Patents

Literature

63results about How to "No-bump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

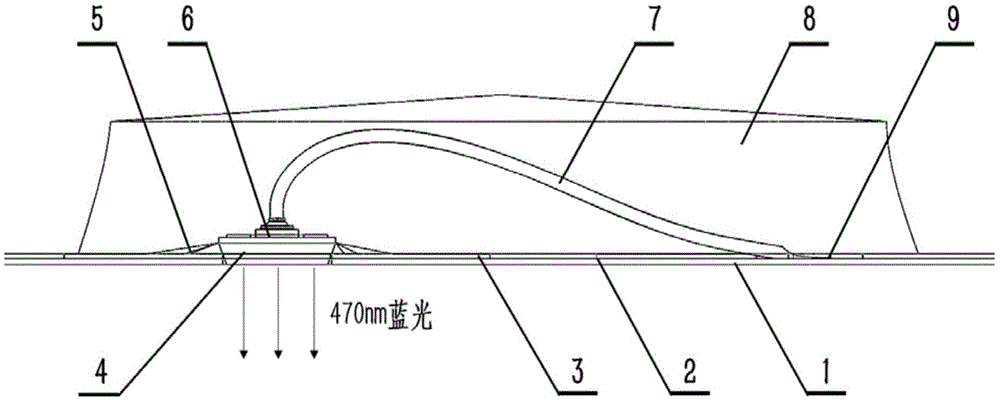

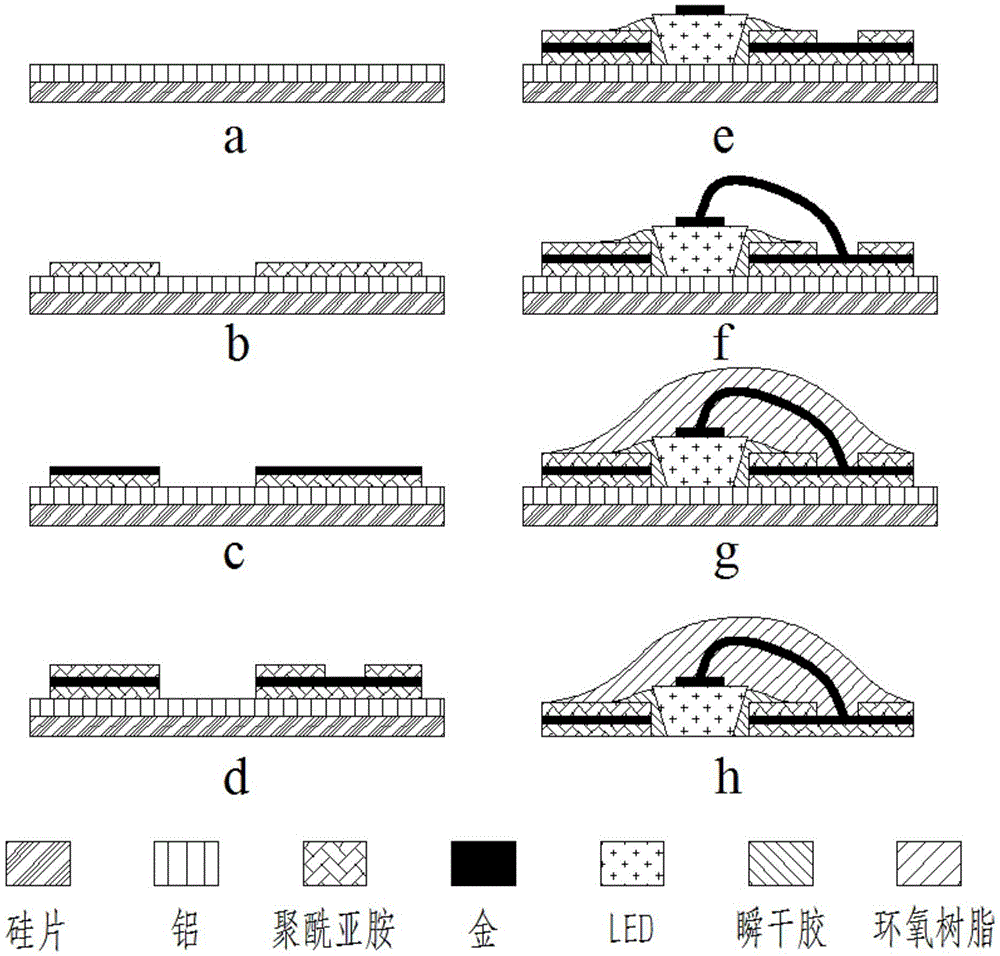

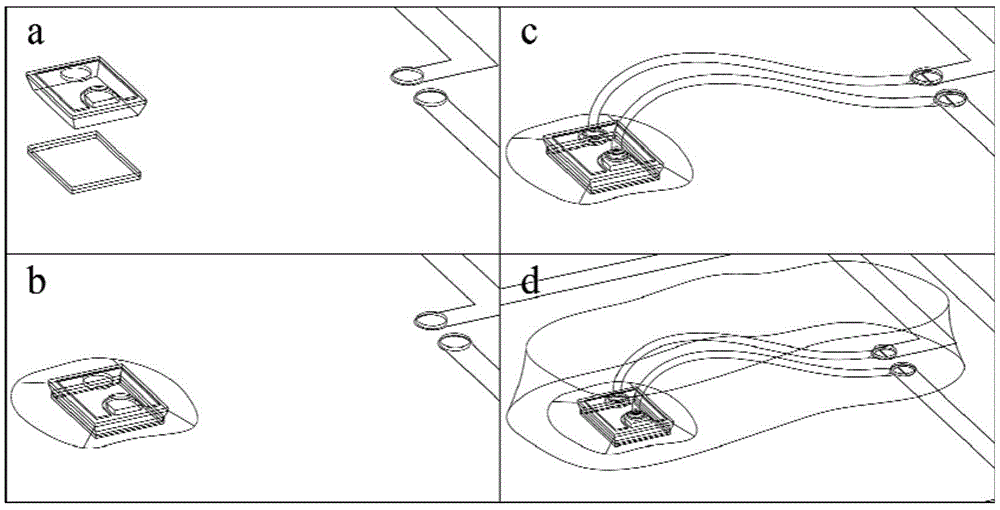

Light-stimulated neural electrode device based on golden wire ball bonding method and manufacturing method thereof

ActiveCN105428488ASimple processTo achieve the purpose of light stimulationLight therapySemiconductor devicesInsulation layerTransfection

The invention provides a light-simulated neural electrode device based on a golden wire ball bonding method and a manufacturing method thereof. The method comprises steps: 1, a patterned bottom polyimide insulation layer is manufactured, and square holes are opened; 2, a middle circuit layer is manufactured; 3; a patterned top polyimide insulation layer is manufactured, and square holes and round holes are opened at the same positions; 4; a micro LED bare chip is placed in two layers of polyimide square holes, and instantaneous drying glue is applied to the periphery of the micro LED bare chip; 5, by adopting the golden wire ball bonding method, the micro LED bare chip and a golden circuit layer are connected; 6, epoxy resin glue is applied for realizing packaging; and 7, a sacrificial layer is corroded, and electrode release is completed. The electrode device of the invention mainly aims at providing power for the micro LED bare chip, and light emitting by the LED carries out light simulation on an experimental animal with specific gene transfection; and the process is simple, the LED is arranged flexibly, devices of different forms can be manufactured according to different simulation areas, and a new tool is provided for implantable medical device development and neuroscience research.

Owner:SHANGHAI JIAO TONG UNIV

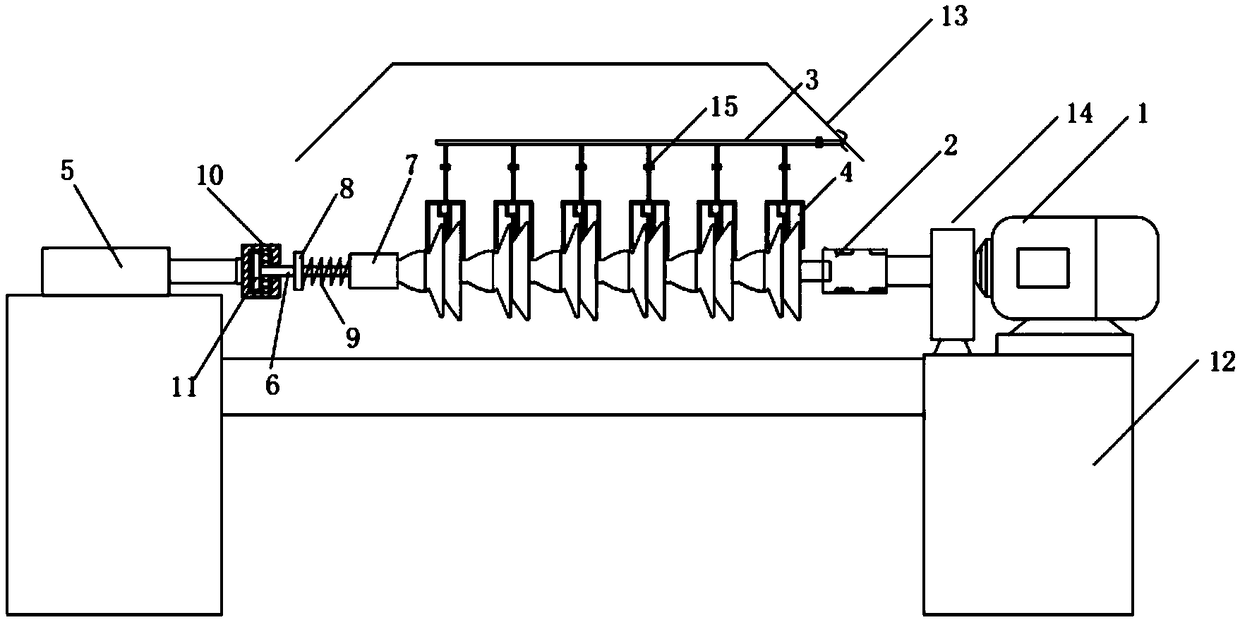

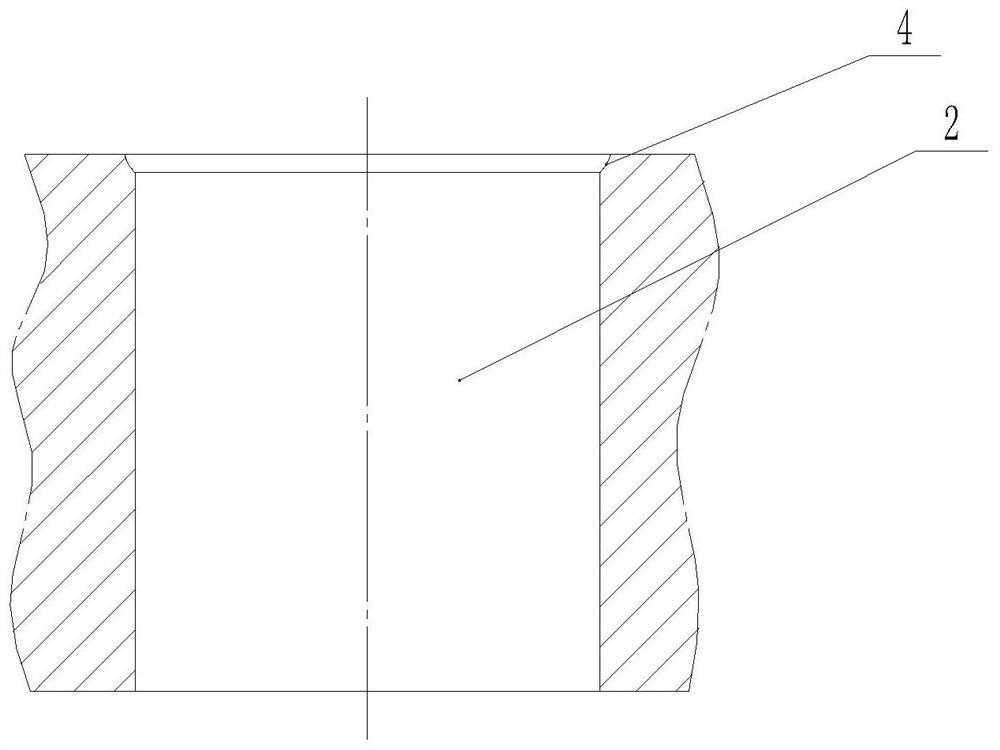

Centrifugal coating device and coating method for prefabricated insulator

The invention belongs to the field of insulator composite anti-pollution flashover coating equipment and method, in particular to a centrifugal coating device and a coating method applied to insulatorcoating. The invention adopts the centrifugal coating method with the rotating coating reagent of the workpiece insulator stationary, the coating thickness is uniform, smooth, free of bubble, bump, hanging flow, concave mark and other defects, and the coating process is convenient to disassemble and assemble. Compared with the traditional way of spraying by manipulator, the safety is greatly improved, and the quality and efficiency of the finished product are significantly improved compared with the artificial dip coating. The device and the coating method of the invention are suitable for coating outer umbrella insulators (single umbrella, double umbrella or multiple umbrellas), column insulators and other insulators.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

