stamping speed is high.

Owner:GUANGDONG BANGGU CHEM TECH +1

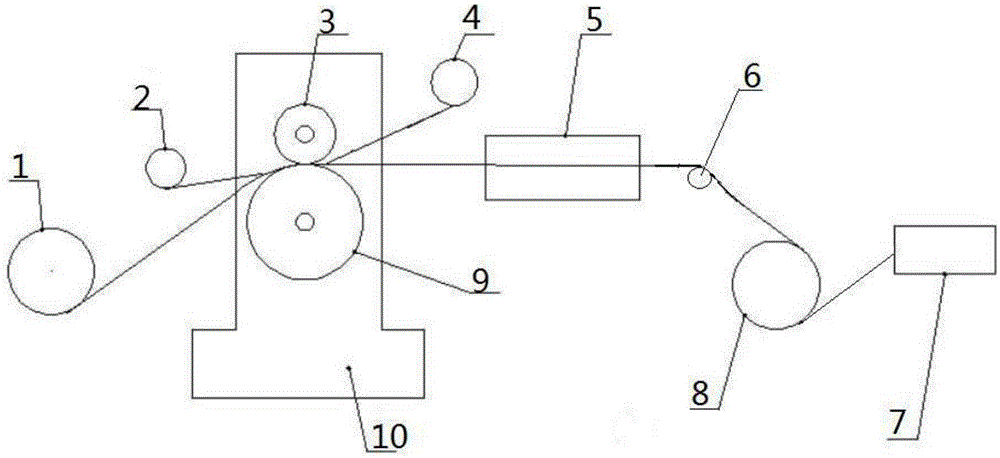

Production process of tobacco tipping paper

ActiveCN110453532AImprove quality requirementsImprove product qualitySpecial paperDecorative surface effectsPunchingPulp and paper industry

The invention discloses a production process of tobacco tipping paper, and relates to the field of tobacco paper. The production process comprises the following steps of S1, humidification treatment,S2, printing, S3, humidification treatment, S4, gold stamping, S5, humidification treatment, S6, slitting, S7, humidification treatment, S8, punching, S9, humidification treatment and S10, rewinding.The production process has the following advantages that the humidification treatment steps are added before the steps of printing, gold stamping, slitting, punching and rewinding, static electricityand dust in the paper are eliminated, and the dyeing and gold stamping effect on the paper is improved; meanwhile, it is ensured that the paper is not wrinkled or deformed or stuck, and therefore theproduct quality of the tobacco tipping paper is improved.

Owner:湖北烟草民意纸业有限公司

Water-based temperature-resistant stampable ink composition for aluminum sprayed paper

InactiveCN109439062AImprove temperature resistance requirementsImprove bronzing effectInksPolypropyleneChloride vinyl

The invention provides a water-based temperature-resistant stampable ink composition for aluminum sprayed paper to solve problems. Evert 100 parts by weight of water-based temperature-resistant stampable ink compositions for the aluminum sprayed paper comprise 10-20 parts of vinyl chloride-vinyl acetate resin, 20-30 parts of water-based polyurethane resin, 5-8 parts of water-based polypropylene wax, 3-5 parts of water-based dispersing agents, 3-8 parts of PH (potential of hydrogen) stabilizers, 10-16 parts of water-based pigments, 3-5 parts of ethyl alcohol and the rest water. The water-basedink is applicable to printing of the aluminum sprayed paper on a gravure press with printing speed capable of reaching 120-150m / min, and has the advantages of good stability and the like. Performanceindexes such as temperature resistance and gold stamping performance of printing materials can be obviously improved, and the printing materials have popularization and application values.

