Micro optical fiber gas sensor covered by adopting graphene

A gas sensor, micro-fiber technology, applied in the measurement of phase influence characteristics, etc., can solve the problems of low reliability, low sensitivity, long response time, etc., and achieve the effect of stable operation, high sensitivity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

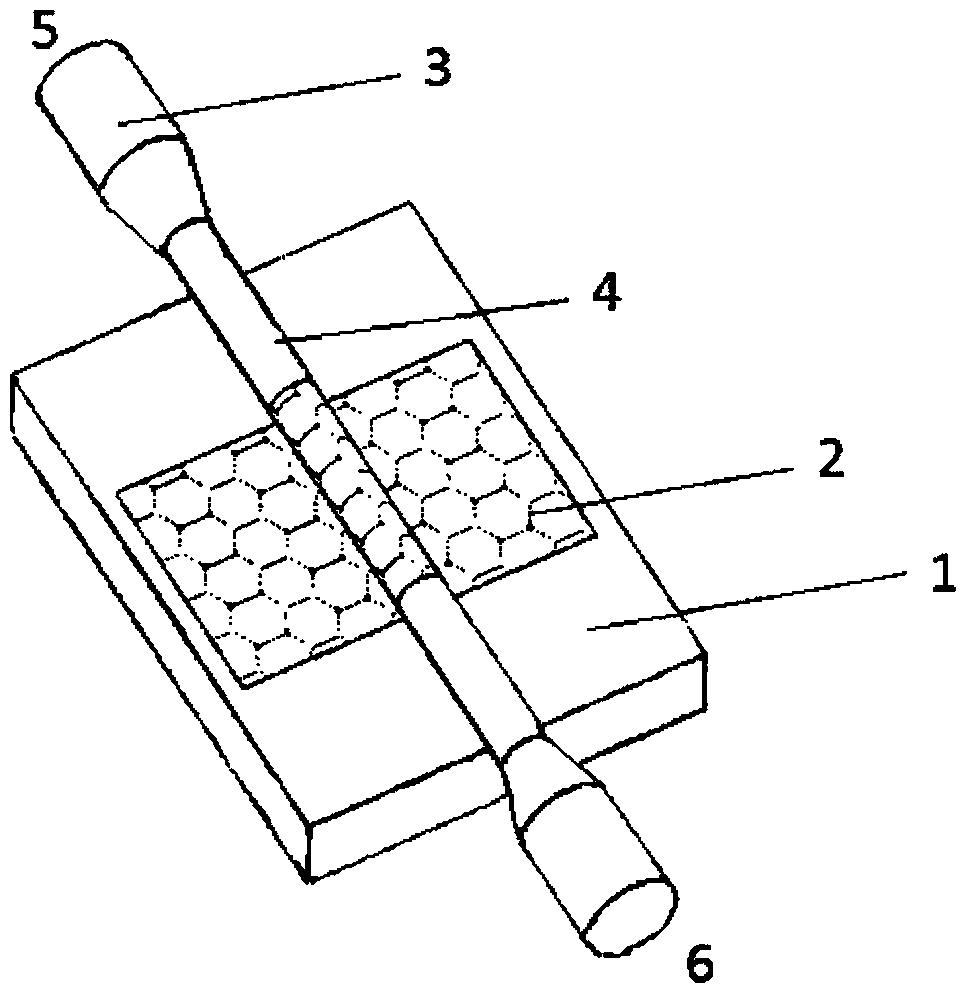

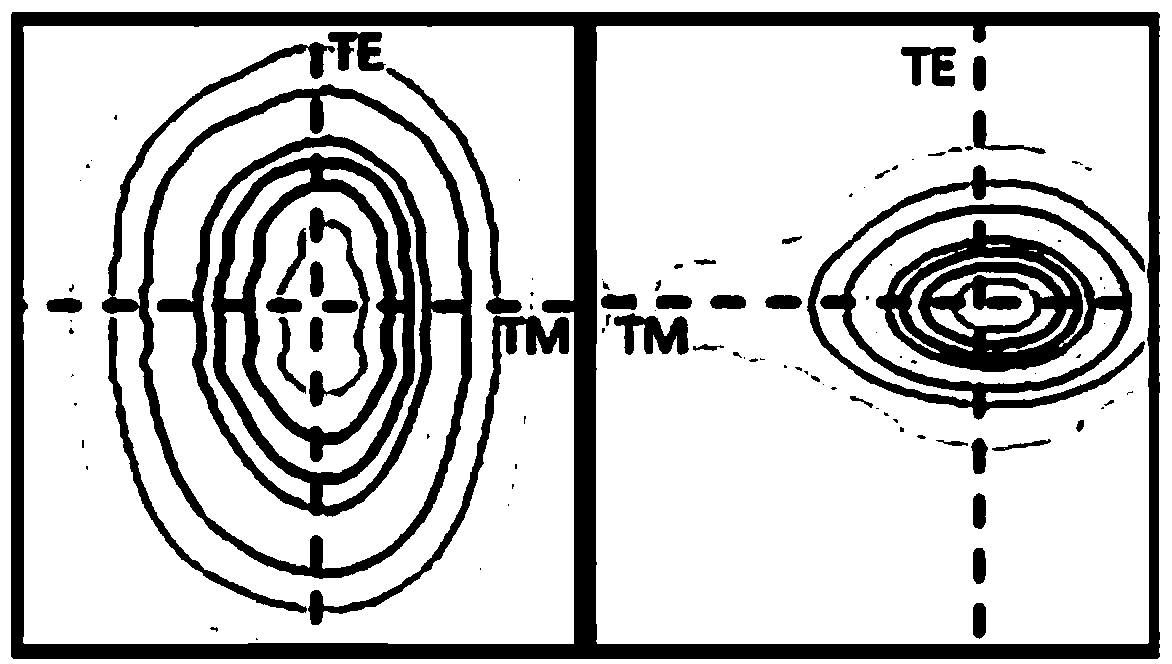

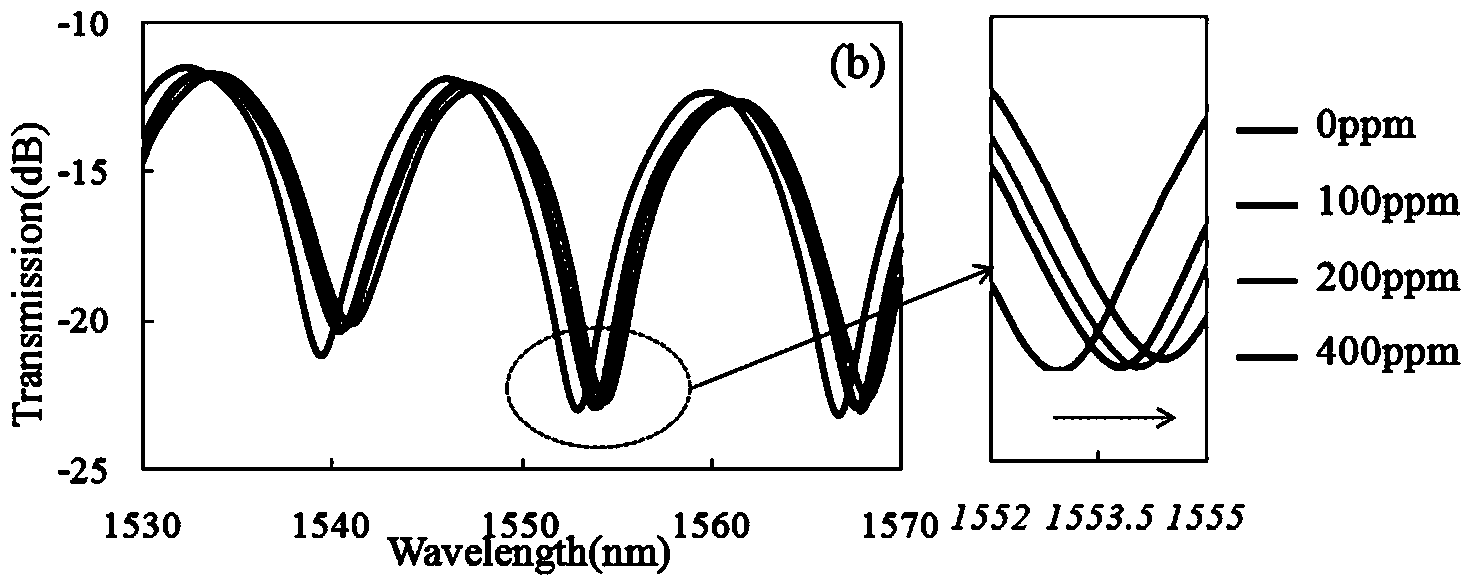

[0014] A micro-fiber gas sensor covered with graphene, the device is composed of a magnesium fluoride substrate, an intermode interference micro-fiber, and a graphene film from bottom to top. Among them, the single-mode optical fiber 3 with a diameter of 125 μm is drawn into a micro-fiber 4 with a diameter of 10 μm by the fusion tapered method, which is attached to the magnesium fluoride substrate, and the middle section of the micro-fiber is wrapped by a single-layer graphene film with a thickness of 0.38 nm. , the wrapped fiber length is 1mm. Optical signals in the communication band (1500-1600 nanometers) are input into the microfiber along the single-mode fiber, which contacts and interacts with the graphene cladding in the form of evanescent waves, and its cladding mode and core mode interfere with each other. The interference signal is output from the ordinary single-mode fiber to the spectrometer, and its inter-mode interference spectrum is analyzed. By changing the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com