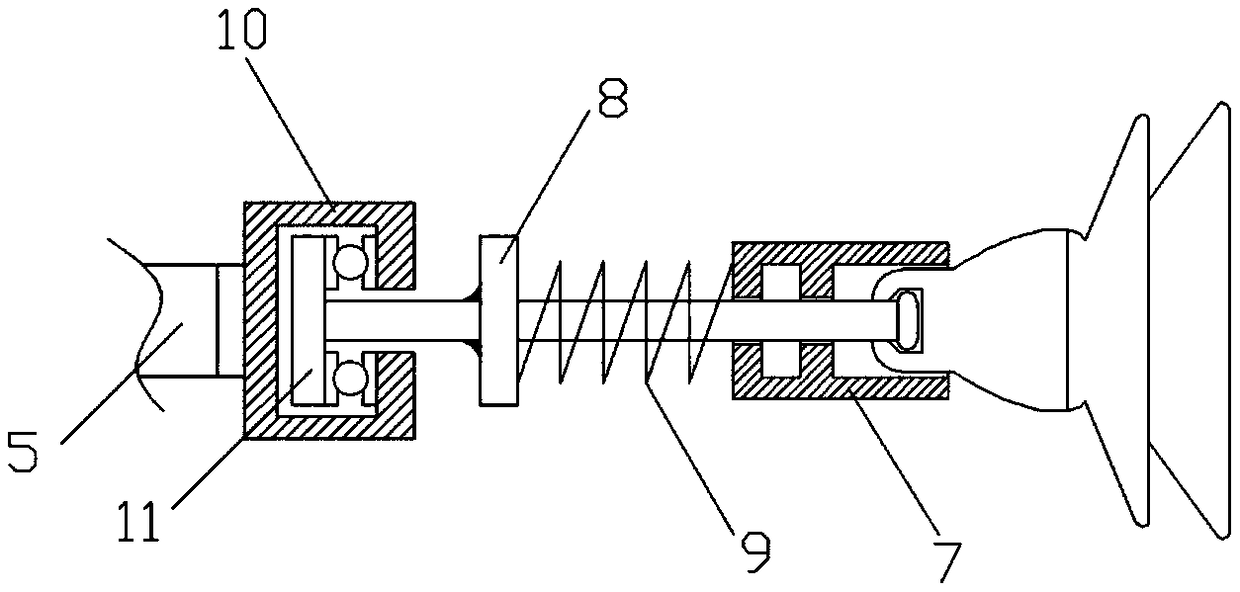

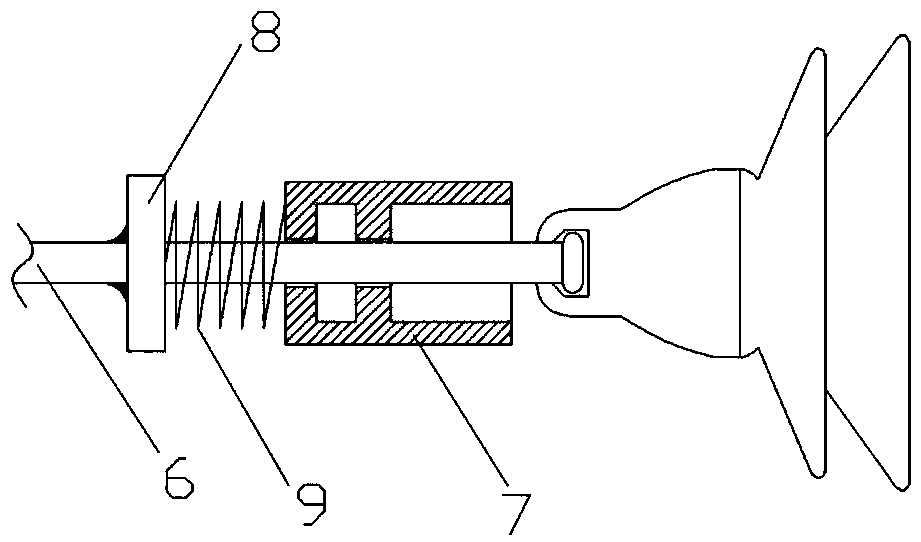

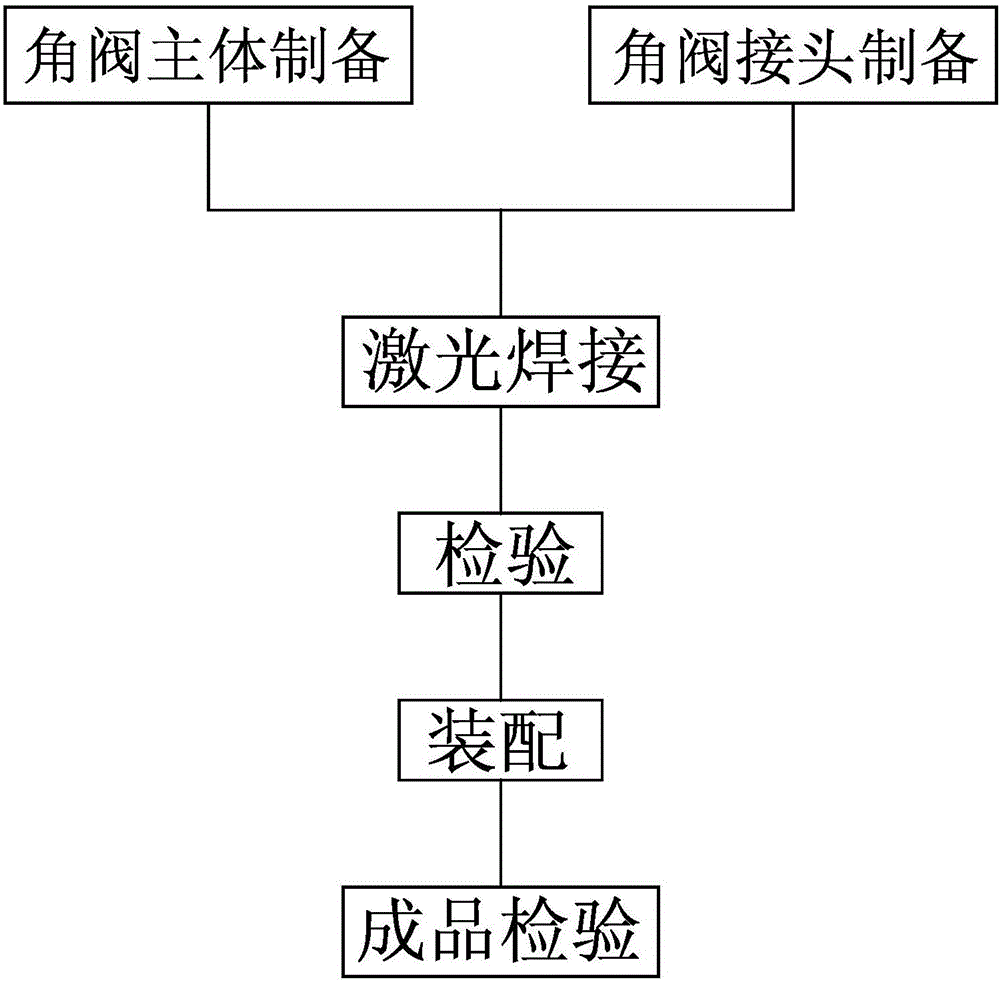

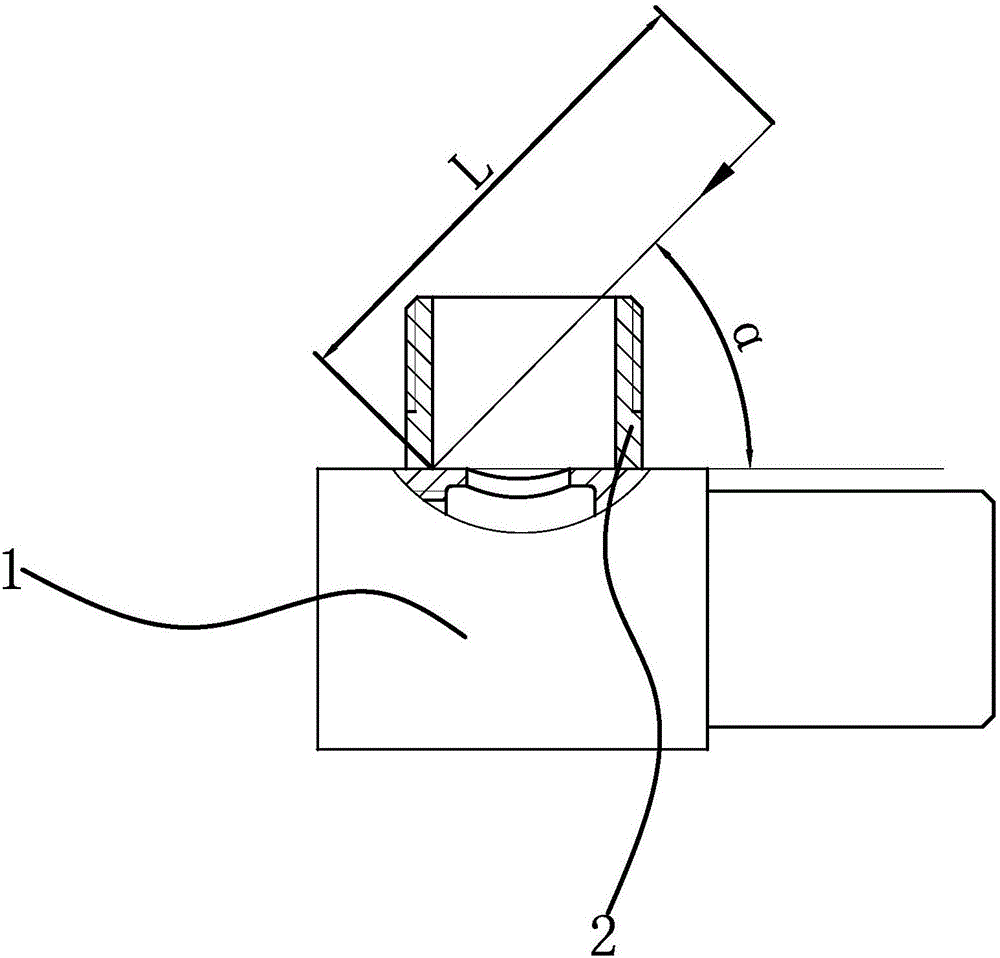

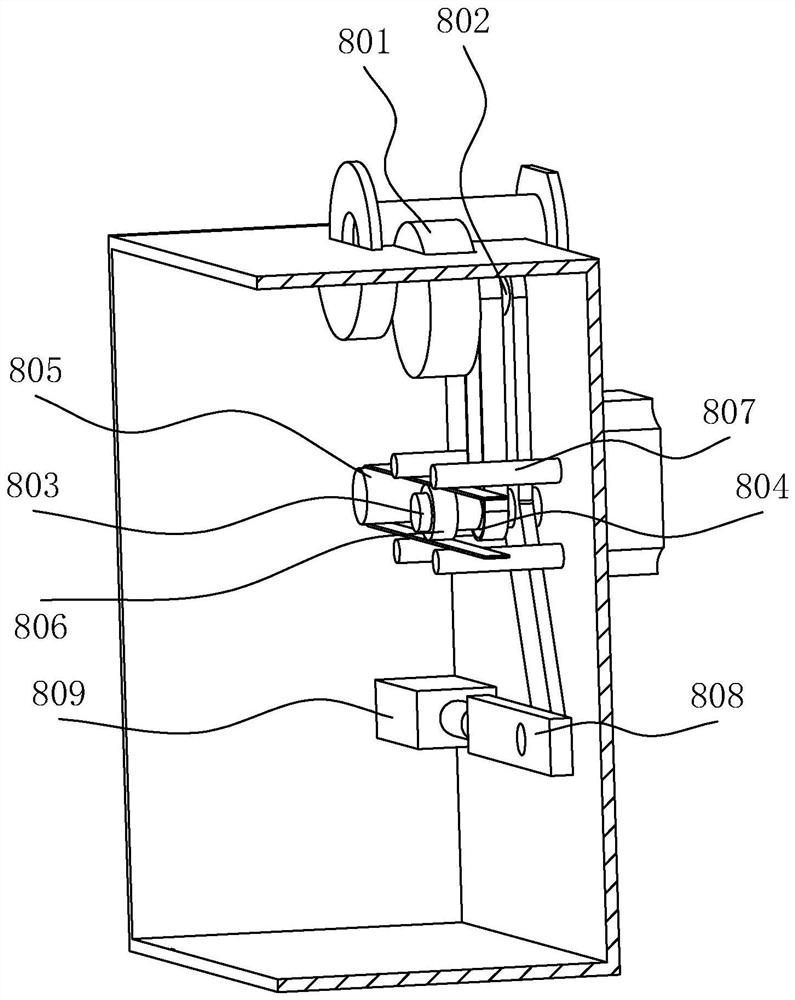

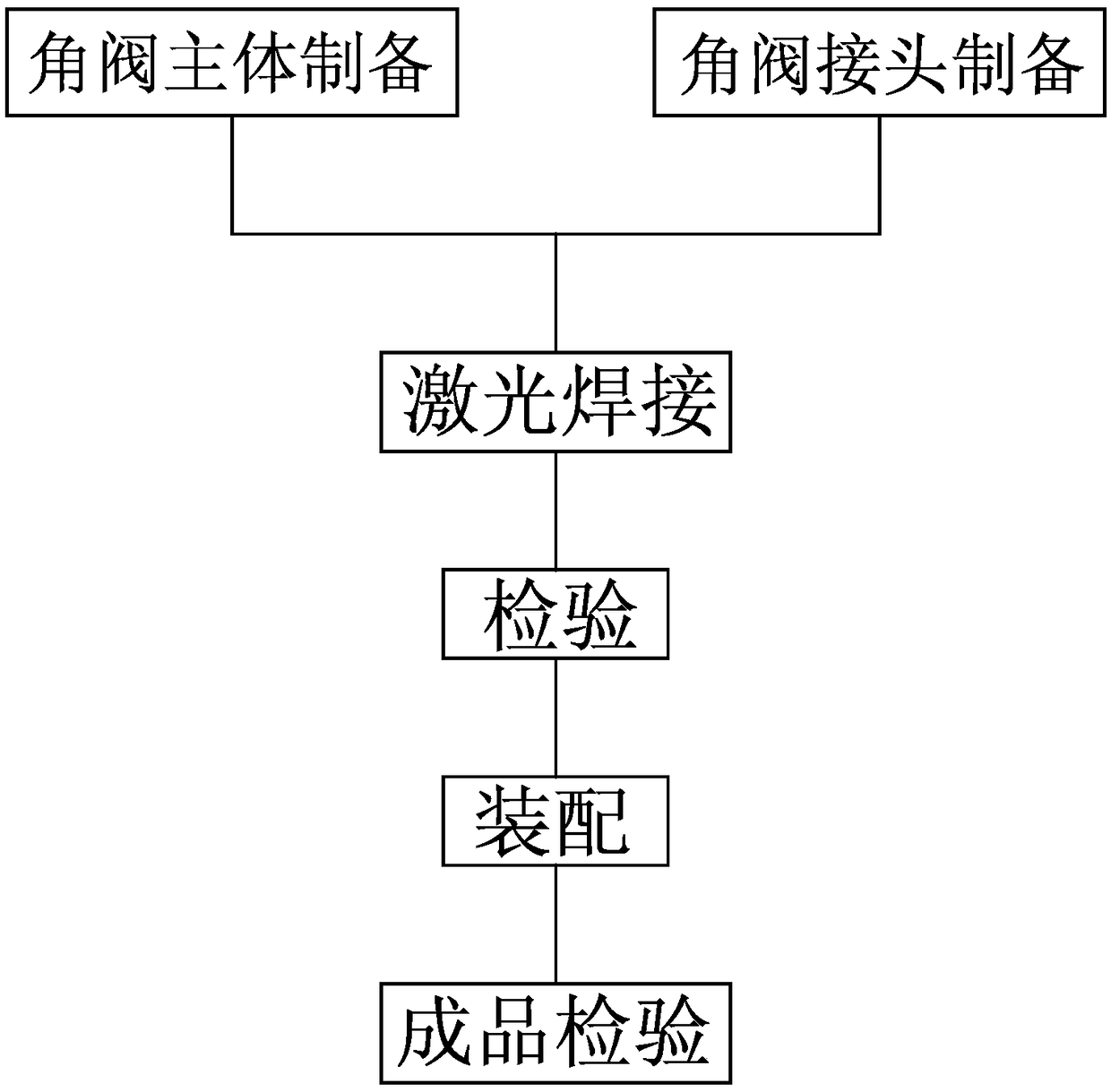

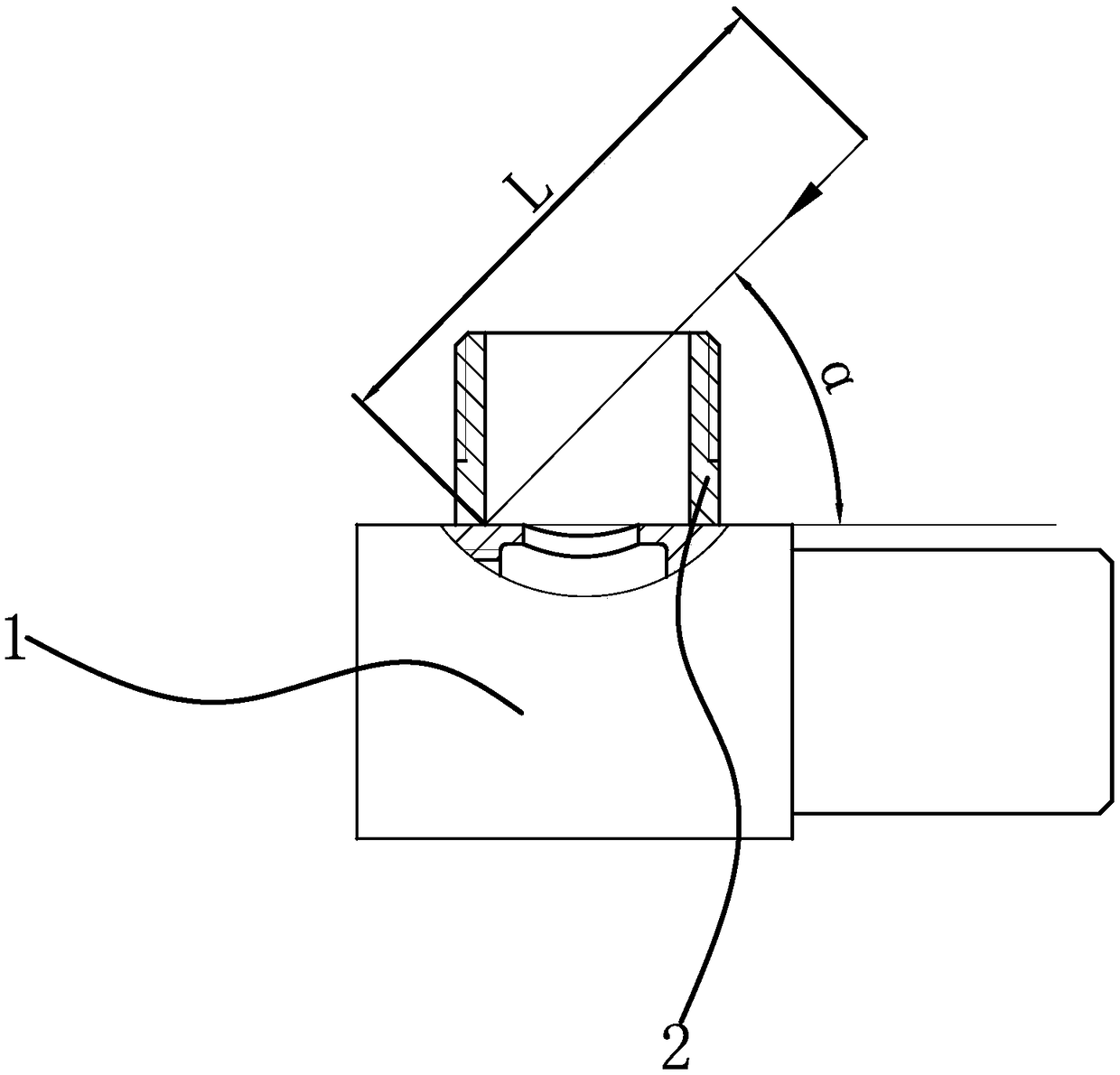

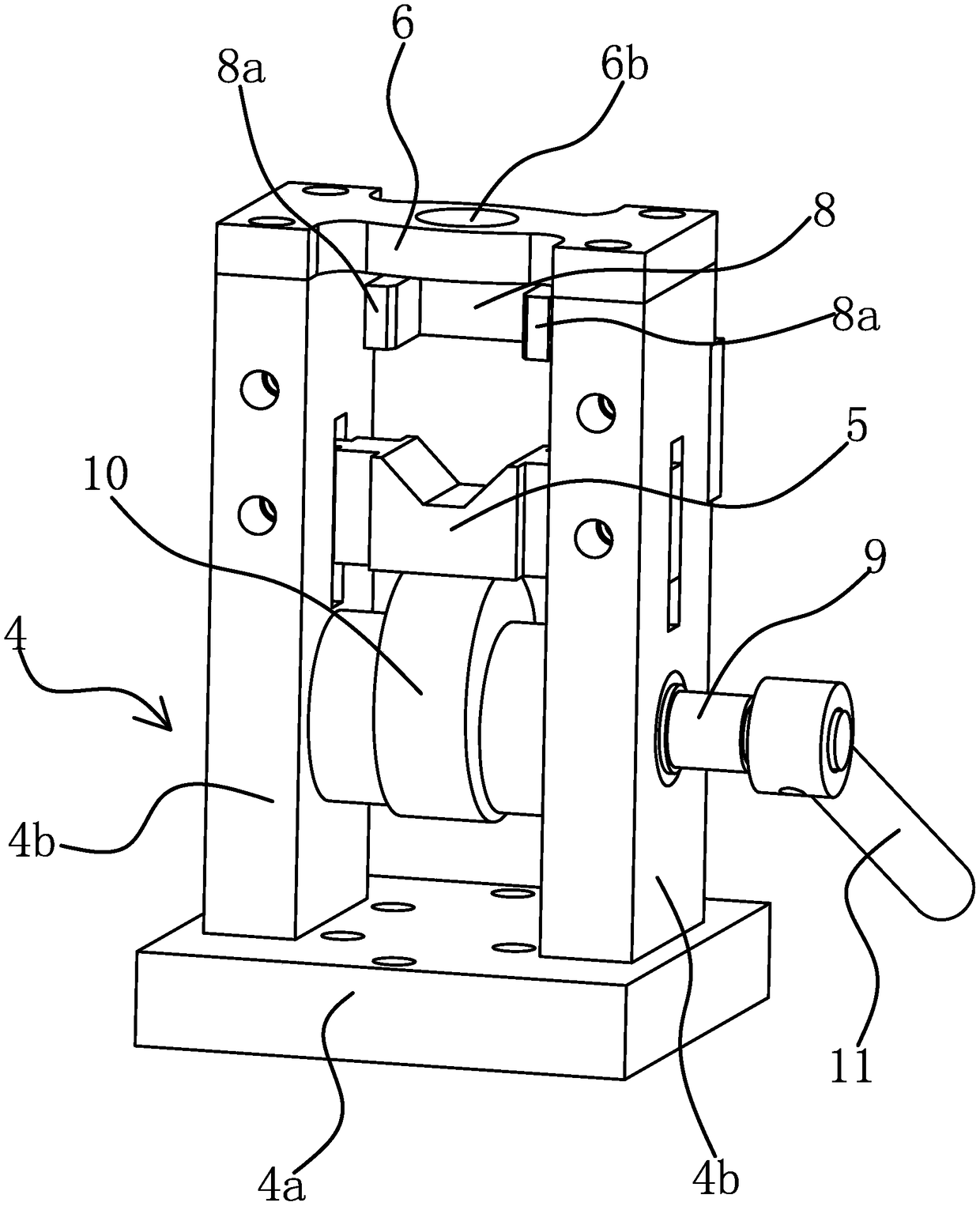

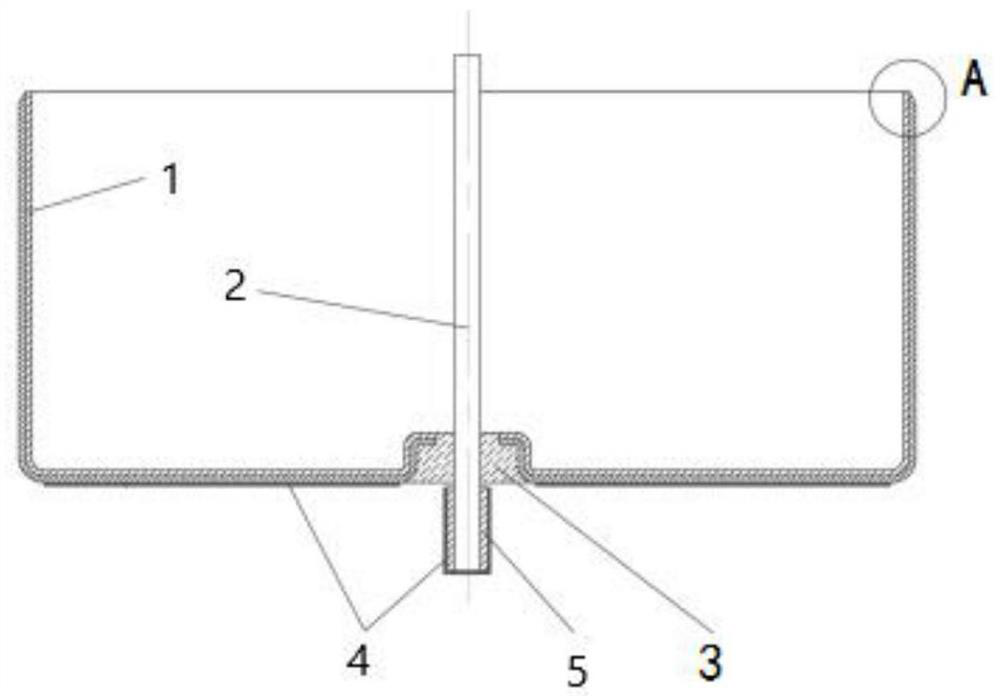

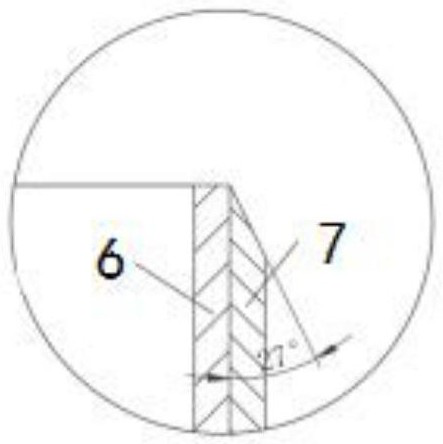

Angle valve as well as angle valve manufacturing process and positioning tool

ActiveCN106392500AImprove the finishImprove consistencyValve housingsProduct inspectionProcess efficiency

The invention provides an angle valve as well as an angle valve manufacturing process and a positioning tool, and belongs to the technical field of valves. The angle valve manufacturing process solves the problems that an existing triangular valve manufacturing method is complex in process and is not environmentally-friendly, and surface consistency of the produced angle valve is relatively poor. The angle valve manufacturing process comprises the following steps: a, manufacturing an angle valve main body; b, manufacturing an angle valve joint; c, positioning the angle valve main body and the angle valve joint by laser welding, enabling the arc-shaped connecting surface of the angle valve joint to fit to the outer wall of the angle valve main body, integrally welding the angle valve main body and the angle valve joint inside the angle valve joint through laser welding, and injecting a laser beam from an inner hole of the angle valve joint; d, inspecting; e, assembling; and f, carrying out finished product inspection. The angle valve manufacturing process simplifies the process, improves producing and processing efficiency, and is more environmentally-friendly; and the outer surface of the manufactured valve body does not have a welding seam, so that the valve body is more flat and smooth, is better in consistency, and is better in mechanical property.

