Broadband reflecting mirror

A reflector and wide-band technology, applied in the field of wide-band reflectors, can solve the problems of warping of stress reflectors and a large number of laminated films, and achieve the effects of reducing the number, simplifying the manufacturing process, and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

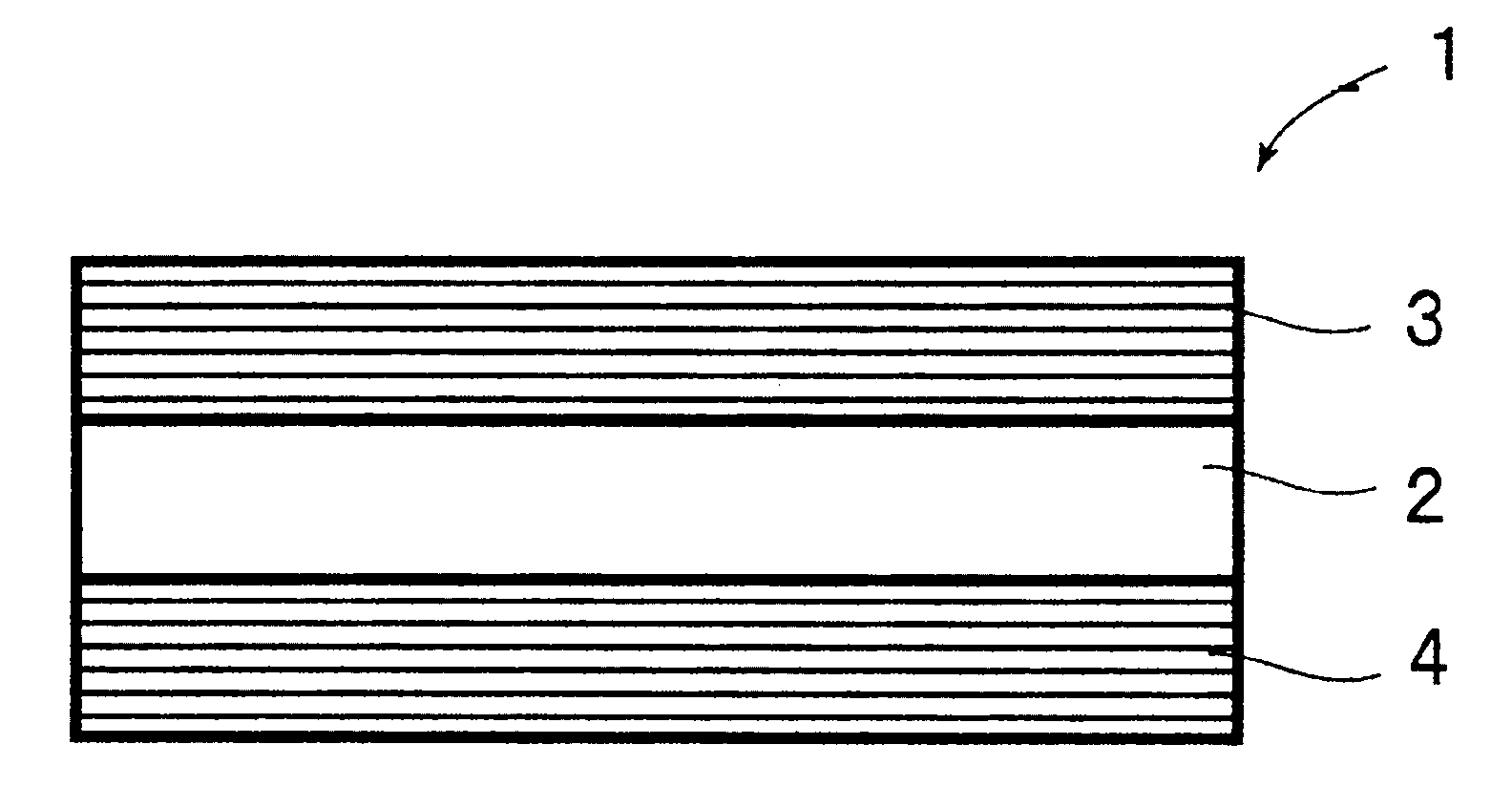

[0070] (Example 1) This example is an example of a broadband mirror in which a first reflective multilayer film is provided on one side of a glass substrate and a second reflective multilayer film is provided on the other side of the glass substrate. The glass substrate was manufactured by NEC Glass with a thickness of 0.3 mm, trade name: "OA-10". As the first high refractive index material layer of the first reflective laminate film, Nb 2 o 5 (Niobium pentoxide), as the first low refractive index material layer, use SiO 2 (silicon oxide). The film thickness and film structure of each layer are shown in Table 1. Layer No. in Table 1 is in order from the glass substrate side. As shown in Table 1, the number of layers of the first reflective multilayer film was 79.