Owner:CHINA TOBACCO ZHEJIANG IND

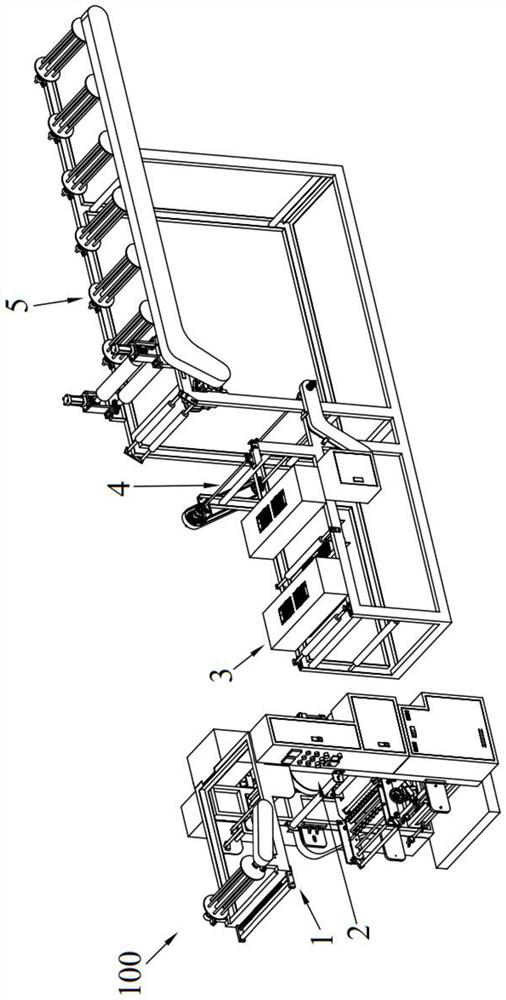

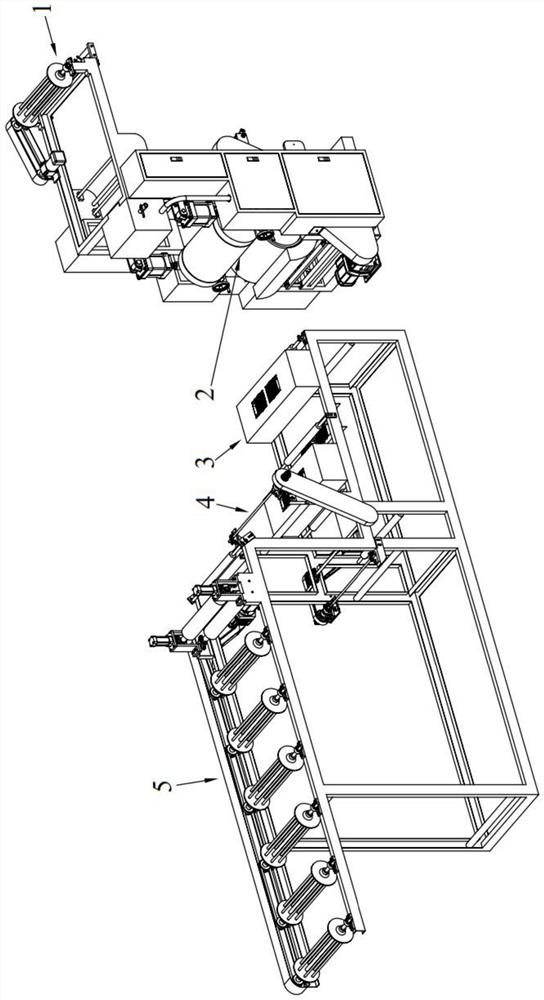

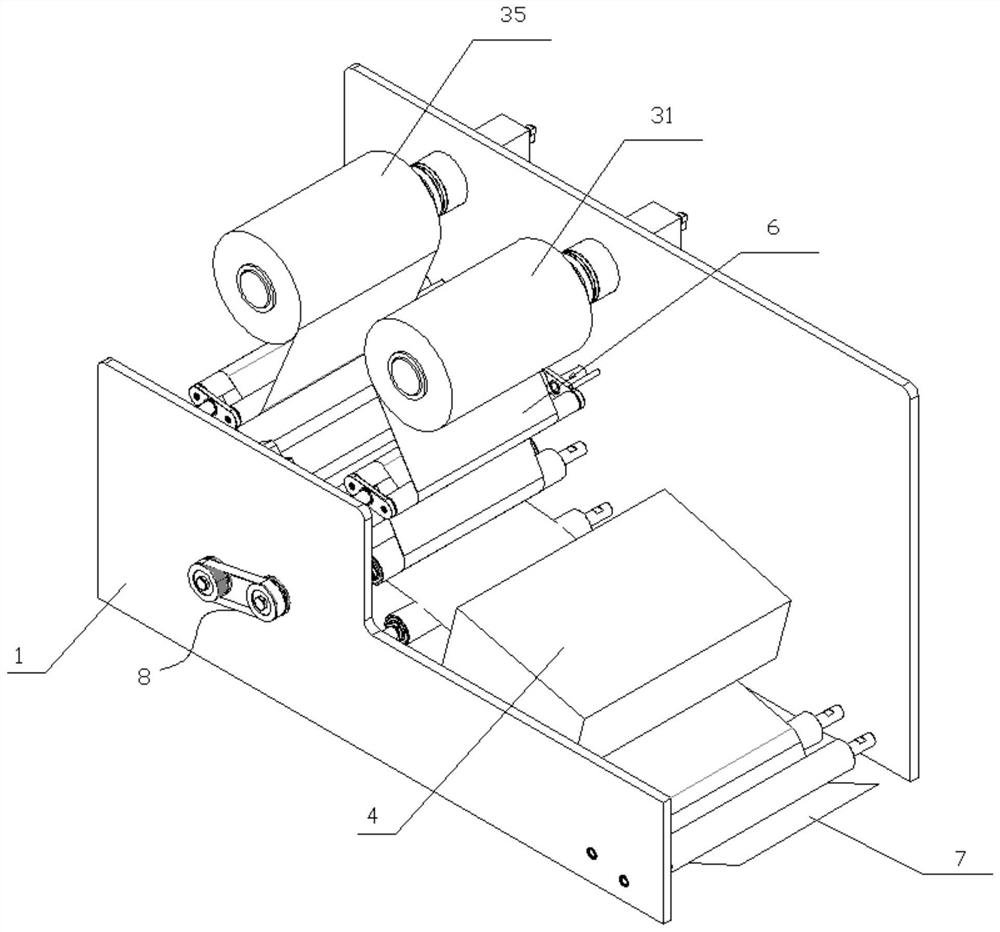

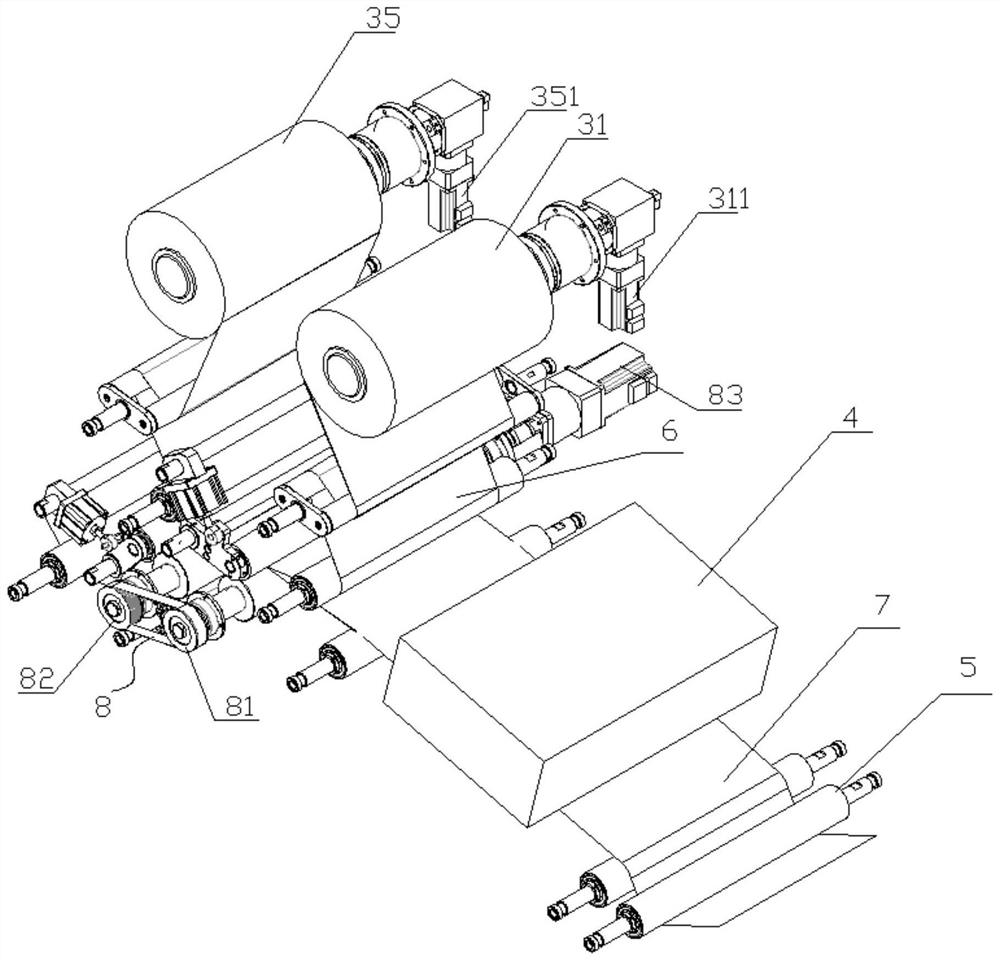

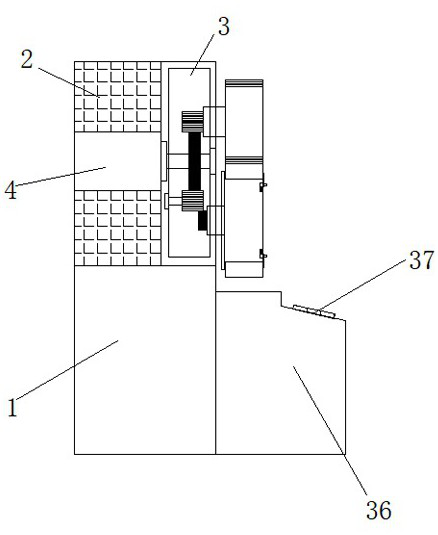

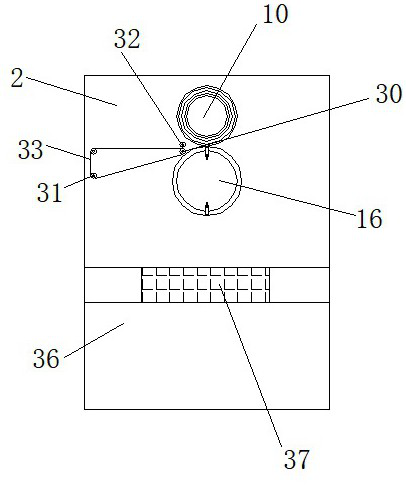

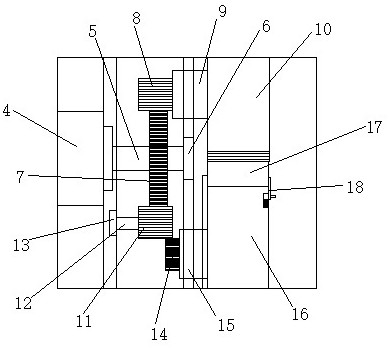

Production system of non-wove hot stamping wallpaper

InactiveCN105058971AReasonable designSimple structurePattern printingRotary pressesHot stampingPulp and paper industry

The invention belongs to the technical field of wallpaper production, and particularly relates to a production system of non-wove hot stamping wallpaper. The production system comprises a base, a finished product roll and a waste film roll are arranged on the rear side of the base, and an alumite gold film roll, a baking box, a non-woven paper roll and a flexible pipe printer are sequentially arranged on the front side of the base in the direction gradually away from the base. A leveling roll flush with the baking box is arranged between the non-woven paper roll and the baking box, a stamping roll and a rubber roll below the stamping roll are arranged on the base, and the surface of the stamping roll is smooth and flat. The production system has the beneficial effects that design is reasonable, the structure is simple, the firmness and effect of stamping both meet regulated requirements, and the quality of non-woven paper as the wallpaper is improved.

