UV-curable coating and application thereof

A technology for curing coatings and raw materials, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of long baking time, low production efficiency, low surface tension, etc., and achieve good bronzing performance, good solvent resistance, firmness strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In one embodiment, the preparation method of the UV-curable coating comprises: mixing thermoplastic acrylic resin and monofunctional acrylate and heating to 75-85°C, stirring and dissolving, adding the remaining preparation raw materials, stirring until uniformly dispersed, and obtaining .

[0065] In a preferred embodiment, the preparation method of the UV curable coating includes: mixing thermoplastic acrylic resin and monofunctional acrylate and heating to 80°C, stirring and dissolving, adding the remaining preparation raw materials, stirring until uniformly dispersed, and obtaining .

[0066] In the present invention, when the weight part of the thermoplastic acrylic resin is 0, no thermoplastic acrylic resin is added in the preparation method of the UV curable coating.

[0067] The second aspect of the present invention provides the UV curable coating for coating PE hoses.

Embodiment

[0069] Hereinafter, the present invention is described in more detail through examples, but it should be understood that these examples are only illustrative and not restrictive. Unless otherwise stated, the raw materials used in the following examples are commercially available.

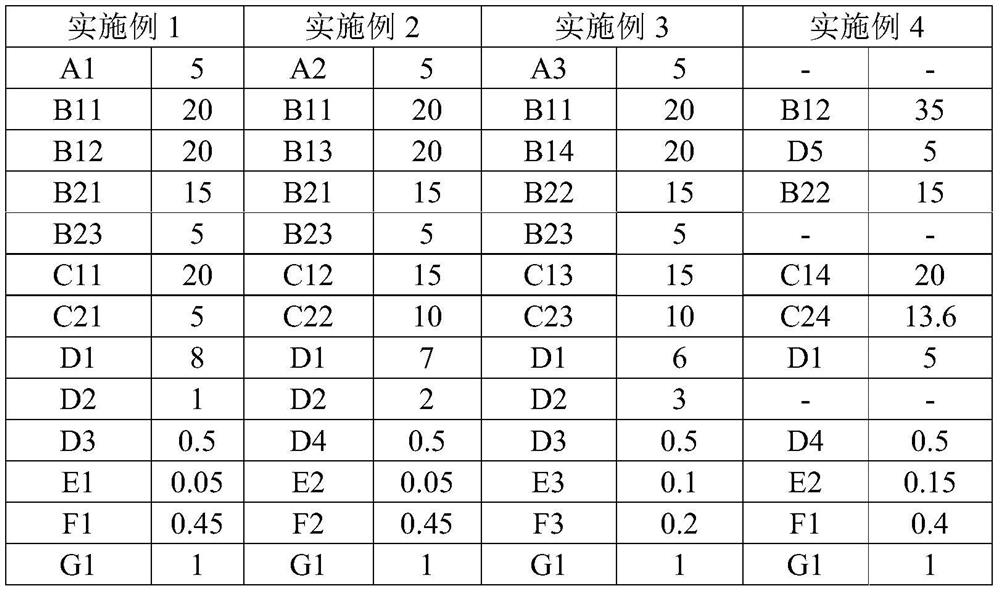

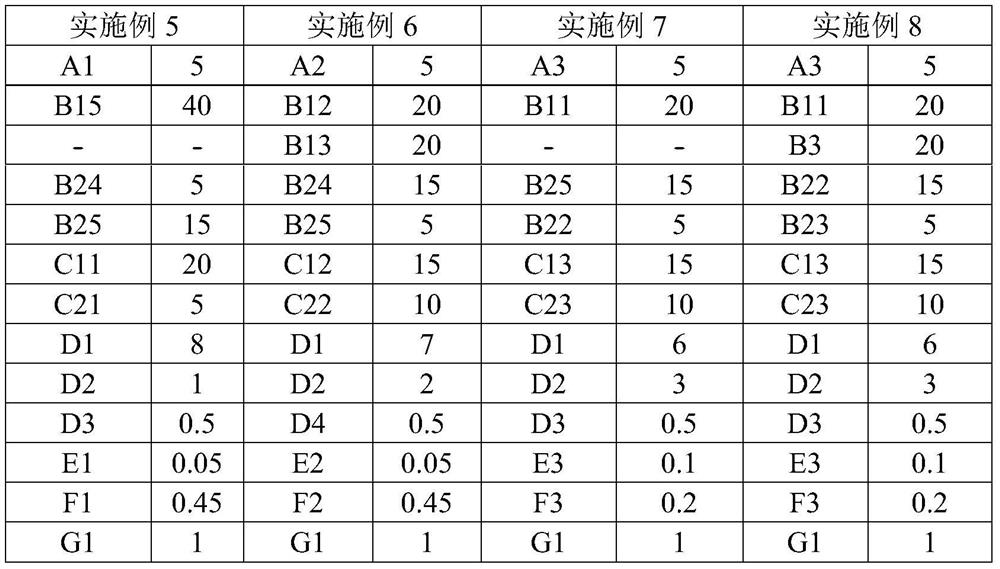

[0070] The raw materials for the preparation of UV-curable coatings in Examples 1-8 are shown in Table 1, where the unit is parts by weight.