[0071] The broadband mirror of this embodiment is a broadband mirror designed to exhibit the highest reflectance when the incident angle of light is about 20°.

[0072] 【Table 1】

[0073]

[0074] In the s...

Embodiment 2

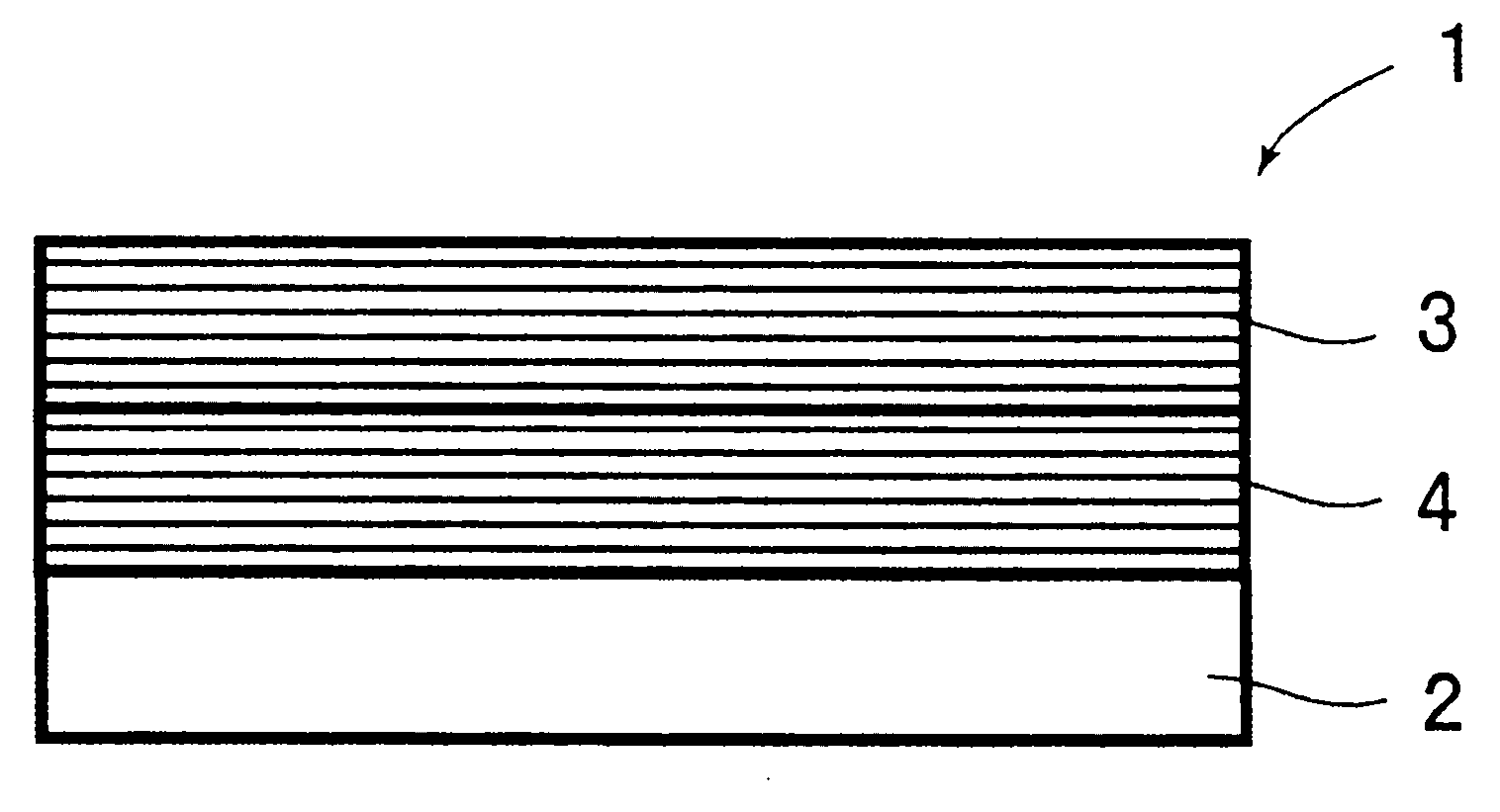

[0093] (Example 2) The broadband mirror of this example is a broadband mirror that exhibits the highest reflectivity at an incident angle of about 16°.

[0094] As in Example 1, Nb was used as the first high refractive index material layer 2 o 5 , using SiO as the first low refractive index material layer 2 . Table 3 shows the film structure of the first reflective multilayer film.