Owner:桂林威迈壁纸有限公司

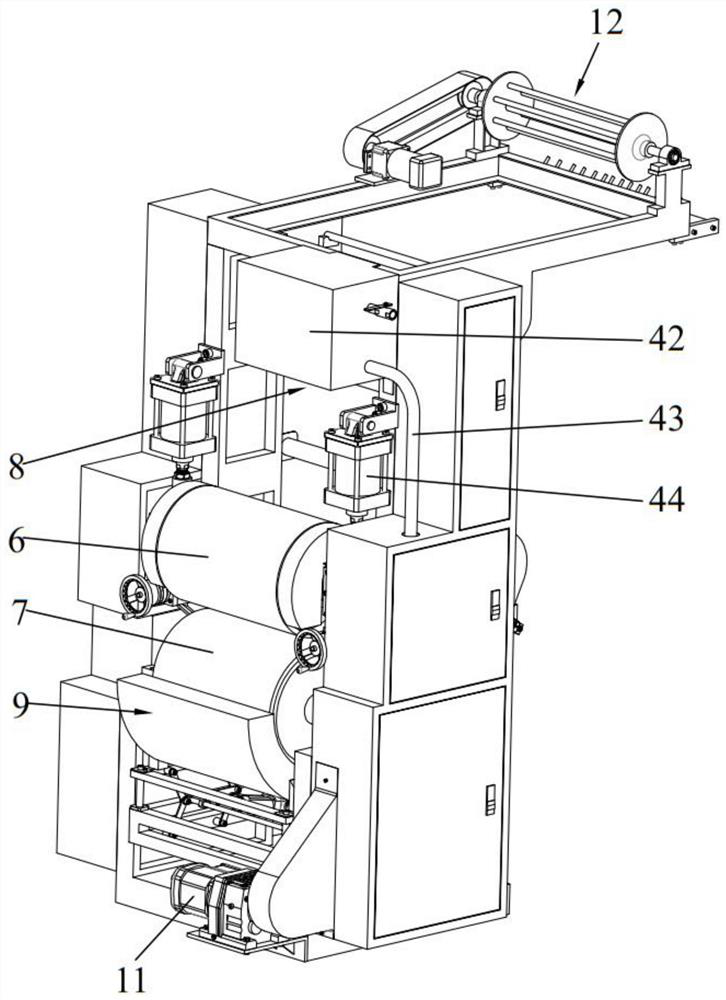

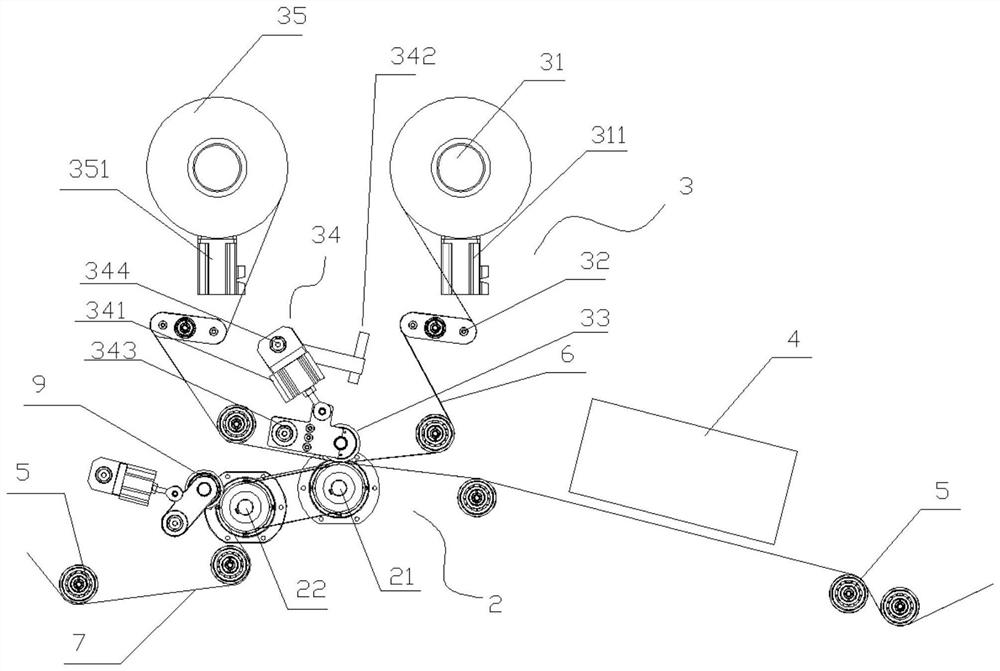

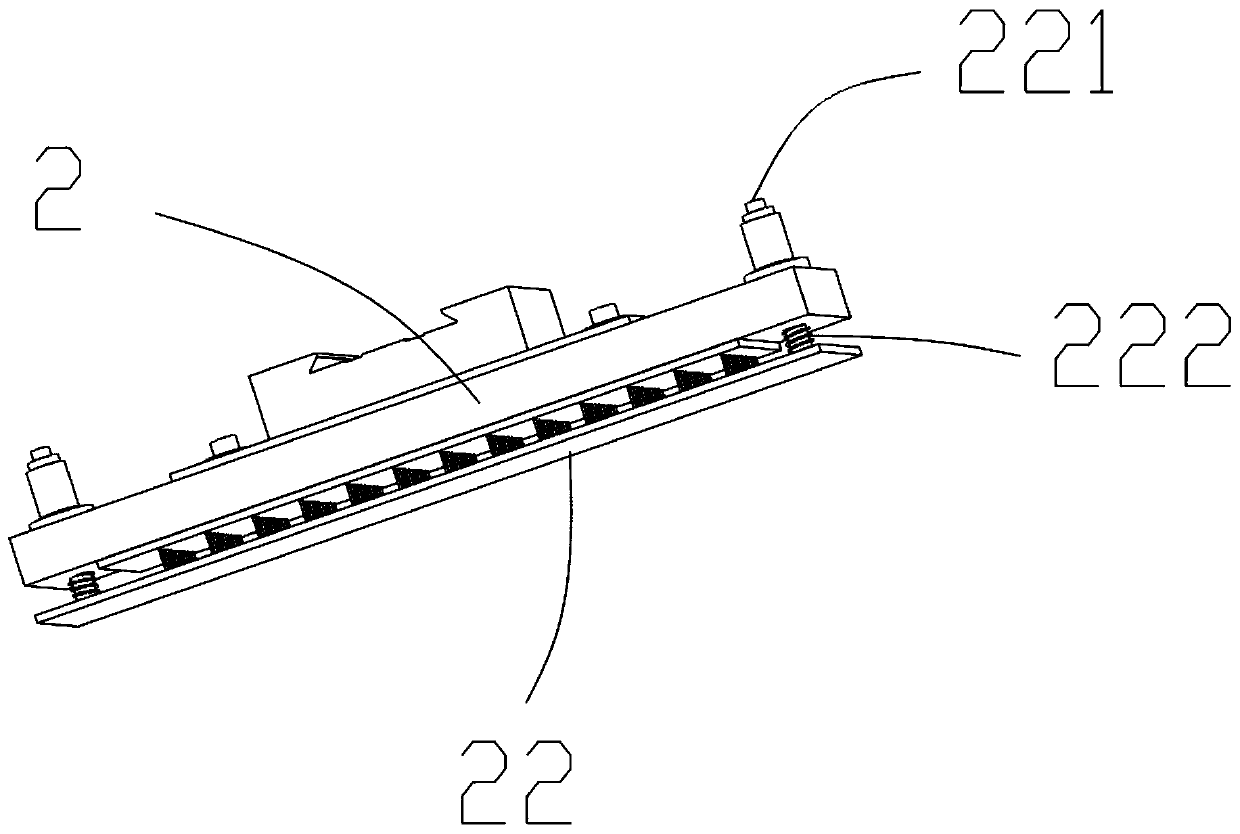

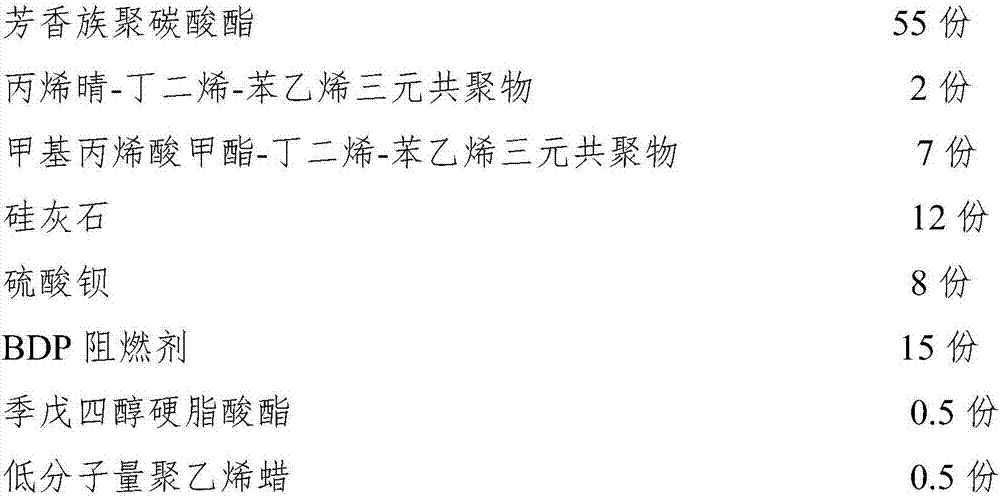

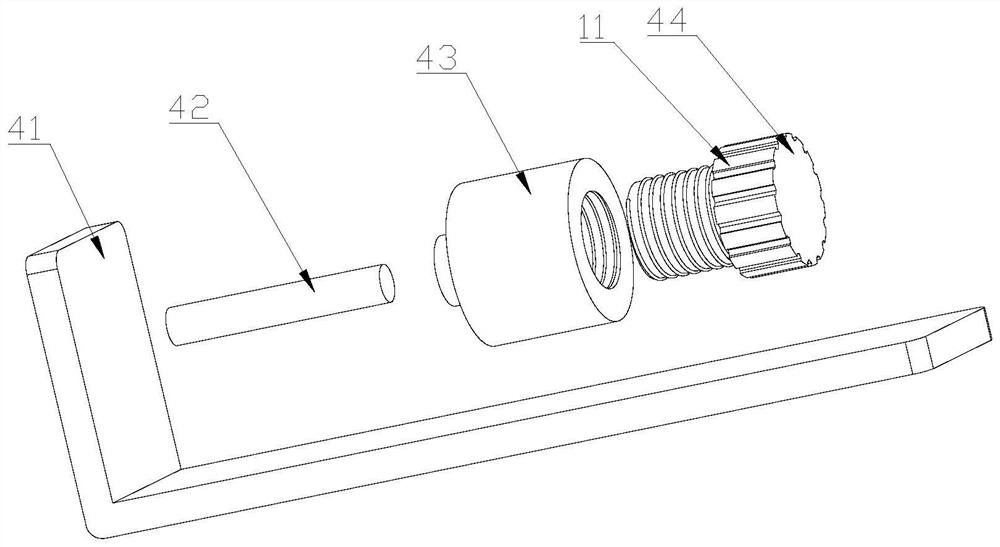

Braid double-sided gold stamping equipment

ActiveCN113306284AIncrease productionImprove bronzing effectRotary pressesTextile printerHot stamping

The invention discloses braid double-sided gold stamping equipment, and relates to the technical field of fabric printing processing equipment. A hard roller is arranged above an elastic roller in parallel, a hard roller heating device can heat the surface of the hard roller, and an elastic roller heating device can heat the surface of the elastic roller. The hard roller and the elastic roller can be driven to rotate through a hot stamping driving device, and the distance between the hard roller and the elastic roller can be adjusted through a distance adjusting device. A feeding device is used for sequentially stacking and conveying an upper electrochemical aluminum foil, a braid and a lower electrochemical aluminum foil to the position between the hard roller and the elastic roller. A cooling device is used for cooling a gold-stamped material belt. Two waste foil collecting devices are used for separating and collecting the upper waste electrochemical aluminum foil and the lower waste electrochemical aluminum foil on the gold-stamped braid from the gold-stamped braid correspondingly. A collecting device is used for collecting the gold-stamped braid. According to the braid double-sided gold stamping equipment, continuous production of braid double-sided gold stamping can be conducted, the yield is large, the gold stamping pressure, temperature and time can be adjusted and controlled, and the gold stamping effect is good.