Owner:浙江苏泊尔卫浴有限公司

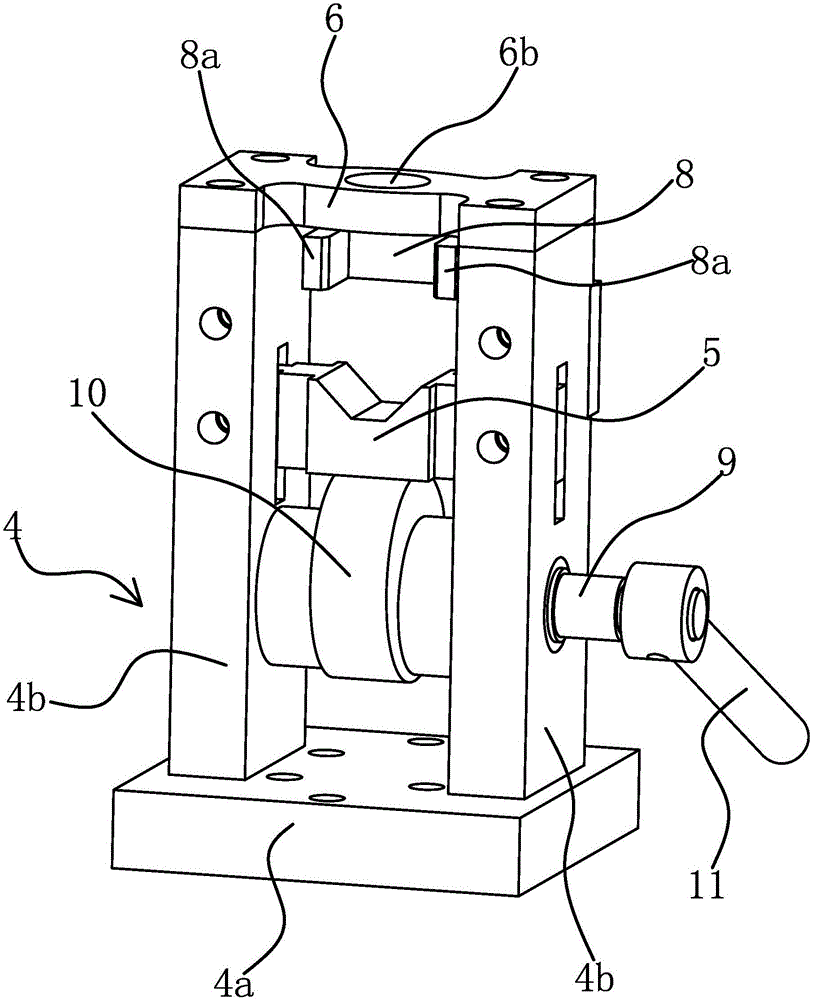

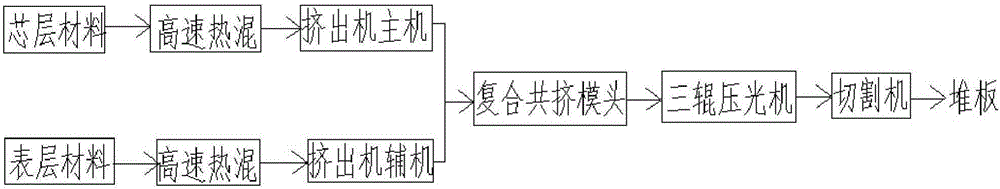

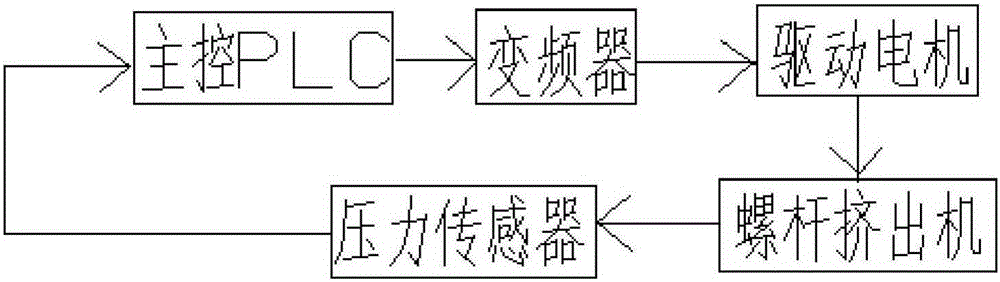

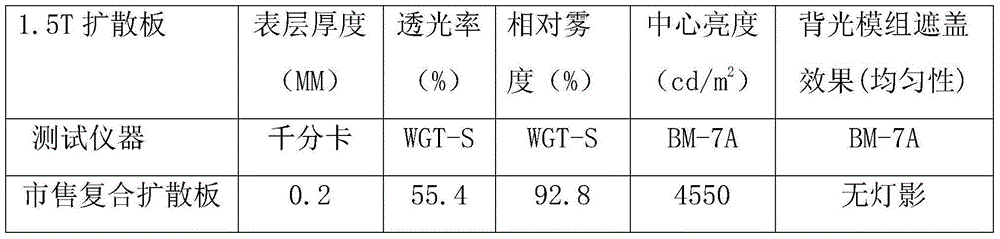

Production technology for composite co-extrusion PS diffuser plate

ActiveCN105175916AImprove optical performance indicatorsGuaranteed Diffusion EffectLuminescent compositionsSurface layerTransmittance

The invention relates to a production technology for a composite co-extrusion PS diffuser plate, and the technology mainly comprises steps of formula design, material mixing, extrusion, cutting, plate piling and the like. The material mixing step comprises high-speed hot mixing and sieving warehousing. The extrusion step employs a composite co-extrusion technology. A core-layer extruder is taken as a main machine, the main machine employs a screw with the diameter of 130 mm and the draw ratio of 38, and the main machine average rotation speed is 70 r / min. A surface-layer extruder is taken as an auxiliary machine, the auxiliary machine employs a screw with the diameter of 60 mm and the draw ratio of 33, and the auxiliary machine average rotation speed is 60 r / min. The main-machine material canister heating temperature is divided into seven stages, and the temperature is gradually raised. The auxiliary-machine material canister heating temperature is divided into five stages. Through formula design, equipment layout and technological parameter improvement, the diffuser plate is improved in light transmittance, relatively haze and center brightness, and the backlight module covering effect is good.

Owner:惠州市凯帝智光电科技有限公司

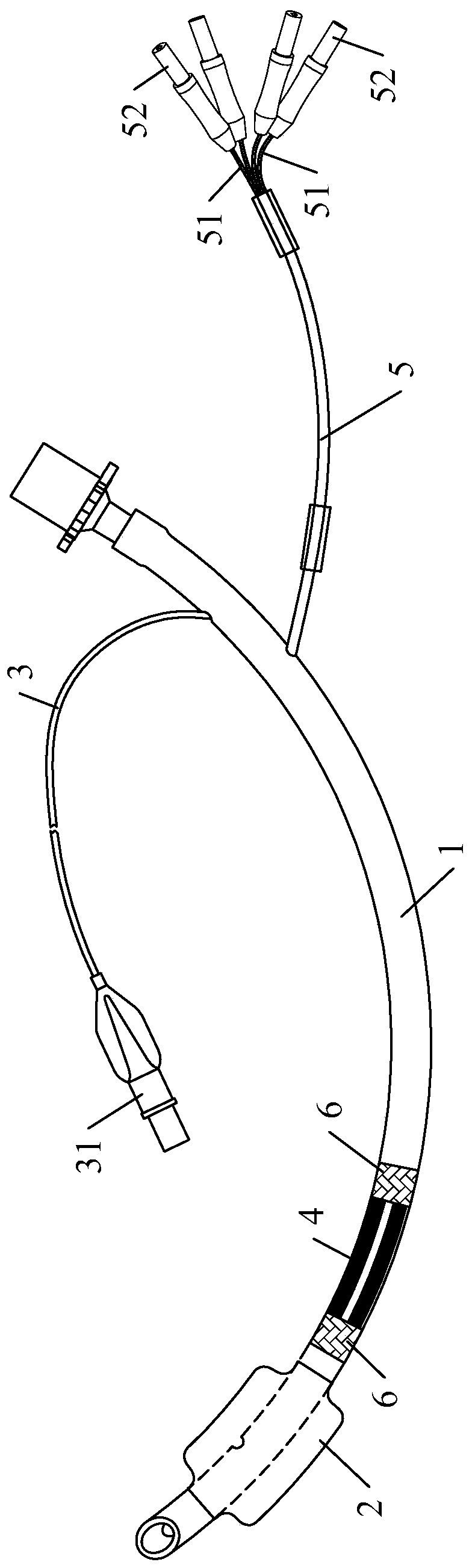

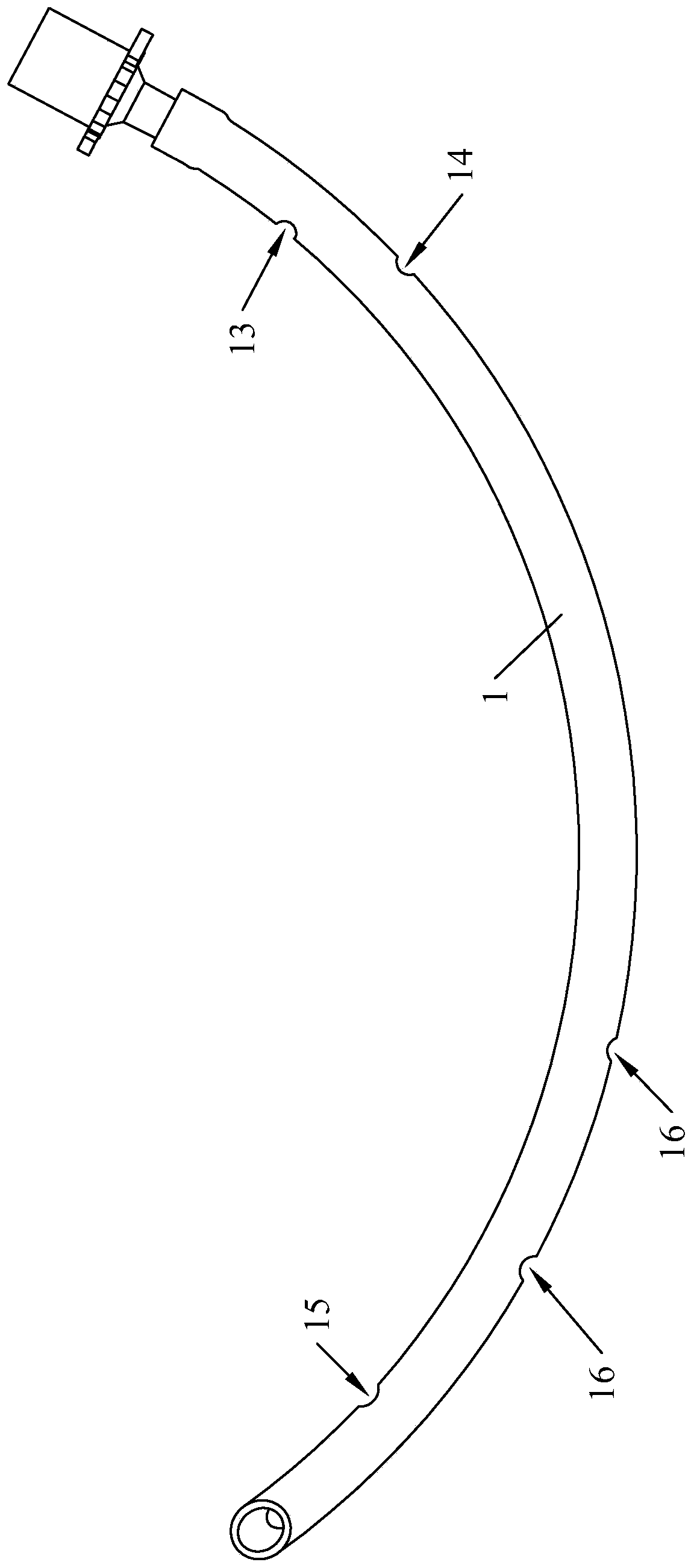

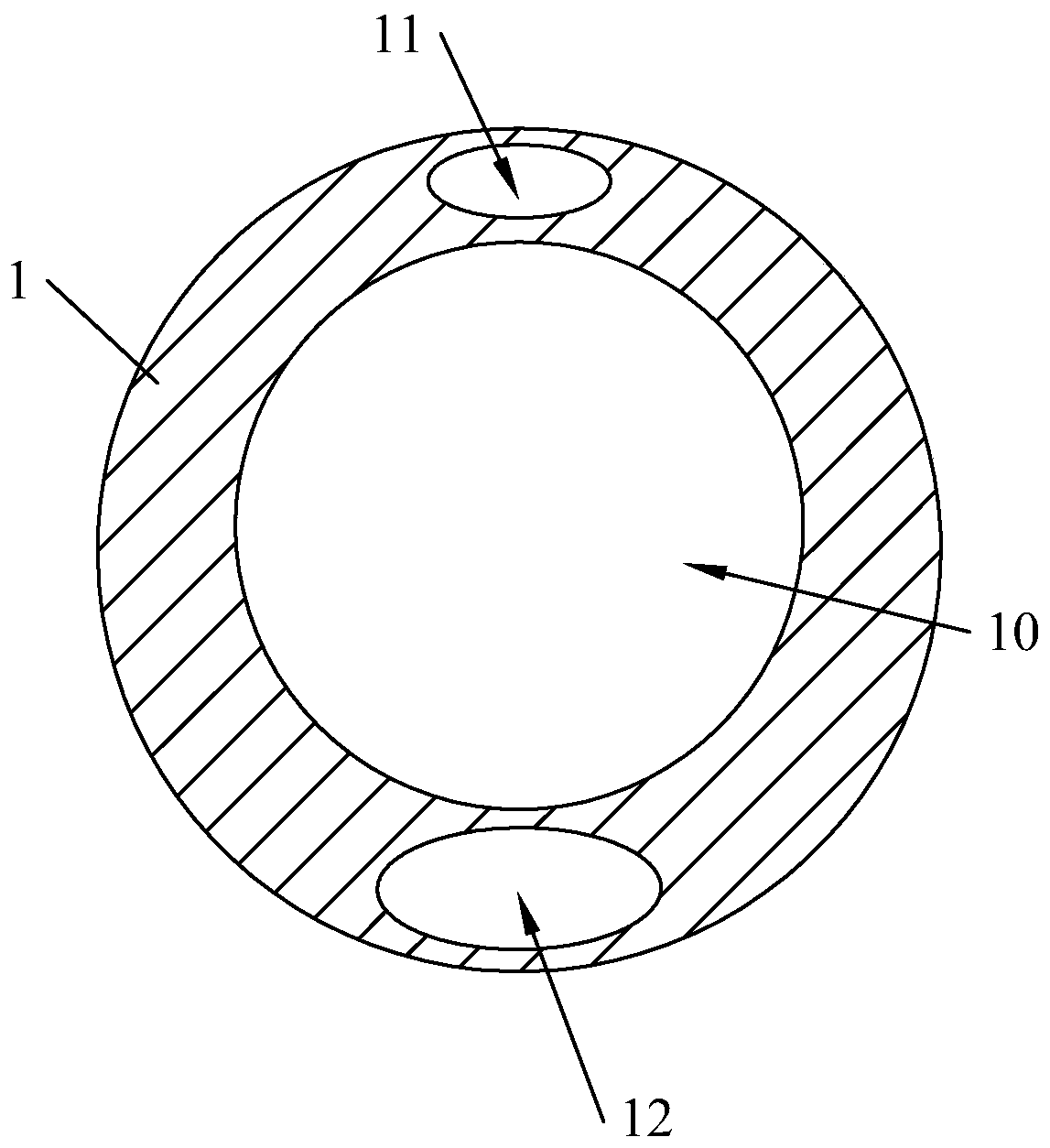

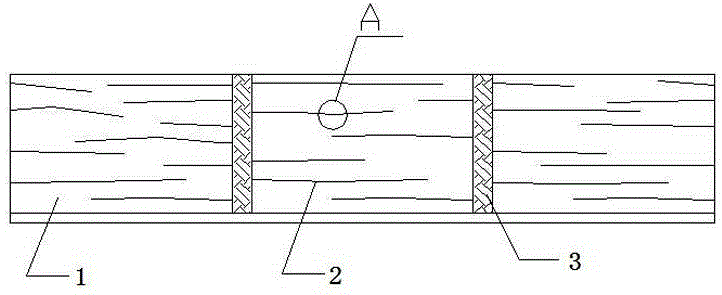

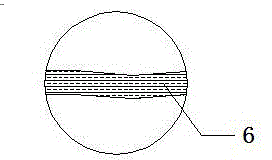

Neurological monitoring tracheal intubation tube

PendingCN110090344AReduce cross section sizeReduce riskTracheal tubesCatheterIntratracheal intubationCuff

The present invention discloses a neurological monitoring tracheal intubation tube. The neurological monitoring tracheal intubation tube comprises a tube body, an inflatable cuff, an inflation tube and an electrode connection wire, the inflatable cuff is fixed to one end of the tube body, a tracheal groove is arranged in a tube wall of the tube body, both ends of the tracheal groove respectively passes through a first inlet and a first outlet of the tube wall, the inflatable tube is accommodated in the tracheal groove, besides, one end of the inflation tube extends out from the first inlet andthe other end is connected with the inflatable cuff through the first outlet, one end of the tube body is also provided with a contact electrode, a wire groove is also arranged in the tube wall of the tube body, both ends of the wire groove is respectively connected with a second inlet and a second outlet, the electrode connection wire is accommodated in the wire groove, and besides, one end of the electrode connection wire extends out from the second inlet and the other end is connected with the contact electrode through the second outlet. The neurological monitoring tracheal intubation tubeenables operations to be simpler when the intubation tube is inserted in an operation by the built-in tube and wire, at the same time also enables outer circumference of the tube body to be more regular without protrusions, thus further reduces risks of abrasion of patient tissues and is higher in safety.

Owner:康柏医疗器械(惠州)有限公司

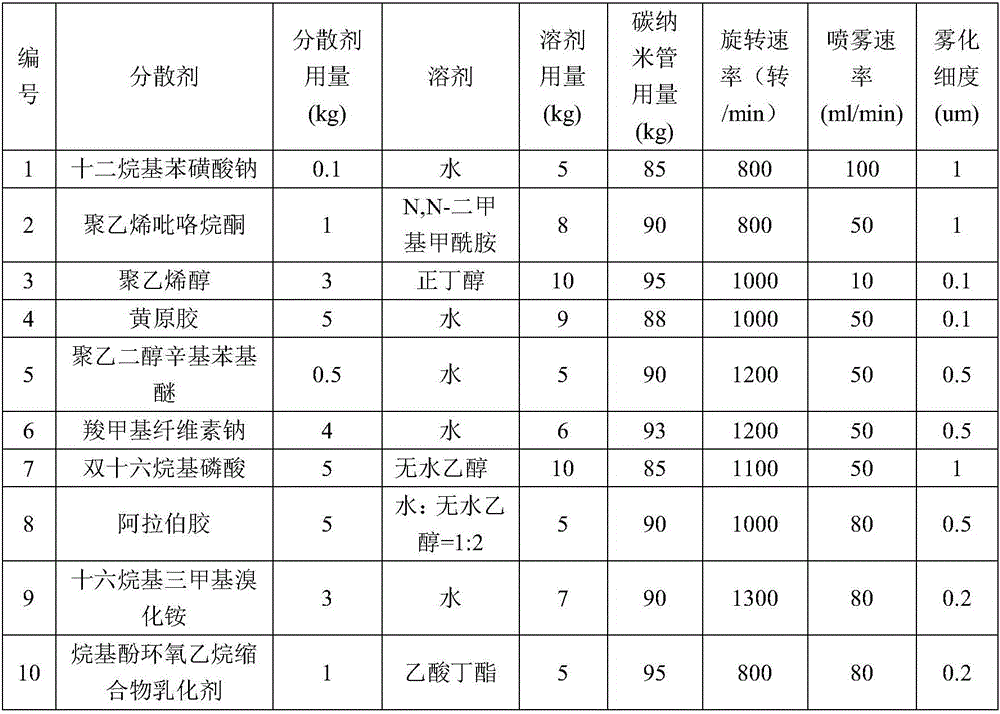

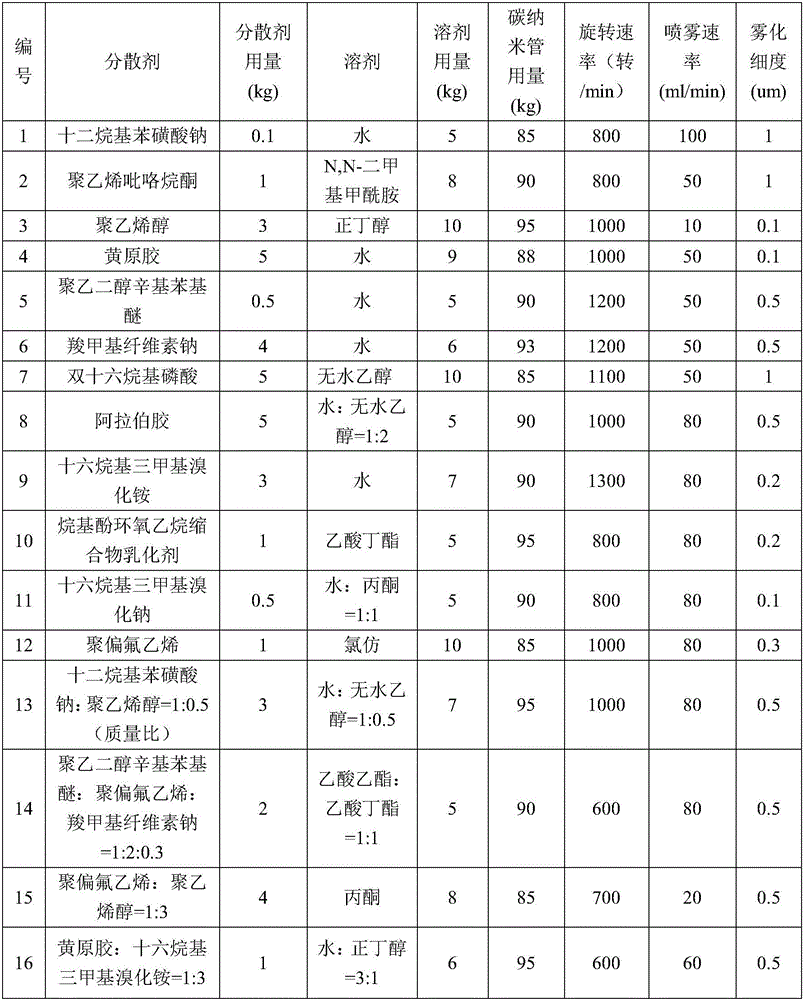

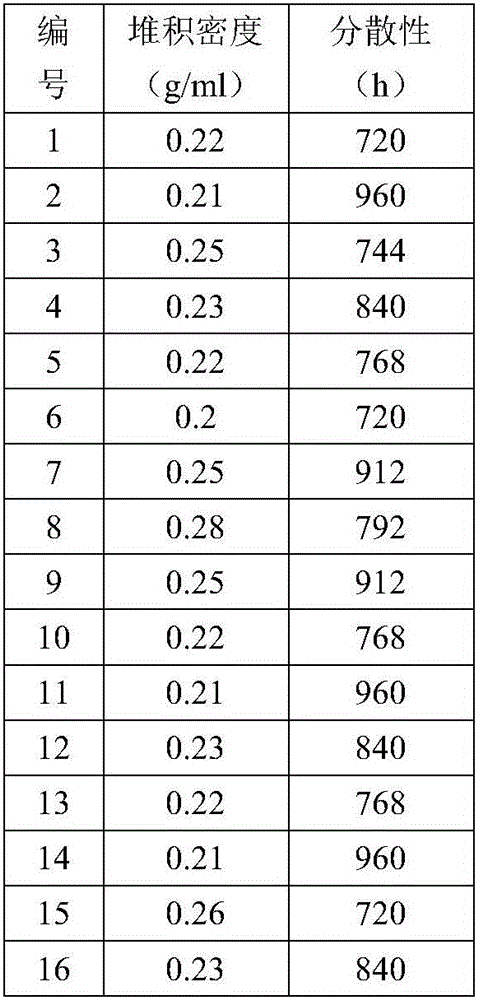

Carbon nanotube modified polypropylene antistatic film

The invention discloses a carbon nanotube modified polypropylene antistatic film which is prepared by the following method: stirring carbon nanotube at high speed and simultaneously dissolving a dispersant in a liquid and spraying the liquid into the stirred carbon nanotube powder by a spraying mode to surface-activating the carbon nanotube, adding the active carbon nanotube used as a conductive filler into a PP material matrix to prepare PP / carbon nanotube conductive master batch with good conductivity, mixing the PP / carbon nanotube conductive master batch with PP matrix resin and a thermal-oxidative stabilizer, a flow modifier, an abrasive agent and other auxiliary agents, and preparing the polypropylene antistatic film by blow molding, tape-casting or two-way stretching technology. The prepared polypropylene antistatic film has good conductivity, strong antistatic endurance and long service life.

