Relay coil processing system

A relay coil, processing system technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information, etc., can solve problems such as the unification of difficult pin positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-6 The application is described in further detail.

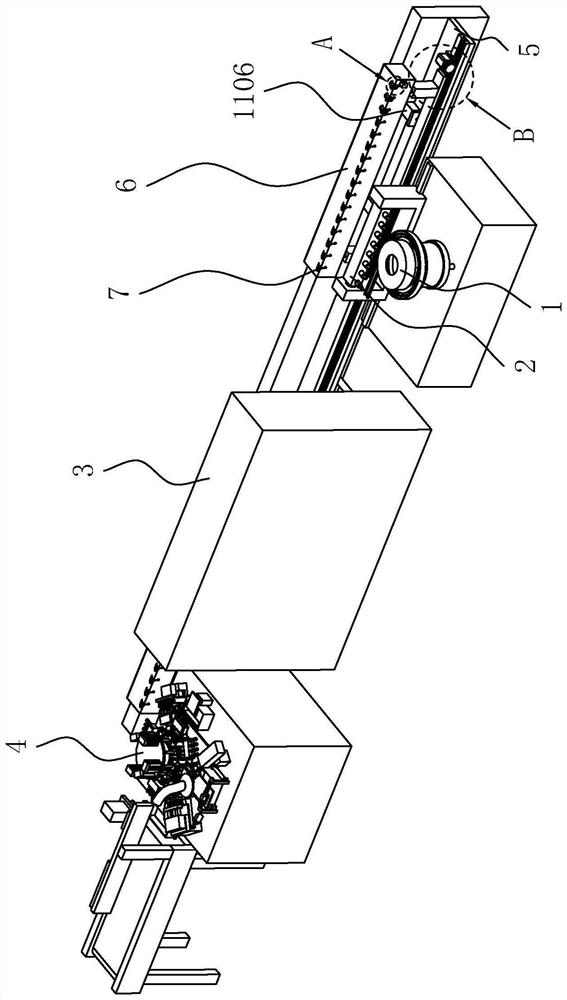

[0042] The embodiment of the present application discloses a relay coil processing system. refer to figure 1 The relay coil processing system includes a vibrating plate 1, a feeding device 2, a winding device 3, a soldering device 4 and a detection device, a guide rail 5 is also arranged between the feeding device 2 and the soldering device 4, the vibrating plate 1, the feeding device 2. The winding device 3, the soldering device 4 and the detection device are all located on the same side of the guide rail 5, the winding device 3 is located between the feeding device 2 and the soldering device 4, and the guide rail 5 is slidably provided with a transmission workpiece for transferring multiple skeletons 6. The guide rail 5 is provided with a first driving mechanism for driving the transport workpiece 6 to reciprocate on the guide rail 5 .

