Flux-cored wire special for maritime work low-temperature high-strength steel

A technology of flux-cored welding wire and high-strength steel, applied in welding medium, manufacturing tools, welding equipment, etc., can solve the problems of unsatisfactory low-temperature impact toughness and poor crack resistance, and achieve good cold crack resistance and excellent welding process performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

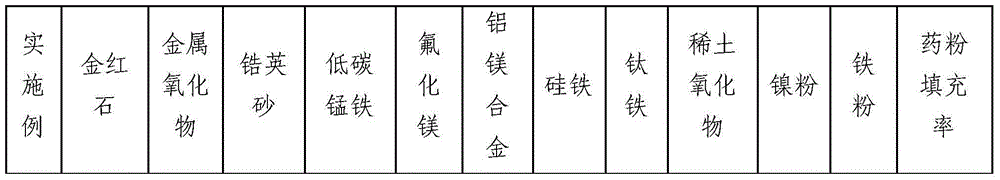

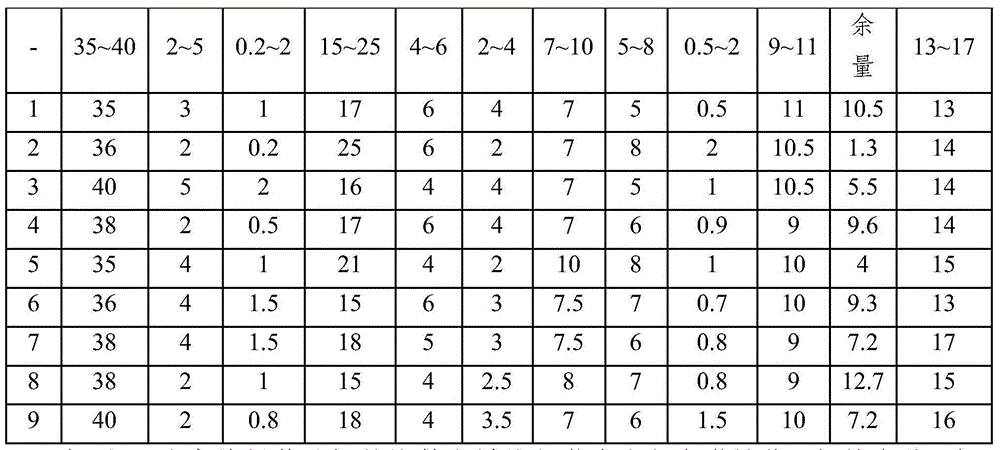

[0031] Examples The formula of the flux-cored welding wire is shown in Table 1, the steel skin is SPCC steel strip, and the conventional flux-cored welding wire manufacturing process is adopted.

[0032] Among them, the metal oxides in Examples 1 and 3 are ordinary magnesia, and the rare earth oxides are yttrium oxide. Example 2 is fused magnesia, and the rare earth oxide is yttrium oxide. The metal oxide of embodiment 4 is calcium oxide, and the rare earth oxide is lanthanum oxide, and the metal oxide of embodiment 5~9 is the mixture of magnesium oxide and calcium oxide, and rare earth oxide is mixed rare earth; Wherein embodiment 5,7 and Magnesium oxide in 9 is capacitor magnesia. The particle size of zircon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com