Centrifugal coating device and coating method for prefabricated insulator

A factory prefabricated and coated device technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of affecting finished products, unreasonable, high maintenance costs, etc., and achieve the effects of improved efficiency, uniform thickness, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

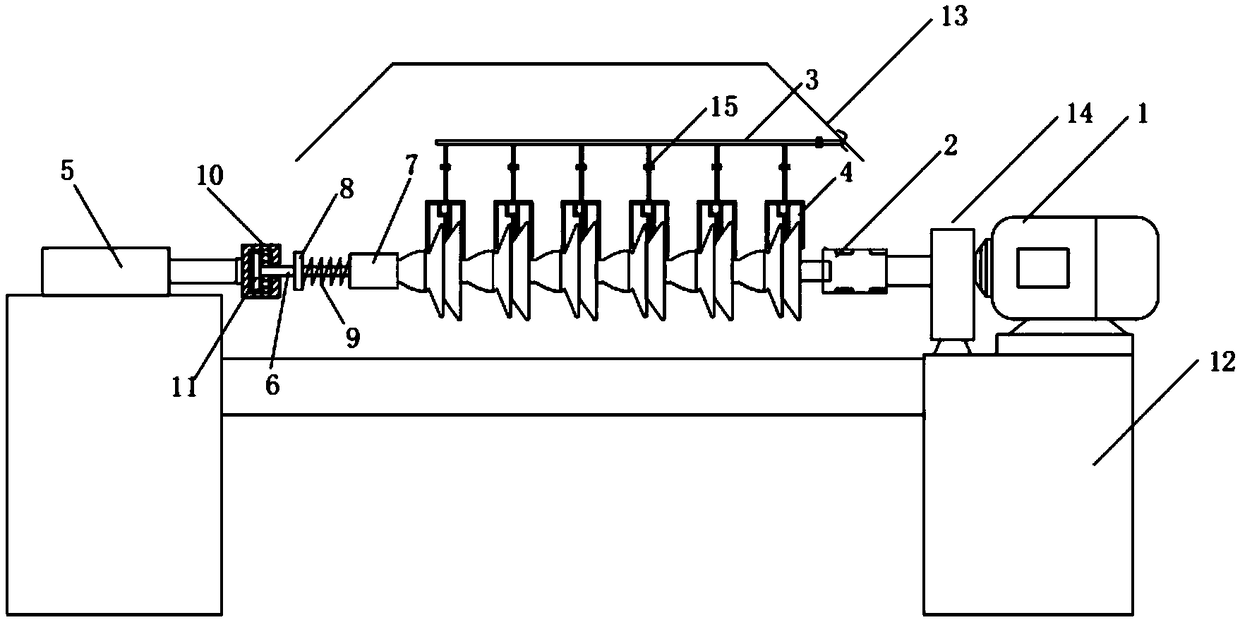

[0046] Specific Example 1: Centrifugal Coating of Chained Double Umbrella Insulators

