Gold stamping device applied to roll-shaped printed product

A printed and rolled technology, applied in the field of hot stamping devices, can solve the problems of large temperature control deviation of the heating roller, poor hot stamping effect, waste and other problems, and achieve the effect of improving the hot stamping effect, saving costs and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

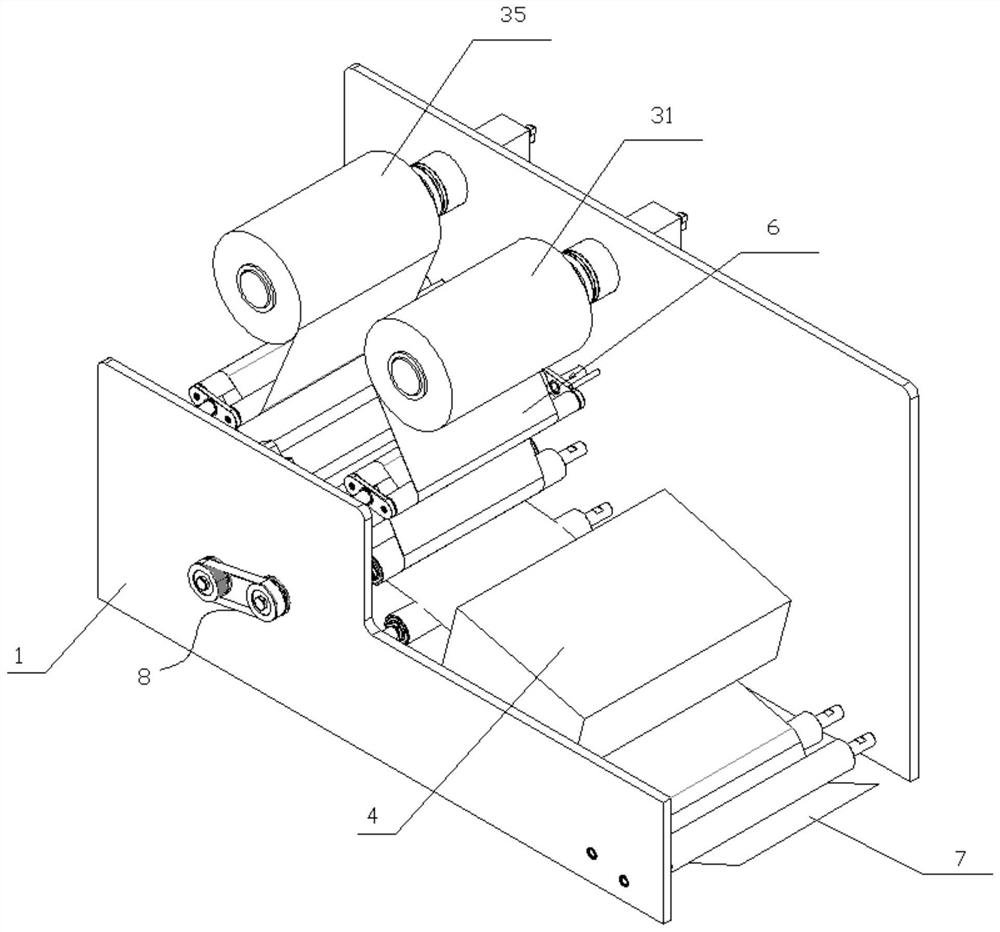

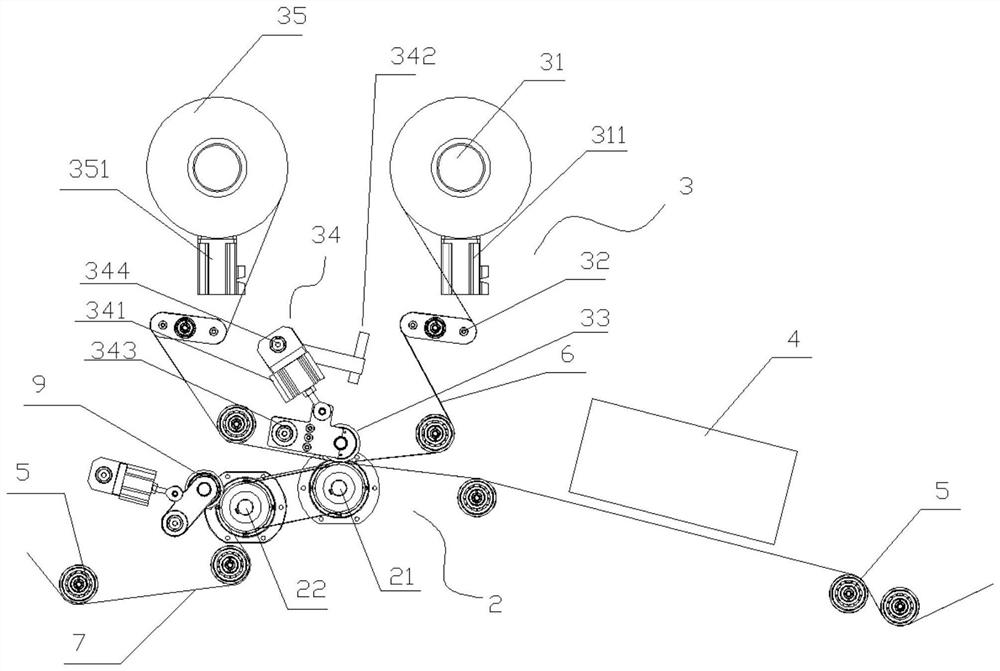

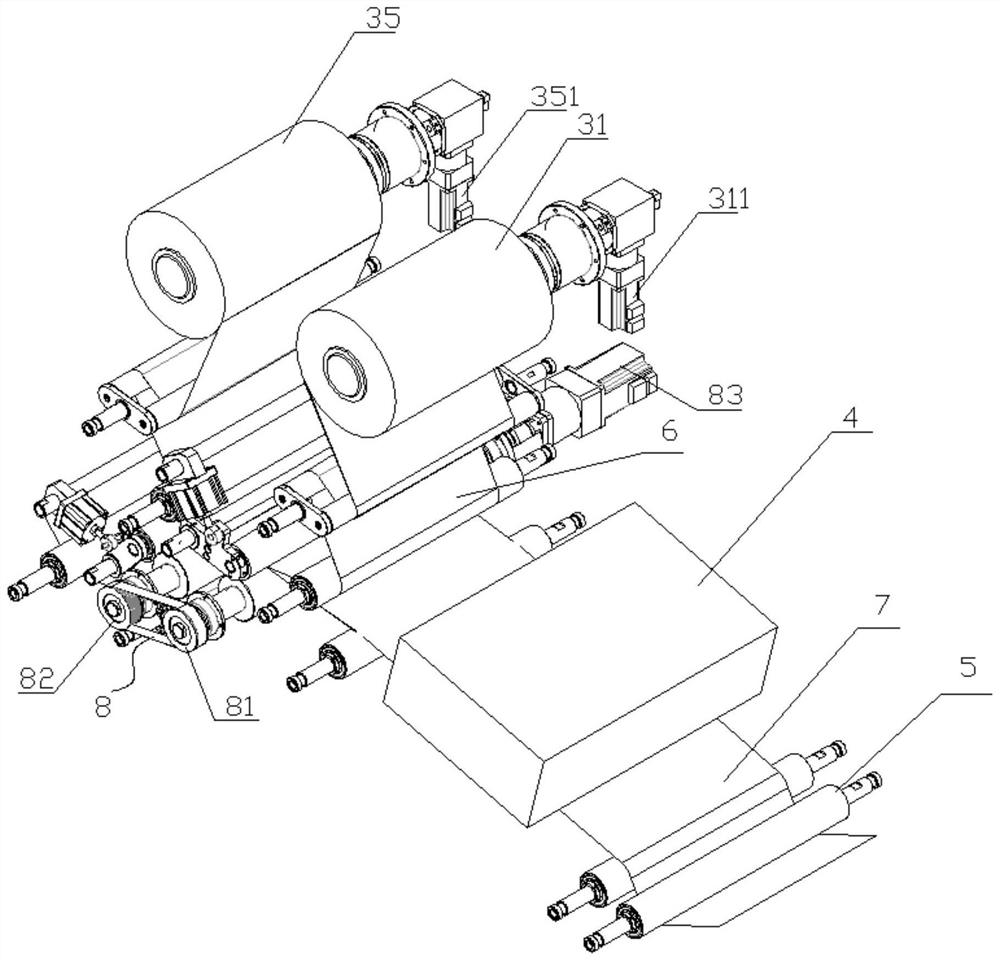

[0023] Such as figure 1 , figure 2 , the hot stamping device that is applied to roll-shaped printed matter of the present embodiment mainly is received by support 1, printed matter driving roller 21, printed matter traction roller 22, transmission unit 8, heating device 4, hot stamping film heating roller 33, and hot stamping film roll Roller 35, bronzing film roll storage roller 31 and two pendulum rollers 32 form.

[0024] Such as figure 2 , the print drive roller 21 and the print traction roller 22 are respectively rotatably supported on the support 1, the print drive roller 21 is connected to the print traction roller 22 through the transmission unit 8 to form a print travel for conveying the print 7 Unit 2.

[0025] The bronzing film heating roller 33 is rotatably and liftably arranged on the support 1 . The pendulum roller 32 is swingably supported on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com