Foaming nitrile rubber metal composite plate and preparation method thereof

A technology of metal composite board and nitrile rubber, which is applied in the direction of chemical instruments and methods, adhesives, adhesive types, etc., to achieve excellent sealing performance, excellent compression rate, and outstanding creep and relaxation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

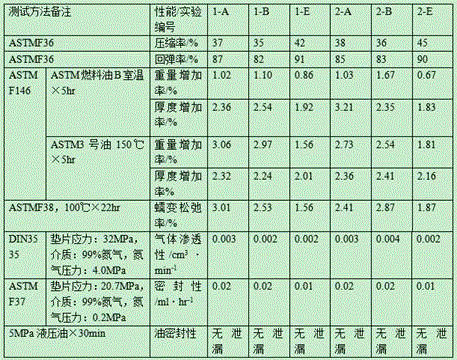

Examples

Embodiment 1

[0028] A foamed nitrile rubber metal composite board, comprising a metal substrate, the surface of the metal substrate is provided with a foamed rubber layer, and the foamed rubber layer is made of the following raw materials in parts by mass: 100 parts of nitrile rubber, zinc oxide 5 parts, 4 parts of accelerator, 1 part of sulfur, 30 parts of carbon black, 2.2 parts of foaming agent, 4 parts of auxiliary agent.

[0029] Among them, the foaming agent is a mixture of azodicarbonamide and CR-4305 at a weight ratio of 1:2, and the auxiliary agent is a mixture of carboxymethyl chitosan and an anti-aging agent at a weight ratio of 1:1. It is anti-aging agent AW and anti-aging agent RD, and the weight ratio of the two is 5:1. The raw materials and dosage of the accelerator are shown in the following table:

[0030] .

[0031] In the present invention, the metal substrate is selected from carbon steel plate, stainless steel plate or aluminum alloy plate, and the thickness is pref...

Embodiment 2

[0038] A foamed nitrile rubber metal composite board, comprising a metal substrate, the surface of the metal substrate is provided with a foamed rubber layer, and the foamed rubber layer is made of the following raw materials in parts by mass: 100 parts of nitrile rubber, zinc oxide 1 part, 2 parts of accelerator, 0.5 part of sulfur, 20 parts of carbon black, 1 part of foaming agent, 1 part of auxiliary agent.

[0039] Among them, the accelerator is tetramethylthiuram disulfide and N-cyclohexyl-2-benzothiazole sulfenamide, the weight ratio of the two is 1:1, and the auxiliary agent is carboxymethyl chitosan and anti-aging Anti-aging agent is a mixture composed of anti-aging agent at a weight ratio of 1:1, wherein the anti-aging agent is anti-aging agent AW and anti-aging agent RD, and the weight ratio of the two is 5:1. The raw materials and dosage of the foaming agent are shown in the following table:

[0040] .

[0041] The embodiment of this group is a kind of preparatio...

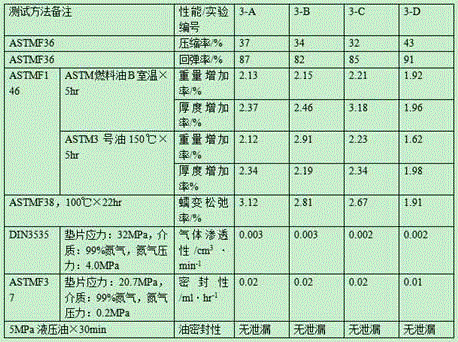

Embodiment 3

[0047] A foamed nitrile rubber metal composite board, comprising a metal substrate, the surface of the metal substrate is provided with a foamed rubber layer, and the foamed rubber layer is made of the following raw materials in parts by mass: 100 parts of nitrile rubber, zinc oxide 10 parts, accelerator 10 parts, sulfur 5 parts, carbon black 40 parts, foaming agent 5 parts, auxiliary agent 10 parts.

[0048] Among them, the blowing agent is a mixture of azodicarbonamide and CR-4305 at a weight ratio of 1:2, and the accelerator is tetramethylthiuram disulfide and N-cyclohexyl-2-benzothiazolesulfen Amide, the weight ratio of the two is 1:1, the raw materials and dosage of the auxiliary agent are as follows:

[0049] .

[0050] The embodiment of this group is a kind of preparation method of foamed nitrile rubber metal composite board, described foamed nitrile rubber metal composite board comprises metal substrate, and the surface of described metal substrate is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com