Wine box gold stamping device

A technology of wine boxes and bronzing paper, which is applied to printing devices, printing, rotary printing machines, etc., can solve the problems of stamped graphics and texts, stamping failure, low temperature, etc., to reduce labor, prevent heat dissipation, Improve the effect of bronzing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

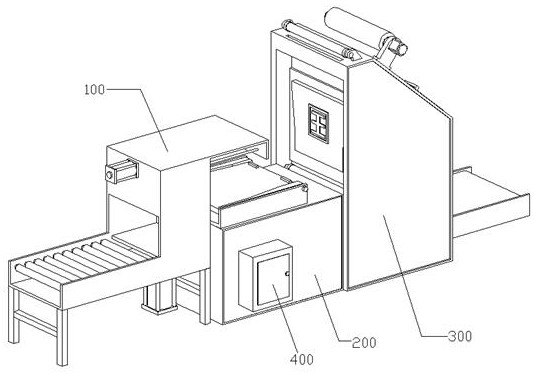

[0033] Embodiment 1 discloses a wine box bronzing device, refer to the attached figure 1 And attached figure 2 , including a feeding mechanism 100, a conveying and flipping hot pressing mechanism 200, a bronzing mechanism 300 and a control cabinet 400, wherein the feeding mechanism 100, the conveying and flipping hot pressing mechanism 200, and the bronzing mechanism 300 are sequentially arranged from left to right.

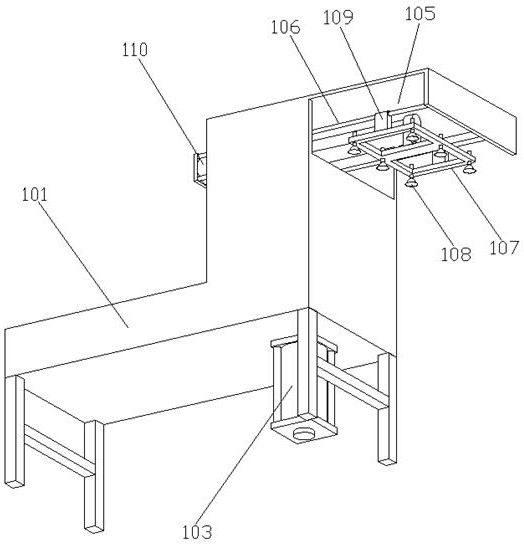

[0034] Reference attached image 3 And attached Figure 4, the feeding mechanism 100 includes an L-shaped frame 101, a row of conveying rollers 102 is arranged at the lower left end of the frame 101, a jacking device 103 is provided at the lower right end of the frame 101, and the jacking device 103 extends The end of the machine frame 101 is connected with a supporting plate 104, and the stacked wine box cardboard is sent to the upper surface of the supporting plate 104 through the transmission roller 102, and the jacking device 103 is a cylinder, which can b...

Embodiment 2

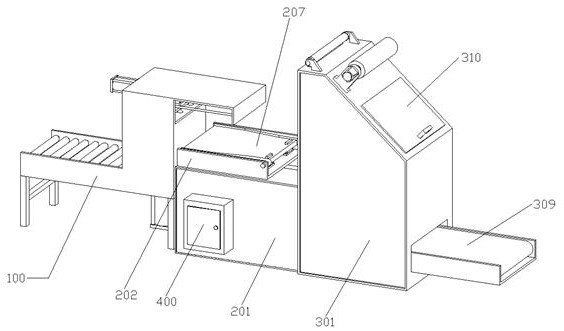

[0042] Embodiment 2 discloses an improved wine box bronzing device based on Embodiment 1, which mainly adds how to realize the neat discharge of the bronzing wine box cardboard and how to quickly replace the bronzing paper. 2 The same part as that of Embodiment 1 will not be described again, and the difference can refer to the appended figure 2 And attached Figure 5 .

[0043] In this embodiment 2, an arc-shaped material guide block 210 is provided on the right end surface of the cabinet 201 extending into the insertion groove 3011, and a discharge channel 3012 is opened in the machine base 301 below the material guide block 210. In the discharge channel 3012 A horizontally arranged finished product discharge conveyor 309 is arranged in the middle, and the finished product discharge conveyor 309 is a conventional belt conveyor. The finished wine box cardboard falls on the finished product discharge conveyor 309 under the action of the material guide block 210 after bronzin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com