Owner:嘉兴高正新材料科技股份有限公司

Bamboo substrate, bamboo floor and manufacturing methods of bamboo substrate and bamboo floor

InactiveCN103552137AFirmly connectedReduce internal stressLaminationLamination apparatusTongue and grooveEngineering

The invention provides a bamboo substrate, a bamboo floor and manufacturing methods of the bamboo substrate and the bamboo floor. The bamboo substrate is provided with an upper surface and a lower surface in regular shapes, as well as flush end faces and side faces, or end faces and side faces with mortice structures. The bamboo substrate comprises at least one bamboo plate with a whole raw bamboo connected surface, and cracks of the bamboo plates are filled with bonding materials. One or more bamboo substrates and a panel are composited to form the bamboo floor. A utilization rate of raw materials is greatly increased, and compared with a bamboo veneer bonded by a plurality of small bamboo battens in the traditional technology, the stability of the bamboo substrate manufactured by one or more bamboo plates flattened entirely, and the bamboo floor composited by the bamboo substrate and the panel is better. Simultaneously, the invention provides the manufacturing methods of the bamboo substrate and the bamboo floor. Procedure steps in the traditional technology are decreased, the labor cost is lowered greatly, and the utilization rate of the raw materials reaches 80-85%.

Owner:ZHEJIANG XINTUO BAMBOO TECH

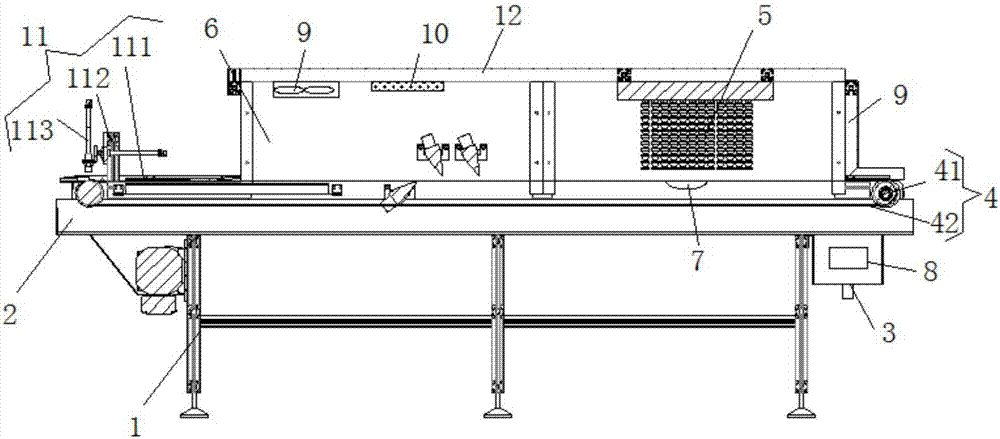

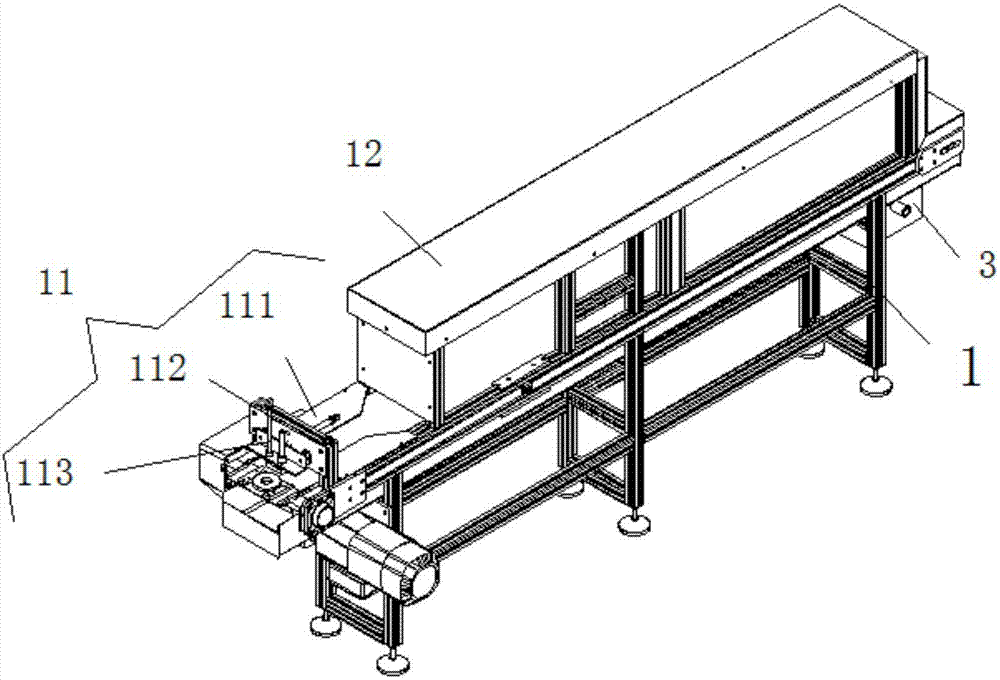

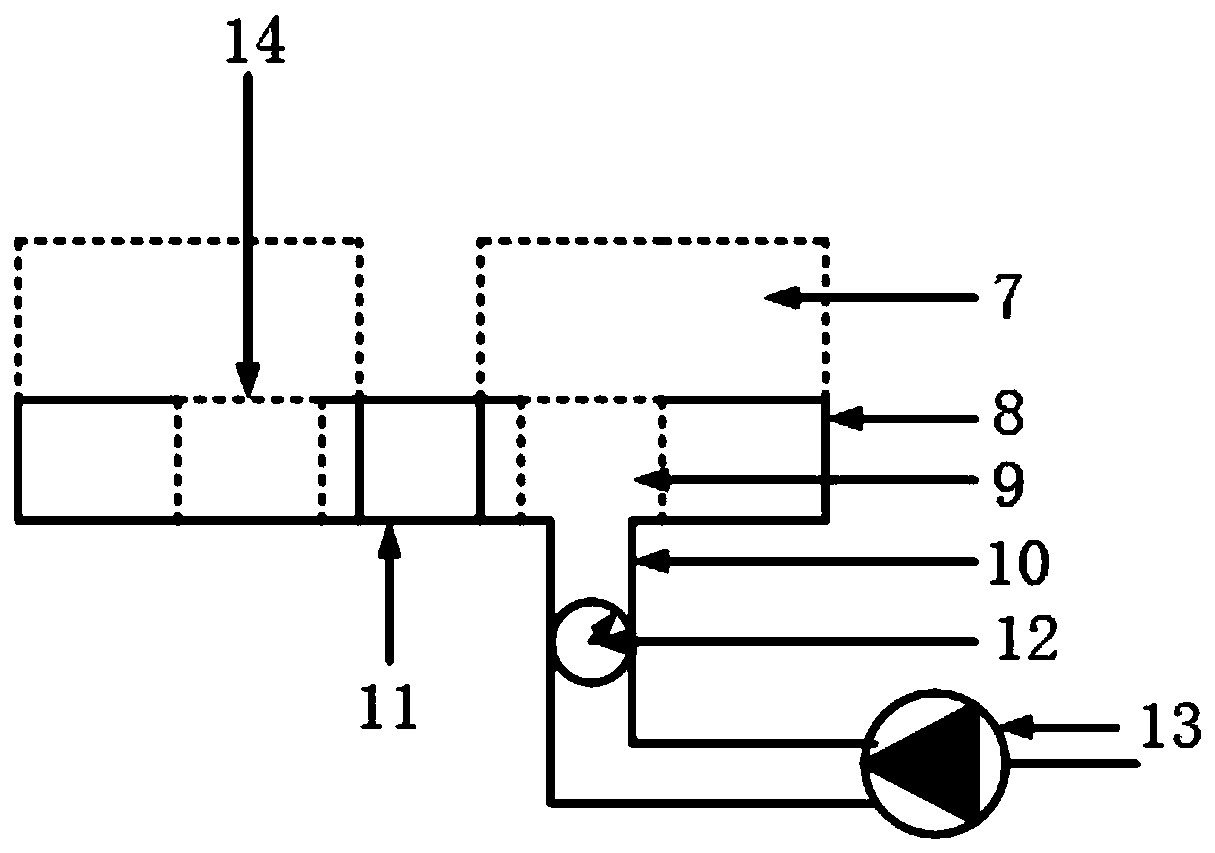

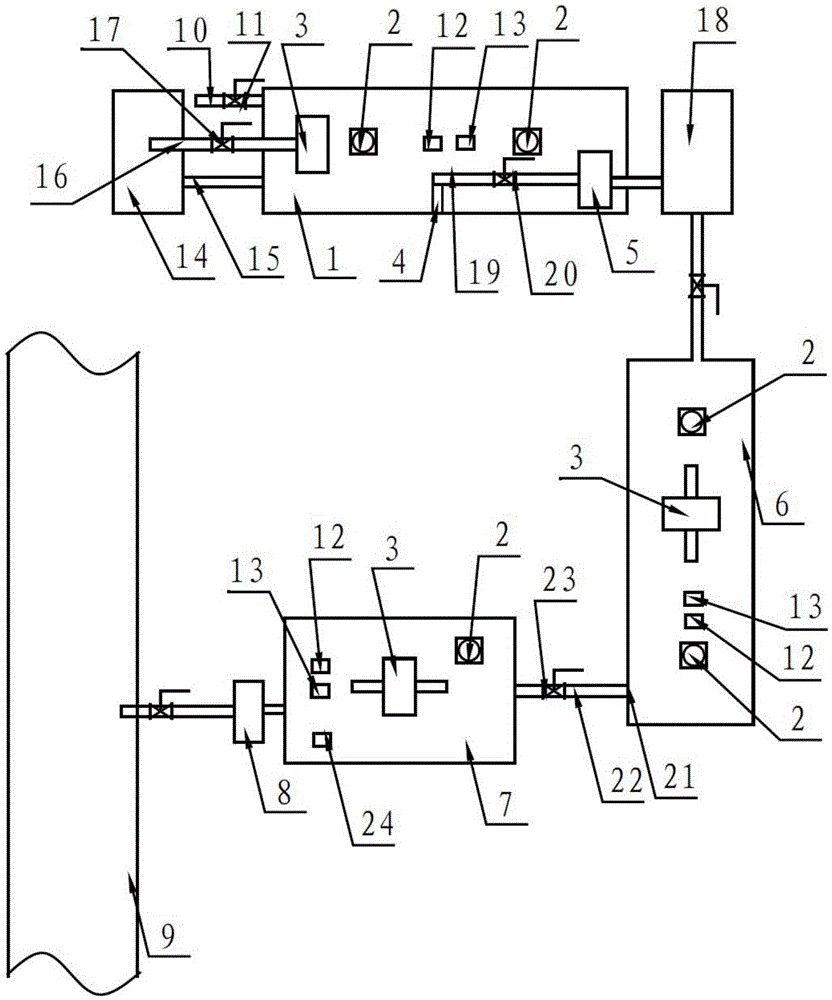

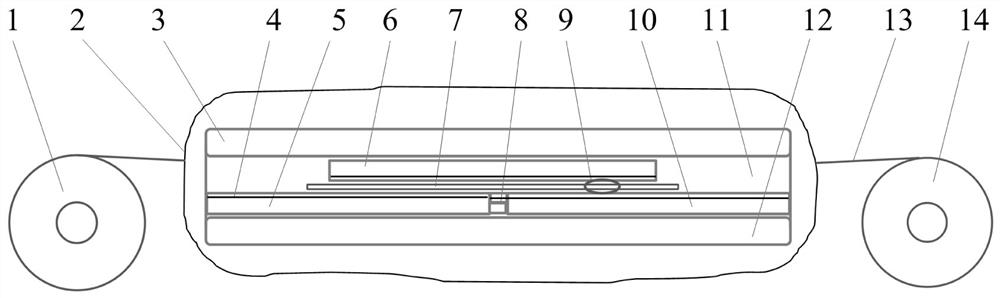

Oil-immersion conveyor

PendingCN107185762ABubble-free cloth oil evenlyNo bumpPretreated surfacesLiquid spraying apparatusElectric machineryHeating system

The invention discloses an oil-immersion conveyor. The oil-immersion conveyor comprises a rack, an oil receiving groove is fixedly arranged on the upper end of the rack, an oil groove is mounted on the right side of the oil receiving groove, and an oil pump is mounted in the oil groove; an oil-spraying conveying mechanism is mounted above the oil groove and comprises a motor and a conveying belt, the motor is connected with the conveying belt through a rotary shaft, an oil baffle plate is arranged on the rear portion of the upper end of the rack, and a spraying system is arranged on the position, located above the conveying belt, of the right end of the oil baffle plate; and an ultrasonic vibrator is mounted on the position, located in the middle of the conveying belt, below the spraying system, a circulating fan and a heating system are mounted on the position, located above the conveying belt, of the left end of the oil baffle plate, and a material pushing system is mounted on the left side of the conveying belt. According to the oil-immersion conveyor, parts enter the oil-spraying conveyor, the conveyor detects the parts entering the conveyor, an oil-spraying pump works, a layer of working oil layer is formed on the surface of each part, under further working of the ultrasonic vibrator, the surfaces of the parts are fully covered with oil liquid, and moreover no bubble is generated and oil distributing is even.

Owner:南京力旷机电科技有限公司

Activated carbon nanotube modified polypropylene (PP) antistatic film

The invention discloses an activated carbon nanotube modified polypropylene (PP) antistatic film. The PP antistatic film is prepared from the following components in parts by mass: 70-95 parts of PP base materials, 0.01-10 parts of activated carbon nanotubes and 0.1-20 parts of an aid, wherein the aid is one or a mixture of two or more of a dispersant B, a coupling agent, an antioxidant, a lubricant and an abrasive agent; an activated carbon nanotube is prepared through the following steps: the dispersant A is dissolved in a solvent, and a dispersant solution is obtained; then, the dispersant solution is sprayed into the carbon nanotube stirred at a high speed with a high pressure spray method, and the activated carbon nanotube is prepared after high-speed stirring and mixing. The PP antistatic film has good conductivity, high antistatic durability and long service life.

