Fast and efficient hydrocyclone

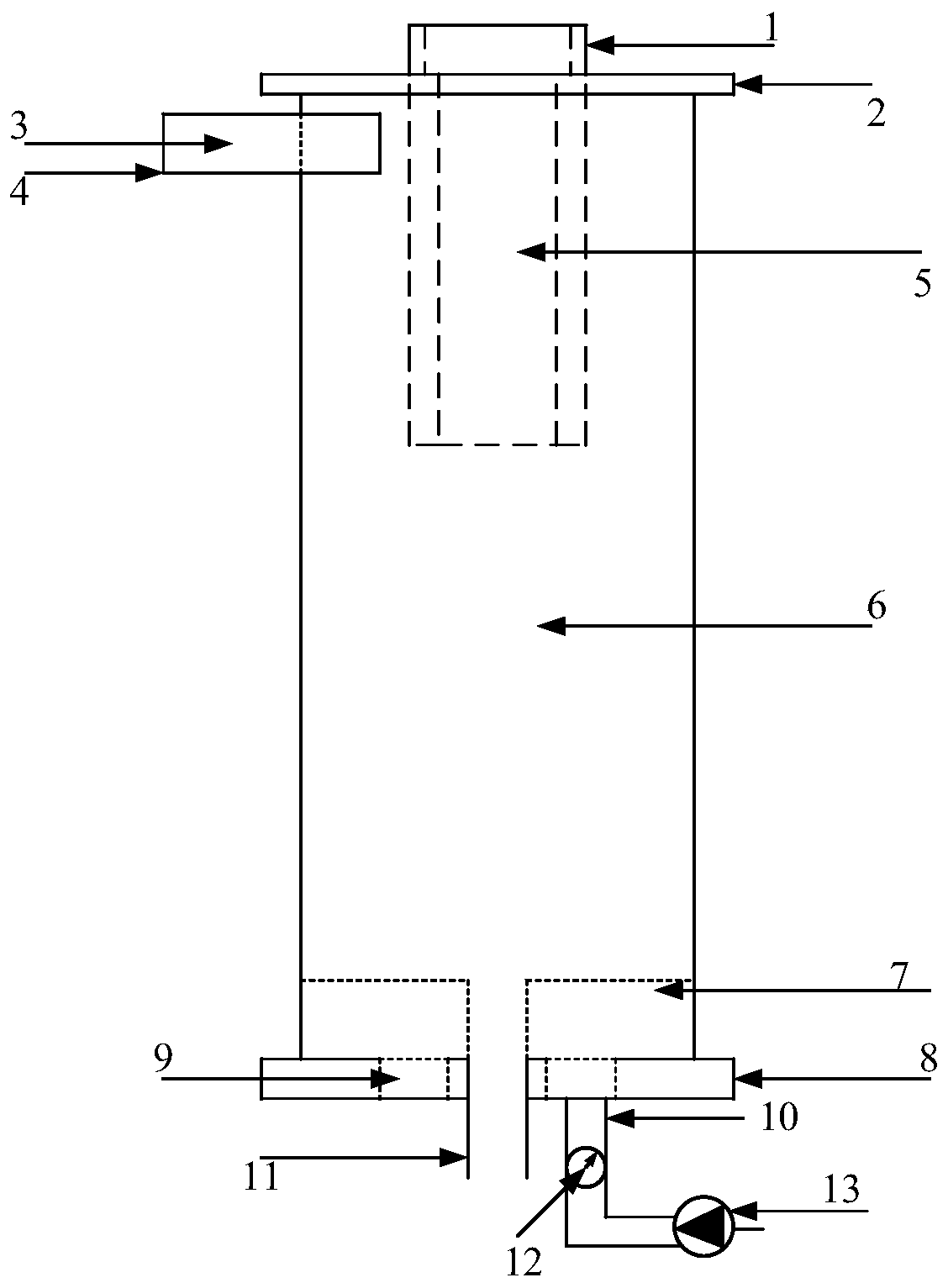

A hydrocyclone and cyclone technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of limited processing capacity, fine underflow and low classification efficiency, etc. Improve separation efficiency, improve processing capacity, and solve the effect of longer residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