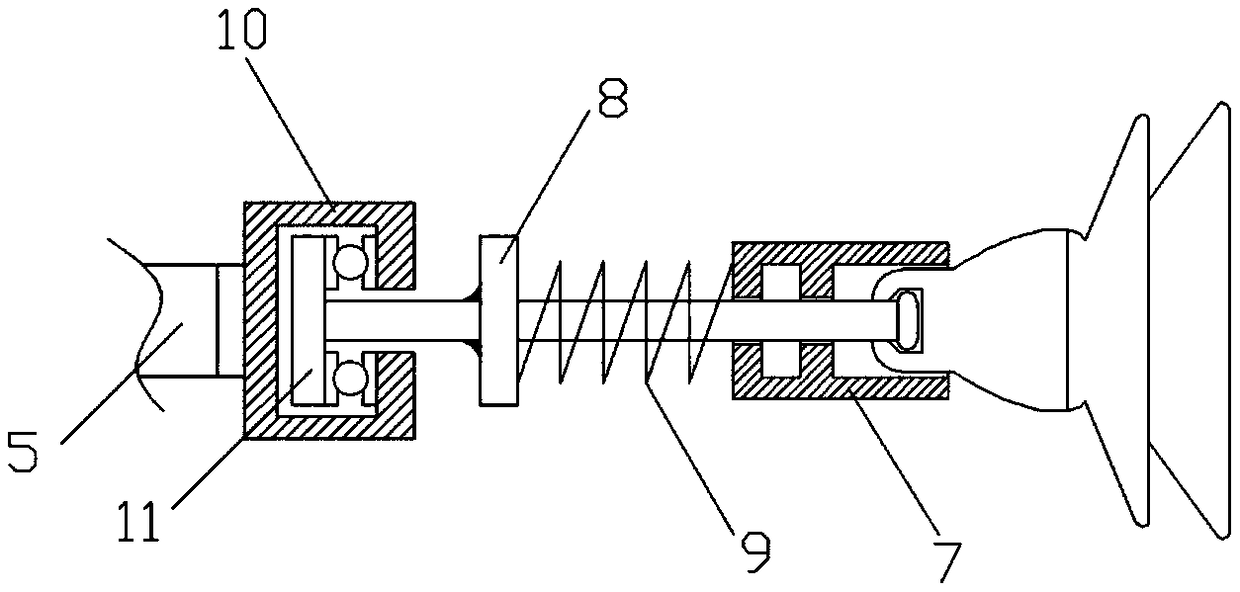

[0047] 1. After the lap joint is completed, the chain-type double-umbrella insulator string is pulled and fixed by the traction device, so that the insulators will not hang down; make the ball-end hanging ring on the tail of the last insulator of the insulator and the bowl head at the end of the coupling 2 The hanging ring is hooked and connected, and the bowl head hanging ring on the head of the first-stage insulator is pulled and fixed by the traction device, which is convenient for hanging after the coating is completed. The motor 1 and the insulator are fixedly connected by a coupling 2, and the coupling 2 has a photoelectric speed sensor for automatic control of the revolution angle. The photoelectric speed sensor is electrically connected with the PLC. The photoelectric speed sensor collects the number of revolutions of the motor, transmits the signal to the PLC, and controls the revo...

specific Embodiment 2

[0052] Specific embodiment 2: column type insulator coating centrifugal coating

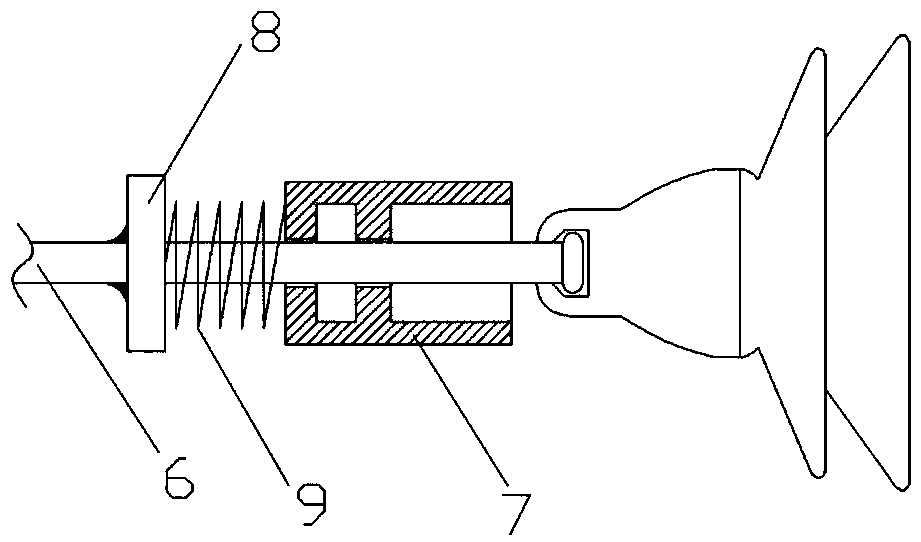

[0053] 1. The post insulator does not need to be fixed by tension. The ball-end hanging ring on the tail of the insulator is hooked to the bowl-head hanging ring at the end of the coupling 2, and the other end is suspended in the air. It is connected to the bottom end of the fitting for convenience after coating is completed. hanging. The motor 1 and the insulator are fixedly connected by a shaft coupling.

[0054] 2. The paint is transported to the root of the shed of the insulator through the paint pipeline, and the motor 1 drives the insulator to perform centrifugal motion, thereby realizing spot coating. Through the action of centrifugal force, the upper and lower sides of the insulator are coated at the same time, and finally meet at the edge of the insulator to form a complete overcoating process. And it is evenly coated round by round to form a closed annular recoating process.

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com