Owner:嘉兴高正新材料科技股份有限公司

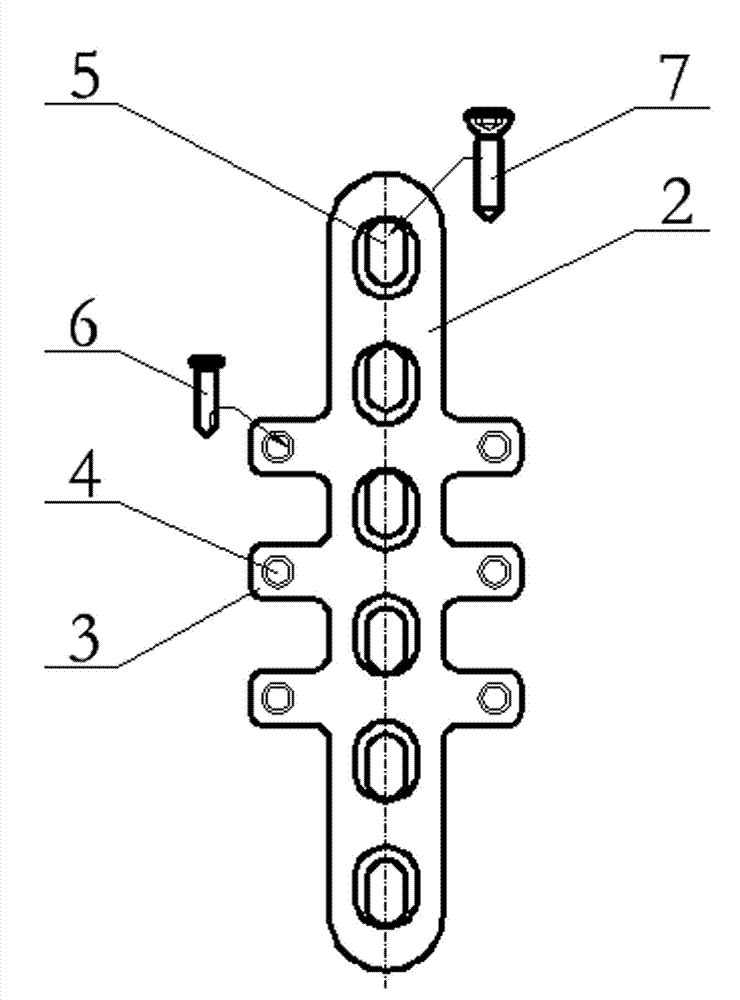

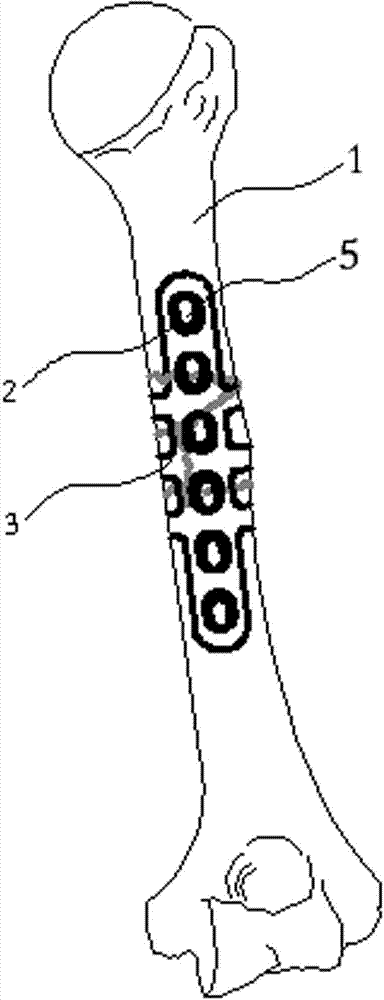

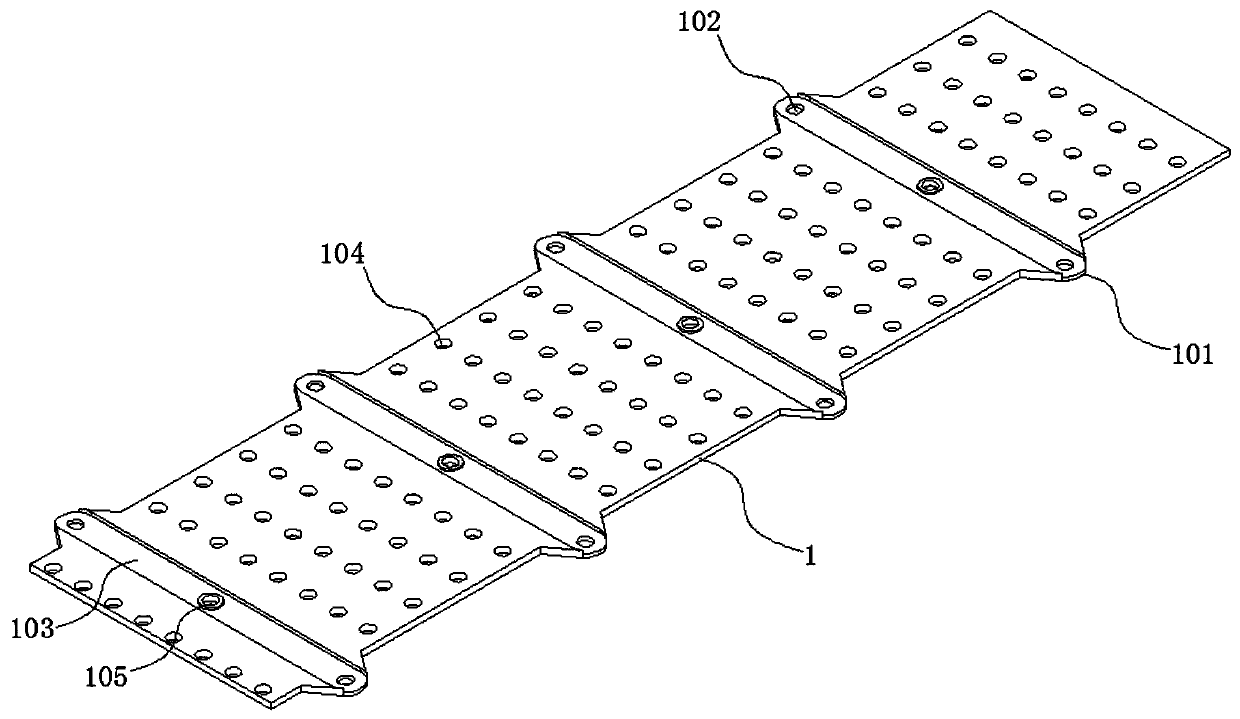

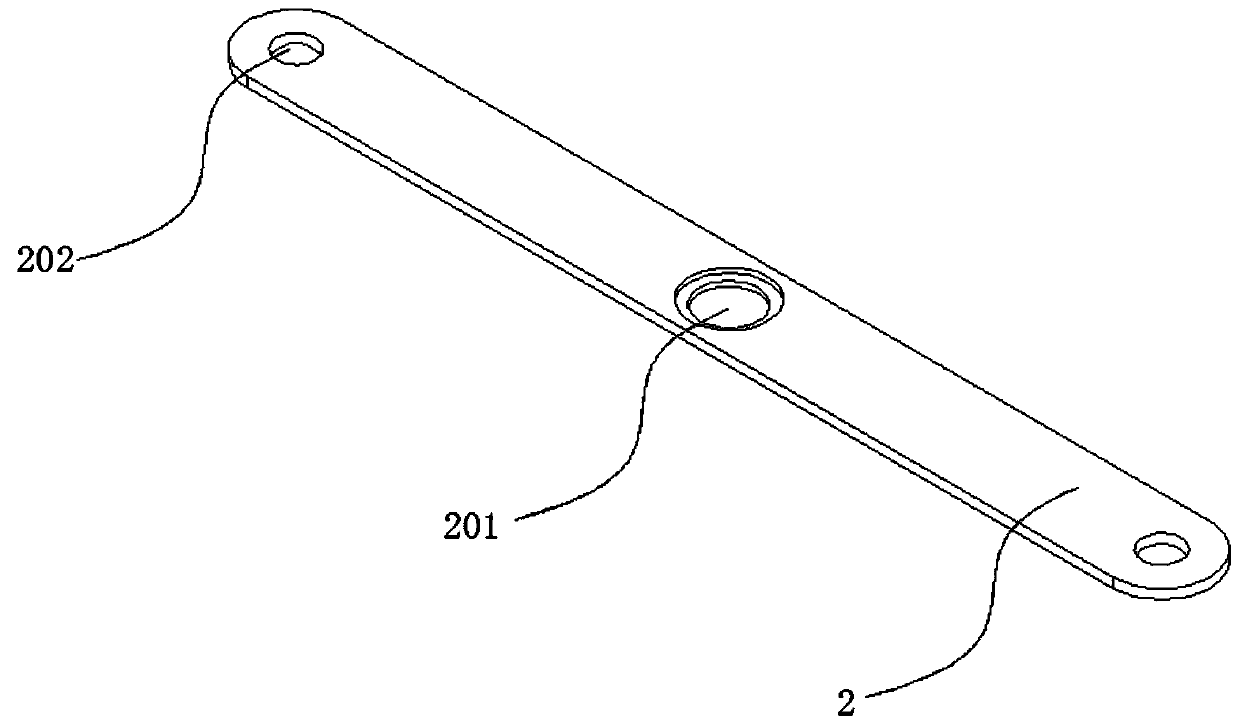

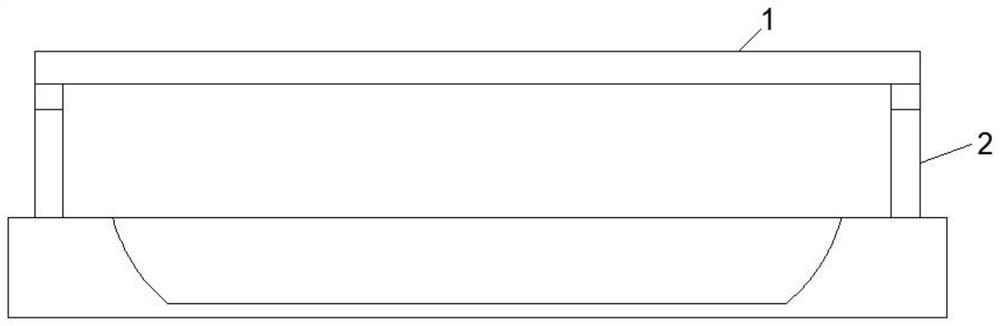

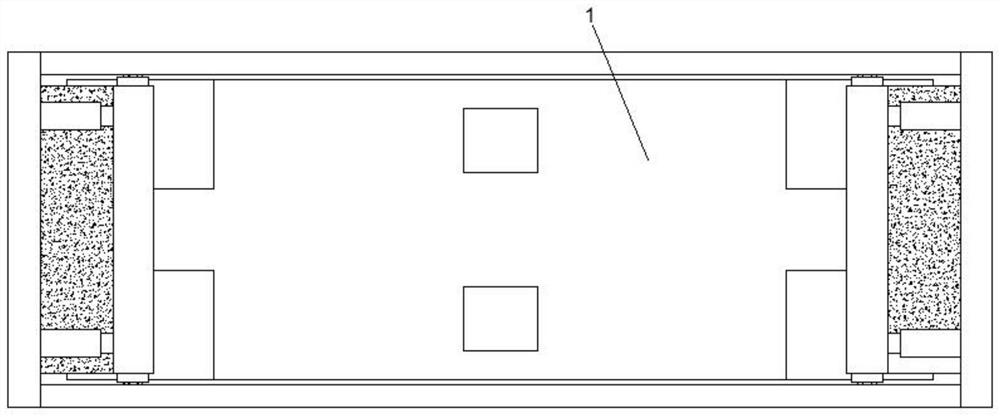

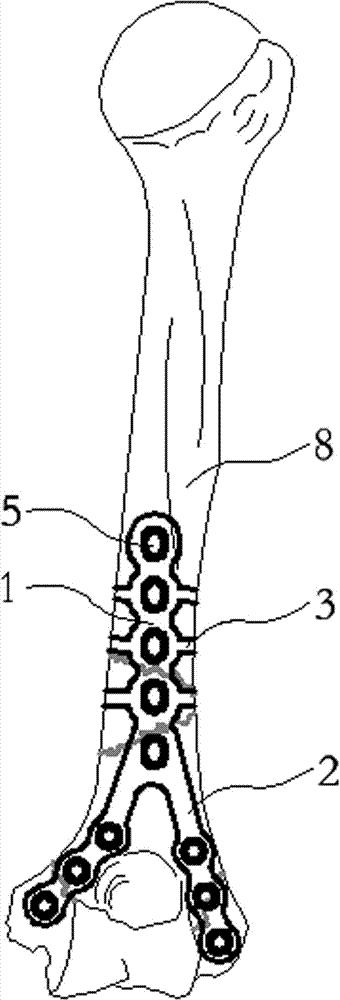

Humerus straight protection steel board

InactiveCN103919601AImprove integrityGood treatment effectInternal osteosythesisFastenersSheet steelTherapeutic effect

A humerus straight protection steel board comprises a straight section which is of a structure with the inner side face matched with the humerus backbone, and a plurality of locating holes are formed in the straight section. The humerus straight protection steel board is characterized by further comprising a plurality of protection wings which are symmetrically arranged on the two sides of the straight section and are in a contained shape towards the inner side face of the straight section; when the straight section is fixed to the humerus backbone, the inner side face of the straight section is attached to the front face of the humerus backbone, the two sides of the protection wings wrap the two sides of the humerus backbone in a containing mode, crush bones on the two sides of the humerus can be stably fixed in the mode that screws or fixing needles penetrate through threaded holes or needle penetrating holes, the completeness of the humerus is protected, and the fracture healing and treatment effect of the humerus is improved; countersunk head screws are flat on the surface of the steel board when used, no protrusion exists, implantation is convenient, pains caused by use of the screws are relieved, and postoperative healing is facilitated; the locking firmness is improved through a countersunk forcing screw.

Owner:泰州市中兴医械科技有限公司

Steering knuckle and bushing push-free process

ActiveCN111922631AReduce resistanceImprove integrityMetal working apparatusStructural engineeringMachine

The invention provides a steering knuckle and bushing push-free process. The process comprises the following steps that S1, a bushing is placed in a numerically controlled lathe, and an excircle guideangle at the bottom of the bushing is turned and formed; S2, a steering knuckle is fixed in a vertical machining center, and main pin holes of an upper lug and a lower lug of the steering knuckle arebored and formed through rough boring, chamfering and fine boring by adopting a fine machining process; S3, pretreatment before press-in is carried out, specifically, the bushing is placed in a liquid nitrogen environment to be treated for 2-3 hours; and S4, press fitting of the bushing is carried out, the bushing is pressed into the main pin holes in the two sides by adopting a press fitting machine. According to the process, the improvements in three aspects of processing technology, structure and mounting operation of the bushing and the steering knuckle are adopted, which are different from the prior art that an ironing rod needs to be used for ironing and pushing the interior of the bushing, so that the steering knuckle and bushing push-free process is realized, the bushing is smallin deformation, free of bulges, good in coaxiality and complete and attractive in inner hole surface of the bushing after pressing, and finally, the purpose of prolonging the service life of the steering knuckle, the bushing, a main pin and even the whole front axle is achieved.

Owner:HUBEI TRI RING FORGING

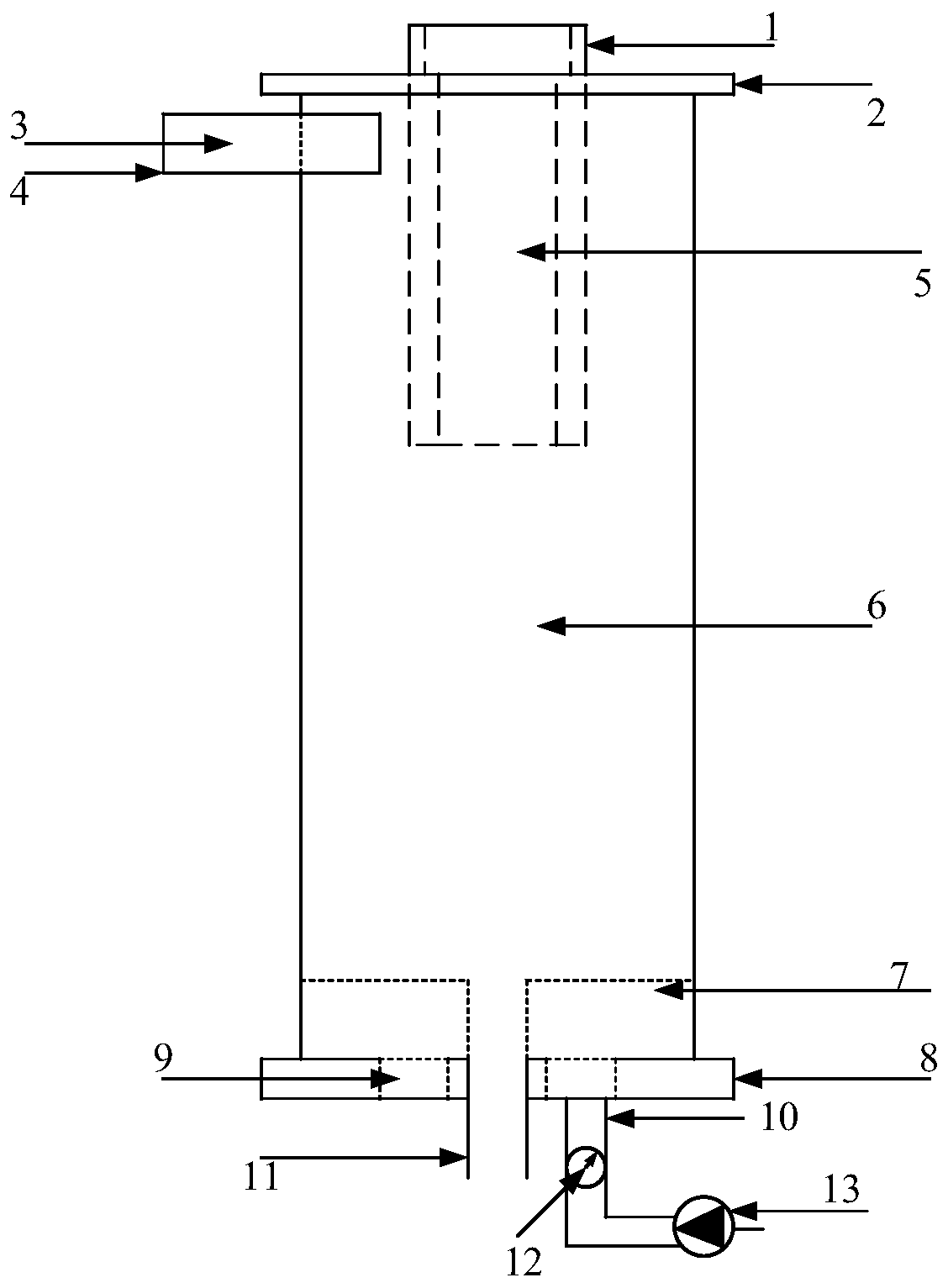

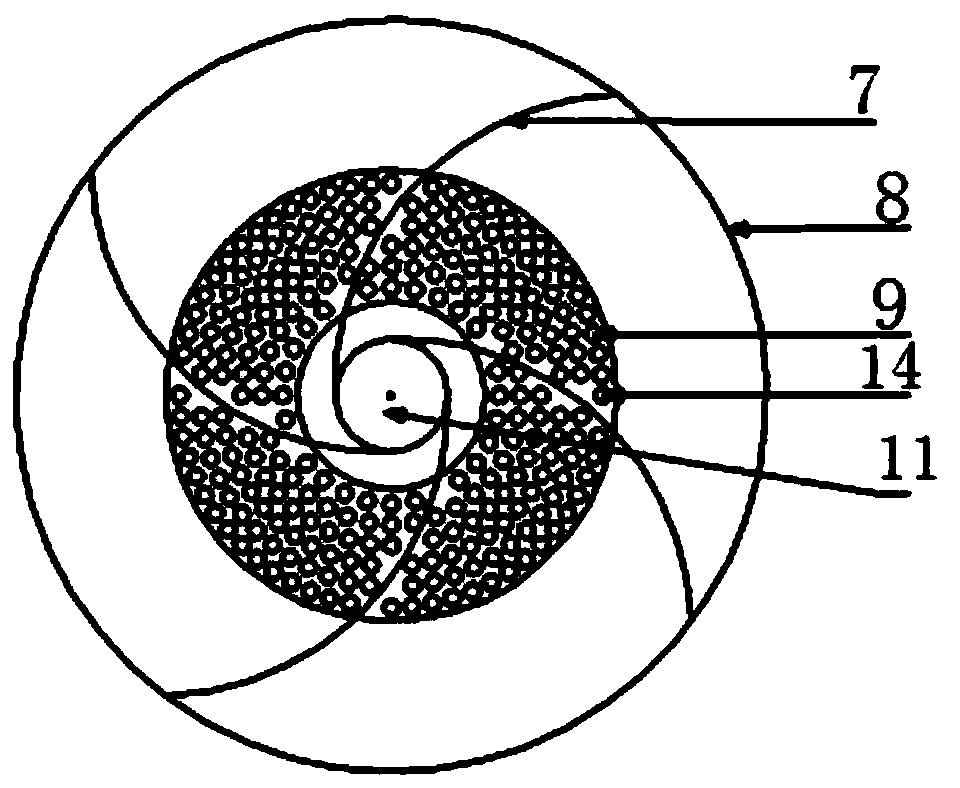

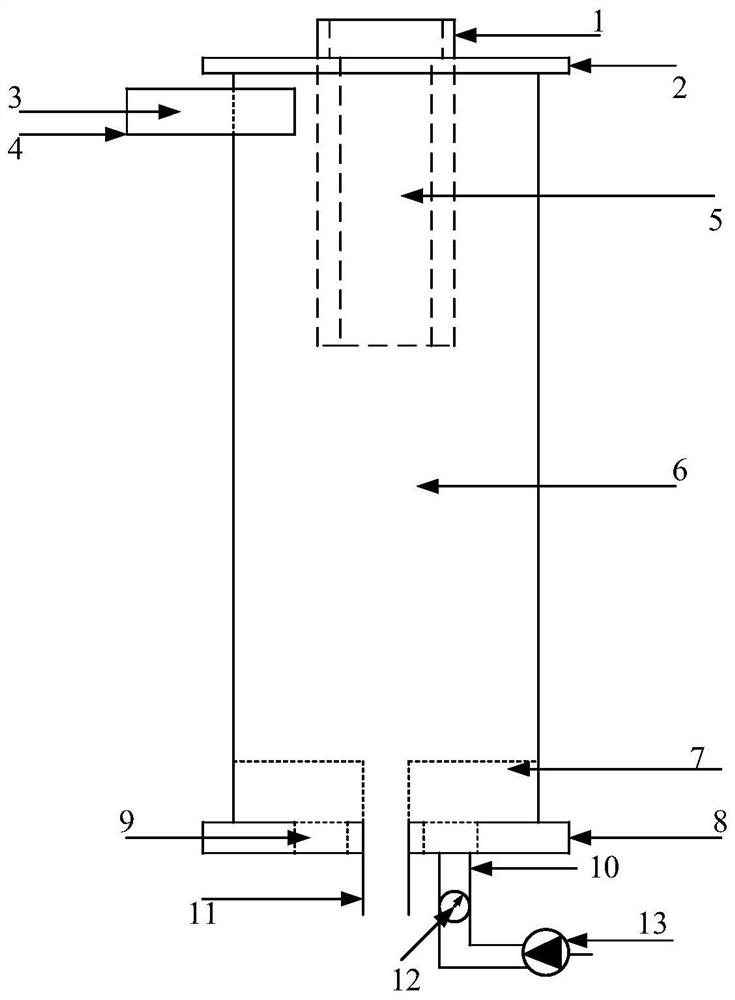

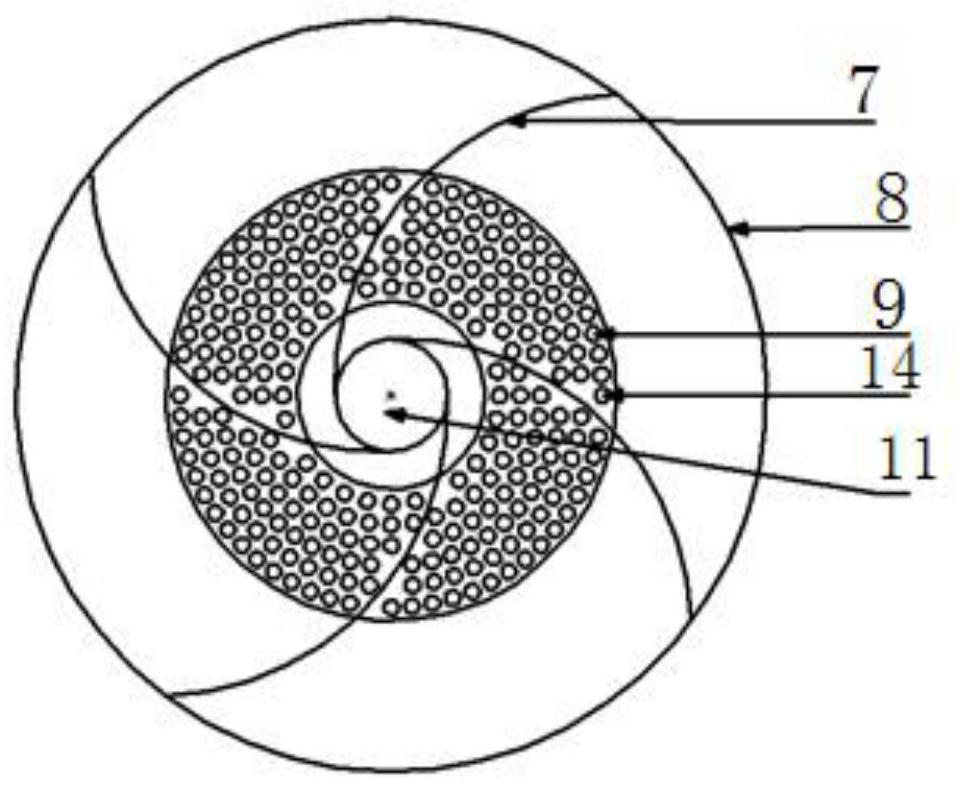

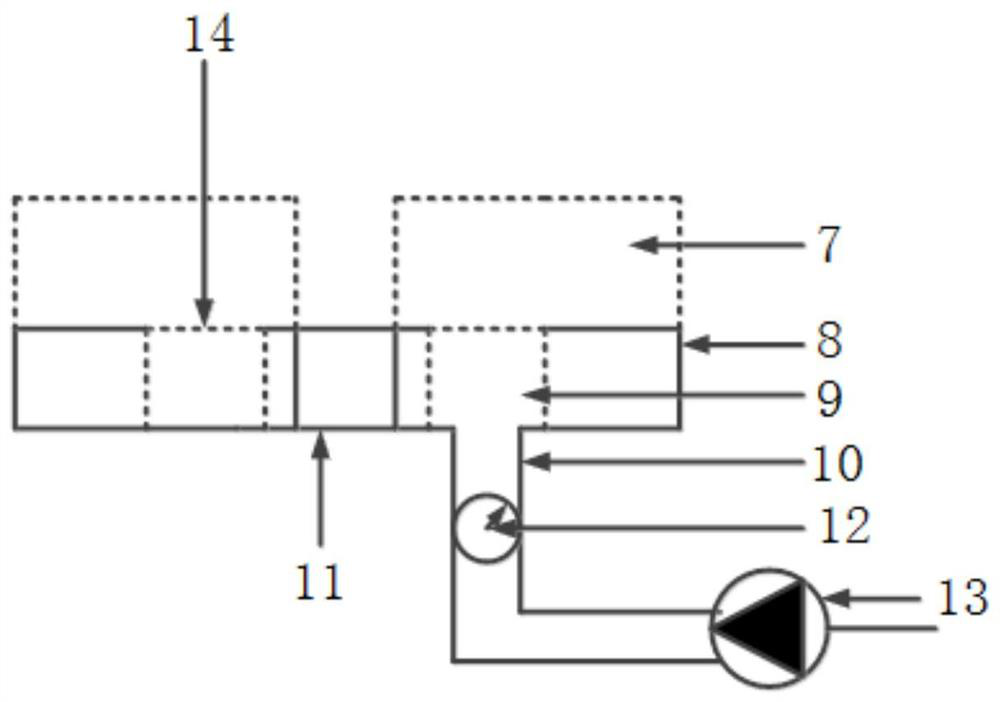

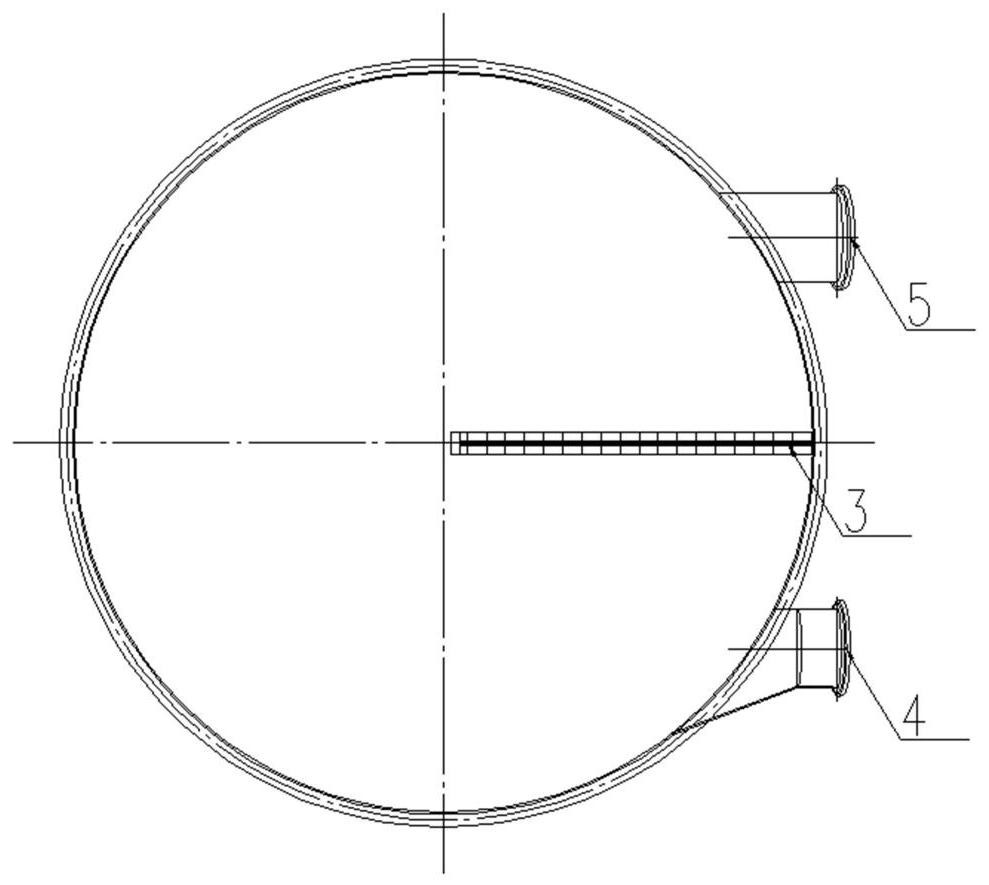

Fast and efficient hydrocyclone

ActiveCN110328062AReduce the amount of clippingImprove separation efficiencyReversed direction vortexEngineeringResidence time

The invention belongs to the technical field of material separation, and discloses a fast and efficient hydrocyclone. The hydrocyclone comprises a hydrocyclone body, and further comprises a flushing water distributor and flow guide plates, the flushing water distributor and the flow guide plate are connected with a bottom cover on the hydrocyclone body through a welding mode, and the flow guide plates are in central symmetry with respect to the center of a cylindrical cavity on the hydrocyclone body and is tangent to a underflow pipe on the hydrocyclone body. Materials are fed from a feeding port and spirally move in the hydrocyclone, when the particles move to the bottom of the hydrocyclone, fine particles are brought out to enter an inner rotational flow under the action of upward flushing water, and meanwhile, under the action of the flow guide plates, separated coarse particles are rapidly guided to an underflow port to be discharged on the basis of the original rotation motion. According to the hydrocyclone, the effect of the internal flow field of the hydrocyclone is strengthened by utilizing a fluidization principle, and the amount of the fine particles in an underflow is reduced, so that the separation efficiency of the wide-grade materials is greatly improved; and meanwhile, the residence time of the coarse particles is reduced, and the treatment capacity of the hydrocyclone is further improved.

