Water-based temperature-resistant stampable ink composition for aluminum sprayed paper

A technology of ink composition and aluminum-sprayed paper, which is applied in the field of ink, can solve problems such as poor temperature resistance, missing patterns, and pasting of printed matter, and achieve the effects of improving performance indicators, improving bronzing performance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

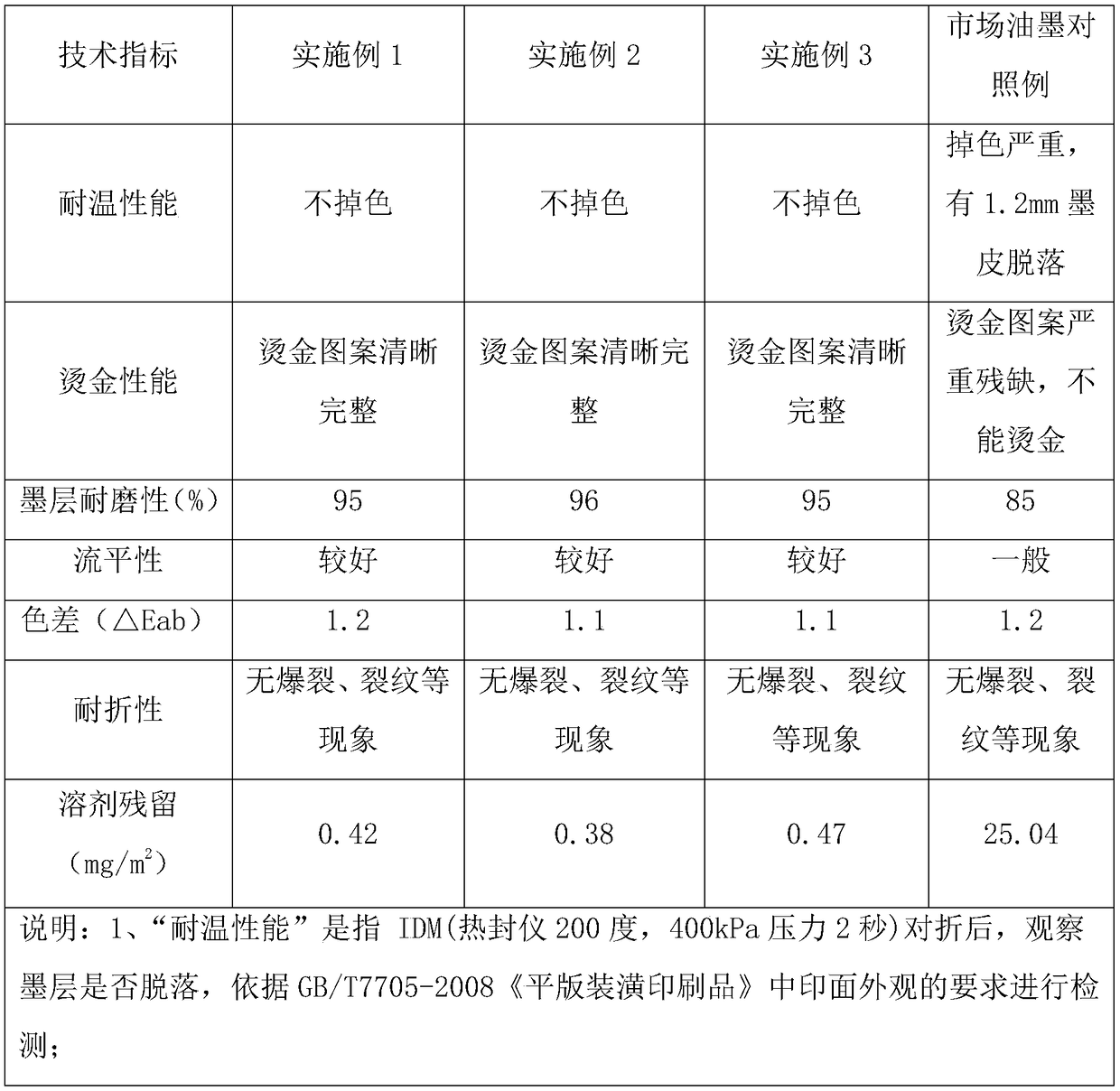

Examples

Embodiment 1

[0015] The 2000g composition contains 300g of water-based vinyl resin 701, 500g of water-based polyurethane resin FW-33-37, 130g of water-based polypropylene wax 2101, 80g of WinSperse4000, 110g of monoethanolamine, 260g of PR57:1, 65g of ethanol, and the rest is water. Use an emulsifier to stir at a high speed (2500-3000 rpm for 30-40 minutes), then use a grinder to grind at a speed of 0.2-0.3L per minute. After grinding three times, do relevant performance tests, directly take 500g of color and add 200g Dilute the 1:1 mixed solution of ethanol and water as ink, and then dilute 30-40% with ethanol and water 1:1 as the ink on the machine, apply the ink to the surface of the aluminum spray paper, put it in an 80-degree oven for 2 seconds to dry After that, let it dry before testing.

Embodiment 2

[0017] The 2000g composition contains 370g of water-based vinyl resin 701, 450g of water-based polyurethane resin FW-33-37, 110g of water-based polypropylene wax 2101, 100g of WinSperse4000, 100g of monoethanolamine, 280g of PR57:1, 80g of ethanol, and the rest is water. Use an emulsifier to stir at high speed (2500-3000 rpm for 30-40 minutes), then use a grinder to grind at a speed of 0.2-0.3L per minute. After grinding three times, do relevant performance tests, directly take 500g of color and add 150g Dilute the 1:1 mixed solution of ethanol and water as ink, and then dilute 30-40% with ethanol and water 1:1 as the ink on the machine, apply the ink to the surface of the aluminum spray paper, put it in an 80-degree oven for 2 seconds to dry After that, let it dry before testing.

Embodiment 3

[0019] The composition of 2000 parts by weight includes 260g of water-based vinyl resin 701, 400g of water-based polyurethane resin FW-33-37400g, 150g of water-based polypropylene wax 2101, 100g of WinSperse4000, 90g of glycol amine, 300g of PR57:1, 100g of ethanol, and the rest are water. Use an emulsifier to stir at high speed (2500-3000 rpm for 30-40 minutes), then use a grinder to grind at a speed of 0.2-0.3L per minute. After grinding three times, do relevant performance tests, directly take 500g of color and add 150g Dilute the 1:1 mixed solution of ethanol and water as ink, and then dilute 30-40% with ethanol and water 1:1 as the ink on the machine, apply the ink to the surface of the aluminum spray paper, put it in an 80-degree oven for 2 seconds to dry After that, let it dry before testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com