Dynamic vulcanization thermoplastic polyurethane/polysiloxane elastomer and preparation method thereof

A thermoplastic polyurethane and polysiloxane technology, which is applied in the field of dynamic vulcanization thermoplastic polyurethane/polysiloxane elastomer and its preparation, can solve the problems of difficult feeding, difficult and uniform dispersion, poor dispersion, etc., and achieves improved interface bonding , to ensure the mechanical properties, improve the effect of the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

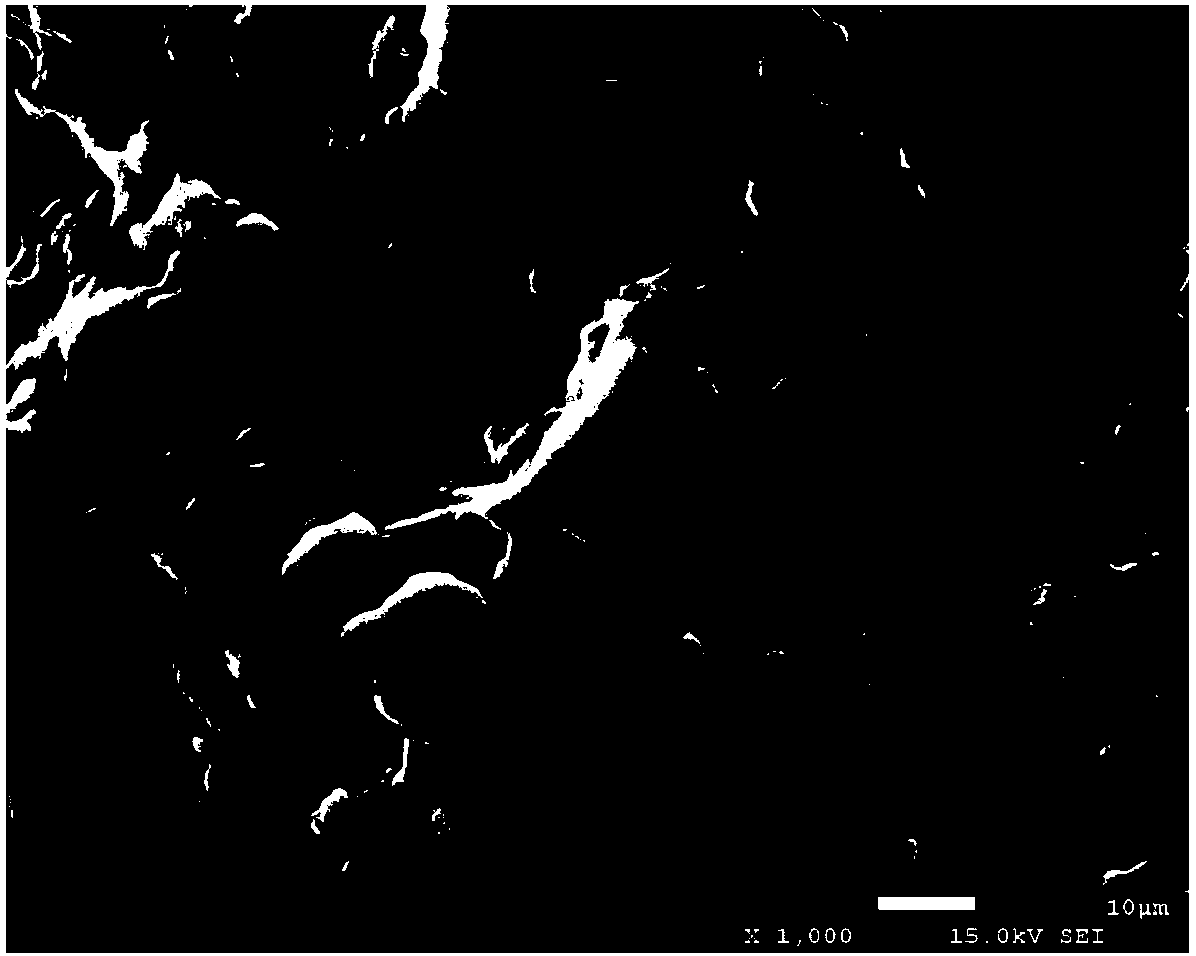

[0065] 100 parts of TPU1, 100 parts of methyl vinyl siloxane 3, 50 parts of reinforcing filler 1 and 1 part of chain extender 2 are premixed and added to a twin-screw extruder with an aspect ratio of 48:1, and then from 0.33 part of catalyst 1 was added to the side feeding port, melted and extruded at 190° C. to granulate, cooled and shaped to obtain granulated polysiloxane masterbatch 1 .