Owner:NORTHEASTERN UNIV

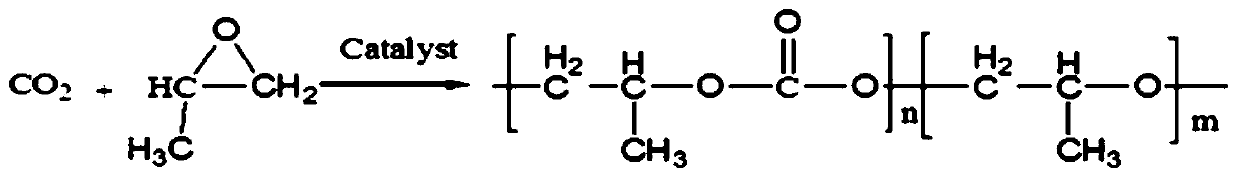

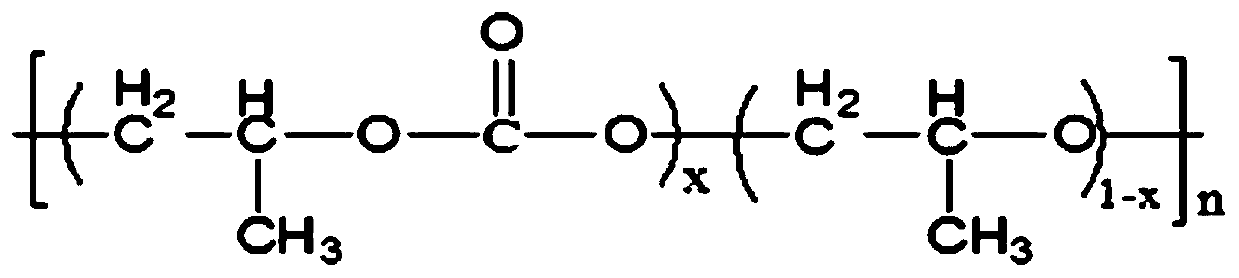

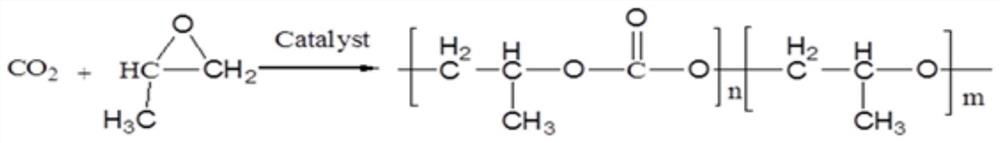

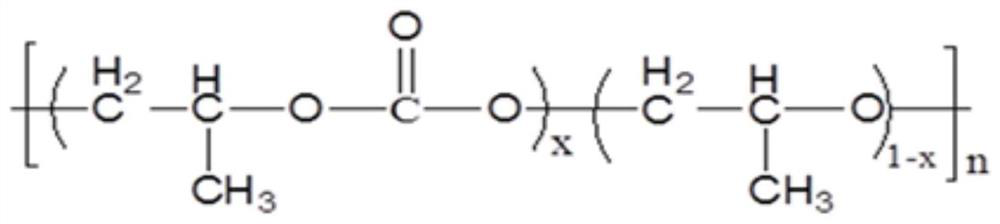

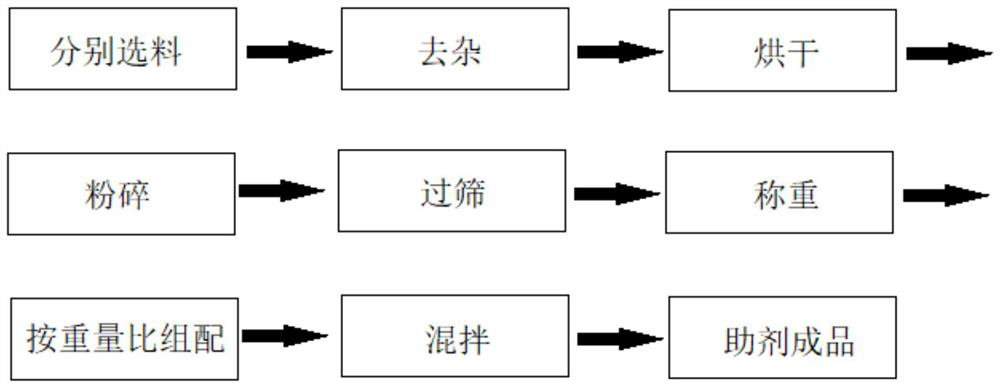

Processing technology and application of degradable water-seepage farmland mulching film

ActiveCN110079070AIncreased longitudinal tear strength at right anglesIncrease productionPlant protective coveringsElastomerWinding machine

The invention discloses a processing technology and an application of a degradable water-seepage farmland mulching film, belongs to the technical field of agricultural plastic forming and mainly solves the problems of small longitudinal tear strength and no seepage of polyester degradation films. The processing technology is characterized in that 1 part of potato flour, 1 part of calcium lactate,shell powder and 50 parts of biological calcium are selected by weight, dried, sieved by a 140-mesh sieve, weighed and blended into an affine water seepage aid; 1 part of an aid and 7 parts of PPC aresubjected to modification, wiredrawing, water cooling and granulation on a double-screw extruder, and affine water seepage master batch is prepared. Materials are prepared in the ratio of PPC, PBAT and the master batch being 700:300:25; a blowing machine is sequentially set as follows: the temperature of each zone is 130-155 DEG C, the blowup ratio is (3-5):1, the thickness of a base film is 0.007 mm plus or minus 0.002 mm, a group of elastomer sand finish floating rolls with the outer diameter of 80 mm, the length of 80-300 mm and the interval of about 1 mm are mounted on a NO.1 winding rolland a NO.2 winding roll on two sides of a winding machine respectively, wherein the NO.1 winding roll and the NO.2 winding roll are spaced by 30-35 mm, the base film penetrates through rods spaced by1-2 mm and is extruded and rolled by rolling friction, and the criss-cross micro microporous degradable water-seepage farmland mulching film is prepared.

Owner:山西微通渗水膜生物科技有限公司

Main-grid-free and anti-subcrack battery assembly

The invention discloses a main-grid-free and anti-subcrack battery assembly. The main-grid-free and anti-subcrack battery assembly comprises main-grid-free battery pieces and copper wire meshes, wherein a plurality of transversal secondary grids are arranged on the front surfaces of the main-grid-free battery pieces; the copper wire meshes are formed by weaving a plurality of longitudinal copper wires and a plurality of transversal copper wires; the copper wire meshes cover the front surfaces of the longitudinally-arranged main-grid-free battery pieces; the copper wires of the copper wire meshes and the secondary grids of the main-grid-free battery pieces are welded at intersections to form battery strings; the plurality of battery strings are connected through bus bars into the battery assembly. The main-grid-free and anti-subcrack battery assembly uses the battery pieces without main grid structures, and the woven copper wire meshes and the secondary grids of a battery are directly intersected and welded. Through thousands of contacts between the woven copper wire meshes and the secondary grids of the battery, current conducting paths at subcrack and microcrack parts of a wafer are more optimized, so that loss caused by subcrack is greatly reduced and hot spot problems of the assembly can be greatly reduced.

Owner:SUZHOU COOP & INNO GREEN ENERGY TECHNOLOGY CO LTD

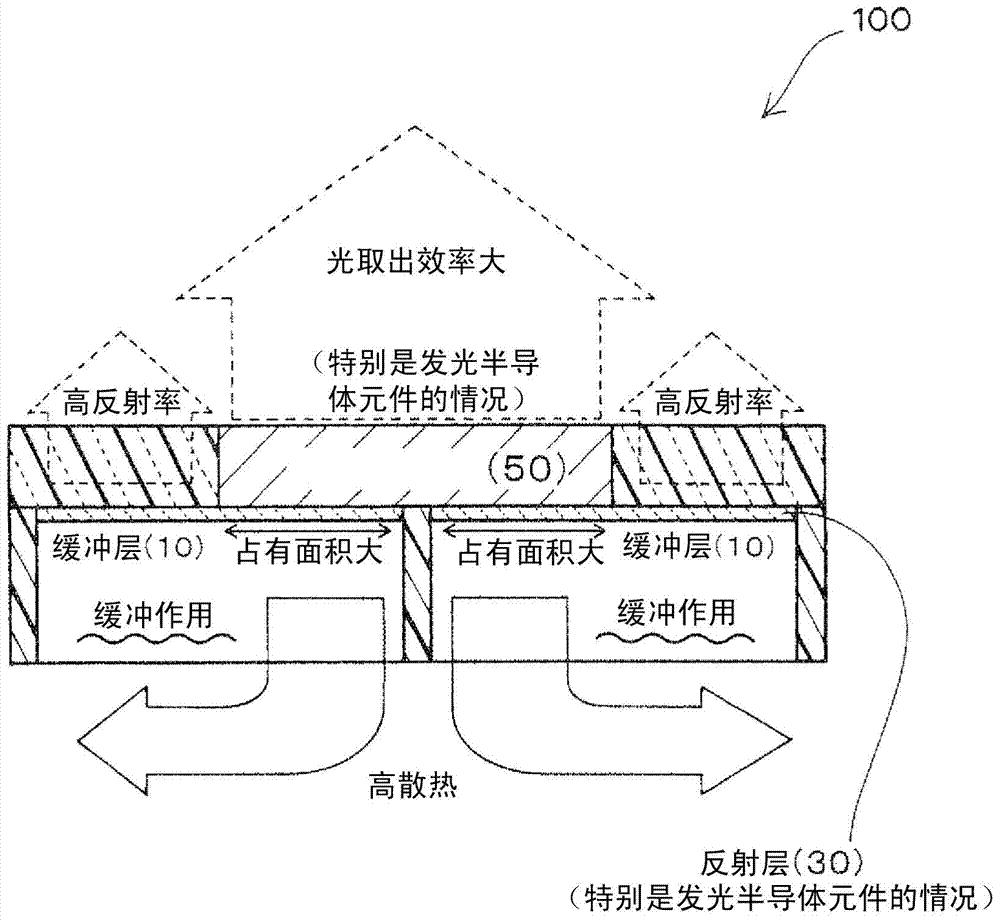

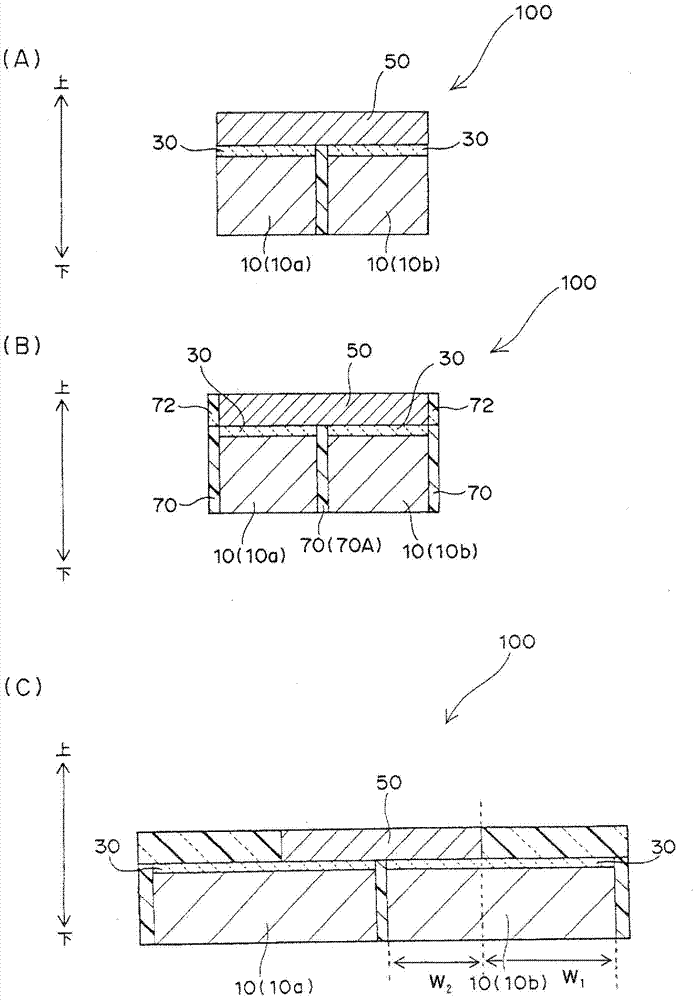

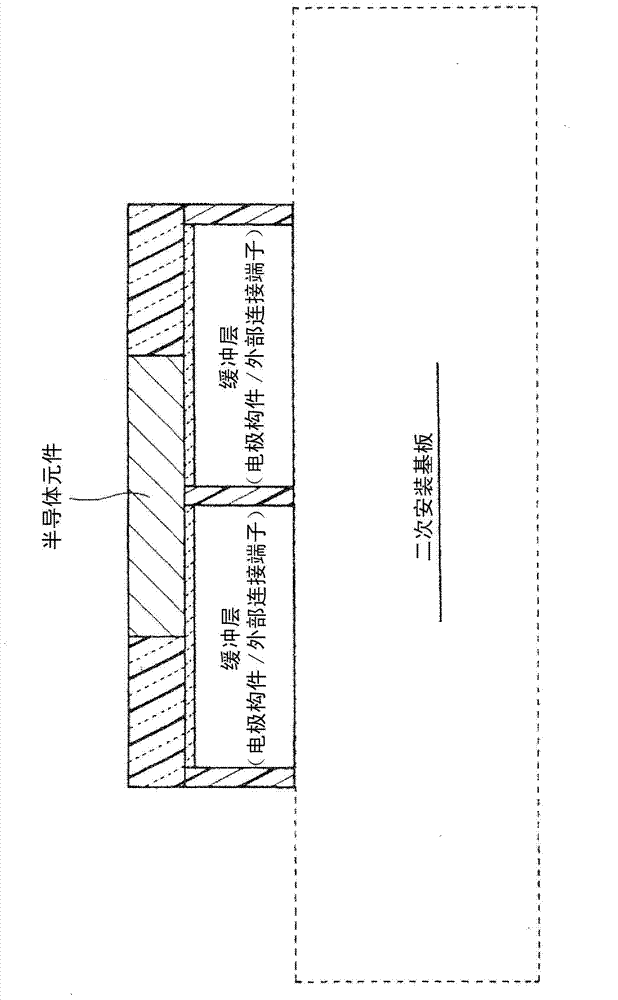

Semiconductor device and method for producing same

InactiveCN104335343AIncrease the areaAchieving "heat dissipation characteristicsSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor device

This semiconductor device includes a semiconductor element and a metal buffer layer electrically connected to the semiconductor element. In this semiconductor device, the metal buffer layer and the semiconductor element are connected with each other in such a form that the metal buffer layer and the semiconductor element are in surface contact with each other. Further, the metal buffer layer functions as an external connection terminal used for the mounting onto a secondary mount substrate, and at the same time, also functions as a buffer member that provides an effect of reducing a stress between the secondary mount substrate and the semiconductor element.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

