A bottle cap side automatic hot stamping machine

A hot stamping machine and automatic technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of poor applicability, inability to fix bottle caps well, time-consuming and labor-intensive efficiency, and achieve cost saving and bronzing effects Better, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

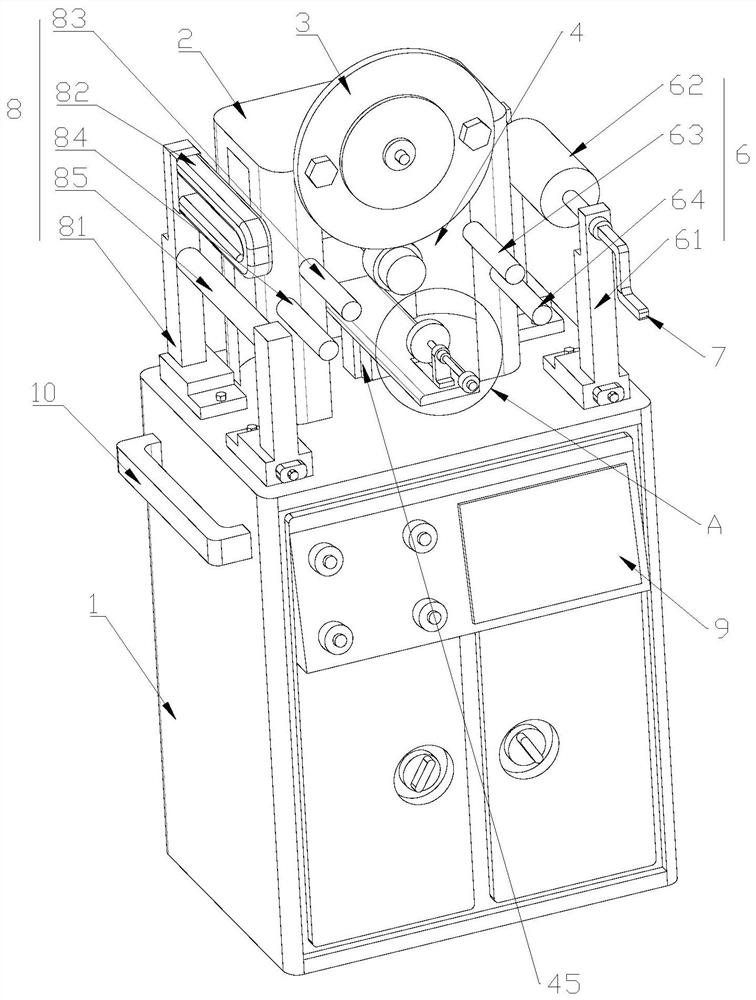

[0025] Such as Figure 1 to Figure 3 , a bottle cap side automatic hot stamping machine includes a workbench 1, a mounting bracket 2 is arranged on the workbench 1, and a hot stamping head 3, the cross section of the hot stamping head 3 is circular, and the hot stamping head 3 is vertically fixed on the installation On the support 2, a fixed assembly 4 is arranged between the bronzing head 3 and the workbench 1, and the bronzing head 3 has a certain temperature;