Owner:厦门良联织带饰品有限公司

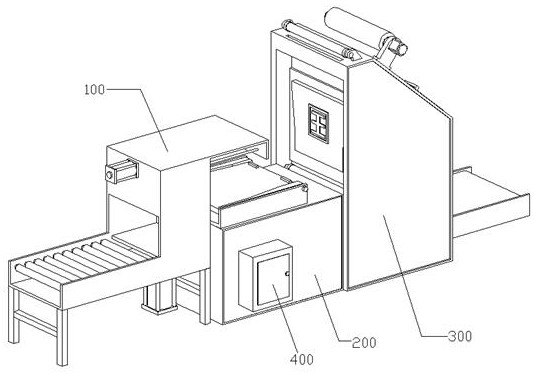

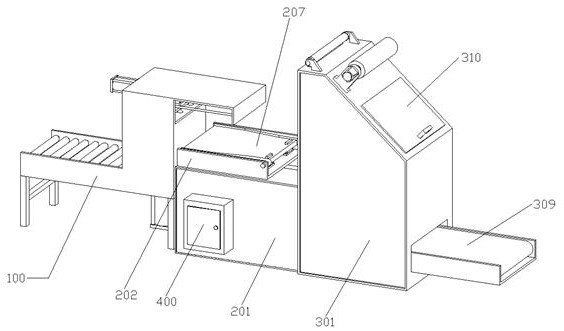

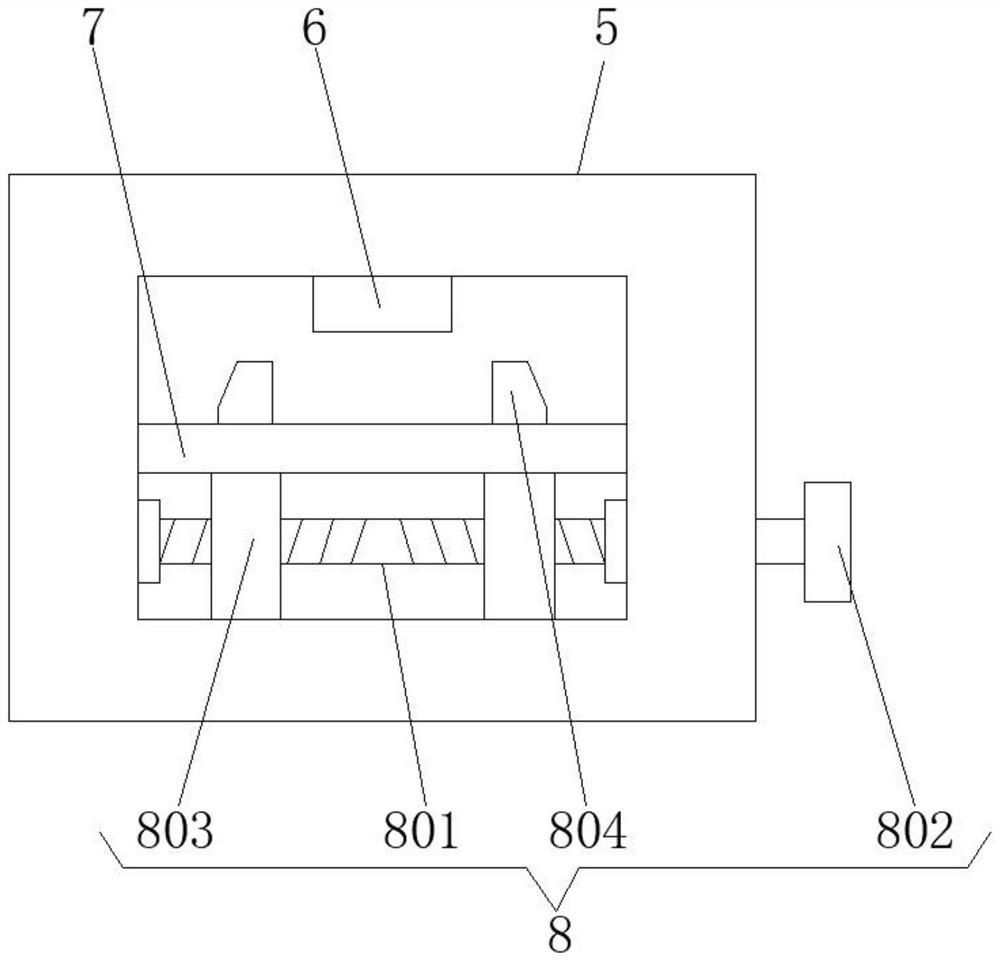

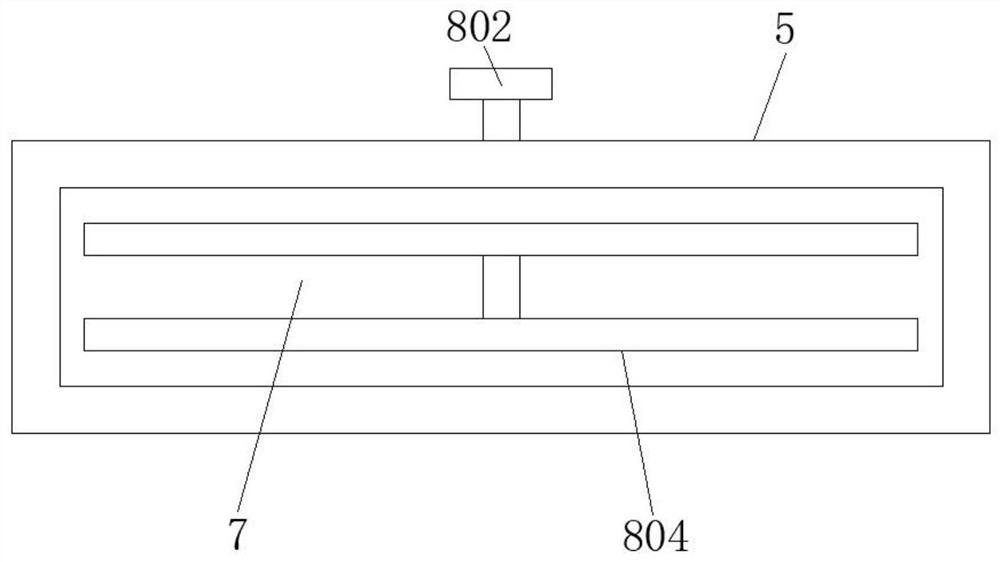

Wine box gold stamping device

ActiveCN113928006AReduce laborImprove bronzing effectRotary pressesOther printing apparatusHot stampingPaperboard

The invention relates to the technical field of packaging box hot stamping equipment, and particularly discloses a wine box gold stamping device. The wine box gold stamping device comprises a feeding mechanism, a conveying, overturning and hot-stamping mechanism and a gold stamping mechanism; and the conveying, overturning and hot-stamping mechanism comprises a case, a moving seat moving along the upper surface of the case and a power device used for driving the moving seat, an overturning pressing plate is rotatably connected to the end, close to the gold stamping mechanism, of the moving seat, a guide positioning groove is formed in the upper surface of the overturning pressing plate, and a paperboard anti-disengaging block is inserted into the end, facing the gold stamping mechanism, of the guide positioning groove and movably arranged in the guide positioning groove through an elastic piece. According to the gold stamping device, automatic feeding and discharging in the wine box gold stamping process can be achieved, so that the labor amount of operators is effectively reduced, the gold stamping effect on wine box paperboards is greatly improved, meanwhile, the problems that gold stamping images and texts are blurred or exposed or cannot be stamped due to the fact that the temperature of an existing gold stamping machine is too low during gold stamping can be effectively solved, and the gold stamping effect on the wine box paperboards is greatly improved.