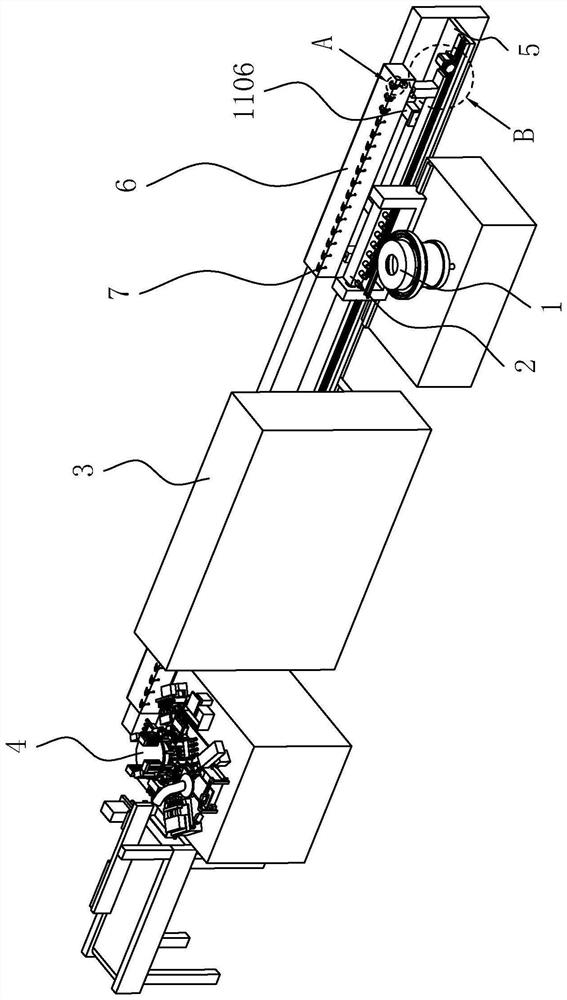

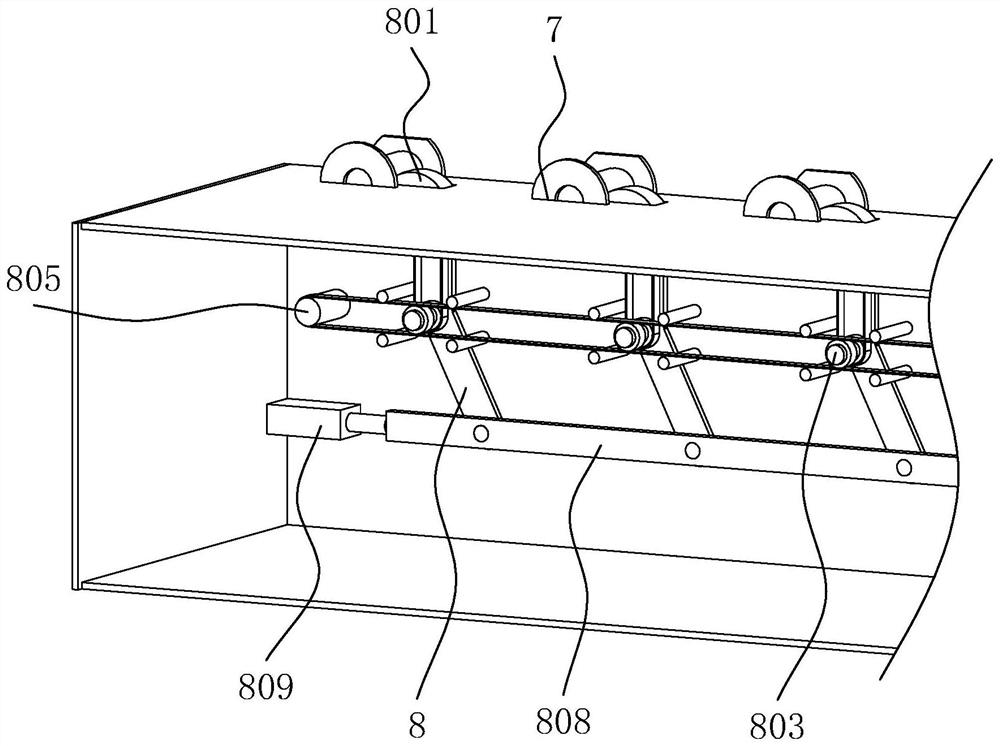

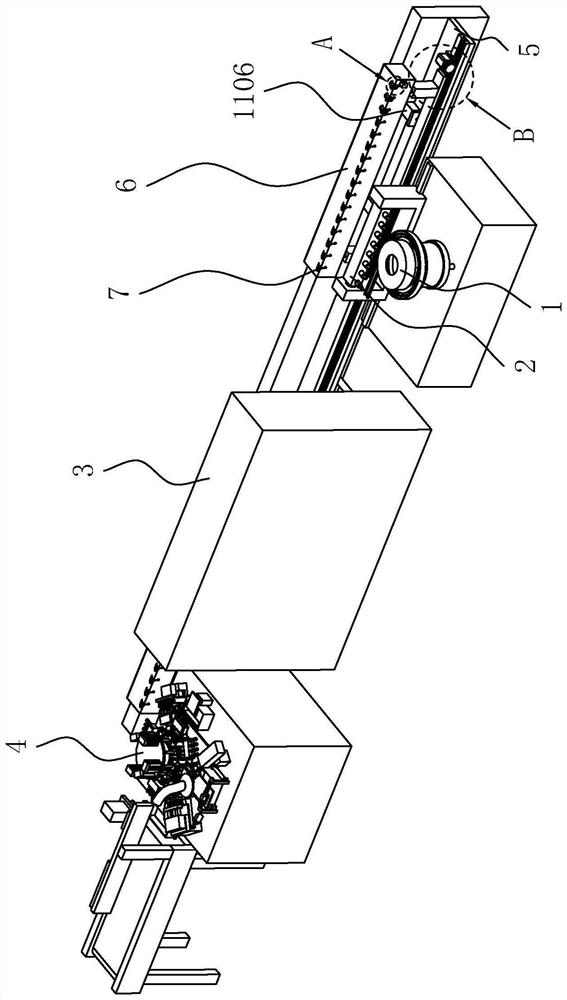

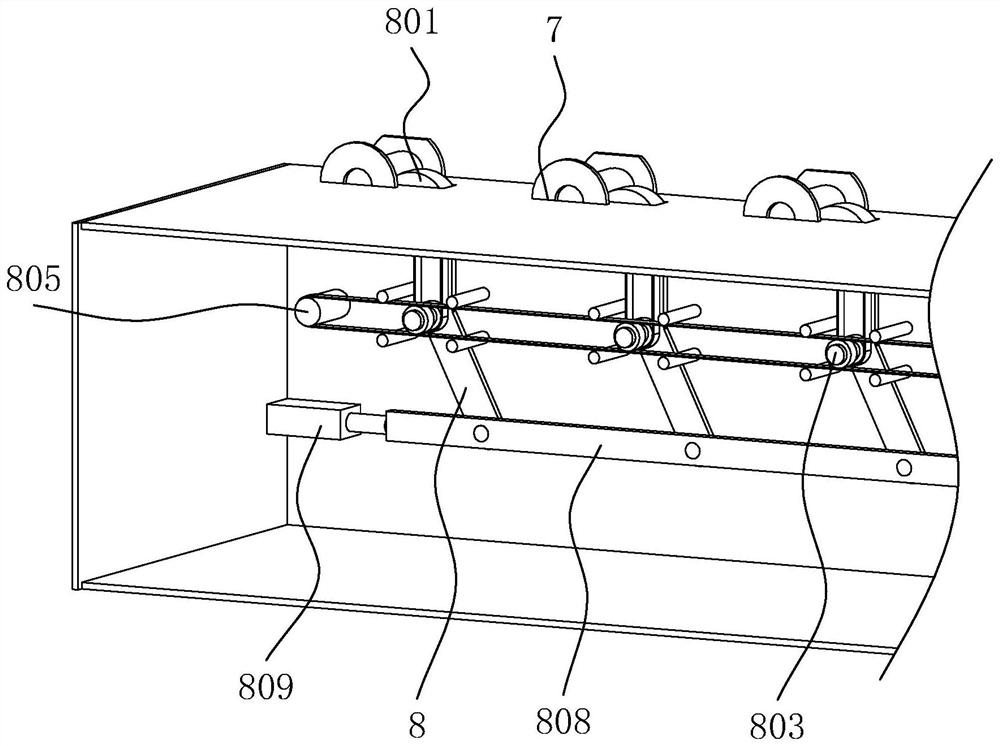

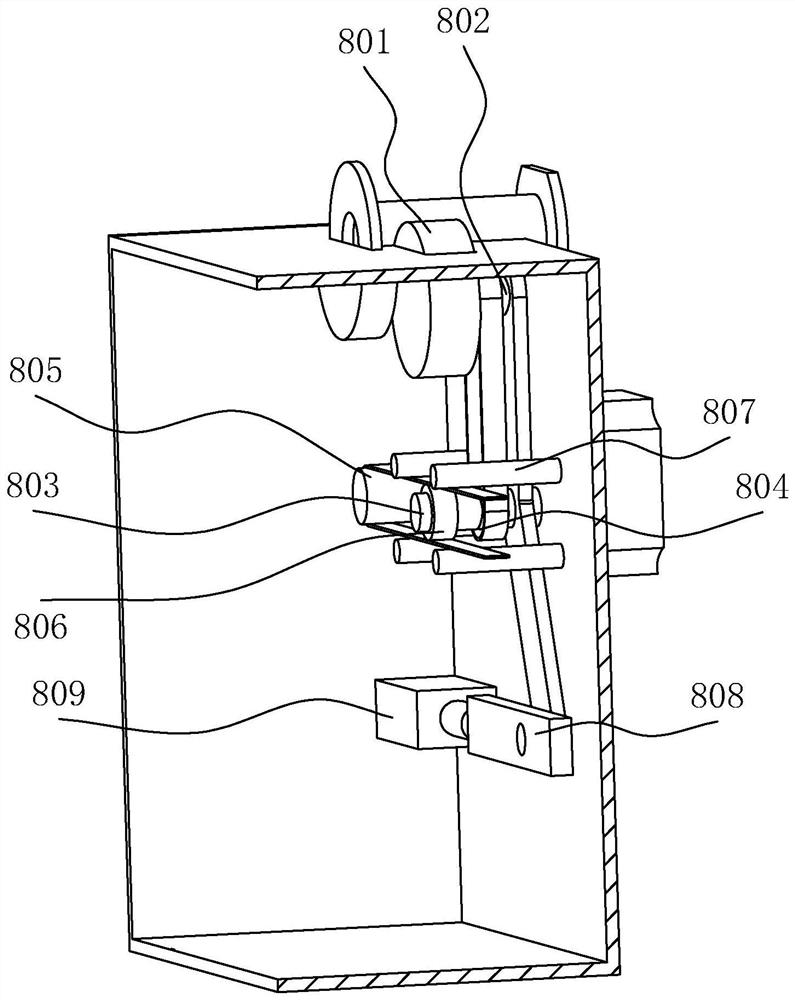

Relay coil processing system

ActiveCN113078028AAchieving synchronous correctionCalibration stops in timeElectromagnetic relay detailsElectrical connectionMachining system

The present invention relates to a relay coil machining system which comprises a vibration disc, a feeding device, a winding device, a tin soldering device, a detection device and a guide rail, a conveying workpiece is slidably arranged on the guide rail, a plurality of placement grooves are formed in the side, close to the vibration disc, of the conveying workpiece, and a cavity is formed in the conveying workpiece; a plurality of correction mechanisms, a plurality of in-place mechanisms and a plurality of control mechanisms which are electrically connected with the in-place mechanisms in a one-to-one correspondence manner are arranged in the cavity; each correction mechanism comprises a connecting rod rotationally arranged on the conveying workpiece, the end, close to the containing groove, of the connecting rod is rotationally connected with a correcting wheel, the side, close to the correcting wheel, of the containing groove communicates with the cavity, and a second driving assembly used for driving the correcting wheel to rotate is arranged on the conveying workpiece; and a swing assembly used for driving the correcting wheel to get close to and stretch into the containing groove or get away from the containing groove is arranged on the conveying workpiece. The pin correction device has the advantages that the pins on the framework can be corrected through the correction wheels, and the single correction wheel can stop correction after correction is completed.

Owner:WANGRONG ELECTRONICS SHENZHEN

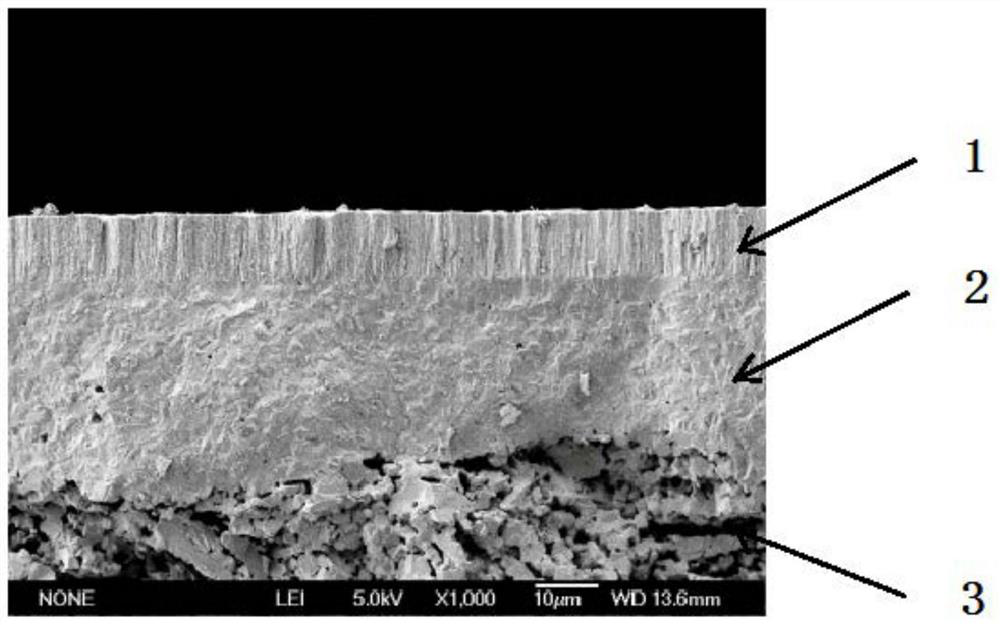

Production process and half cell of a solid oxide fuel cell half cell

ActiveCN113471493BImprove flatnessNo bending deformationFinal product manufactureSolid electrolyte fuel cellsFuel cellsPhysical chemistry

The invention discloses a production process of a solid oxide fuel cell half cell, comprising the following steps: S1: preparing anode functional layer slurry and anode slurry; S2: applying the anode functional layer slurry on the surface of the carrier tape, and drying to obtain a Anode functional layer; S3: apply anode slurry on the surface of the anode functional layer, remove the carrier tape after drying, to obtain a green anode substrate; S4: sinter the green anode substrate for the first time to obtain an anode substrate; S5 : prepare an electrolyte film on the surface of the anode functional layer of the anode substrate; S6: sinter the anode substrate with the electrolyte film for the second time to obtain a solid oxide fuel cell half cell; the temperature of the second sintering is higher than that of the first sintering The sintering temperature is 25~150℃ higher. In the solid oxide fuel cell half-cell, through the processes of first sintering and second sintering, the shrinkage rates of the anode substrate and the electrolyte film are matched, and the flatness is improved. The invention also discloses a solid oxide fuel cell half cell.

Owner:UNIV OF SCI & TECH OF CHINA

Angle valve and angle valve manufacturing process and positioning tool

ActiveCN106392500BMetallographic change range is smallImprove mechanical propertiesValve housingsProduct inspectionEngineering

The invention provides an angle valve as well as an angle valve manufacturing process and a positioning tool, and belongs to the technical field of valves. The angle valve manufacturing process solves the problems that an existing triangular valve manufacturing method is complex in process and is not environmentally-friendly, and surface consistency of the produced angle valve is relatively poor. The angle valve manufacturing process comprises the following steps: a, manufacturing an angle valve main body; b, manufacturing an angle valve joint; c, positioning the angle valve main body and the angle valve joint by laser welding, enabling the arc-shaped connecting surface of the angle valve joint to fit to the outer wall of the angle valve main body, integrally welding the angle valve main body and the angle valve joint inside the angle valve joint through laser welding, and injecting a laser beam from an inner hole of the angle valve joint; d, inspecting; e, assembling; and f, carrying out finished product inspection. The angle valve manufacturing process simplifies the process, improves producing and processing efficiency, and is more environmentally-friendly; and the outer surface of the manufactured valve body does not have a welding seam, so that the valve body is more flat and smooth, is better in consistency, and is better in mechanical property.

Owner:浙江苏泊尔卫浴有限公司

Surface-mounted tantalum insulator shell and preparation method thereof

PendingCN113345719AGuaranteed long-term stabilityImprove long-term stabilityLiquid electrolytic capacitorsCapacitor housing/encapsulationExplosive claddingTantalum capacitor

The invention relates to the technical field of insulators, and particularly provides a surface-mounted tantalum insulator shell and a preparation method thereof. The preparation method specifically comprises the following steps: explosive cladding, multi-pass rolling and vacuum annealing treatment are performed on a tantalum plate and a nickel plate to obtain a tantalum-nickel composite plate; the nickel layer of the tantalum-nickel composite plate is in contact with the female die, the tantalum layer of the tantalum-nickel composite plate is in contact with the male die, punching is conducted, and small holes are punched in the bottom to obtain a shell; glass, the composite tantalum wire and the shell are assembled and then subjected to high-temperature sintering, and an insulator shell is obtained; a nickel tube sleeves on the composite tantalum wire below the bottom of the shell, and the nickel tube and the composite tantalum wire are fixed by adopting a laser welding method to obtain an insulator shell with the nickel tube; and the shell bottom of the insulator shell with the nickel tube is immersed into the lead-tin solder to obtain the surface-mounted tantalum insulator shell. According to the surface-mounted insulator shell, the weight of the tantalum capacitor can be reduced, the cost is saved, the production efficiency is improved, and the assembly reliability and long-term stability are improved.

Owner:湖南华冉科技有限公司

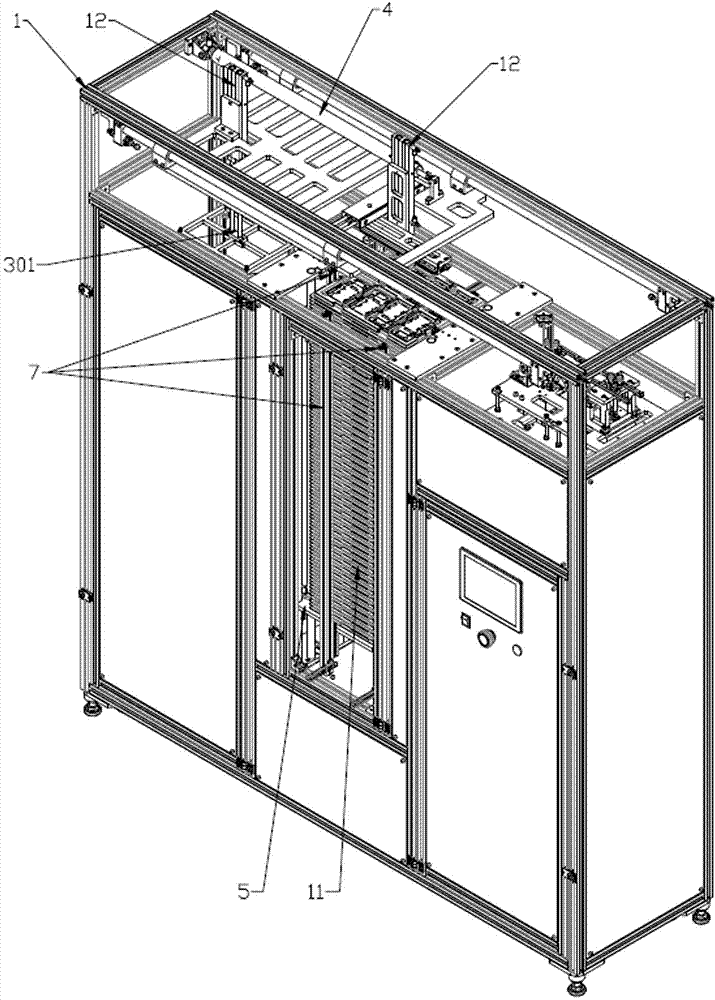

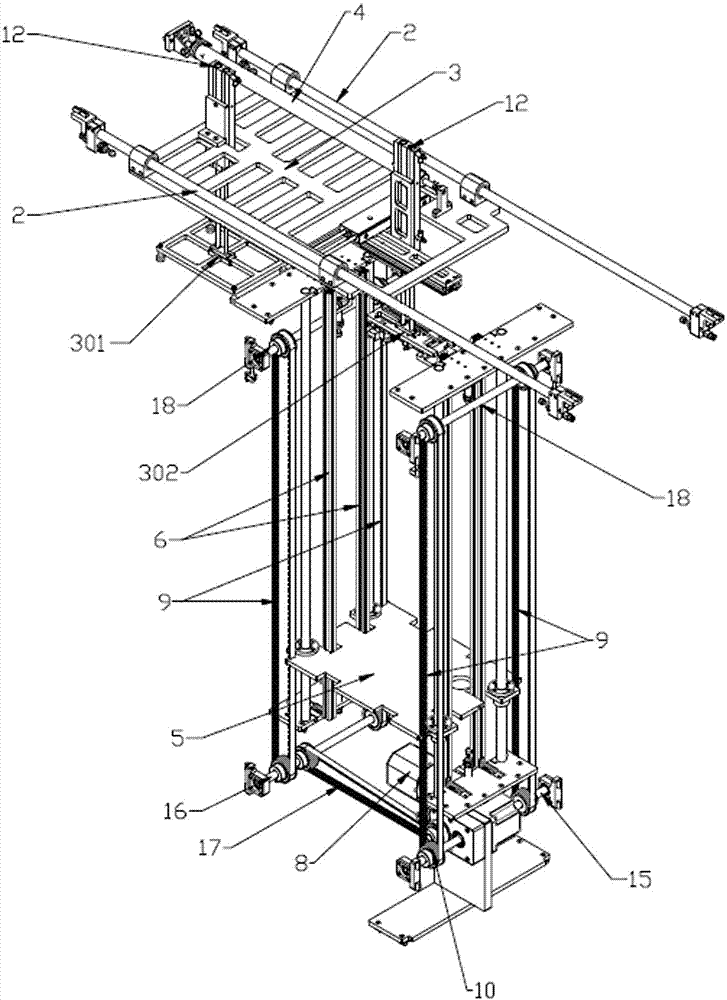

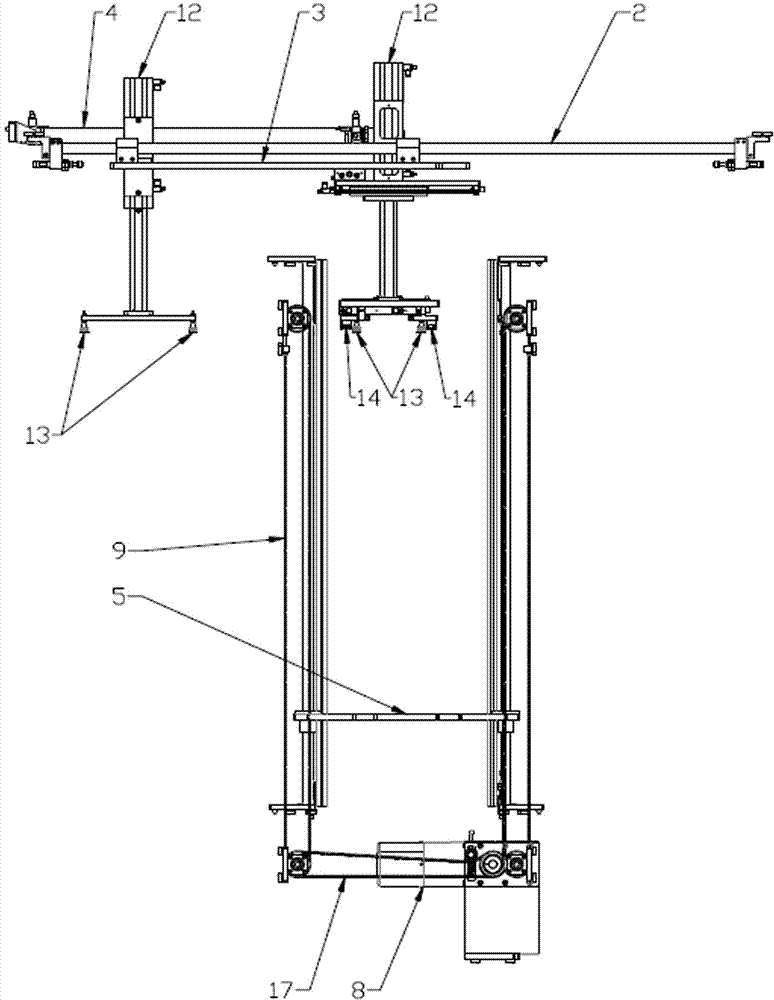

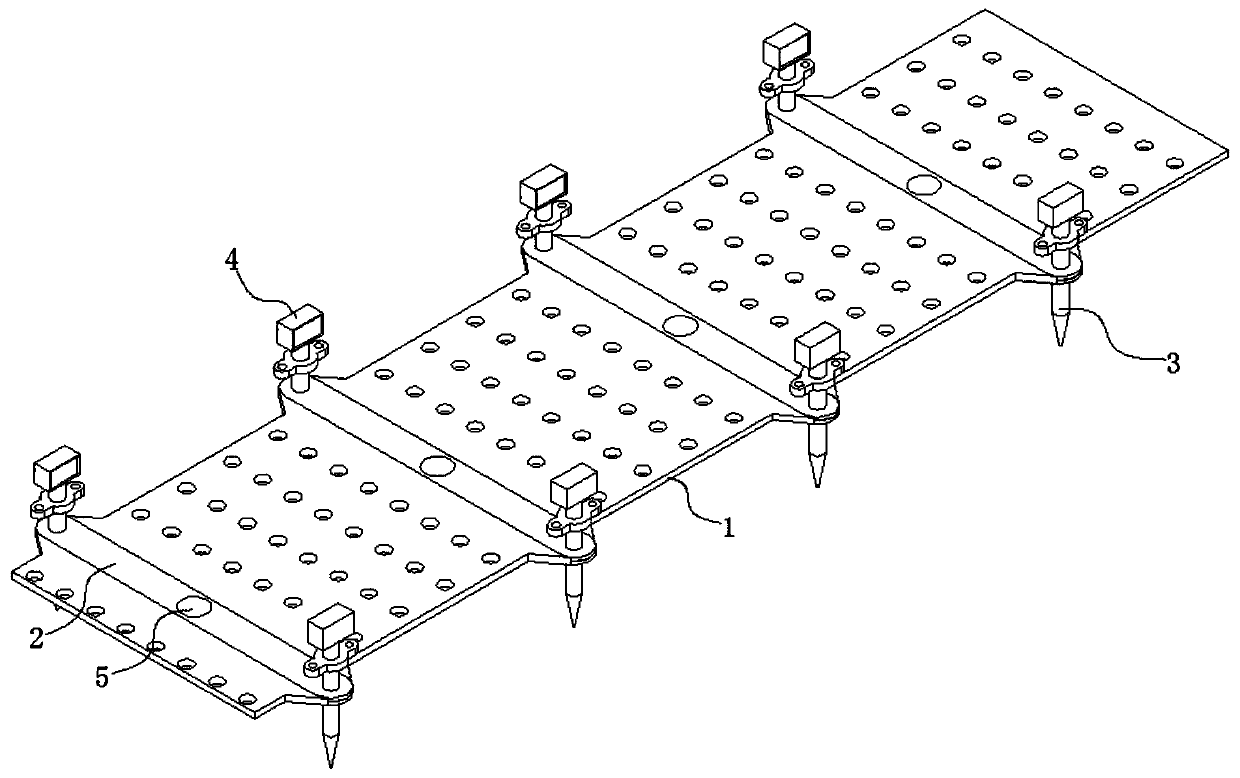

Automatic steel disc placing machine

The invention discloses an automatic steel disc placing machine, which comprises a bracket, wherein the bracket is partitioned into three regions including a plastic absorption box accommodating region, a steel disc supply region and a steel disc fine positioning region in sequence; a guide rod which spans the three regions is arranged above the bracket; a sliding workbench is fixed on the guide rod through a linear bearing; and the sliding workbench is connected with an air cylinder which is fixed on the bracket and is used for driving the sliding workbench to move in a reciprocating way among the three regions along the guide rod. A steel disc is placed into a plastic absorption box, is accurately positioned secondly, and is placed into a die through a mechanical hand, and an entire process is performed automatically, so that labor cost is saved, the molding period is shortened, yield is increased, and the appearance quality of the steel disc is also ensured.

