Thermal insulation TPU thin film for automobile film pasting and preparation method thereof

A technology for car sticking film and film, which is applied in the field of thermal insulation TPU film and its preparation to achieve the effects of improving printing performance, being easy to print and applying adhesives, and improving surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment adopts following method to prepare TPU film:

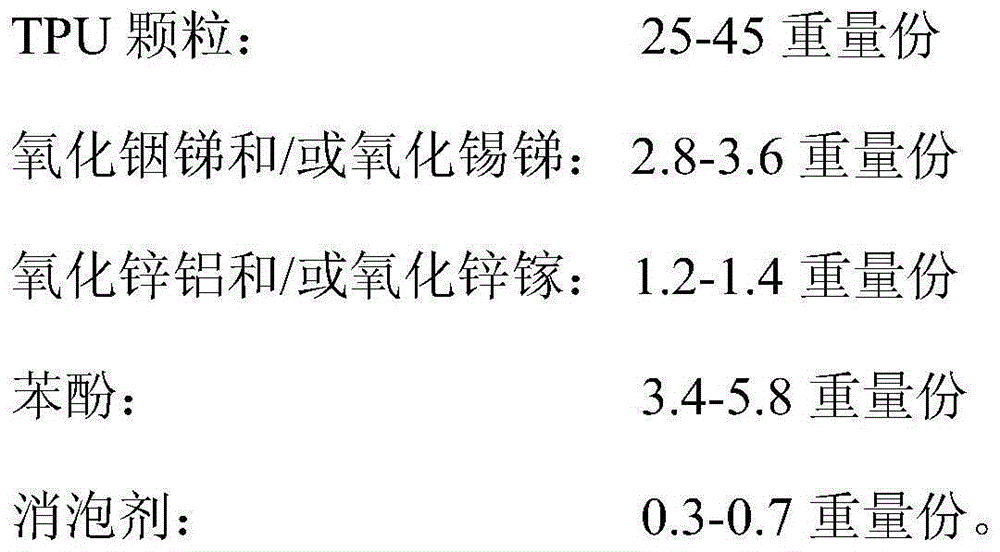

[0039] (1) Composition of raw materials:

[0040]

[0041] In TPU particles, its raw material components include 45% diisocyanate, 1% chain extender, 35% polymer polyol, 5% cycloalkyl imidazoline and 4% tetrahydrophthalimide by mass percentage .

[0042] (2) Preparation method:

[0043] ①Vacuumize and dehydrate the raw materials of each component in (1) at 90°C, and the time for the vacuum dehydration is 1.5h;

[0044] ② Stir and mix the raw materials after vacuum dehydration, and then extrude them with a casting extruder. The barrel temperature of the casting extruder is 160°C, the filter screen temperature is 180°C, and the elbow temperature is 180°C. The temperature of the die head was 190° C., and the heat-insulating TPU film for automobile film was obtained.

Embodiment 2

[0046] The present embodiment adopts following method to prepare TPU film:

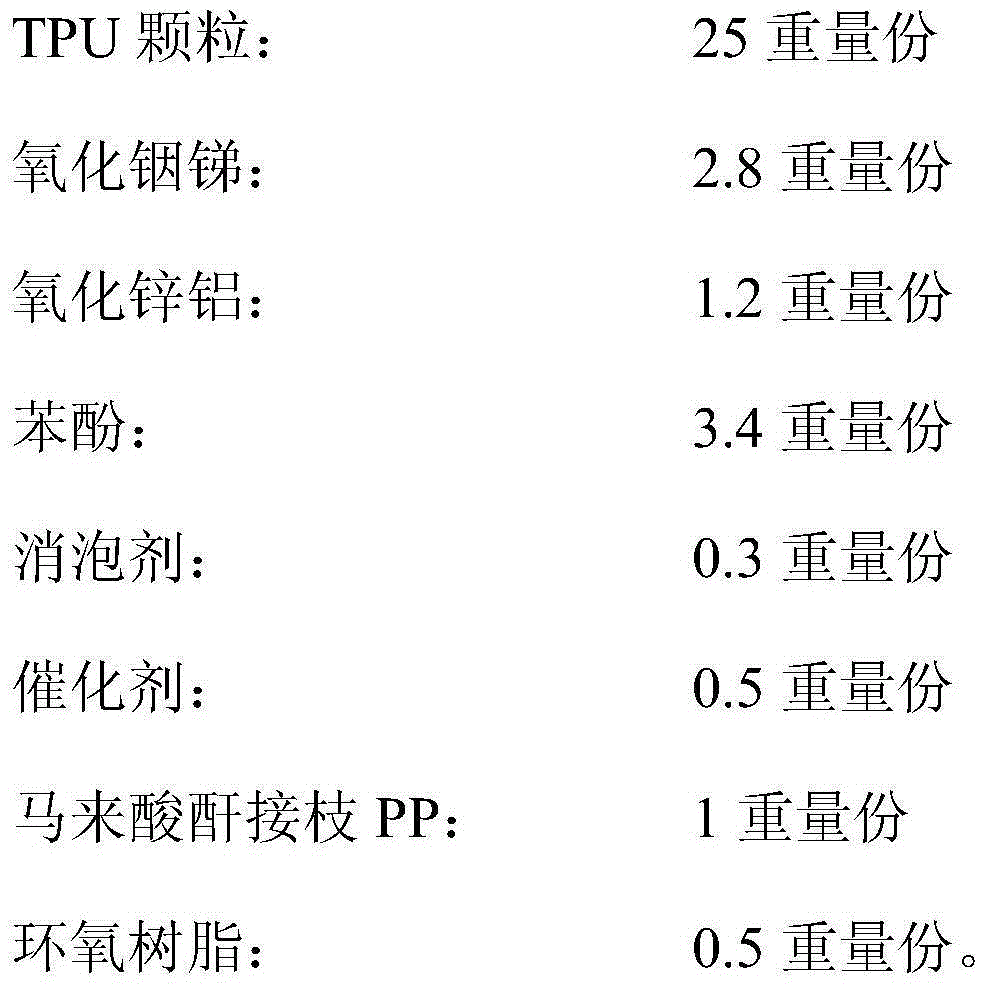

[0047] (1) Composition of raw materials:

[0048]

[0049] In TPU particles, its raw material components include 45% diisocyanate, 1% chain extender, 35% polymer polyol, 5% cycloalkyl imidazoline and 4% tetrahydrophthalimide by mass percentage .

[0050] (2) Preparation method:

[0051] ①The raw materials of each component in (1) are vacuum dehydrated at 120°C, and the time of the vacuum dehydration is 4.5h;

[0052] ② Stir and mix the raw materials after vacuum dehydration, and then extrude them with a casting extruder. The temperature of the barrel of the casting extruder is 250°C, the temperature of the filter screen is 240°C, and the temperature of the elbow is 240°C. The temperature of the die head was 210° C., and the heat-insulating TPU film for automobile film was obtained.

Embodiment 3

[0054] The present embodiment adopts following method to prepare TPU film:

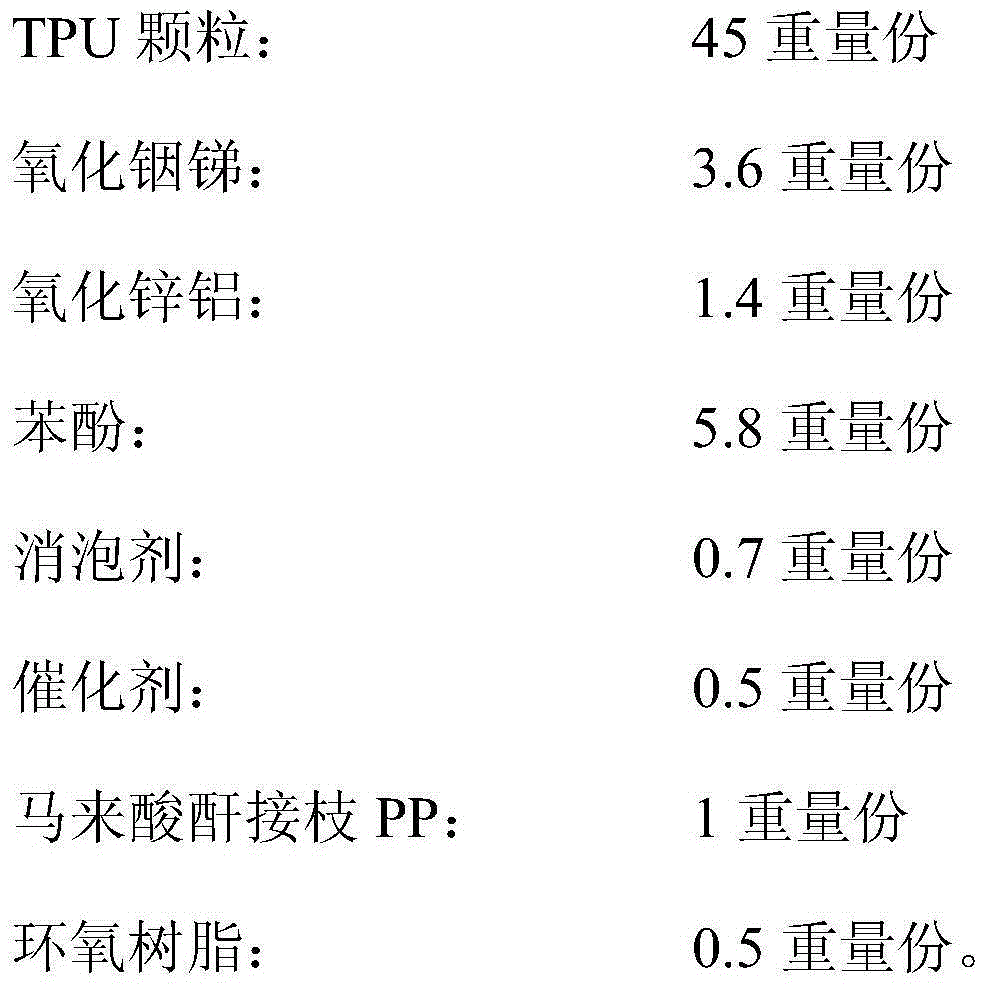

[0055] (1) Composition of raw materials:

[0056]

[0057] In TPU particles, its raw material components include 45% diisocyanate, 1% chain extender, 35% polymer polyol, 5% cycloalkyl imidazoline and 4% tetrahydrophthalimide by mass percentage .

[0058] (2) Preparation method:

[0059] ①Vacuumize and dehydrate the raw materials of each component in (1) at 105° C., and the time for the vacuum dehydration is 3 hours;

[0060] ② Stir and mix the raw materials after vacuum dehydration, and then extrude them with a casting extruder. The temperature of the barrel of the casting extruder is 205°C, the temperature of the filter screen is 210°C, and the temperature of the elbow is 210°C. The temperature of the die head is 200° C., and the heat-insulating TPU film for automobile film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com