High-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and preparation method thereof

A golden light and field technology, applied in the field of high-gloss wear-resistant UV bronzing oil and its preparation, can solve the problems of corroding offset plates, poor repainting bronzing effect, affecting the quality effect of varnish bronzing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

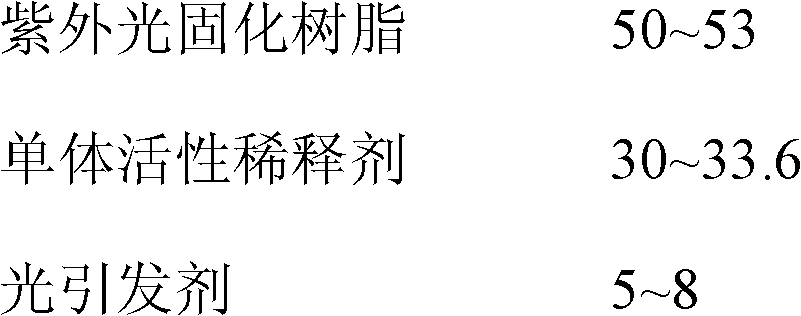

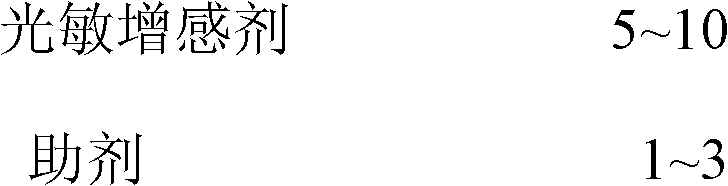

[0020] Embodiment 1: a kind of high-gloss wear-resistant UV bronzing varnish used in the field of cigarette pack printing is characterized in that it consists of the following components in parts by weight:

[0021]

[0022] A method for preparing the above-mentioned high-gloss wear-resistant UV bronzing varnish, comprising a stainless steel stirring container, is characterized in that it comprises the following steps:

[0023] (1) Weigh 20 to 25 parts by mass of hexafunctional urethane acrylate CN9006N, 25 parts by mass of modified epoxy acrylate CN117, 15.6 parts by mass of dipentaerythritol penta / hexaacrylate of SR399NS, 18 parts by mass model is 1,6-hexanediol diacrylate of SR238NS, 5 parts by mass of photoinitiator (JRCure ITX), 10 parts by mass of photosensitizer EHA, 0.3 part by mass of leveling agent RF339, 0.5 part by mass of Foaming agent DF258, 0.5 parts by mass of dispersant 497 and 0.1 parts by mass of 2,5-di-tert-hydroquinone;

[0024] (2) 15.6 parts by mass ...

Embodiment 2

[0027] A high-gloss wear-resistant UV bronzing varnish used in the field of cigarette pack printing is characterized in that it consists of components in parts by weight:

[0028]

[0029]

[0030] A method for preparing the above-mentioned high-gloss wear-resistant UV bronzing varnish, comprising a stainless steel stirring container, is characterized in that it comprises the following steps:

[0031] (1) Weighing 20 mass parts model is the hexafunctional polyurethane acrylate of CN9006N, 30 mass parts model is the modified epoxy acrylate of CN117, 15.6 mass parts model is the dipentaerythritol penta / hexaacrylate of SR399NS, 18 mass parts Parts model is 1,6-hexanediol diacrylate of SR238NS, 5 parts by mass of photoinitiator (JRCure DETX), 10 parts by mass of photosensitizer EHA, 0.3 parts by mass of leveling agent RF339, 0.5 parts by mass of defoamer DF258, 0.5 parts by mass of dispersant 497 and 0.1 parts by mass of 2,5-di-tert-hydroquinone;

[0032] (2) 15.6 parts by ...

Embodiment 3

[0035] A high-gloss wear-resistant UV bronzing varnish used in the field of cigarette pack printing is characterized in that it consists of the following components in weight percentage:

[0036]

[0037]

[0038] A method for preparing the above-mentioned high-gloss wear-resistant UV bronzing varnish, comprising a stainless steel stirring container, is characterized in that it comprises the following steps:

[0039] (1) Take by weighing 23 parts by mass models the hexafunctional urethane acrylate of CN9006N, 28 parts by mass of the modified epoxy acrylate of CN117, 15.6 parts by mass of the dipentaerythritol penta / hexaacrylate of SR399NS, 17 mass parts Parts model is 1,6-hexanediol diacrylate of SR238NS, 2 mass parts photoinitiators (JRCure DETX), 3 mass parts photoinitiators (JRCureITX), 10 mass parts photosensitizer EHA, 0.3 mass parts flow Leveling agent RF339, 0.5 parts by mass of defoamer DF258, 0.5 parts by mass of dispersant 497 and 0.1 parts by mass of 2,5-di-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com