Efficient flat hot stamping device

A flat hot stamping and high-efficiency technology, which is applied in gold powder printing, printing, rotary printing machines, etc., can solve the problems affecting the quality of hot stamping and the inability to improve the efficiency of flat hot stamping, so as to improve the hot stamping effect, increase the contact time, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

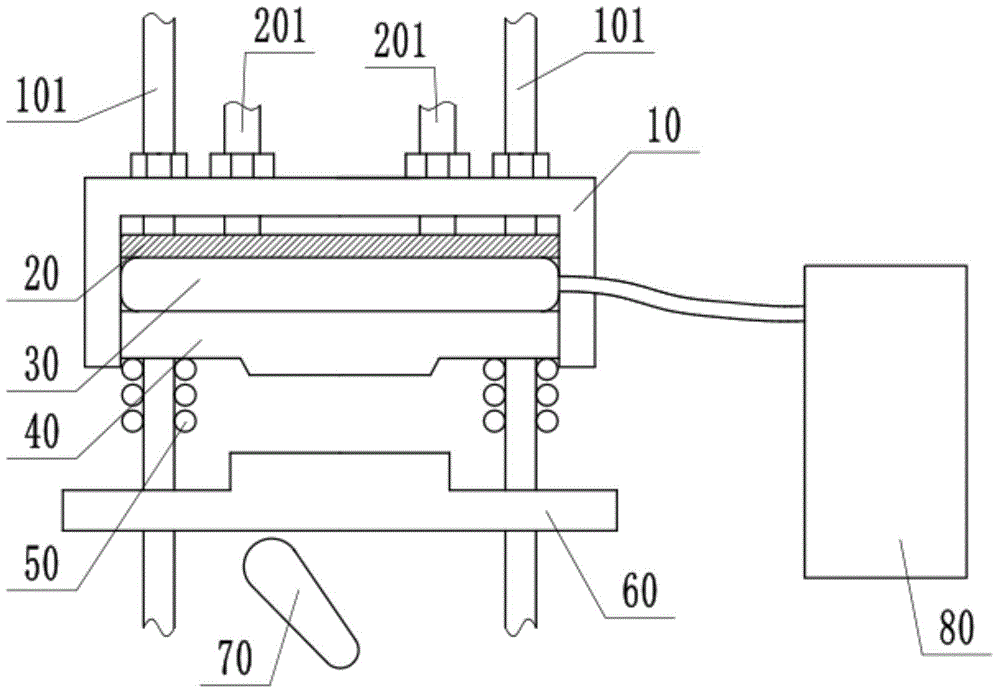

[0011] Such as figure 1 As shown, a high-efficiency flat stamping device includes a "冂"-shaped frame cover 10, an installation hole is opened on the upper panel of the frame cover 10, and the guide post 101 passes through the lock symmetrically with respect to the center line of the "冂"-shaped The tightening nut is installed on the frame cover 10. In order to enable other components to slide freely on the guide post 101, the guide post 101 must ensure that its surface roughness is low, and it is arranged in turn under the "冂"-shaped frame cover 10. There is a final pressure regulating plate 20, a bronzing plate 40 and a pressing plate 60, and a cam mechanism is arranged under the pressing plate 60.

[0012] On the inner side of the "冂"-shaped frame cover 10, a final pressure regulating plate 20 is provided below the upper panel of the frame cover 10, and a through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com