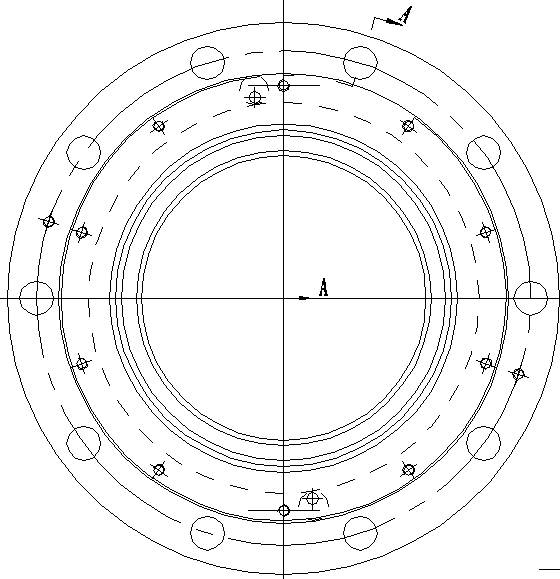

Heavy track rear hub bearing combination

A heavy-duty truck, rear wheel hub technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of easy jumping, easy breakage of the wheel hub, affecting the service life of the wheel hub, etc., to achieve the effect of good rigidity and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

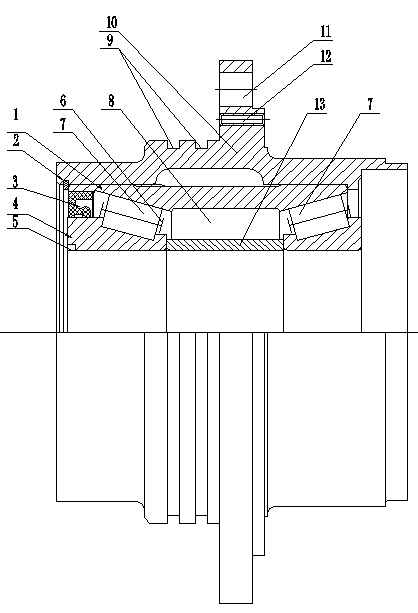

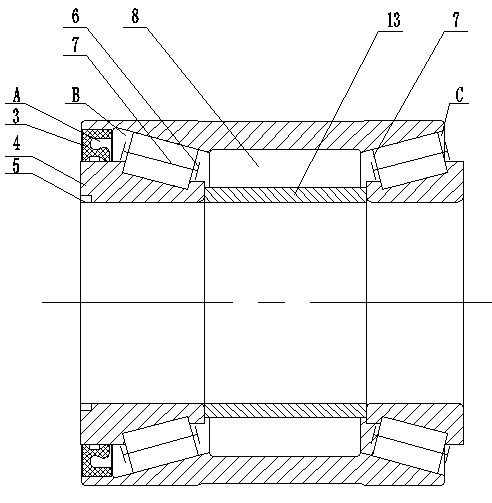

[0021] Selected embodiments of the present invention are now explained with reference to the accompanying drawings. The following descriptions of the embodiments of the present invention disclosed by those skilled in the art are only exemplary and not intended to limit the solutions of the present invention.

[0022] A heavy-duty truck rear wheel hub bearing combination, including a hub 10 and a bearing assembly arranged in the hub 10, the bearing assembly is an integrated structure, including an outer ring 1, two inner rings 4, a spacer ring 13, and two cages 6 and two rows of tapered rollers 7, two inner rings 4 are spaced in the outer ring 1 through the spacer ring 13, and a chamber is formed between the outer wall of the inner ring 4, the inner wall of the spacer ring 13 and the inner wall of the outer ring 1, and the chamber includes sequentially Set the sealing part A, the first mounting part B, the oil passage 8 and the second mounting part C, two rows of tapered rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com