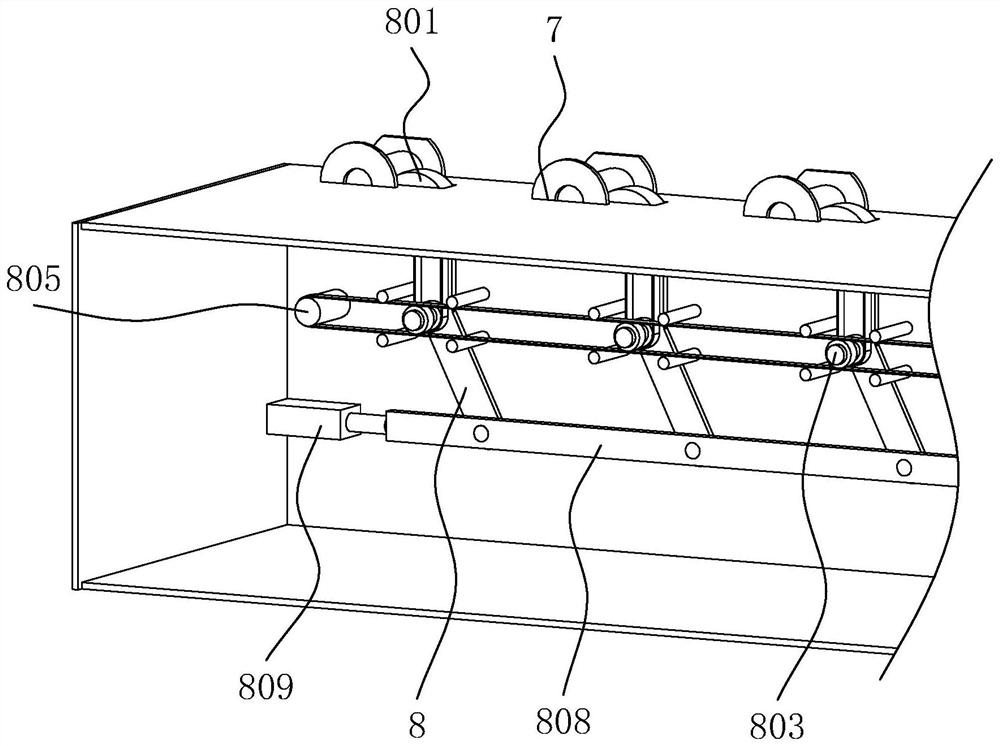

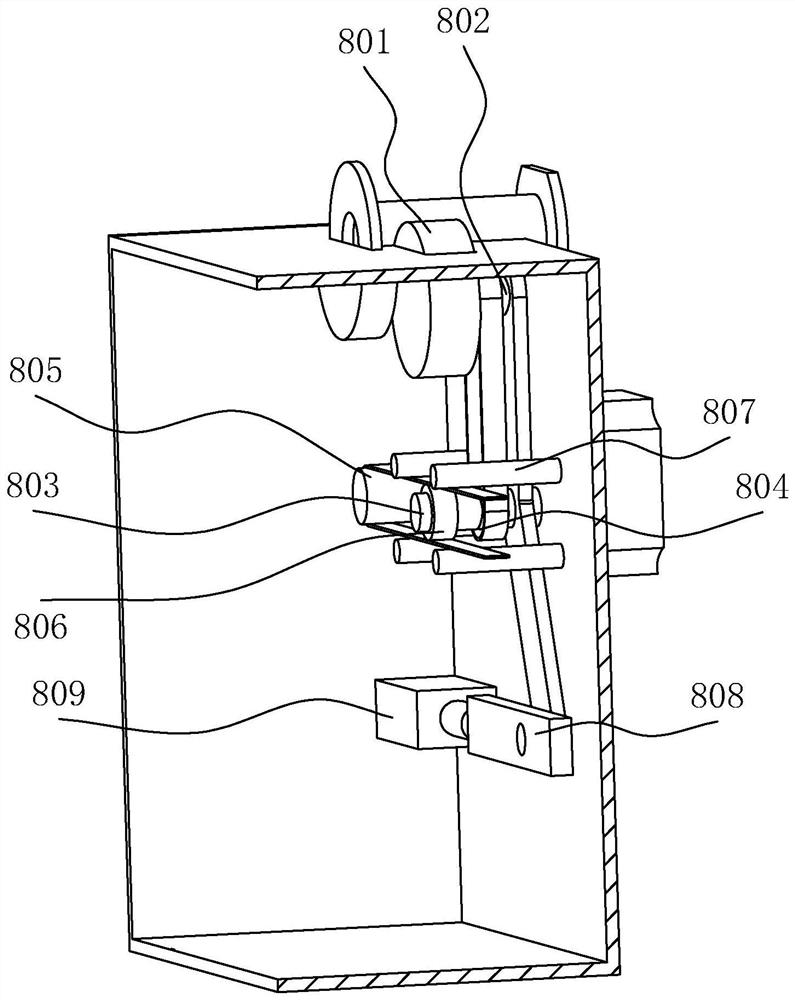

[0043] refer to figure 1 with figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com