[0071] A: Thermoplastic acrylic resin.

[0072] A1: B-805, the brand is DSM Likang;

[0073] A2: A-11, purchased from American Dow Chemical;

[0074] A3: BR-85, purchased from Mitsubishi Rayon;

[0075] B: Acrylic

[0076] B1: Monofunctional acrylate

[0077] B11: Hydroxyethyl acrylate, free acid content ≤ 0.5wt%, dynamic viscosity at 25°C is 5.34cps, purchased from Jiangsu Sanmu;

[0078] B12: Hydroxyethyl methacrylate, free acid content ≤ 0.5wt%, dynamic viscosity at 25°C is 6.79cps, purchased from Jiangsu Sanmu;

[0079] B13: Acryloylmorpholine, the...

Embodiment 4

[0121] The preparation method of the UV curable coating described in Example 4 includes: mixing and heating the monofunctional acrylate to 80° C., stirring and dissolving, adding the remaining preparation raw materials, and stirring until uniformly dispersed.

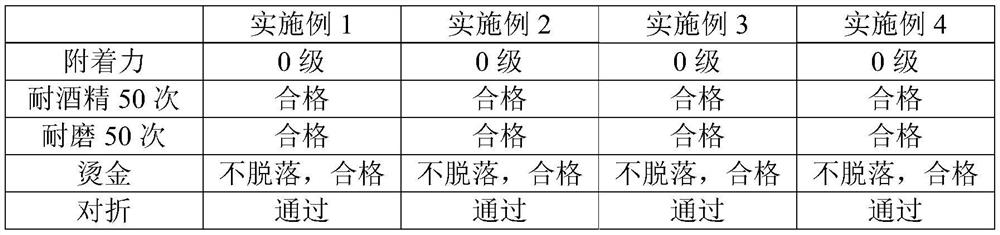

[0122] performance evaluation

[0123] Use RDS#4 scraping rod, on the PE hose that flame treatment surface reaches 42 dynes, coat the coating of above-mentioned embodiment 1~8, dry 10 seconds with 60 ℃ of blast ovens, then carry out UV irradiation (high-pressure mercury lamp, Light energy 100mJ / cm 2 ), form a 9 μm bright coating on a PE hose with a thickness of 450 μm, and thus prepare a sample for evaluation. The test items and methods of the obtained evaluation sample are as follows:

[0124] 1. Adhesion test: According to the ISO test method, use the cross-cut test and 3M 810 cellophane tape to determine the adhesion of the hardcoat to the coating film. Adhesion is divided into six grades from 0 to 5, where grade 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com