Owner:JIESHOU CITY CHANGXING PRINTING PACKAGING CO LTD

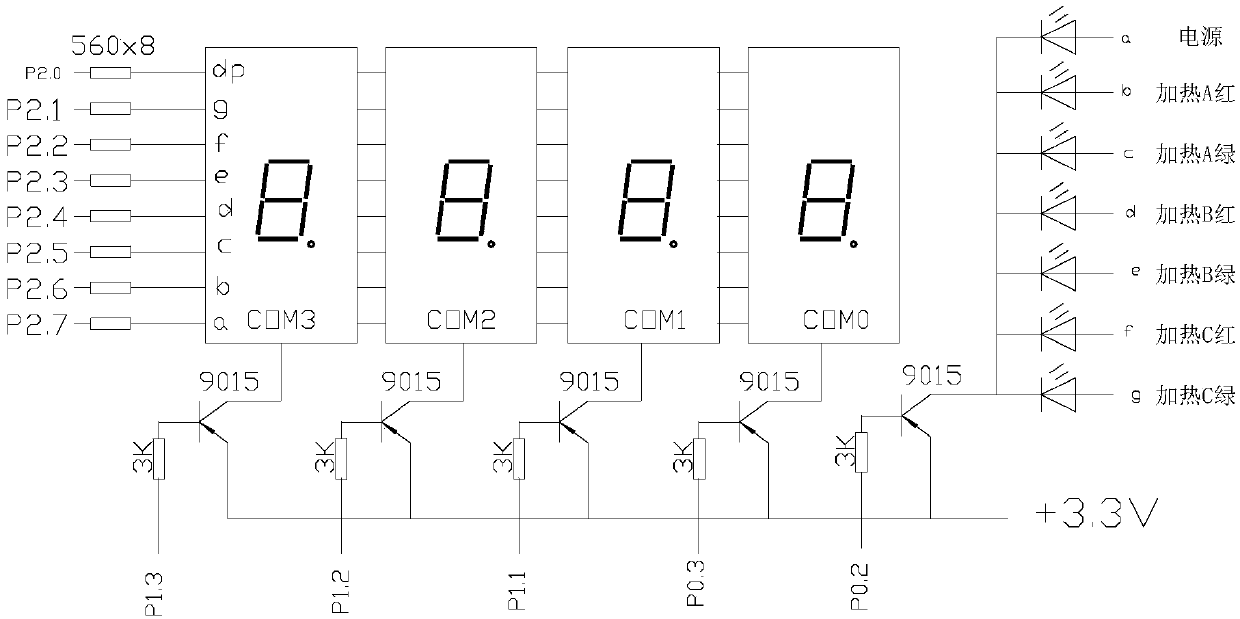

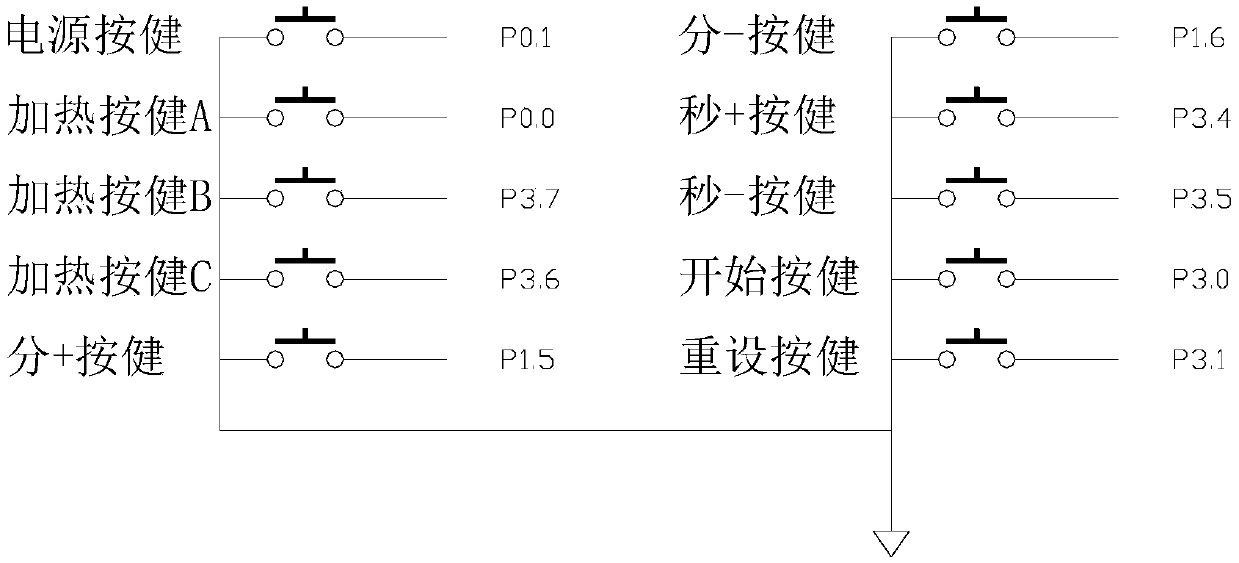

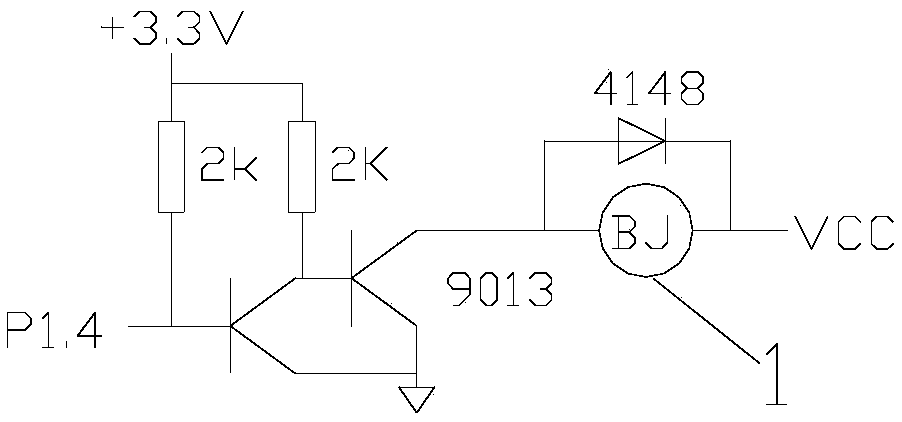

Multifunctional gilding press with time and temperature control system

InactiveCN109624496AOperational securityImprove bronzing effectRotary pressesPrinting press partsThree levelTemperature control

The invention discloses a multifunctional gilding press with a time and temperature control system. The multifunctional gilding press comprises a charging base and a heating plate capable of being separated; a control system and a temperature control module are arranged on the charging base; the heating plate comprises a heating piece and a surface silica gel gridding plate; an input end of the temperature control module is connected with a temperature sampling circuit for sampling the temperature of the heating plate in real time; the control system comprises a PLC for controlling the heatingtime and the heating temperature of the heating plate, and a starting key for controlling the initial action of the gilding press; the temperature control module comprises high, medium and low levelsof the temperature control; and an output end of the temperature control module is connected with the PLC. The gilding press achieves the time and temperature control functions; the temperature control is divided into three levels; under three-level temperature control, safe operation and good gilding effect are achieved; and the multifunctional gilding press is convenient to operate, and improves the product quality and the equipment working efficiency.

Owner:SHANGHAI EKE CREATIVE & CULTURAL DEV HLDG CO LTD

Method for improving bronzing effect of non-ferrous metal cardboard

The invention discloses a method for improving the bronzing effect on a non-ferrous metal paperboard, which comprises printing layer of UV honed oil on the part of the non-ferrous metal paperboard for bronzing before bronzing, and then performing the bronzing. If the honed effect is needed, the back part of a part needing the bronzing on the non-ferrous metal paperboard can be printed with a layer of the UV honed oil, and then the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of the UV honed oil again. Before the bronzing, if the UV honed oil is used for printing, for not influencing the bronzing effect, the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of UB honed oil contained in the UV honed oil before performing the bronzing, and then the part needing the bronzing is subjected to the bronzing.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

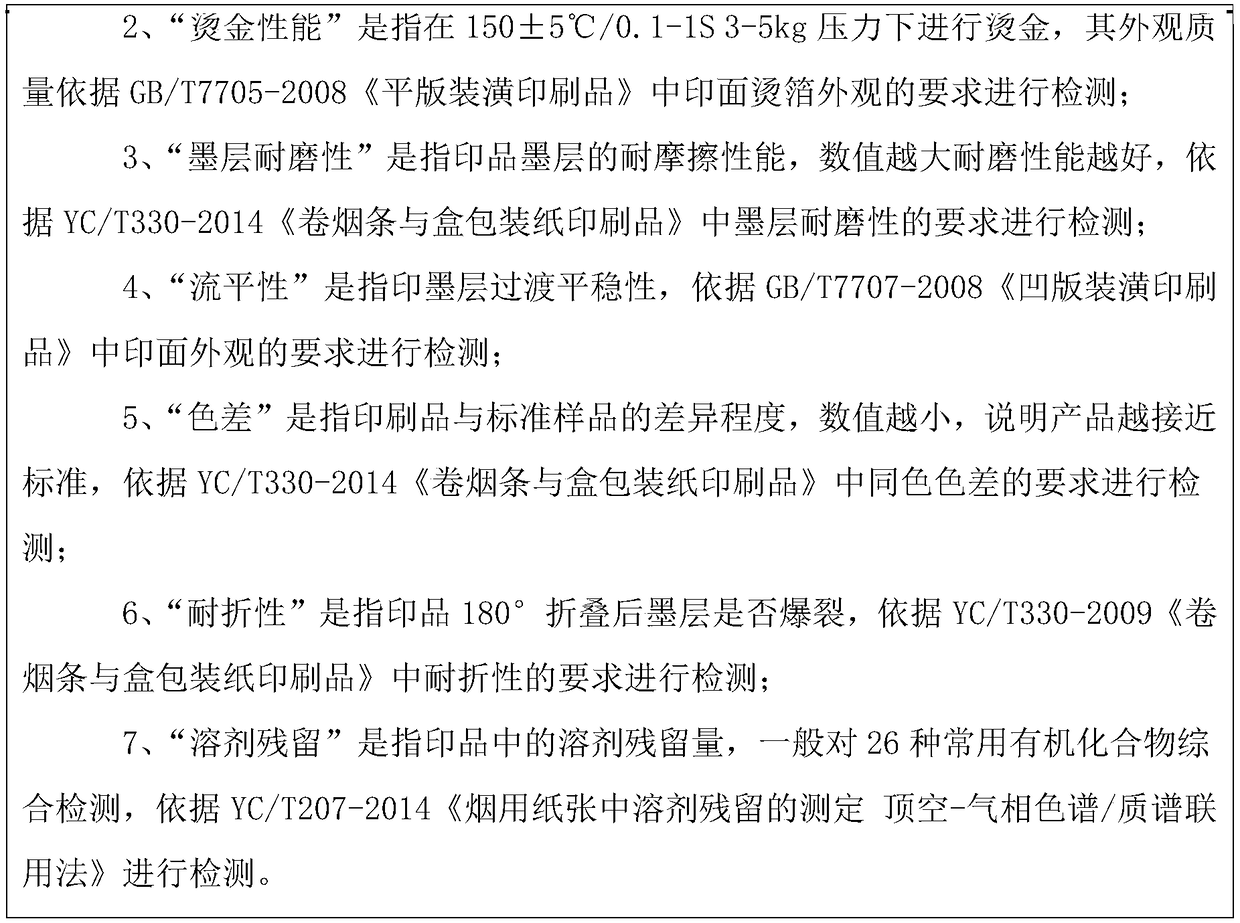

Gold stamping device applied to roll-shaped printed product

The invention discloses a gold stamping device applied to a roll-shaped printed product comprising a support, a printed product driving roller, a printed product traction roller, a transmission unit,a heating device, a gold stamping film heating roller, a gold stamping film roll receiving roller, a gold stamping film roll storage roller and two swing rollers, wherein the printed product driving roller and the printed product traction roller are rotationally supported on the support, the printed product driving roller is in transmission connection with the printed product traction roller through the transmission unit to form a printed product walking unit used for conveying printed products, the gold stamping film heating roller is rotationally arranged on the support in a lifting mode, the swing rollers are supported on the support on two sides of the gold stamping film heating roller in a swing mode to form a gold stamping film walking unit, and a gold stamping film is discharged from the gold stamping film roll storage roller and then passes through the swing roller to be subjected to gold stamping operation on the printed product through the gold stamping film heating roller, and stored on the gold stamping film roll receiving roller through the other swing roller. The gold stamping device has the advantages that the gold stamping film materials are saved, the cost is saved, and the gold stamping effect is improved.

