Special antimicrobial-function environment-friendly matte finish paint for children and preparation method thereof

An environmentally friendly, children's technology, applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as health hazards, and achieve the effect of strong sterilization ability, not easy to foam, and stable gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

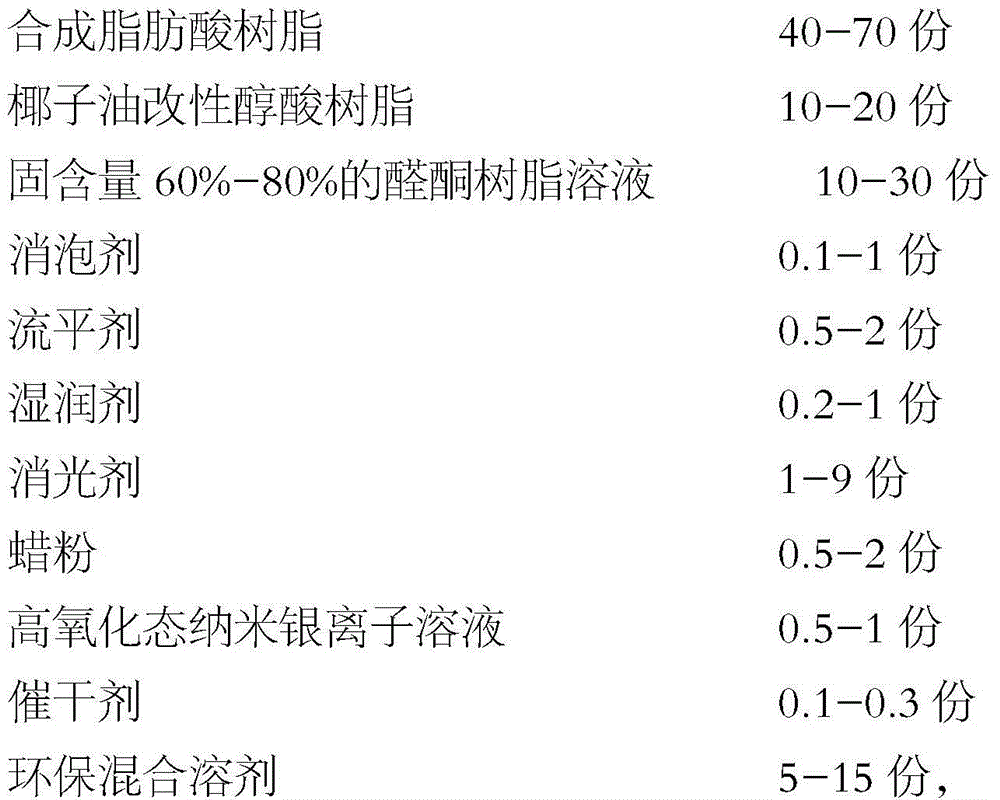

Method used

Image

Examples

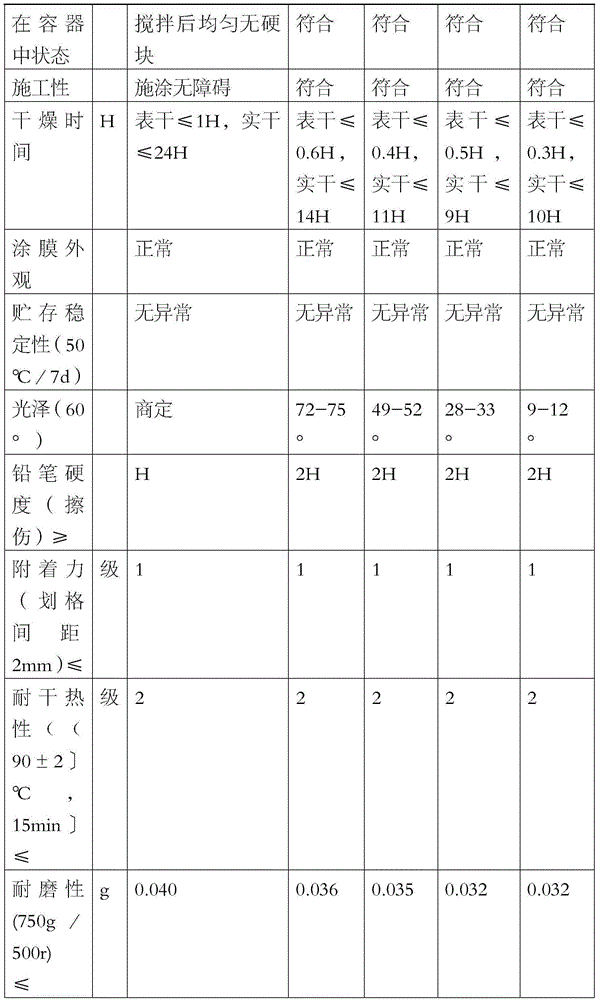

Embodiment 1

[0043] Preparation method of main paint

[0044] The main paint is prepared by the following steps:

[0045] (1) butyl acetate, propylene glycol methyl ether acetate, and divalent ester are mixed according to the weight ratio of 50:45:20 to form an environmentally friendly mixed solvent;

[0046] (2) Dibutyltin dilaurate and butyl acetate are mixed according to a weight ratio of 1:1 to form a drier;

[0047] (3) After mixing 57 parts of synthetic fatty acid resin, 20 parts of coconut oil modified alkyd resin, 12 parts of aldehyde and ketone resin solution with a solid content of 70%, and 3 parts of environmentally friendly mixed solvent, disperse for 9 minutes at a speed of 700 rpm ; While dispersing, add 0.5 parts of BYK-996, 1 part of ED-2, disperse for 15 minutes at a speed of 1500 rpm until the fineness is ≤25um, then add 0.5 parts of BYK-066N, 1.2 parts of glide450, BYK 0.5 parts of -333, 0.5 parts of nano-silver ion solution in high oxidation state, 0.1 parts of drier ...

Embodiment 2

[0057] Embodiment 2 (preferred embodiment)

[0058] Preparation method of main paint

[0059] The main paint is prepared by the following steps:

[0060] (1) butyl acetate, propylene glycol methyl ether acetate, and divalent ester are mixed according to the weight ratio of 50:45:20 to form an environmentally friendly mixed solvent;