Embodiment 2

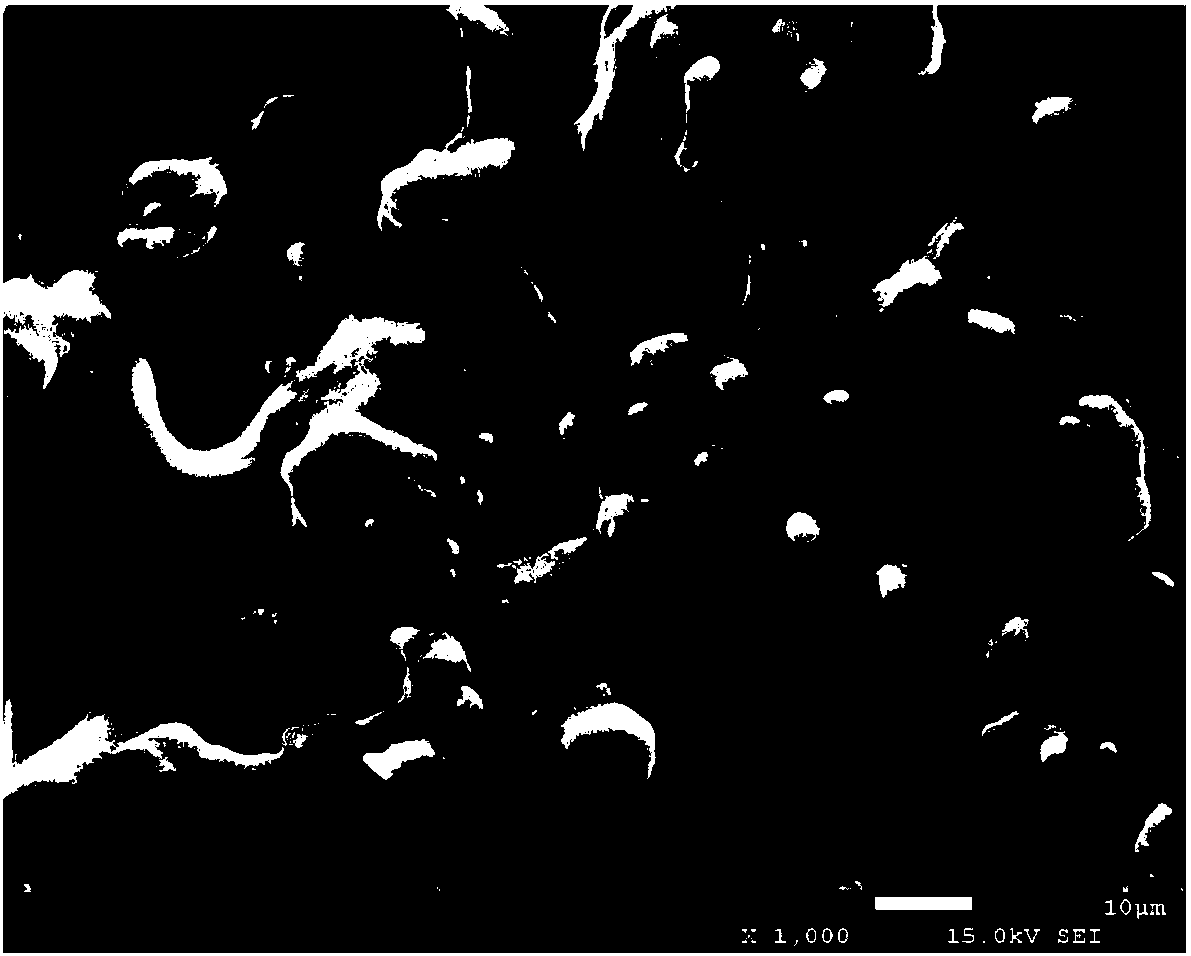

[0067] 100 parts of TPU1, 155 parts of methyl vinyl siloxane 3, 50 parts of reinforcing filler 1, 25 parts of reinforcing filler 2, and 6 parts of chain extender 2 are premixed and then added to the twin-screw extruder with an aspect ratio of 48:1. In the machine, 0.43 parts of catalyst 1 was added from the side feeding port, melted and extruded at 190° C. to pelletize, cooled and shaped to obtain granular polysiloxane masterbatch 2 .