Owner:江苏科思机电工程有限公司

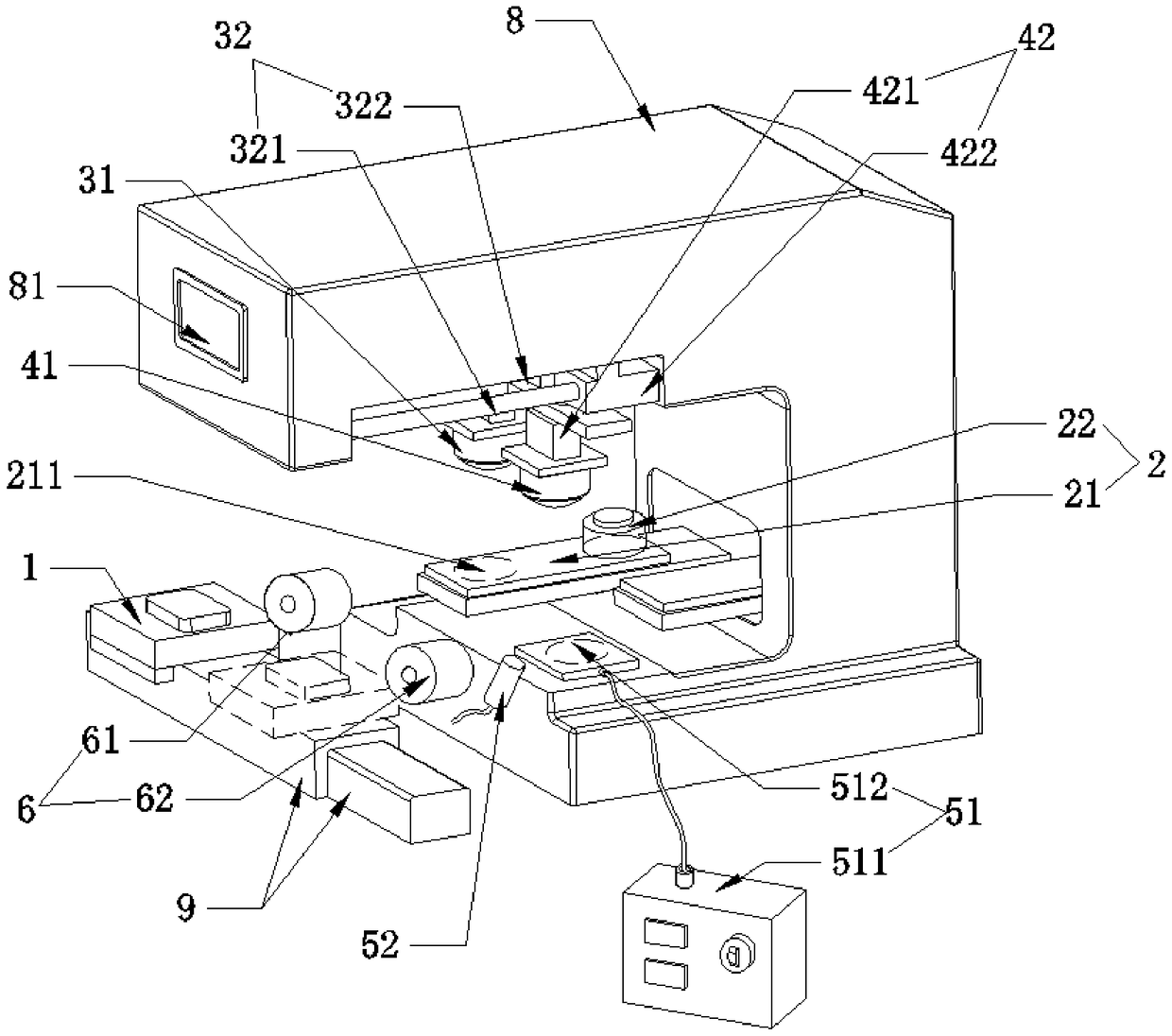

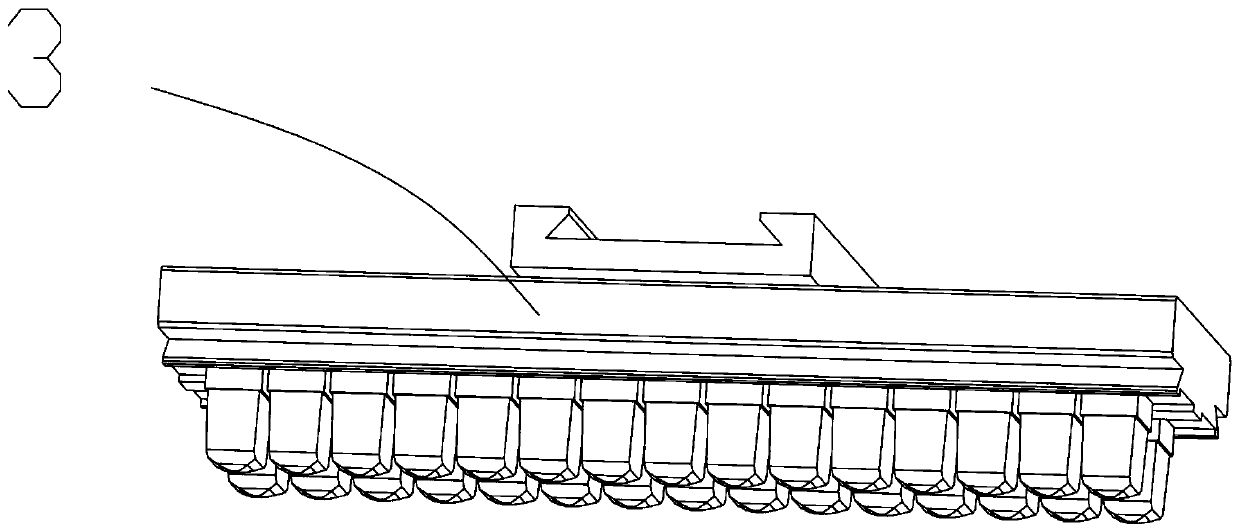

Gold stamping device and transfer printing gold stamping equipment

PendingCN110561903AMake up for the defect of poor ductilityEasy to liftTransfer printingHot stampingWrinkle skin

The invention relates to the technical field of surface decoration, in particular to a gold stamping device and transfer printing gold stamping equipment. The gold stamping device comprises a transferdevice, a pin mounting frame, a glue head mounting frame, a first driving mechanism and a second driving mechanism, wherein the pin mounting frame and the glue head mounting frame are sequentially arranged in the transferring direction of hot stamping foil; a plurality of pins are arranged on the pin mounting frame; the glue head mounting frame is used for mounting at least one glue head; the first driving mechanism is connected to the pin mounting frame; and the second driving mechanism is connected to the glue head mounting frame. According to the gold stamping device and the transfer printing gold stamping equipment, before the glue heads perform the gold stamping operation, the first driving mechanism firstly drives the pin mounting frame to move towards the hot stamping foil, so thata plurality of pinholes are formed in the hot stamping foil through the pins on the glue head mounting frame, due to the existence of the pinholes, the hot stamping foil among the pinholes is easilystretched when the hot stamping foil is pressed on a non-planar surface by the glue heads for gold stamping, and therefore the defect that the hot stamping foil is poor in ductility can be overcome, the gold stamping effect is improved; and meanwhile, generated wrinkles cannot easily continue to expand outwards when expanded to the pinholes, and therefore the subsequent gold stamping effect is notaffected.