Owner:DONGGUAN HUAQING OPTICAL TECH

Road surface anti-sliding structure and use method thereof

InactiveCN110565477AFaster melting rateImprove driving safetyPaving detailsTraffic signalsDriving safetyEngineering

The invention discloses a road surface anti-sliding structure and a use method thereof, and relates to the technical field of road surface sliding prevention. The structure comprises a road surface base body layer, convex sides are symmetrically and evenly arranged on the edges of the two sides of the road surface base body layer, fixed holes are formed in the convex sides, grooves are linearly formed in the road surface base body layer along two symmetric convex sides, fastening plates are arranged in the grooves, and penetrating holes are formed in the position, between the two adjacent grooves, of the road surface base body layer at equal distances; through combined use of the road surface base body layer, the fastening plate, and fixed columns, in the use process of the road surface base body layer, the road surface base body layer is attached tightly to the road surface, it is ensured that the anti-sliding structure is gentle in surface and free of protrusions, it is ensured thata vehicle can stably run on the road surface, through the penetrating holes in the road surface base body layer, the air circulation is increased, industrial salt or snow-melting agents can be storedin the penetrating holes, the melting rate of an iced road surface can be improved, the friction force with the ground and traveling tires can be increased, and traveling safety is improved.

Owner:FOSHAN UNIVERSITY

Productive cell shutting method of aluminum cell

The invention relates to the aluminum electrolytic cell technical field, in particular relating to a protective cell-shutting method of an aluminum electrolytic cell. The method aims to solve the problems of cracking, deformation and doming up, etc. caused by an inner lining directly exposed in the air during the prior cell shutting, and comprises the following steps that: (1) part aluminum liquid inside an electrolytic cell is pumped out at first; (2) then, part electrolyte liquid inside the electrolytic cell is taken out; (3) an anode is put into the aluminum liquid and is raised after all aluminum liquid is pumped out, and thermocouples are distributed inside the electrolytic cell; (4) the surface of the anode is provided with an alumina heat-preservation material, and a feeding port and an aluminum outlet are sealed closely; moreover, a cell cover plate is covered; (5) a purifying smoke evacuation pipe is closed, and rockwool is used to cork up a side heat dissipation hole of a basin and to carry out bottom heat preservation; a factory building, a trench window and an air grid section are closed, and a window inside a closed workshop is closed; and (6) when temperature inside the electrolytic cell is lowered to normal temperature, cell shutting is completed. The protective cell-shutting method ensures reasonable gradient lowering of the temperature of an electrolytic cell inner lining, and reduces inner lining damage caused during cell shutting; meanwhile, the method has better anodic protection, strong commonality, simple operation and outstanding effects, and can continue to be used.

Owner:山西华圣铝业有限公司

Desalination cultivation method for juvenile crabs

InactiveCN113545309ADesalination is easy to cultivateImprove survival rateClimate change adaptationPisciculture and aquariaJuvenileDesalination

The invention discloses a desalination cultivation method for juvenile crabs which comprises the following steps: S1, firstly, selecting a culture pond, building a sunshade blocking piece at the upper part of a pond body, and putting floating objects for shielding sunlight into the pond body for juvenile crab growth; S2, equipment application: adding oxygenation equipment and water pumping equipment into the culture pond; S3, region division: dividing the culture pond into four sections for juvenile crab activity, wherein the four sections are located at the four corners of the culture pond respectively, and oxygenation equipment is arranged in each of the four activity sections; S4, juvenile crab selection: wherein the selected juvenile crabs have the following characteristics that the juvenile crabs are normal in color and glossy, the juvenile crabs are vigorous, the surfaces of juvenile shells are intact and free of collision, pits and protrusions, the crab legs are not incomplete, and the sizes and specifications are uniform; S5, pond water planning: wherein the salinity of the pond water for the first time is 30. According to the desalination cultivation method for juvenile crabs, the survival rate of the juvenile crabs is increased, desalination cultivation of the juvenile crabs is facilitated, and growth of the juvenile crabs is facilitated.

Owner:SHEYANG ZHUPING AQUATIC FINGERLINGS CO LTD

A Fast and Efficient Hydrocyclone

ActiveCN110328062BSolve the problem of thinningEnhanced secondary separationReversed direction vortexThermodynamicsRinse water

The invention belongs to the technical field of material separation, and discloses a fast and high-efficiency hydrocyclone, which includes a cyclone body, a flushing water distributor and a deflector, and the flushing water distributor and the deflector are respectively connected with the hydrocyclone on the cyclone body. The bottom covers are connected by welding, and the deflector is symmetrical to the center of the cylindrical cavity on the cyclone body and tangent to the bottom flow tube on the cyclone body. The material is fed in from the feed port and performs a spiral movement in the cyclone. When the particles move to the bottom of the cyclone, under the action of the upward flushing water, the fine particles are taken out and enter the internal cyclone. Under the action of the plate, the separated coarse particles are quickly diverted to the bottom flow port and discharged on the basis of the original rotary motion. The invention utilizes the principle of fluidization to strengthen the internal flow field effect of the hydrocyclone, reduces the amount of fines contained in the bottom flow, and greatly improves the separation efficiency of wide-grade materials; meanwhile, the residence time of coarse particles is reduced, and the processing capacity of the hydrocyclone is further improved .

Owner:NORTHEASTERN UNIV LIAONING

Relay coil processing system

ActiveCN113078028BAchieving synchronous correctionCalibration stops in timeElectromagnetic relay detailsElectrical connectionEngineering

This application relates to a relay coil processing system, which includes a vibrating plate, a feeding device, a winding device, a soldering device, a detection device and a guide rail. A transmission workpiece is slidably arranged on the guide rail. A placement slot, a cavity is provided in the transmission workpiece, and a plurality of correction mechanisms, a plurality of in-position mechanisms and a plurality of control mechanisms that are electrically connected to the plurality of in-position mechanisms are arranged in the cavity; the correction mechanism includes a rotation set on The connecting rod on the transmission workpiece, the end of the connecting rod close to the placement groove is rotatably connected with the correction wheel, the side of the placement groove close to the correction wheel communicates with the cavity, and the transmission workpiece is provided with a second drive assembly for driving the correction wheel to rotate, the transmission The workpiece is provided with a swing assembly for driving the correction wheel to approach and extend into the placement groove or to move away from the placement groove. The application has the effect that the pins on the skeleton can be calibrated by the correction wheel, and the correction can be stopped by a single correction wheel after the correction is completed.

Owner:WANGRONG ELECTRONICS SHENZHEN

A kind of silver plating solution pre-dissolving process

ActiveCN103741199BSolve the problem of difficult concentration controlReduce use costCellsPotassium cyanideSilver cyanide

The invention discloses a silvering solution pre-dissolving process. The process comprises the following steps: adding pure water into a dissolving tank, starting a heater arranged in the dissolving tank and a circulating pump arranged on the dissolving tank; then adding potassium cyanide into the dissolving tank; under the circulating stirring action of the circulating pump, adding silver cyanide after potassium cyanide is dissolved fully into water; injecting the dissolved liquid medicine into a storing tank through a liquid outlet pipeline, a valve and an extracting pump which are arranged on the dissolving tank; after the liquid medicine is injected into the storing tank, starting the heater and a liquid medicine circulating pump which are arranged in the storing tank; introducing the liquid medicine in the storing tank into a titrating tank, and then starting the circulating pump and the heater which are arranged in the titrating tank, then starting a titration metering pump so as to add the liquid medicine into a plating bath with an appointed flow rate due to the adoption of the titration metering pump. Due to the adoption of the process, the thickness of a silver layer on the surface of a silvered product can be uniform without salient points, and furthermore, a large amount of silvering raw materials can be saved.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

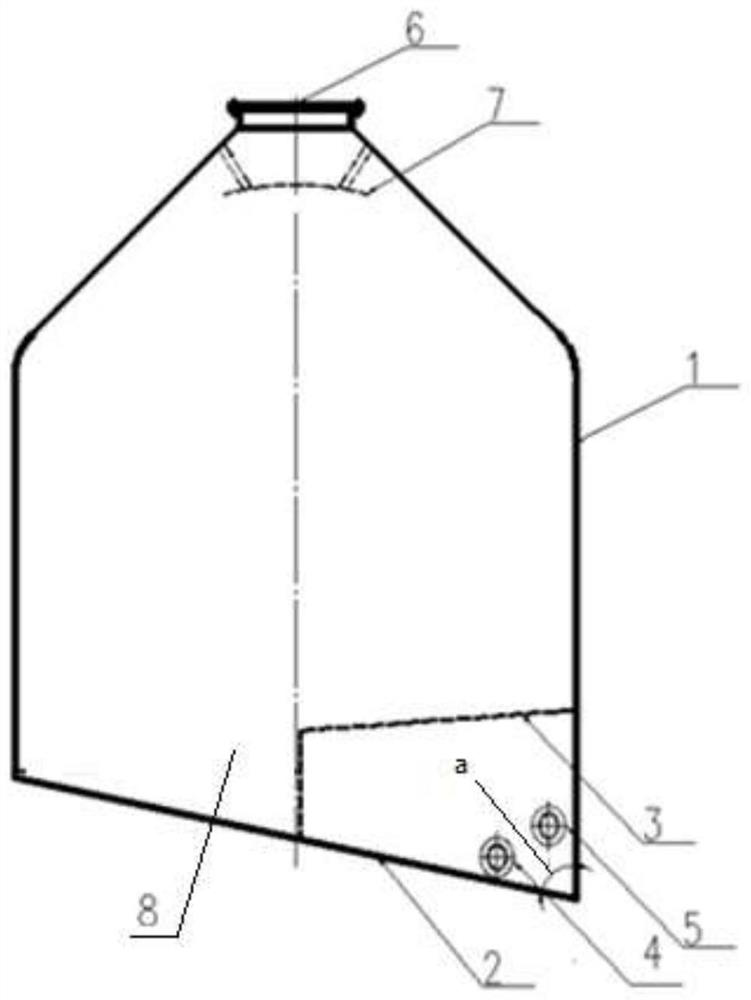

High Level Flash Cooler for Wet Process Phosphoric Acid

ActiveCN112973163BReduce intensityGuaranteed StrengthVacuum distillation separationFlash distillationO-Phosphoric AcidCooling effect

The invention discloses a high-level flash cooler for wet-process phosphoric acid, which solves the problems of the existing high-level flash cooler that materials are easy to boil, easy to accumulate, difficult to clean and high investment cost. The technical solution includes a casing provided with a feed pipe, a discharge pipe and a gas outlet, the bottom surface of the casing is a slope, the feed pipe and the discharge pipe are located on the side wall of the casing at the lower end of the slope, the A partition is arranged between the feed pipe and the discharge pipe at the bottom of the housing, the rear end of the partition is fixed on the housing side wall at the lower end of the slope, and there is a gap between the front end and the housing side wall at the high end of the slope. The invention has extremely simple structure, easy operation, low production cost and investment cost, effectively reduces the occurrence of accumulation and blockage problems, high safety and reliability, and good flash cooling effect.

Owner:WUHUAN ENG

A processing technology for degrading water seepage farmland cover film and its application

ActiveCN110079070BIncreased longitudinal tear strength at right anglesIncrease productionPlant protective coveringsPolyesterCALCIUM LACTOBIONATE

The invention discloses a processing technique for degrading water-permeable farmland covering film and its application, belongs to the technical field of agricultural plastic molding, and mainly solves the problems of low longitudinal tear strength and water impermeability of the polyester degradable film. Features: 1 part of potato flour, 1 part of calcium lactate, 50 parts of shell powder and other biological minerals, dried and crushed through a 140-mesh sieve, weighed and mixed to form an affinity water seepage additive; 1 part of the additive is mixed with PPC7 Parts, modified by twin-screw machine, pelletized into affinity water seepage masterbatch. According to PPC:PBAT:Masterbatch=700:300:25 ingredients, set the temperature of each zone of the blow molding machine in sequence at 130-155°C, inflation ratio 3-5:1, blank film thickness 0.007mm±0.003mm, No. 1 on both sides and No. 2 take-up rollers with a gap of 30mm to 35mm, install the segmented steel core polyurethane sand grain rough surface friction floating roller with an outer diameter of 80mm, a length of 80mm to 300mm, and a gap of about 1mm, and wear it on a rod with a gap of 1mm to 2mm, rolling and rolling friction The blank film is formed with a pore length of 20 μm to 200 μm and a pore density of 1 to 2 million pcs / m 2 Fully biodegradable permeable farmland cover film with criss-cross micropores.

Owner:山西微通渗水膜生物科技有限公司

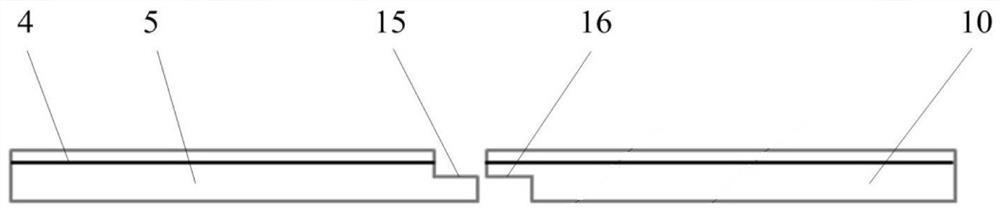

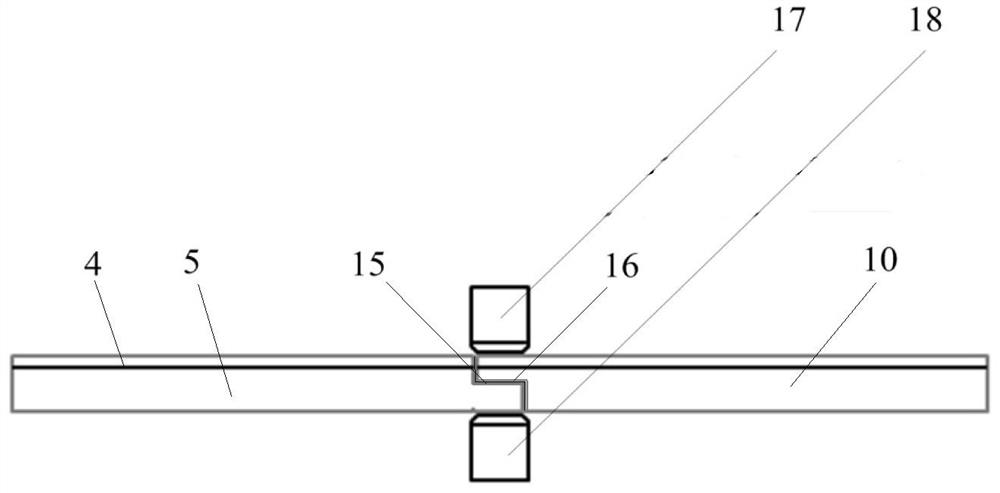

Welding and packaging integrated method for high-temperature superconducting tape

InactiveCN111715958ASmooth appearanceUniform thicknessSoldering apparatusHigh temperature superconductingEngineering

The invention provides a welding and packaging integrated method for a high-temperature superconducting tape. The welding and packaging integrated method mainly solves the technical problems that thestrength of a joint welded after the existing high-temperature superconducting tape is packaged is lower, the thickness difference between the joint and the original tape is large, the surface is uneven, the mechanical property and the bending property are poorer, and the like. According to the technical scheme, the welding and packaging integrated method comprises the following steps that a, a superconducting core tape A and a superconducting core tape B are welded together in a resistance spot welding or metal ultrasonic spot welding mode; b, the superconducting core tape C is uniformly brazing at the joint of the superconducting core tape A and the superconducting core tape B by adopting a high-melting-point solder sheet; and c, an upper packaging layer, a superconducting core tape partand a lower packaging layer are packaged together by adopting a soldering tin lamination packaging device to form the superconducting tape with an interlayer structure. The method is suitable for industrial production of second-generation high-temperature superconducting tapes.

Owner:SHANGHAI SHANGCHUANG SUPERCONDUCTING TECH CO LTD

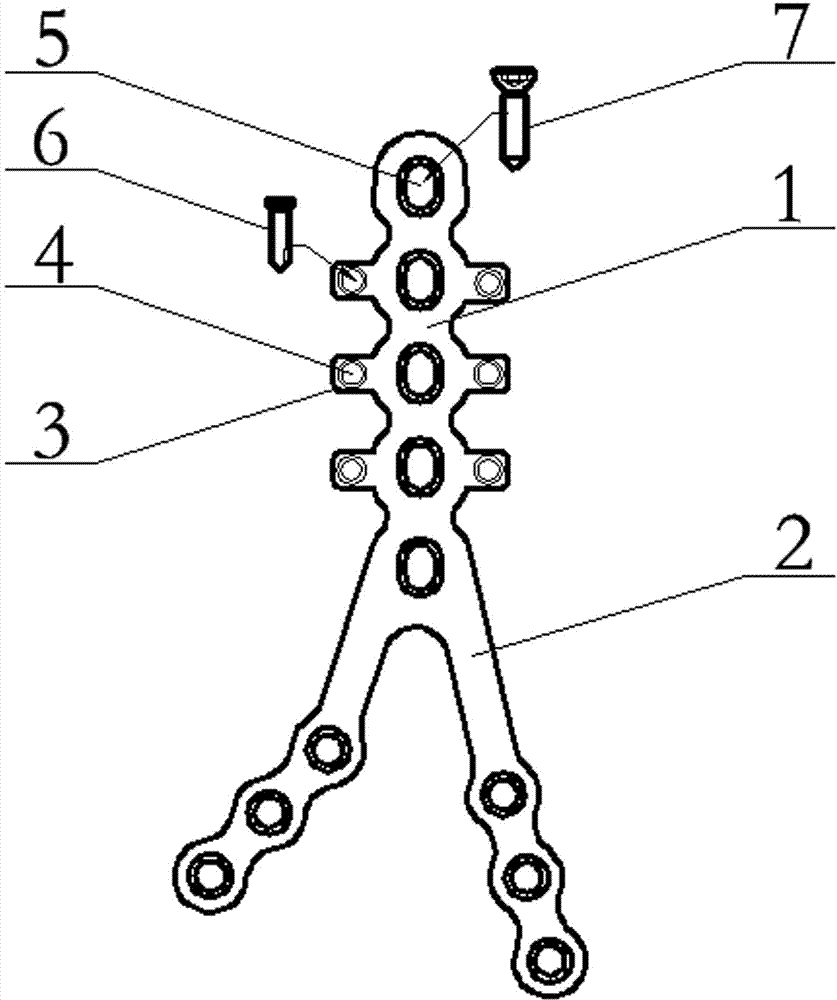

Humerus Y-type protection steel board

InactiveCN103919599AImprove integrityPromotes fracture healingInternal osteosythesisBone platesTreatment effectEngineering

A humerus Y-type protection steel board is formed by connecting a straight section and two forks and is in an inversed-Y-type structure with the inner side face and the far end of the humerus being matched, and a plurality of locating holes are formed in the straight section and the forks. The humerus Y-type protection steel board is characterized by further comprising a plurality of protection wings which are symmetrically arranged on the two sides of the straight section and are in a contained shape towards the inner side face of the straight section; when the straight section is fixed to the far end of the humerus, the inner side face of the straight section is attached to the front face of the far end of the humerus, the two sides of the protection wings wrap the two sides of the far end of the humerus in a containing mode, crush bones on the two sides of the humerus can be stably fixed in the mode that screws or fixing needles penetrate through threaded holes or needle penetrating holes, the completeness of the humerus is protected, and the fracture healing and treatment effect of the humerus is improved; countersunk head screws are flat on the surface of the steel board when used, no protrusion exists, implantation is convenient, pains caused by use of the screws are relieved, and postoperative healing is facilitated; the locking firmness is improved through a countersunk forcing screw.

Owner:泰州市中兴医械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com