Manufacturing method for metal interconnection layer

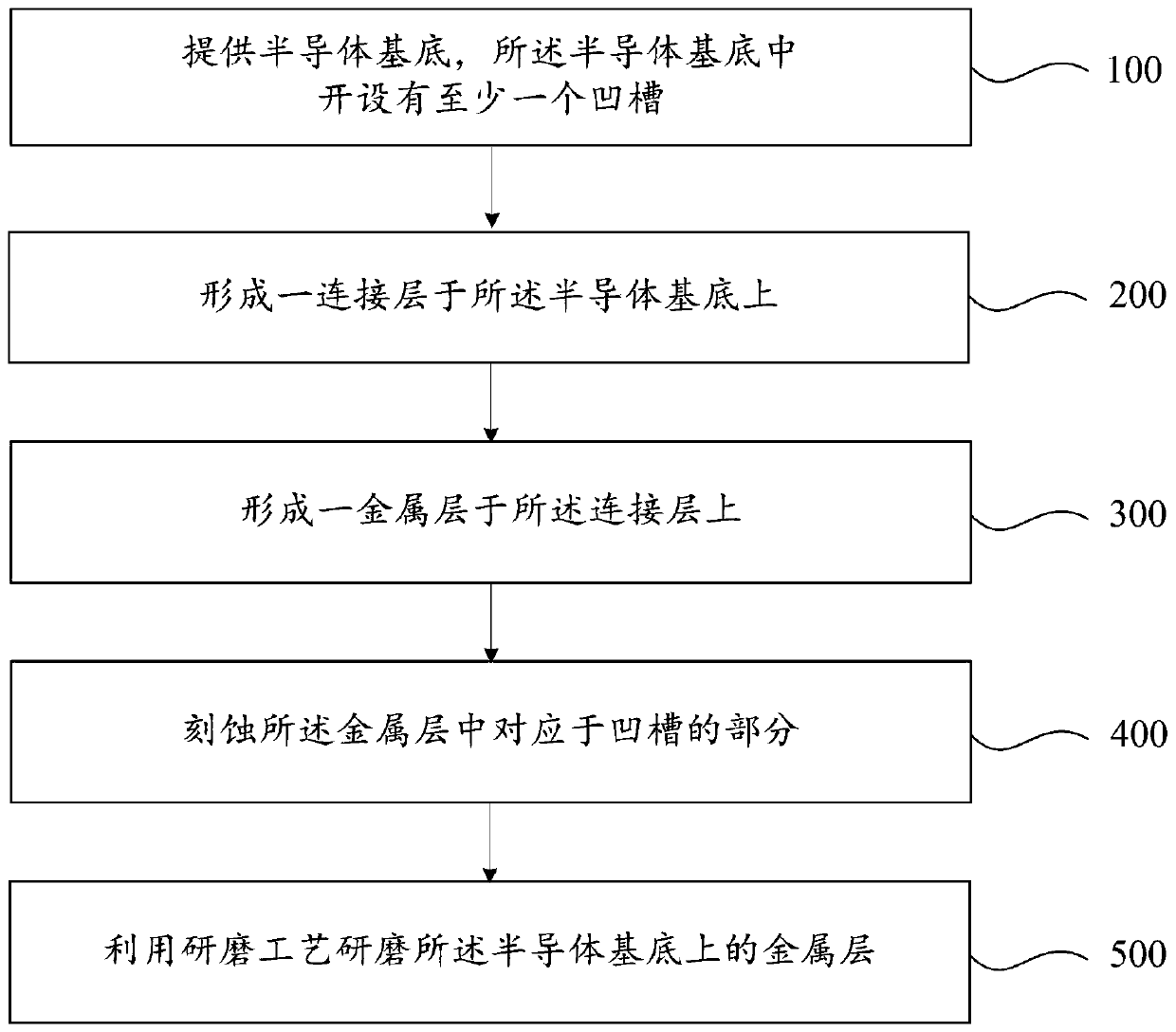

A technology of metal interconnection layer and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of low resistance characteristics and stability of metal interconnection layer, surface depression of metal interconnection layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