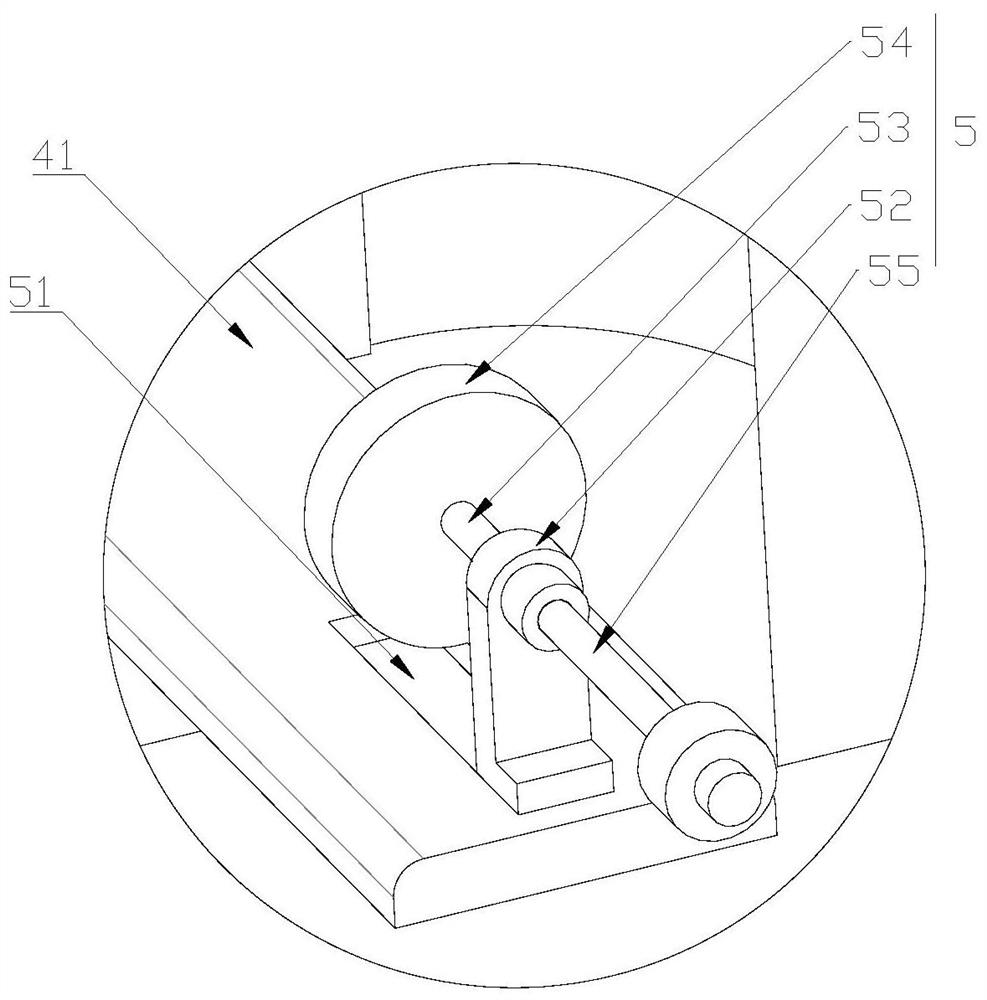

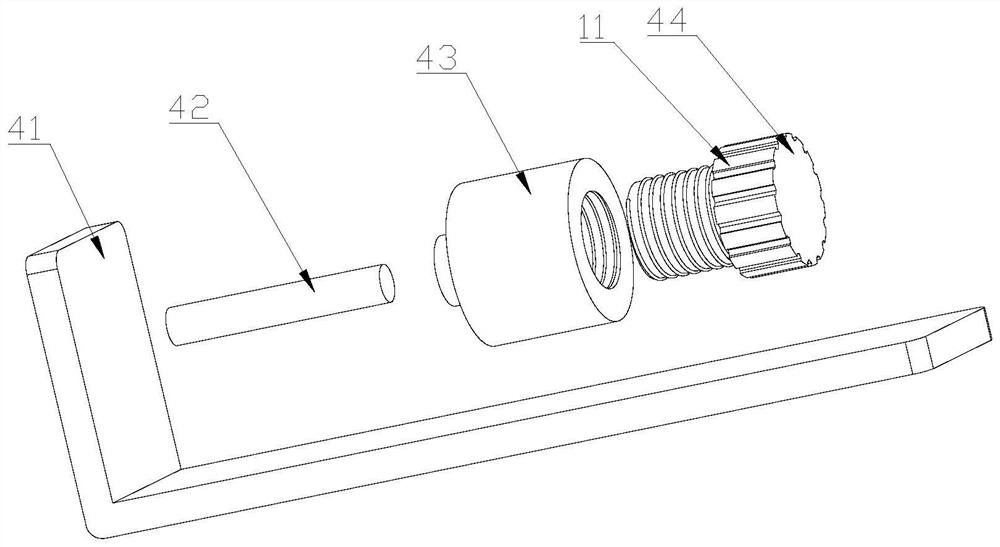

[0026] The fixing assembly 4 includes an L-shaped mounting plate 41, a rotating shaft 42, a mounting base 43, a T-shaped mounting base 44, and a first cylinder 45. The mounting plate 41, the rotating shaft 42, the mounting base 43, and the mounting base 44 are sequentially arranged from back to front. arrangement, the vertical end of the mounting plate 41 is rotationally connected with one end of the rotating shaft 42, the other end of the rotating shaft 42 is sleeved on one end of the mounting seat 43, the inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com