Owner:KENT ENG GAOYAO

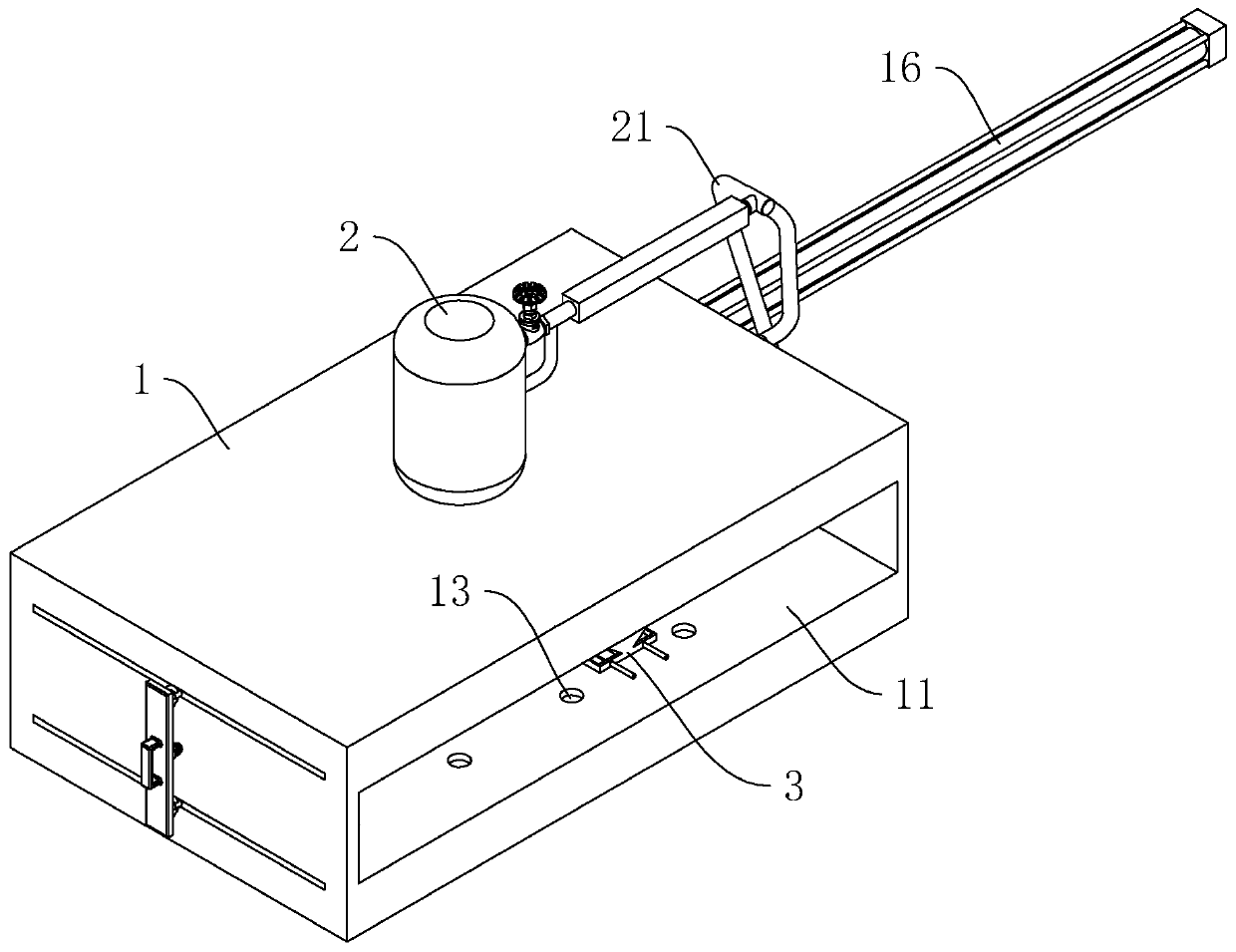

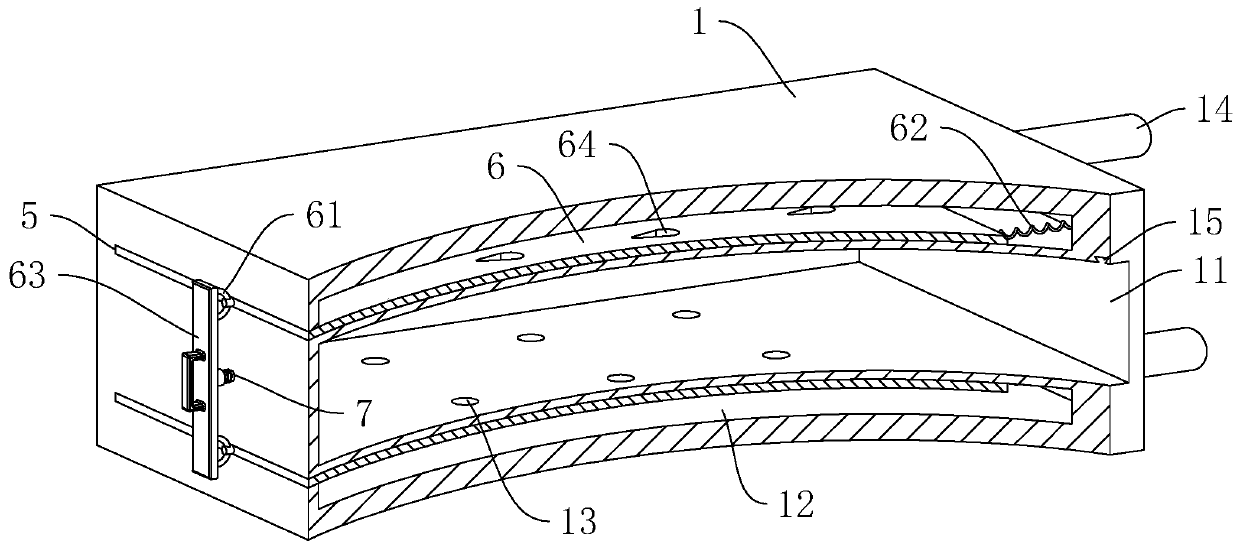

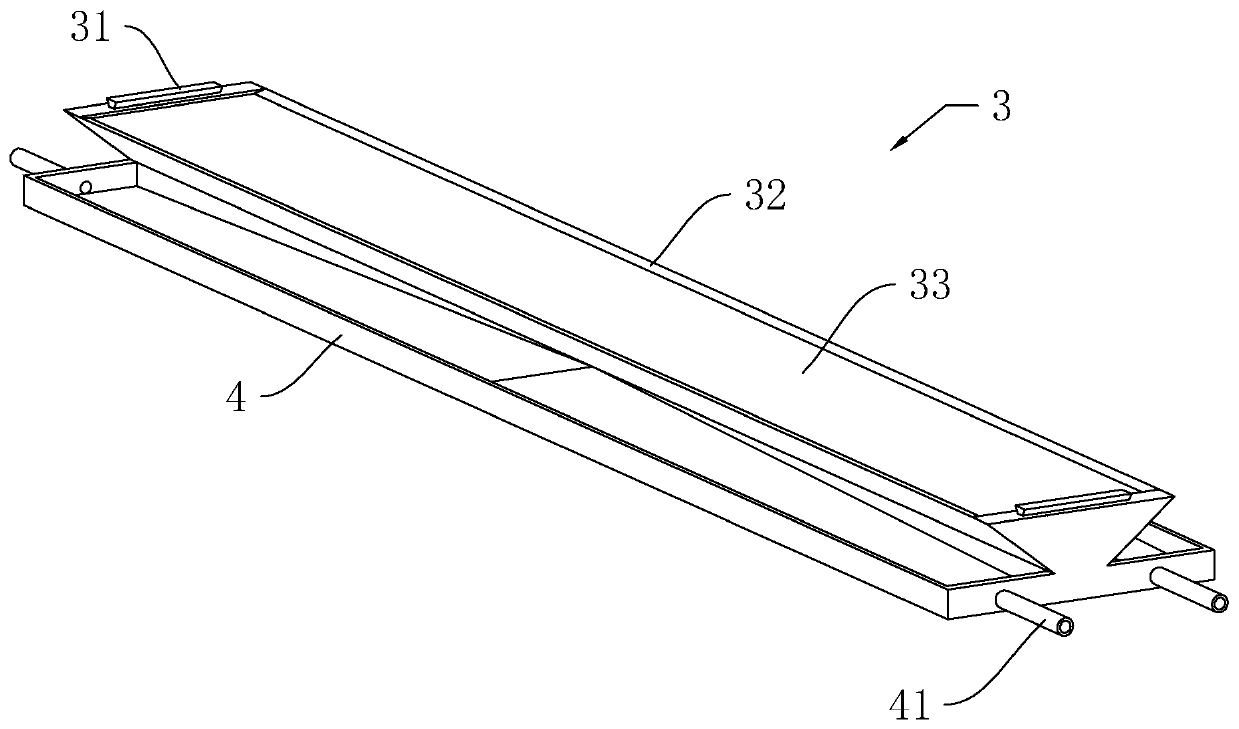

Energy-saving and environment-friendly tipping paper gold stamping device

The invention discloses an energy-saving and environment-friendly tipping paper gold stamping device. The device comprises a supporting box body, and a driving assembly is arranged at the top of the supporting box body. The driving assembly is composed of a motor box, a gear cavity, a first servo motor, a first rotating shaft, a first bearing, a driving gear, a first driven gear, a first connecting shaft, a rotating shaft, a second driven gear, a center shaft, a second bearing, a third driven gear, a second connecting shaft and a bearing rotating shaft, and a gold stamping assembly is arrangedoutside the driving assembly. The energy-saving and environment-friendly tipping paper gold stamping device has the advantages that resources are saved, the production cost of equipment is reduced, the gold stamping effect is better, operation is convenient, the gold stamping position is not prone to deflection, and bearing paper with different thicknesses can be automatically adjusted and matched according to needs; and the problems that resources are wasted, the production cost of equipment is improved, the gold stamping effect is poor, operation is complex, the gold stamping g position isprone to deflection, and the equipment cannot be automatically adjusted according to the thickness of bearing paper are solved.

Owner:驻马店黄金叶实业有限责任公司

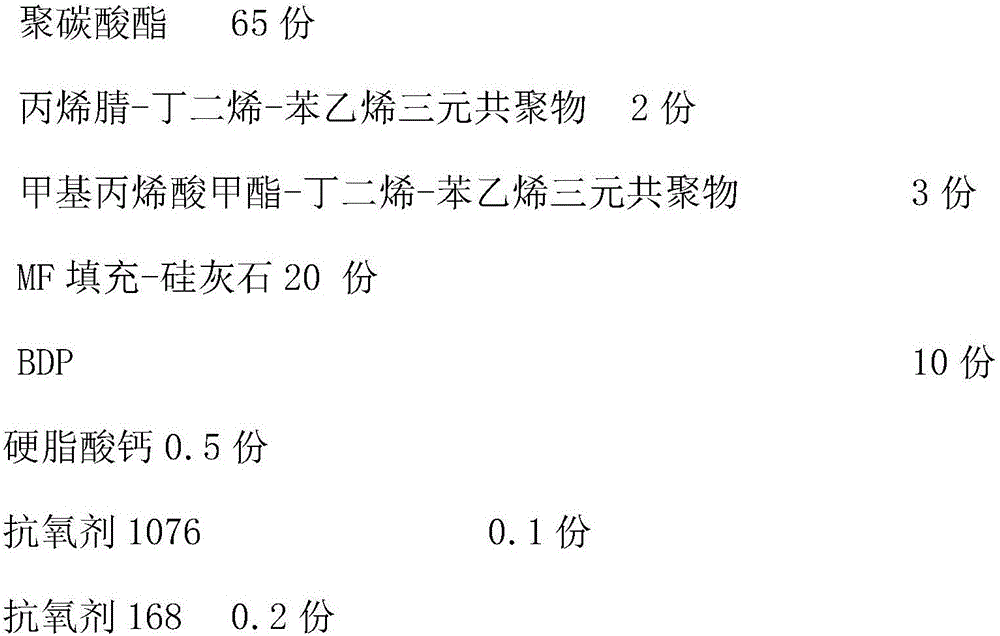

High-light free-spraying material and preparation method thereof

The invention provides a high-light free-spraying material and a preparation method thereof, and relates to the technical field of high polymer materials. The high-light free-spraying material is prepared from the following raw materials of PC resin, AS resin, BDP flame retardant, mineral filler, flexibilizer, an antioxidant and a lubricant. The high-light free-spraying material shows good balance of strength and toughness, the molding shrinkage rate is 0.35-0.45%, the modulus is larger than or equal to 4,000 Mpa, the shock is larger than or equal to 60 J / m, the density is smaller than 1.32 g / cm<3>, the high-light free-spraying material is applied to large size television back cover in the mainstream market, the high-light free-spraying mirror effect is achieved without using an RHCM mold, the production efficiency is improved, the fixed equipment investment is lowered, and an innovative material is provided for green development of the television industry.