[0061] (2) Dibutyltin dilaurate and butyl acetate are mixed according to a weight ratio of 1:1 to form a drier;

[0062] (3) After mixing 56.2 parts of synthetic fatty acid resin, 10 parts of coconut oil modified alkyd resin, 13 parts of aldehyde and ketone resin solution with a solid content of 70%, and 6 parts of environmentally friendly mixed solvent, disperse for 9 minutes at a speed of 700 rpm ;While dispersing, add 2 parts of BYK-996, 4.5 parts of ED-2, disperse for 15 minutes at a speed of 1500 rpm until the fineness is ≤25um, then add 0.5 parts of BYK-066N, 1 part of glide450, BYK 0.8 parts of -333, 1 part of high oxidation state nano-s...

Embodiment 3

[0073] Preparation method of main paint

[0074] The main paint is prepared by the following steps:

[0075] (1) butyl acetate, propylene glycol methyl ether acetate, and divalent ester are mixed according to the weight ratio of 10:9:4 to form an environmentally friendly mixed solvent;

[0076] (2) Dibutyltin dilaurate and butyl acetate are mixed according to a weight ratio of 1:1 to form a drier;

[0077] (3) After mixing 48 parts of synthetic fatty acid resins, 15 parts of coconut oil modified alkyd resins, 15 parts of aldehyde and ketone resin solutions with a solid content of 70%, and 7 parts of environmentally friendly mixed solvents, disperse for 9 minutes at a speed of 700 rpm; While dispersing, add 1 part of BYK-996, 6.5 parts of ED-2 and disperse for 15 minutes at a speed of 1500 rpm until the fineness is ≤25um, then add 1 part of BYK-066N, 1.5 parts of glide450, BYK- 0.5 parts of 333 meter, 1 part of high oxidation state nano-silver ion solution, 0.1 part of drier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com