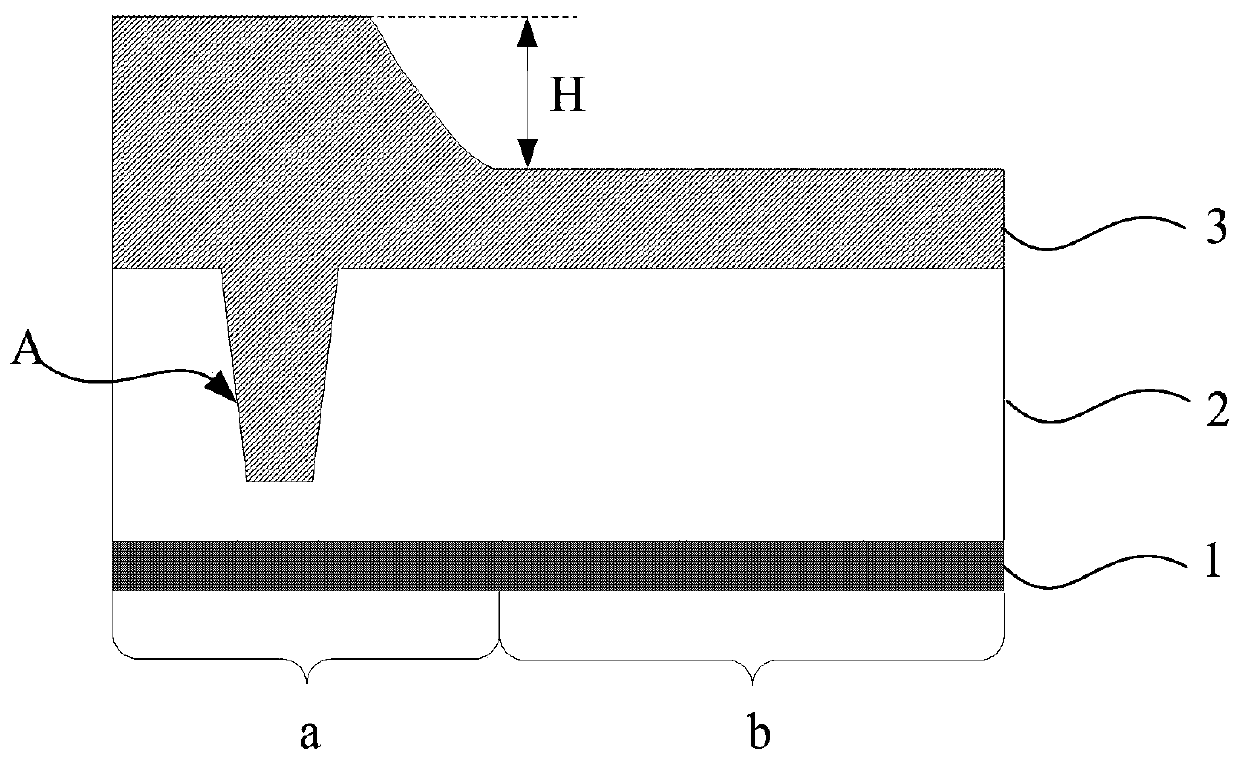

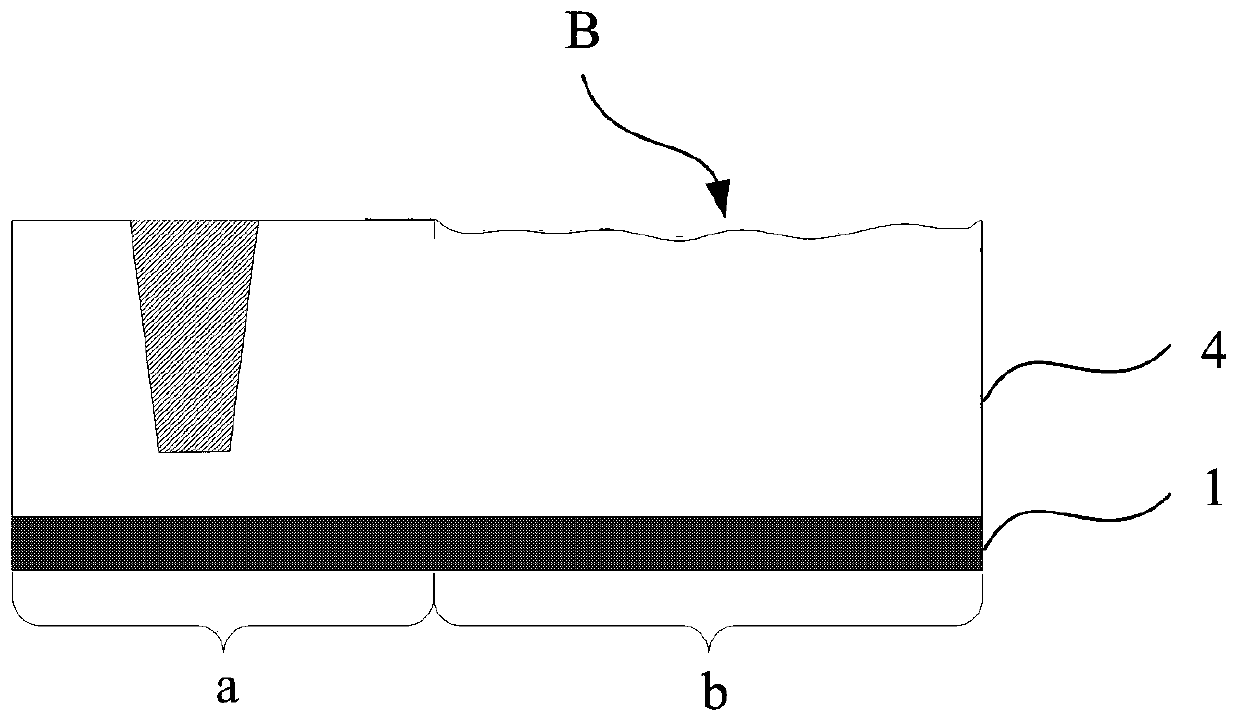

[0030] As described in the background art, in the related art, when forming a metal interconnection layer, it is usually provided such as figure 1 A semiconductor substrate 1 is shown and an insulating layer 2 formed on the semiconductor substrate 1, wherein the semiconductor substrate 1 defines a groove area a and a flat area b. And, a groove A is also formed in a portion of the insulating layer 2 corresponding to the groove region a. After that, a copper layer 3 is electroplated on the insulating layer 2 , so that the copper layer 3 fills the groove A. The semiconductor substrate 1 is then ground by a grinding process, and the copper layer above the insulating layer 2 is ground away to expose the surface of the insulating layer 2, thereby preparing a metal interconnection layer.

[0031] However, in the related art, when the copper layer 3 is electroplated, since the copper layer 3 needs to fill the groove A, the growth rate of the copper layer corresponding to the groove A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com