Long-range surface plasma resonance sensor and preparation method thereof

A surface plasmon and resonance sensor technology, applied in ion implantation plating, vacuum evaporation plating, coating, etc., can solve problems such as unstable chemical properties, achieve good biological affinity, improve sensitivity, and easy deposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

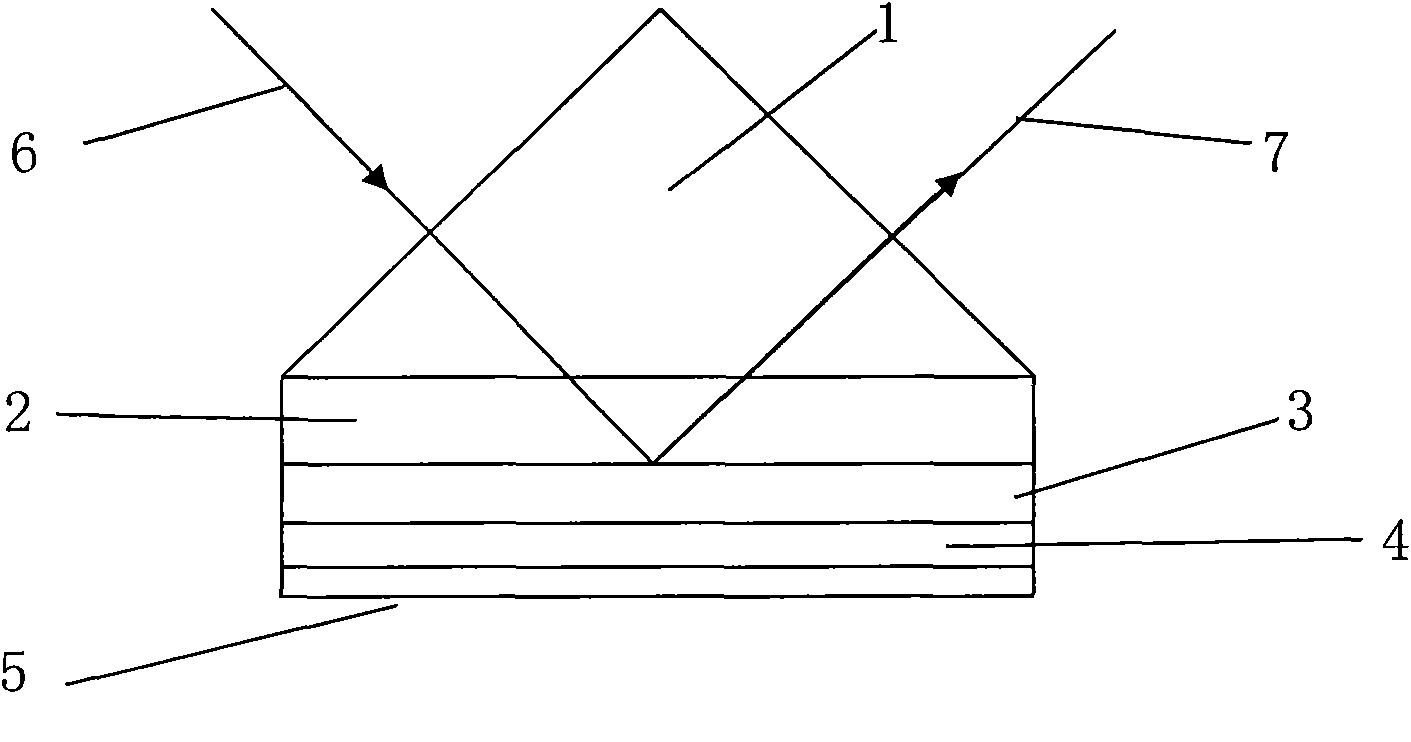

[0024] refer to figure 1 , the sensor of the present invention is formed by bonding a BK7 prism 1 with cedar oil and a glass slide 2, and the outer surface of the glass slide 2 is sequentially coated with a magnesium fluoride film 3, a silver film 4 and a gold film 5; direct contact with the biological solution; the incident P polarized light 6 is totally reflected at the interface between the slide glass 2 and the magnesium fluoride film 3, and the reflected light 7 is received by the detector.

[0025] Preparation Process:

[0026] The three layers of films on the glass slide 2 are all plated by magnetron sputtering to ensure the coating quality and accurately control the film thickness; first, the magnesium fluoride film 3 is plated on the glass slide, and the vacuum degree of the vacuum chamber is 5× 10 -4 Pa, argon partial pressure is 0.5Pa, sputtering voltage is radio frequency 700V (frequency is 13.56MHz), sputtering current is 0.18A, sputtering power is 85W, self-bia...

Embodiment 2

[0029] The structure of the sensor is the same as in Embodiment 1.

[0030] Preparation Process:

[0031] The three-layer films on the glass slide are all plated by magnetron sputtering to ensure the quality of the coating and accurately control the film thickness. First, a magnesium fluoride film 3 is coated on the glass slide, and the vacuum degree of the vacuum chamber is 5×10 -4 Pa, the argon partial pressure is 0.5Pa, the sputtering voltage is radio frequency 720V (frequency is 13.56MHz), the sputtering current is 0.21A, the sputtering power is 102W, the self-bias voltage is 440V, and the sputtering time is 43 minutes; The thickness of the magnesium fluoride thin film 3 is 650nm; then the surface of the magnesium fluoride thin film 3 is plated with a silver thin film 4, and the vacuum degree of the vacuum chamber is 5×10 -4 Pa, the argon partial pressure is 0.6Pa, the sputtering voltage is DC 310V, the current is 0.06A, and the time is 2 minutes and 15 seconds; the thic...

Embodiment 3

[0034] The structure of the sensor is the same as in Embodiment 1.

[0035] Preparation Process:

[0036] The three-layer films on the glass slide are all plated by magnetron sputtering to ensure the quality of the coating and accurately control the film thickness. First, a magnesium fluoride film 3 is coated on the glass slide, and the vacuum degree of the vacuum chamber is 5×10 -4 Pa, the argon partial pressure is 0.5Pa, the sputtering voltage is radio frequency 750V (frequency is 13.56MHz), the sputtering current is 0.23A, the sputtering power is 117W, the self-bias voltage is 460V, and the sputtering time is 38 minutes; The thickness of the magnesium fluoride thin film 3 is 650nm; then the surface of the magnesium fluoride thin film 3 is plated with a silver thin film 4; the vacuum degree of the vacuum chamber is 5×10 -4 Pa, the argon partial pressure is 0.6Pa, the sputtering voltage is DC 300V, the current is 0.05A, and the time is 2 minutes and 45 seconds; the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com