Processing technology and application of degradable water-seepage farmland mulching film

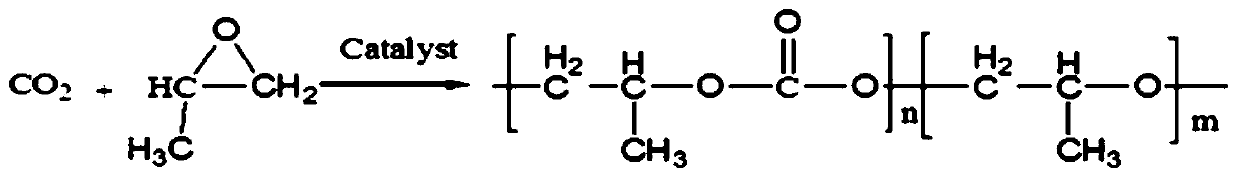

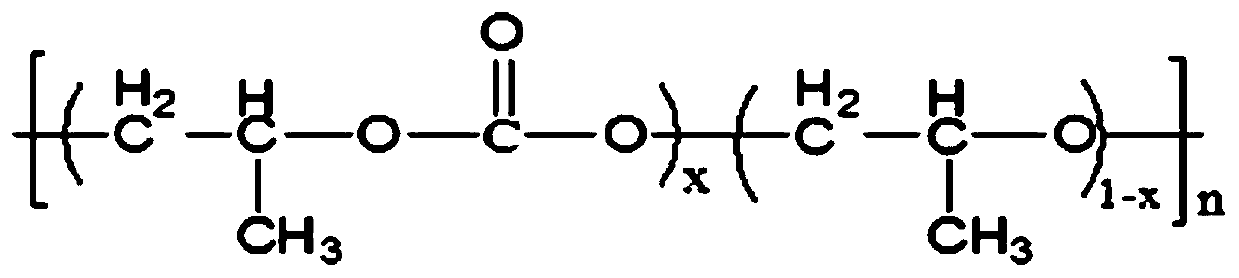

A covering film and processing technology, which is applied in the field of processing technology for degrading water-permeable farmland covering films, can solve the problems of low longitudinal right-angle tear strength, impermeability of water, and no ventilation, etc., to increase the longitudinal right-angle tear strength and be suitable for the market. The effect of promotion and reduction of the amount per mu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

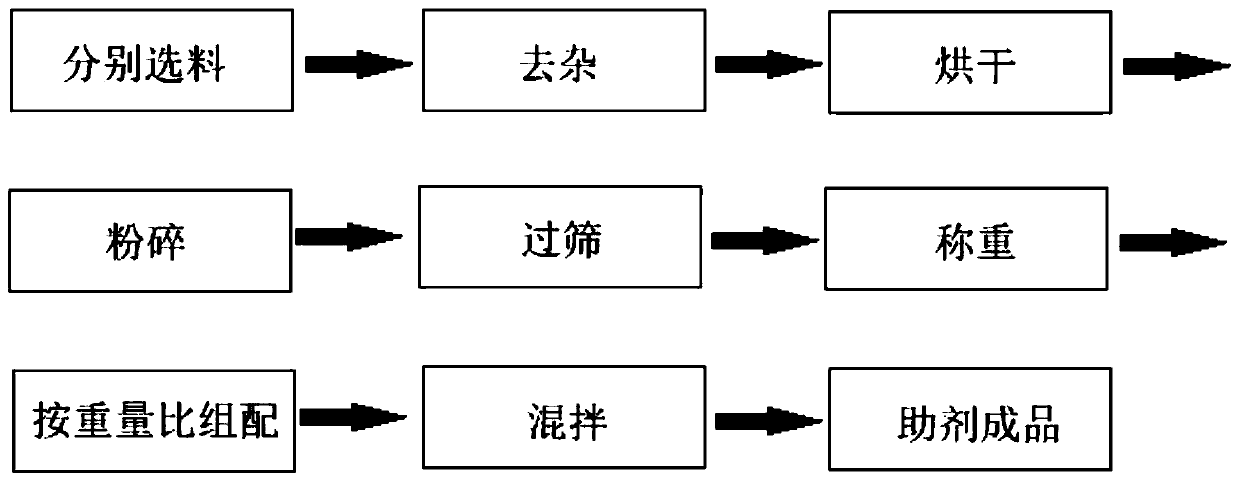

Method used

Image

Examples

Embodiment 1

[0046] Use the PPC material with number average molecular weight of 159,000 (ie weight average molecular weight of 320,000): number average molecular weight of 150,000 PBAT: affinity water seepage aid masterbatch=700:300:25 blending, in the blowing machine with a die head diameter of 180mm On the plastic machine, the heating temperature of the feeding area is 130°C, the heating temperature of the front area is 140°C, the heating temperature of the middle area is 140°C, the heating temperature of the rear area is 140°C, the heating temperature of the die head is 140°C, and the blown thickness is 0.0065mm And the blank film with a width of 1200mm, after slitting, on the front and rear coilers, it is squeezed and rolled by friction floating rollers with an outer diameter of 80mm and a length of 300mm, respectively, to form a 5kg degradation permeable farmland covering film. After testing by the Plastics Research Institute of Taiyuan City, Shanxi Province, all indicators have reach...

Embodiment 2

[0052] Use the PPC material of number average molecular weight 300,000 (that is, weight average molecular weight 600,000): number average molecular weight 150,000 PBAT: affinity water seepage aid masterbatch=700:300:25 blending, in the blowing machine with a die head diameter of 180mm On the molding machine, the heating temperature of the feeding area is 135°C, the heating temperature of the front area is 150°C, the heating temperature of the middle area is 150°C, the heating temperature of the rear area is 155°C, the heating temperature of the die head is 155°C, and the blown thickness is 0.007mm And the blank film with a width of 1300mm, after slitting, on the front and rear coilers, it is squeezed and rolled by friction floating rollers with an outer diameter of 80mm and a length of 300mm, respectively, to form a 5kg degradable permeable farmland covering film. After testing by the Plastics Research Institute of Taiyuan City, Shanxi Province, all indicators have reached the ...

Embodiment 3

[0058] In March 2017, PPC raw materials purchased from Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, PBAT purchased from Guangzhou Kingfa Technology Co., Ltd., and degradable water-permeable farmland cover film produced by Shanxi Weitong Water-permeable Membrane Biotechnology Co., Ltd., with a width of 800mm , thickness 0.006mm.

[0059] The test results are shown in the table below:

[0060] Decomposition rate test results table of degraded seepage farmland mulch film soil under different climatic soil vegetation conditions

[0061]

[0062] In April 2018, PPC raw materials purchased from Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, PBAT purchased from Shanxi Jinhui Energy Group Co., Ltd., degradable water-permeable farmland cover film produced by Shanxi Weitong Water-permeable Membrane Biotechnology Co., Ltd., with a width of 800mm , thickness 0.007mm.

[0063] Such as Figure 8 As shown, the test results of Changchun ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com