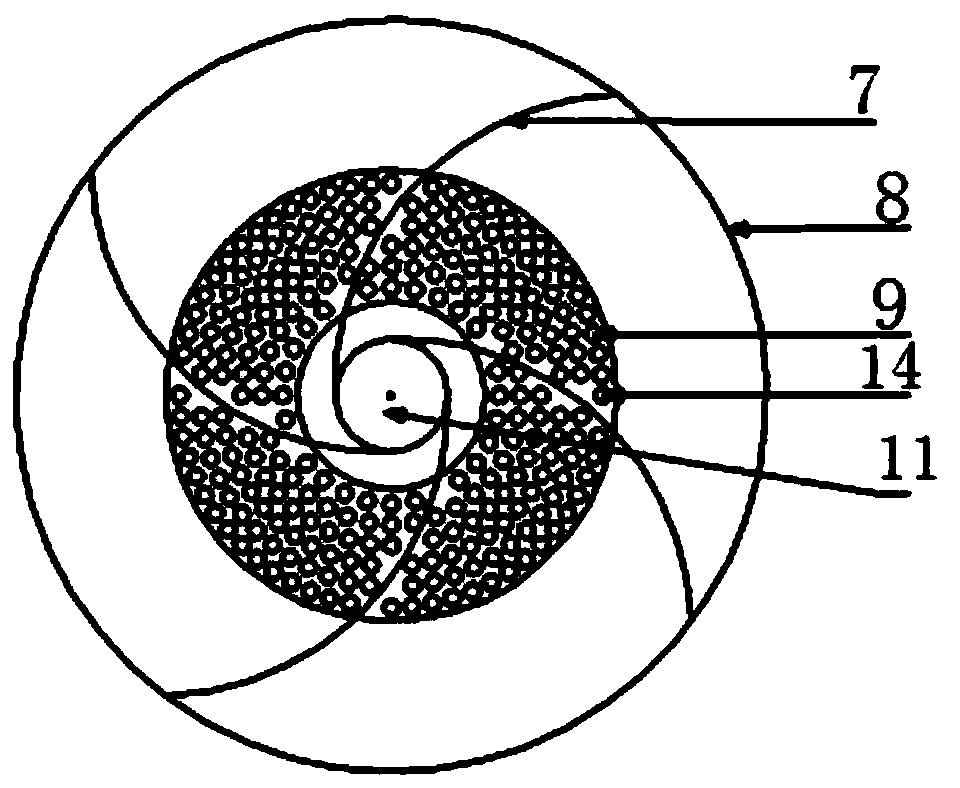

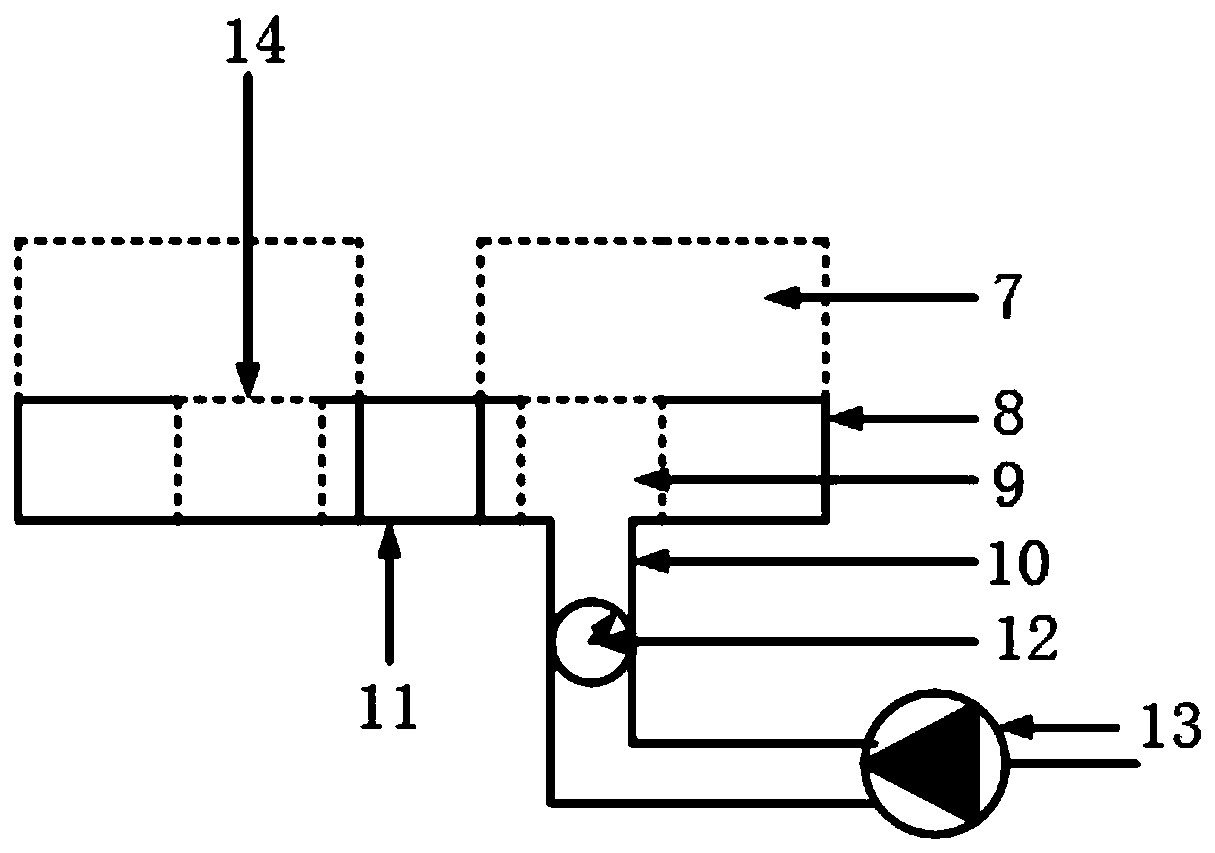

Embodiment 1

[0033] In this embodiment, a fast and high-efficiency hydrocyclone with a structure of four-divided baffles 7 is adopted, and the baffles 7 are distributed symmetrically in the center, but the number is not limited to four. In this embodiment, the height of the deflector 7 is set to 30mm. The deflector 7 is symmetric about the center of the cylindrical cavity 6 and is tangent to the underflow tube 11. The diameter and pressure of each flushing water outlet 14 are the same. When the particles enter the cyclone Then, the flushing water is fed into the flushing water inlet 10 at a certain pressure, and the flushing water is discharged from the flushing water outlet 14 at a certain speed. According to the theory of fluidization, under the action of flushing water, when the axial velocity of the flushing water is greater than the initial fluidization velocity (Umf), the particles entering the bottom of the cyclone are loose and floating, forming fluidization. When the flow velocity ...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the height of the deflector 7 in this embodiment is set to 45mm, and the deflector 7 is centrally symmetric about the center of the cylindrical cavity 6 and is tangent to the underflow tube 11, so that the system runs stably. After that, the increase in calculation processing amount and the increase in classification efficiency are recorded.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that the height of the deflector 7 in this embodiment is set to 60mm, and the deflector 7 is symmetric about the center of the cylindrical cavity 6 and is tangent to the underflow tube 11, so that the system is stable. After that, the increase in calculation processing amount and the increase in classification efficiency are recorded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com