Embodiment 3

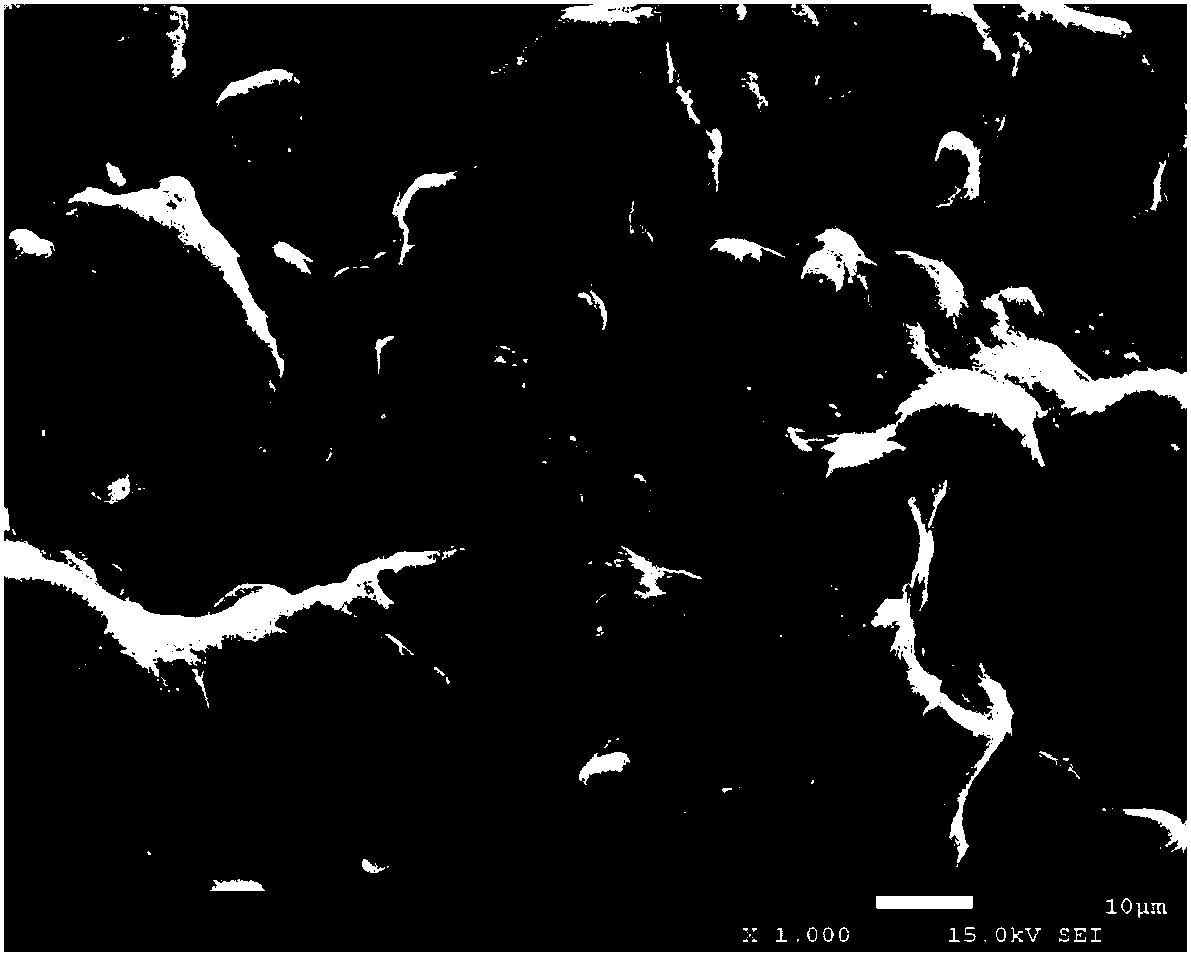

[0069] 100 parts of TPU1, 200 parts of methyl vinyl siloxane 5, 60 parts of reinforcing filler 1, 40 parts of reinforcing filler 2, and 10 parts of chain extender 2 are premixed and then added to the twin-screw extruder with an aspect ratio of 48:1. In the machine, 0.54 parts of catalyst 1 was added from the side feed port, melted and extruded at 190° C. to pelletize, cooled and shaped to obtain granular polysiloxane masterbatch 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com