High-liquidity high-toughness reinforced PC composite material and preparing method thereof

A composite material and high toughness technology, which is applied in the field of high flow and high toughness reinforced PC composite materials and its preparation, can solve the problems of ultra-thin mobile phones, narrow frames, and reduced rigidity of PC materials, and achieve good high-gloss surface effects, extremely Excellent surface effect, excellent bronzing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

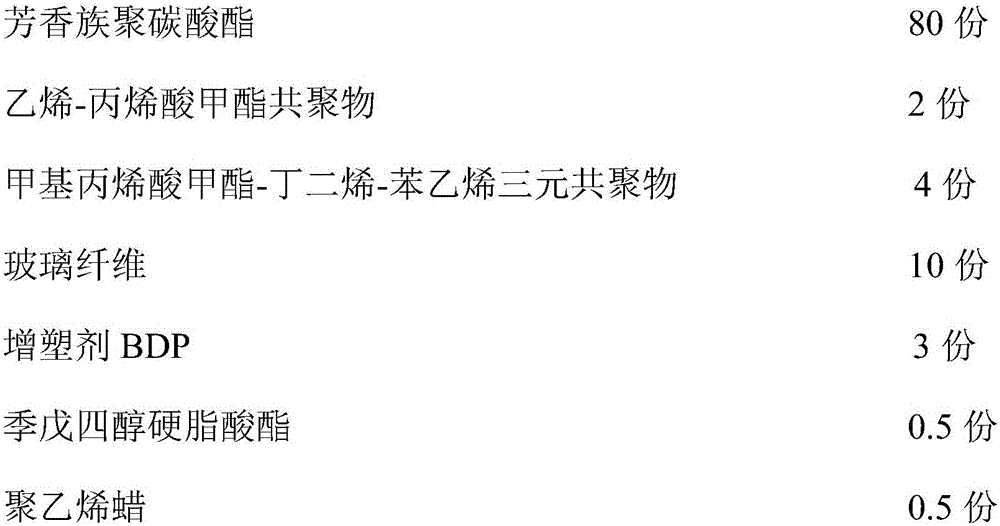

[0025] The high flow and high toughness reinforced PC composite material in the present embodiment is made up of following raw materials by weight:

[0026]

[0027]

[0028] Concrete preparation method comprises the following steps:

[0029] (1) 80 parts of aromatic polycarbonate, 2 parts of ethylene-methyl acrylate copolymer, 4 parts of methyl methacrylate-butadiene-styrene terpolymer, 0.1 part of antioxidant 1076, 0.2 part Antioxidant 168, 0.2 part of antioxidant DLTP, 0.5 part of pentaerythritol stearate, 0.5 part of polyethylene wax, added to a mixer with nitrogen protection and mixed at high speed for 6 minutes;

[0030] (2) Under the protection of nitrogen, put the mixed material of (1) into the parallel twin-screw extruder to melt, and then add 10 parts of glass fiber (510H, boulder) from the side feeding port of the extruder, and at the same time pass the liquid pump in Add 3 parts of plasticizer BDP to the side feed port of the extruder, extrude and granulate ...

Embodiment 2

[0032] The high flow and high toughness reinforced PC composite material in this example is made up of the following raw materials by weight:

[0033]

[0034]

[0035] Concrete preparation method comprises the following steps:

[0036] (1) 68 parts of aliphatic polycarbonate, 2 parts of ethylene-methyl acrylate copolymer, 1 part of methyl methacrylate-butadiene-styrene terpolymer, 0.1 part of antioxidant 1076, 0.1 part Antioxidant 168, 0.5 parts of silicone masterbatch, added to a mixer with nitrogen protection and mixed at high speed for 10 minutes;

[0037] (2) Under the protection of nitrogen, put (1) the mixed material into the parallel twin-screw extruder to melt, then add 20 parts of glass fiber (510, boulder) from the side feeding port of the extruder, and simultaneously pass the liquid pump in Add 6 parts of plasticizer BDP to the side feeding port of the extruder, and extrude and granulate to obtain a high-flow, high-toughness reinforced PC composite material;...

Embodiment 3

[0039] The high flow and high toughness reinforced PC composite material in the present embodiment is made up of following raw materials by weight:

[0040]

[0041] Concrete preparation method comprises the following steps:

[0042] (1) 74 parts of polycarbonate, 3.5 parts of ethylene-methyl acrylate copolymer, 1.5 parts of ethylene-butyl acrylate-glycidyl methacrylate, 0.5 parts of antioxidant 1076, 0.3 parts of antioxidant 168, 0.2 1 part of antioxidant DLTP, 0.5 part of pentaerythritol stearate, 0.5 part of montan wax, added to a mixer with nitrogen protection and mixed at high speed for 2 minutes;

[0043] (2) Under the protection of nitrogen, put the mixed material of (1) into the parallel twin-screw extruder to melt, and then add 20 parts of glass fiber (510, boulder) from the side feeding port of the extruder, and extrude, make pellets to obtain high-flow and high-toughness reinforced PC composite materials; where the barrel temperature of the extruder is 260°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com