Alumite hot stamping foil suitable for offset printing and cold stamping technology and preparation method thereof

An offset cold stamping and anodized aluminum technology, which is applied in the directions of copying/marking methods, processes for producing decorative surface effects, printing, etc. and other problems, to achieve the effects of significant environmental protection benefits, small peeling force and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

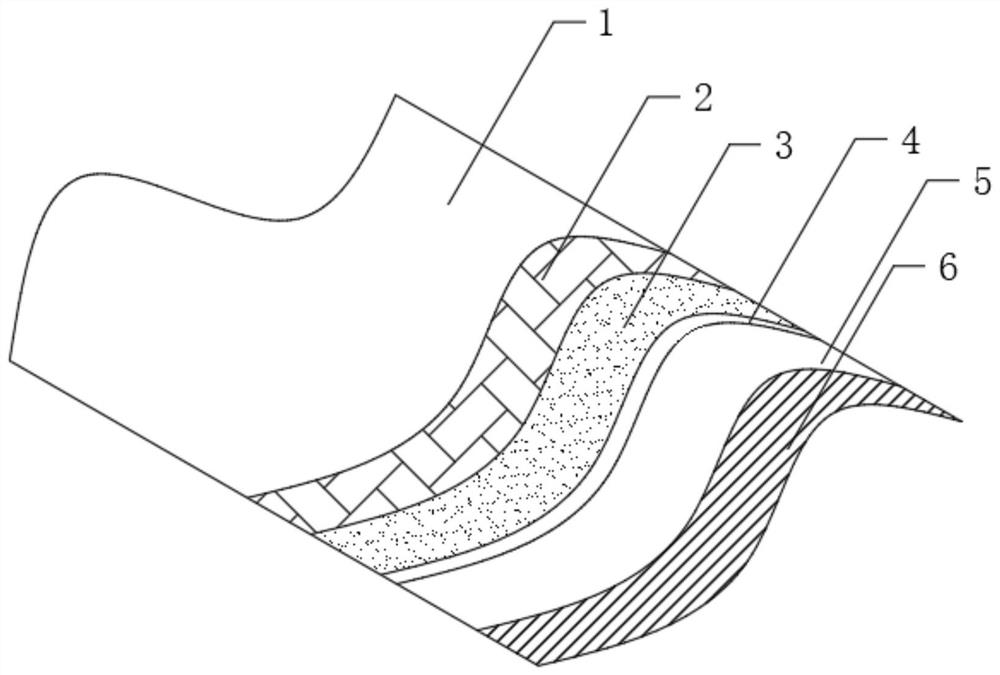

Image

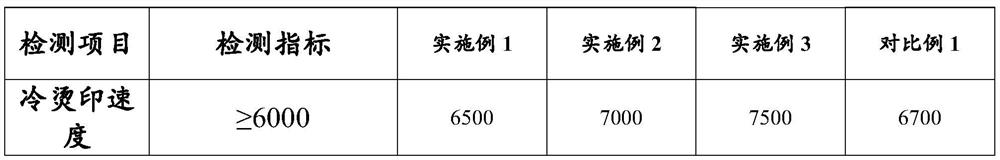

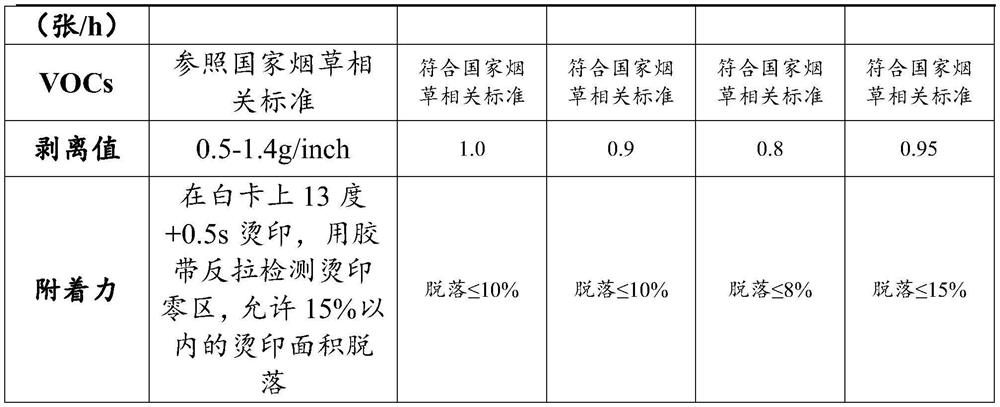

Examples

Embodiment 1

[0035] This embodiment provides an electrochemical aluminum hot printed foil preparation method suitable for adhesive and frotting techniques, and the electrochemical aluminum hot printing foil preparation method includes the following steps:

[0036] S1, coating isolation: coating the isolation layer on the sheet base, 150 mesh roller printing, wet coating is 4.8 g ± 0.5 / m2;

[0037] Specifically, the specific formulation of the isolator is as follows: 1% emulsified water-based wax, 50% absolute ethanol and 49% deionized water;

[0038] S2, coated resin coating: coating the stained layer on the isolation layer, 200-350 mesh roller printing, dry coating is 1.5 ± 0.05 g / m2;

[0039] Specifically, resin coating selectively 15% silicon modified acrylic resin, 35% thermoplastic methacrylic resin, 25% butanone, 15% butyl ester and 2% toner mixing uniform stirring, then add 0.5 % Active agents and 0.7% modifier;

[0040] Among them, the active agent is selected from the group consis...

Embodiment 2

[0047] In this example, an electrochemical aluminum hot printing foil for rubbing and hot techniques, the preparation method of the electrochemical aluminum hot printing foil includes the following steps:

[0048] S1, coating isolation: coating the isolation layer on the sheet base, 180 mesh roller printing, wet amount of 4.8 g ± 0.5 / m2;

[0049] S2, coating resin coating: coating a stained layer on the isolation layer, 250 mesh roller printing, dry coating 1.5 ± 0.05 g / m2;

[0050] Specifically, resin coating selects 18% silicon modified acrylic resin, 33% thermoplastic methacrylic resin, 26% butanone, 17% butyl ester and 2.2% toner mix uniformly stir form, then add 0.5 % Active agents and 0.7% modifier;

[0051] Among them, the active agent uses the proportion of monode sodium sulfosuccinate monode sodium sulfosuccinate monode sodium and fatty alcohol polyoxyethylene ether, and the modifier selects a styrene-butadiene-styrene ternary block copolymer. Proportion of acrylonitr...

Embodiment 3

[0058] In this example, an electrochemical aluminum hot printing foil for rubbing and hot techniques, the preparation method of the electrochemical aluminum hot printing foil includes the following steps:

[0059] S1, coating isolation: coating the isolation layer, 200 mesh roller printing, wet coating is 4.8g ± 0.5 / m2;

[0060] S2, coating resin coating: coating a staining layer on the isolation layer, 350 mesh roller printing, dry coating 1.5 ± 0.05 g / m2;

[0061] Specifically, resin coating selectively 20.5% silicon modified acrylic resin, 30.2% thermoplastic methacrylic resin, 27.5% butyl butyl butyl acrylic resin, 27.5% ketone, 20% butyl butyl butyl butyl mix uniformly mixed, then add 0.8 % Active agents and 1.3% modifier;

[0062] Among them, the active agent is a polyether modified polysiloxane, a monode sodium monode sulfosuccinate monode sodium sulfosuccinic acid monode sodium and fatty alcohol polyoxide ether, and the modifier is methyl methacrylate - Diishie - Styre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com