Owner:ORINKO NEW MATERIAL CO LTD

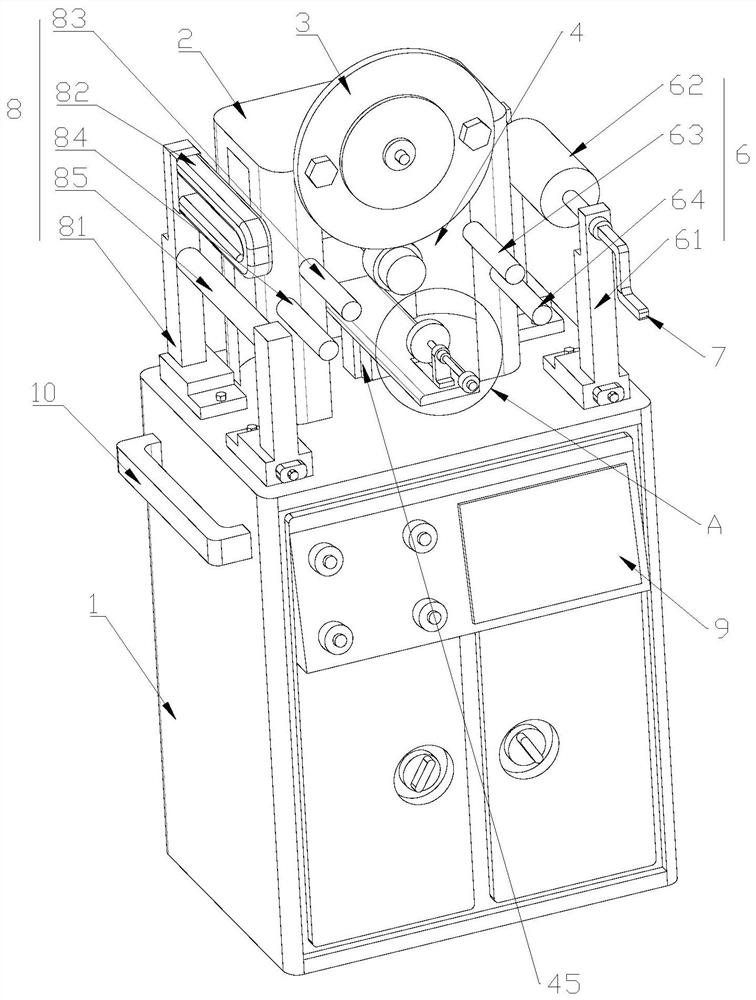

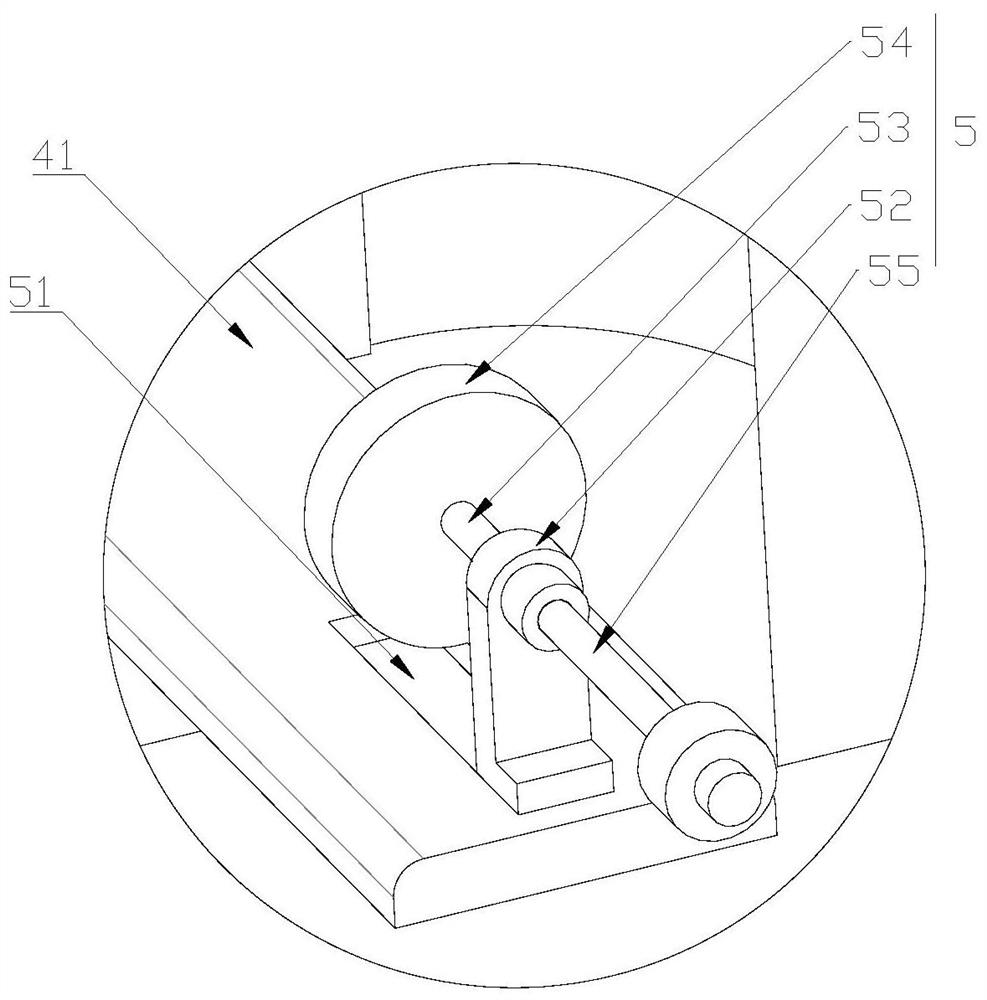

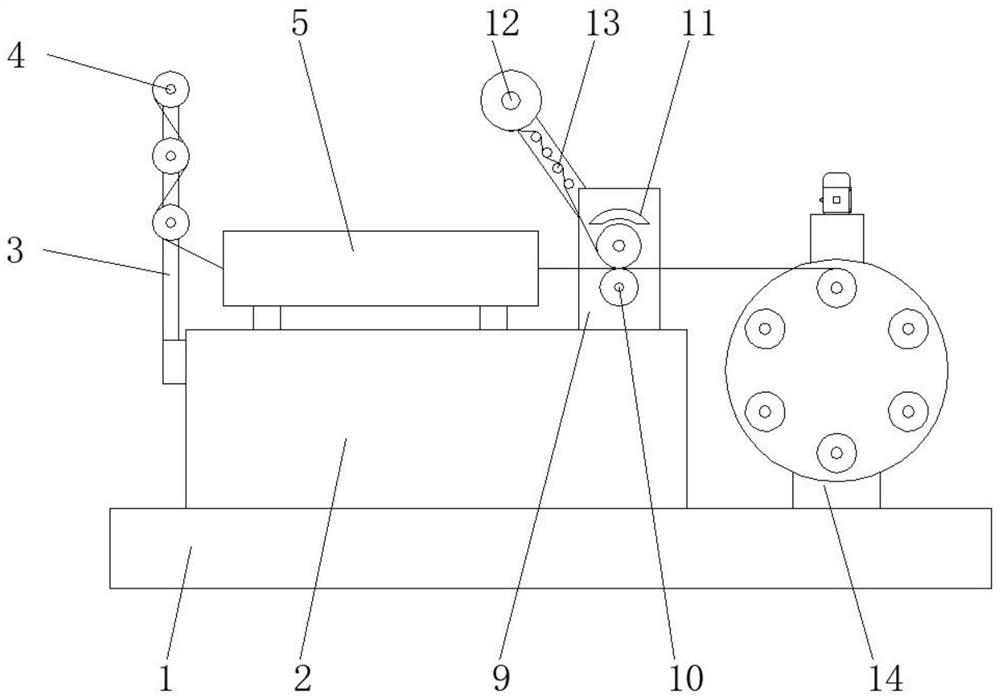

A bottle cap side automatic hot stamping machine

ActiveCN110039895BAffect bronzing effectImprove bronzing effectRotary pressesHot stampingEngineering

The invention discloses a bottle cap side surface automatic gilding press and relates to the technical field of package printing. The bottle cap side surface automatic gilding press comprises a workbench. A mounting support is arranged on the workbench. The bottle cap side surface automatic gilding press further comprises a gilding head. The section of the gilding head is circular. The gilding head is vertically fixed to the mounting support. A fixing assembly is arranged between the gilding head and the workbench. By means of the bottle cap side surface automatic gilding press, the productionefficiency is improved, and meanwhile, the requirement for gilding of different types of bottle caps is met.

Owner:重庆乔远环保科技有限公司

Packaging box foil stamping process

InactiveCN111959145AReduce processing difficultyReduce temperature differenceDuplicating/marking methodsOther printing apparatusHot stampingDust control

The invention relates to the technical field of packaging box processing, in particular to a packaging box foil stamping process. The packaging box foil stamping process comprises the following stepsthat a pattern to be subjected to hot stamping is scanned by using a scanner, data are stored into a computer, then three-dimensional carving is carried out under the control of the computer and software to form a hot stamping gravure with a three-dimensional pattern and a bottom die relief printing plate matched with the hot stamping gravure; the hot stamping gravure is installed on a stamping machine head of a hot stamping machine; after surface dust removal is conducted on a hot stamping material, the bottom die relief printing plate is positioned on the hot stamping material, and preheating treatment is conducted; the preheated surface of the bottom die relief printing plate is subjected to dust removal again; and the preheated bottom die relief printing plate and the hot stamping material are placed on a stamping platform of the hot stamping machine together, and then under the action of the stamping machine head, the hot stamping gravure is driven to be rapidly pressed down at acertain pressure and temperature. And therefore, the temperature difference between the bottom die relief printing plate and the hot stamping gravure is reduced, the machining difficulty of the bottomdie relief printing plate is effectively reduced, meanwhile, the occurrence rate of the problem that the matching effect is poor due to the temperature difference is effectively reduced, and the foilstamping effect is guaranteed.

Owner:TIANJIN YIHONG PRINTING DEV

Zipper gilding press

ActiveCN112937112AInhibit sheddingAvoid bronzing effectsRotary pressesWebs handlingEngineeringRotating disc

The invention discloses a zipper gilding press. The zipper gilding press comprises a base, an adjusting mechanism, a gilding device, a material collecting mechanism, a rotating disc, a fixing mechanism and a fixing frame, a machine box is fixed to the top of the base, a first lead screw is rotationally connected to the lower portion of the inner side of a preheating box, a gear is rotationally connected to the surface of a fixing base, the gear is connected with the rotating disc, the rotating disc is rotatably connected to the surface of the fixing base, a movable rod is slidably connected to the inside of a material collecting disc. The zipper gilding press is provided with a heating pipe and clamping plates, the heating pipe in the preheating box can preheat zippers when the zippers are conveyed, so that the gilding effect is improved, the phenomenon that the gilding foil falls off from the zippers after gilding is avoided, and the first screw rod in the preheating box is matched to drive two groups of first movable blocks and the clamping plates to adjust the distance between the first movable blocks and the clamping plates, so that the zippers can be conveniently kept in the middle in the conveying process, the situation that the zippers and the gilding foil are misplaced due to deviation, and the gilding effect is affected is avoided, and the practicability is improved.

Owner:义乌市旭丰拉链有限公司

Gold stamping device for glass bottle

PendingCN114290797ABronzing effect is goodSimple structureTransfer printingStampingStructural engineering

The invention discloses a gilding device for glass bottles. The gilding device comprises a frame body and a gilding mechanism, the gold stamping mechanism comprises a mounting plate, a displacement assembly, a gold stamping head and a material belt delivery assembly; wherein the displacement assembly comprises a first displacement assembly vertically arranged on the mounting plate and a second displacement assembly horizontally arranged on the first displacement assembly through a moving plate; the suspension frame is arranged on the second displacement assembly; the gilding device further comprises a clamping assembly arranged at the bottom of the gilding head. And the clamping assembly is used for clamping and rotating the glass bottle. The first displacement assembly, the second displacement assembly and the clamping assembly are used in cooperation; and the gold stamping effect is remarkable, products of different shapes can be subjected to gold stamping, and flexibility and multiple purposes are achieved.

Owner:杭州振华日化包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com