Aqueous PU self-curing paint and preparation method thereof

A self-drying paint, water-based technology, applied in the field of paint, can solve the problems of insufficient fullness and high gloss of the paint film, high hardness and poor chemical resistance, insufficient color development and leveling, etc., to achieve excellent Fullness and high gloss, excellent scratch and abrasion resistance, good color development and leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

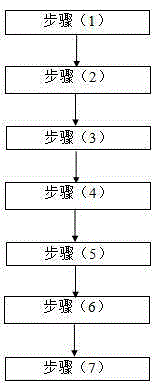

Method used

Image

Examples

Embodiment Construction

[0047] As a preferred solution, the components of the water-based PU self-drying paint are in parts by weight: water-based hydroxyacrylic acid emulsion: 760 parts, TeGo270 wetting agent: 4 parts, TeGo822 defoamer: 6 parts, AMP95: 4 parts, TeGo4100 leveling Agent: 4 parts, diethylene glycol ethyl ether acetate: 40 parts, dipropylene glycol butyl ether: 50 parts, negative ion water: 65 parts, BYK425 polyurethane rheology additive: 6 parts, anti-flash rust agent: 7 parts, TeGo760 emulsifier Wet dispersant: 8 parts, silicone wear-resistant powder (UNICONET-2050): 40 parts, water-based resin-free color paste: 120 parts, preservative: 1.2 parts, freeze-thaw resistance (SYNTHRO-STABUEB): 20 parts, anti-freeze Sinking rheological agent (SCA-SCR430BX-40): 10 parts, broad-spectrum fungicide (PROX-SANIT540F): 6 parts, water-resistant agent (SYNTHRO-WAXP-101D): 10 parts.

[0048] When the aforementioned water-based PU self-drying paint is used, in order to improve its solidification perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com