[0095] 【table 3】

[0096]

[0097] In addition, in the present embodiment, the second reflective multilayer film can have the same film structure as that of the first embodiment. Therefore, the film structure shown in Table 2 is possible.

Embodiment 3

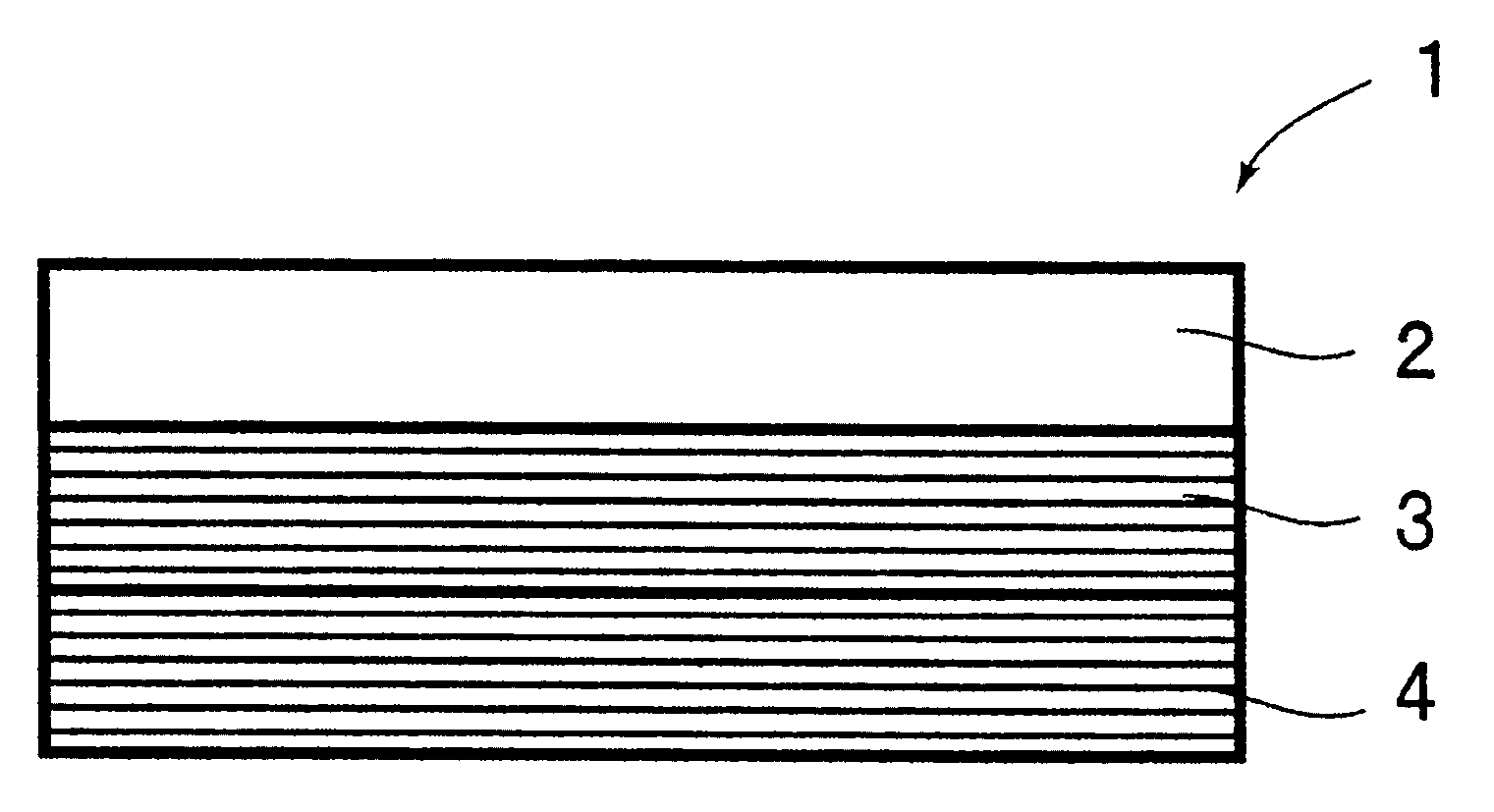

[0098] (Example 3) The broadband mirror of this example is a broadband mirror that exhibits the highest reflectivity at an incident angle of about 23°.

[0099] As in Example 1, Nb was used as the first high refractive index material layer 2 o 5 , using SiO as the first low refractive index material layer 2 . Table 4 shows the film structure of the first reflective multilayer film.

[0100] 【Table 4】

[0101]

[0102] In addition, in the present embodiment, the second reflective multilayer film can have the same film structure as that of the first embodiment. Therefore, the film structure shown in Table 2 is possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com